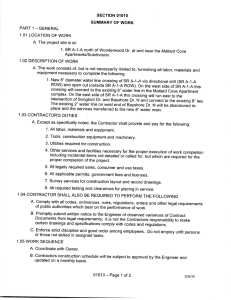

Technical Services Department Contractors Code of Practice

advertisement