Model: PURY-HP144TSKMU-AH

advertisement

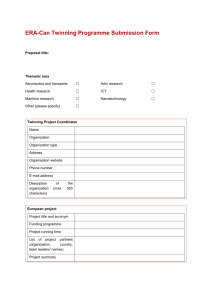

Model: PUR Y-HP144TSKMU-A-H (Consists of Two PUR Y-HP72TKMU-A and One CMY-R 100C BK2 Twinning Kit) Job Name: Location: Engineer Name: Contractor: System No.: Date: OUTDOOR VRF SYSTEM FEATURES • Innovative flash technology enables tremendous heating capacity at lower outdoor temperatures • Built-in base pan heater to prevent ice in drain pan • Air-source, simultaneous cooling and heating • Provides up to 100% of rated heating capacity at 0ºF (-17.7ºC) in standard mode. • Modular design; two small capacity units can be piped together to form a large capacity system • Connects to CITY MULTI indoor units • Controlled via CITY MULTI Controls Network (CMCN) • Minimum outdoor temperature for simultaneous cooling and heating operation is -20ºC • Inverter-driven (variable speed) scroll compressor • External finish: Pre-coated Galvanized-steel Sheets • Operating Temperature Range Cooling (Outdoor): 23° ~ 115°F (-5° ~ 46°C) DB Heating (Outdoor): -13° ~ 60°F (-25° ~ 15.5°C) WB Specifications Unit Type Nominal Cooling Capacity Btu/h Nominal Heating Capacity Btu/h External Dimensions (H x W x D) In. / mm PURY-HP72TKMU-A-H PURY-HP72TKMU-A-H OPTIONAL PARTS □ □ □ □ □ □ □ Twinning Kit*.……………….........………...….…..........CMY-R100CBK2 T-Branch Joint (≤ 72,000 Btu/h).…............…….…….CMY-Y102SS-G2 T-Branch Joint (73,000 - 144,000 Btu/h).…….……...........CMY-Y102LS-G2 T-Branch Joint (145,000 - 234,000 Btu/h).………........CMY-Y202S-G2 Joint Adapter (Port Connector > 54,000 Btu/h).….…….......CMY-R160C-J Main BC Controller.…….......CMB-P108/1010/1013/1016NU-GA/1016NU-HA Sub BC Controller.………………….....CMB-P104/108NU-GB/P1016NU-HB * Twinning Kit is necessary to combine the refrigerant flows of the modules and is sold separately. System PURY-HP144TSKMU-A-H 144,000 160,000 Refer to Module Data Net Weight Lbs. / kg Electrical Power Requirements Voltage, Phase, Hertz Cooling Power Input kW 10.85 Heating Power Input Cooling Current (208/230V) Heating Current (208/230V) Minimum Circuit Ampacity (MCA)** kW A A 13.16 33.4 / 30.2 40.5 / 36.7 1,104/ 500 Module 1 PURY-HP72TKMU-A-H 72,000 80,000 64-31/32 x 48-1/16 x 29-5/32 / 1,650 x 1,220 x 740 552 / 250 Refer to Module Data** Module 2 PURY-HP72TKMU-A-H 72,000 80,000 64-31/32 x 48-1/16 x 29-5/32 / 1,650 x 1,220 x 740 552/ 250 208 / 230V, 3-phase, 60Hz** Refer to System Data Refer to System Data A Refer to Module Data** 44 / 40** 44 / 40** Maximum Circuit Breaker Size** Piping Diameter A Refer to Module Data** 60** 60** From Twinning Kit to Indoor Units (Brazed) (In. / mm) Liquid (High Pressure) Gas (Low Pressure) Liquid (High Pressure) Gas (Low Pressure) Total Capacity Model / Quantity From Modules to Twinning Kit (Brazed) (In. / mm) Indoor Unit Sound Pressure Level Fan Type x Quantity Airflow Rate Direct-drive Inverter Motor Output dB(A) CFM kW Compressor Operating Range Compressor Type x Quantity Compressor Motor Output kW Compressor Crankcase Heater kW Refrigerant Lubricant High-pressure Protection Device Compressor / Fan Protection Device Inverter Protection Device Refer to System Data 7/8 / 22.2 1-1/8 / 28.58 Refer to Module Data 5/8 / 15.88 3/4 / 19.05 50 to 150% of ODUs P06 ~ P96 / 1 to 36 61 Refer to Module Data Cooling: 15% to 100% Heating: 7% to 100% Refer to Module Data Refer to Module Data Refer to Module Data 5/8 / 15.88 3/4 / 19.05 Refer to System Data 58 58 Propeller Fan x 1 6,200 0.92 Propeller Fan x 1 6,200 0.92 Refer to System Data Inverter-driven Scroll Hermetic x 1 Inverter-driven Scroll Hermetic x 1 5.3 5.3 R410A MEL32 601 psi / 4.15 MPa 601 psi / 4.15 MPa Overheat Protection / Thermal Switch Overheat Protection / Thermal Switch Overheat / Overcurrent Protection Overheat / Overcurrent Protection ** Each individual module requires a separate electrical connection. Reference electrical data for each individual module. Left view 1650 (64-31/32) Intake air d f e Intake air a To BC controller Twinning pipe(High pressure) <optional parts> b To BC controller Outdoor unit 2 1220 (48-1/16) HP144 HP192 Unit model Component HP72 HP96 HP72 HP96 unit model Twinning Kit High pressure c ø15.88(5/8) e ø15.88(5/8) c ø19.05(3/4) e ø19.05(3/4) ~Outdoor unit Low pressure d - (Note 5) f ø19.05(3/4) d - (Note 5) f ø22.2(7/8) Front view c 30 (1-3/16) Twinning pipe(Low pressure) <optional parts> Outdoor unit 1 1220 (48-1/16) Note 1. Connect the pipes as shown in the figure above. Refer to the table aboveforthe pipe size. 2. Twinning pipe (High pressure) should not be tilted more than 15 degrees from the horizontal plane. Be sure to see the Installation Manual for details of Twinning pipe installation. 3. The pipe section before the Twinning pipe (section "a" in the figure) must have at least 500mm(19-11/16) of straight section (*including the straight pipe that is supplied with the Twinning pipe). 4. Only use the Twinning pipe by Mitsubishi (optional parts). 5. Connect the outdoor unit 1 with the Twinning pipe (Low pressure) (section "d" in the figure). Component unit name PURY-HP144TSKMU-A-H(-BS) PURY-HP192TSKMU-A-H(-BS) Package unit name PURY-HP72TKMU-A-H(-BS) PURY-HP96TKMU-A-H(-BS) Outdoor unit 1 PURY-HP72TKMU-A-H(-BS) PURY-HP96TKMU-A-H(-BS) Outdoor unit 2 Outdoor Twinning Kit(optional parts) CMY-R100CBK2 ø22.2(7/8) High pressure a BC controller~Twinning pipe ø28.58(1-1/8) Low pressure b Twinning pipe connection size Intake air Discharge air 740 (29-5/32) Outdoor Unit: PUR Y-HP144TSKMU-A-H – DIMENSIONS Unit : mm(in) Twinning Kit: CMY-R100CBK2 Low-pressure pipe twinning kit CMY-R 100C BK2 1” (Outside diameter) <Elbow pipe(Accessory)> 1-5/32" 7/8” 1” 21/32” (Outside 4-5/32” 1-3/32” 5-1/4” 1-31/32" 7/8" 7/8" 1-7/16” 1-1/4” 3-17/32” 1-5/32” (Outside diameter) 6-15/16” 1-31/32" 1-5/32" 1-7/16” diameter) 17-1/32” <Deformed pipe(Accessory)> <Low-pressure pipe twinning kit(Accessory)> 1” 2-3/8” 1” 7/8" (Outside diameter) 3/4” 2-15/32" 3-5/32" High-pressure twinning pipe <Pipe for routing through the bottom (Accessory)> <Pipe for routing through the front (Accessory)> 3-5/32" 3/4" 8-7/16” 1" 21/32" 1-13/32” 3/4" (Outside diameter) <Deformed pipe(Accessory)> 5/8” 3/4” (Outside diameter) 2-15/32" (3Pcs.) 15 Distributer The angle ang of the branch pipe for hign pressure is within 15 2.. Use the attached pipe to braze the port-opening of the distribute 3.. Pipe diameter is indicated by inside diamete 4.. Only use the Twinning pipe by Mitsubishi (optional parts) 3/4" 4-17/32" 7-17/32" 2-5/16" 1" 3/4" 7/8" 57 (2-1/4) Left side view 20 20 (13/16) (13/16) 586(23-3/32) Intake air Control box 19.5 (25/32) 150 (5-29/32) 57 (2-1/4) 7 6 (10-23/32) (11-7/8) (8-15/16) (9-5/16) (9-29/32) (10-23/32) 2 80 (3-5/32) Refrigerant service valve <High pressure> 262 (10-11/32) Refrigerant service valve <Low pressure> Refrigerant service valve <High pressure> 4 217 (8-9/16) Discharge air 4X5-ø4.6(3/16) Hole (Make hole at the plastic fan guard for snow hood attachment) <Snow hood attachment hole> (5-23/32) 145 Intake air 54(2-5/32) (23-5/8) =(5-29/32)X4 (2-25/32) 600=150×4 70 196 (7-23/32) 146 (5-3/4) 121 (4-25/32) 272 301 227 236 251 272 8 1 Bottom view 1060(41-3/4) (Mounting pitch) 3 Refrigerant service valve <Low pressure> 150 (5-29/32) 83 (3-9/32) Front view 75(2-31/32) 58(2-5/16) 140(5-17/32) 5 Top view 1181(46-1/2) 1220(48-1/16) 77 (3-1/16) Service panel Intake air 19.5 (25/32) 740(29-5/32) 2X2-14(9/16)X20(13/16) Oval hole 2X2-80(3-5/32)X35(1-13/32) Oval hole <Sling hole> 146 (5-3/4) 84 (3-5/16) 94 (3-23/32) 29.5 (1-3/16) The ISO 14000 series is a set of standards applying to environmental protection set by the International Standard Organization (ISO). 80 (3-5/32) 29.5 (1-3/16) Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired environmental management system standard ISO 14001 certification. 89 (3-17/32) 303 (11-15/16) 1650(64-31/32) Certificate Number EC97J1227 1347(53-1/16) Certificate Number FM33568 ISO Authorization System The ISO 9000 series is a plant authorization system relating to quality warranties as stipulated by the ISO. ISO 9001 certifies quality warranties based on the "design, development, production, installation and auxiliary services" for products built at an authorized plant. (26-13/16) 681(678~684) (26-23/32~26-15/16) (Mounting pitch) (740)(29-5/32) ø25.4 (1) ø25.4 (1) Service valve High Low pressure pressure ø25.4 ø25.4 (1) (1) 8 7 6 5 4 3 2 1 NO. Specifications 140 × 77 Knockout hole (5-17/32) (3-1/16) Front through hole ø45 Knockout hole (Uses when twinning (1-25/32) kit (optional parts) is mounted.) 150 × 94 Knockout hole Bottom through hole (5-29/32) (3-23/32) ø62.7 or ø34.5 Knockout hole Front through hole (2-15/32) (1-3/8) ø43.7 or ø22.2 Knockout hole Front through hole (1-3/4) (7/8) For wires ø65 Knockout hole Bottom through hole (2-9/16) ø52 Knockout hole Bottom through hole (2-1/16) ø34 Knockout hole For transmission cables Front through hole (1-11/32) For pipes Front through hole Usage 1 Use the pipe * joint(field supply) and connect to the refrigerant service valve piping. PURY-HP72TKMU-A-H(-BS) ø15.88 Brazed ø19.05 Brazed (3/4) *1 (5/8) *1 PURY-HP96TKMU-A-H(-BS) ø19.05 Brazed ø22.2 Brazed (3/4) *1 (7/8) *1 Model Diameter Refrigerant pipe High Low pressure pressure Connecting pipe specifications At brazing of pipes,wrap the refrigerant service valve with wet cloth and keep the temperature of refrigerant service valve under 120°C(248°F). Unit: mm (in.) Model: PUR Y-HP72TKMU-A-H – DIMENSIONS Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired ISO 9001 certification under Series 9000 of the International Standard Organization (ISO) based on a review of quality warranties for the production of refrigeration and air conditioning equipment. Mitsubishi Electric Sales Canada Inc. www.MitsubishiElectric.ca Specifications are subject to change without notice. PR_SB_PURY-HP144TSKMU-A-H_201401