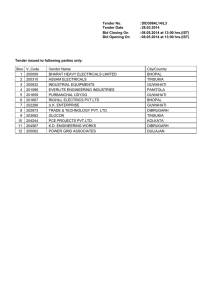

tender technical specification for supply, erection (including

advertisement