Safety Manager`s Quarterly Report – 2015: Q4 Electrical Program

advertisement

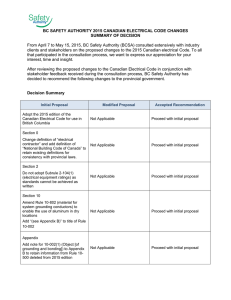

Safety Manager’s Quarterly Report – 2015: Q4 Electrical Program Electrical Technology Advisory Committee [Please note: This report includes preliminary data. Accuracy of data is based on available information provided at the time this report was prepared. Final published data may vary from this report] Understanding Electrical Safety Risks Hazard Mapping The hazard assessment consists of two general processes and should be considered separately: Inspection – identify errors and non-compliances Hazard assessment – use hazard map to identify basic hazard and assess the degree to which the inherent hazard is exposed. The BC Electrical Code addresses the fundamental principles of protection for safety. These principles are described in the Object and Appendix K, and can be summarized as addressing five basic hazards as follows: Electrical Shock; Thermal effects; Equipment damage; System operation; and Power supply interruption The Electrical Hazard Map has been updated and revised to reflect feedback from safety officers, and safety managers from other technologies. Descriptions of basic as-found conditions allow safety officers to quickly identify and describe hazards found during physical inspections. Safety officers began using the updated hazard map in July. Data collected through site inspections is not sufficient to make comprehensive determinations about trends. However, findings did show a significant number of hazards related to exposed conductors and mechanical damage to conductors. These findings correlate with incident investigation results which show a significant number of incidents related to exposed conductors ; mechanical damage to conductors has been identified as a significant contributor to incidents in previous reports. Incidents: 15 incidents were reported to BCSA in Q3. 12 incident investigations have been completed. fires Shock 7 5 Basic causes for Q3 incidents: Electric Shock Mechanical Damage Not electrical Overcurrent / Fault Current System Interruption Thermal Undetermined 4 1 1 2 1 1 2 Permits Installation permits issued in Q3: Permit Class YTD Q3 11,327 3,918 2,650 882 25,116 9,675 Homeowner Addition / Modification/ Alteration 551 260 Homeowner Service Install / Upgrade 297 155 1,185 404 Permit Class YTD Q3 General User 365 144 Municipal / School District 73 63 Private Distribution System 8 5 1,684 591 33 7 303 148 Contractor Commercial / Industrial Contractor Residential Multi-Unit Dwelling Contractor Residential Single Family Dwelling Silver Label Operating permits issued in Q3: Temporary Construction Service – Contractor Temporary Construction Service – Homeowner Temporary Operating Quarterly Report to Electrical Technology Advisory Committee October -2015 Physical Inspections (YTD) As found conditions by inspection type Inspection Type EL OP: Acceptance EL OP: Dust Assessment EL OP: Regular Scheduled EL OP: SO Scheduled Assessment EL: Final EL: Rough Wiring-Complete EL: Rough Wiring-Partial EL: Service Connection EL IN: 180-Day Safety Check EL IN: Work-in-Progress EL IN: Unsafe Condition 0 11 46 60 8 1639 950 512 1263 53 285 55 1 2 5 10 2 124 95 35 131 5 32 41 3 15 3 147 93 27 161 5 16 75 3 1 1 14 5 64 33 16 79 1 8 48 4 0 1 2 3 4 5 Contractor Commercial / Industrial 1053 76 68 24 8 2 Contractor Residential Multi-Unit Dwelling 225 13 24 10 1 Contractor Residential Single Family Dwelling 2125 207 242 112 26 3 Homeowner Addition / Modification/ Alteration 431 42 38 14 6 1 Homeowner Service Install / Upgrade 320 35 32 21 4 General User 87 13 16 15 5 Municipal / School District 26 4 6 5 1 Private Distribution System 1 15 13 7 2 1 2 3 21 9 4 18 3 16 5 1 2 1 1 1 4 As-found conditions by permit class Permit Class Temporary Construction Service - Contractor 155 Temporary Construction Service - Homeowner 10 Temporary Operating 16 EL 69 45 77 48 16 Silver Label 381 32 30 13 8 Quarterly Report to Electrical Technology Advisory Committee October -2015 1 2 1 4 Electrical Technology Risk Register There were no significant changes to the EL Risk Register during Q2. Summary of EL Risk Register items is provided below. EL-16 - FSR Code Knowledge (HIGH): Potential unsafe practices by Field Safety Representatives due to their lack of up-to-date knowledge of codes and standards. FSR’s are not updating their information in registry Current education and training programs do not adequately prepare FSR’s for their roles Current practices for examining FSR’s do not adequately assess competency to perform expected duties Expectations for FSR’s are not clearly understood by industry Gaps in knowledge occur when training is not maintained or updated Regular renewal of FSR certificates will enable improved contact with FSR’s, and will allow information to be updated regularly. BCSA is also currently exploring options for improved training, assessment, and updating of FSR’s through an ETAC working group. EL-18 - EL Operating Permits - Low Market Penetration (HIGH): Owners operating electrical systems may not be complying with safety and permitting requirements. Requirements for operating permits are not clearly understood by owners. Many owners who require operating permits do not currently have valid permits to operate their equipment. Owners, contractors, and FSR’s do not clearly understand their roles, duties, and responsibilities under operating permits. BCSA is continuing its efforts to engage with owners to obtain compliance with operating permit requirements. The directive on operating permits has been updated to reflect current conditions, with an accompanying information bulletin that describes and clarifies roles, duties, and responsibilities of owners, contractors, and FSR’s under electrical operating permits. EL-21 - Untrained individuals performing electrical work (HIGH): Unqualified or inadequately trained individuals are performing electrical work. This item was included on the risk register at the recommendation of ETAC. BCSA is continuing to seek advice from stakeholder groups, such as ETAC, on how to engage industry and owners to ensure improved understanding of requirements for training and qualifications for individuals who perform work on or around electrical equipment. Quarterly Report to Electrical Technology Advisory Committee October -2015 EL-22 - Explosion hazard areas with combustible wood dust (HIGH) : Explosion may occur where electrical equipment is located in areas with hazardous levels of combustible wood dust. BCSA is currently training additional safety officers in preparation for continued follow up at sawmill sites. BCSA plans to conduct follow up assessments of approximately 150 sawmill sites in 2015. EL-07 - Unpermitted Homeowner Work (MEDIUM): Unpermitted homeowner work is not inspected or the risk is not controlled. A number of education programs have been implemented over the past 5 years. Although some success was achieved, home owners continue to perform electrical work without having obtained electrical permits. BCSA is continuing to seek advice from stakeholder groups, such as ETAC, on how to engage industry and home owners. EL-15 - Improper Use - Electrical Appliances (WATCH 1): Fire arising from improper use of electrical appliances. BCSA is continuing to monitor this items. EL-19 - Hazard Associated With Aluminium Wiring (WATCH 1): Potential hazards associated with the alteration of aluminum wiring done by homeowners. BCSA is continuing to monitor this items. EL-20 - Working on energized system (WATCH 1): Injuries resulting from working on energized equipment. The directive and information bulletin on live work were issued in 2013. Workers are continuing to remove barriers for electrical equipment, exposing themselves to electrical shock and arc flash hazards. BCSA is continuing to seek the advice of stakeholders, such as ETAC, on how to work with industry to improve understanding of the hazards related to working on or around energized electrical equipment. Quarterly Report to Electrical Technology Advisory Committee October -2015 Managing Electrical Safety Risks Electrical Tech Talks & Other Learning Events BCSA has scheduled a number of Electrical Tech Talks and learning events throughout the Province. Information about scheduled events is available at: http://www.safetyauthority.ca/safety-infotraining/learning-events BCSA has completed development of Tech Talk materials for 2015 BC Electrical Code. Tech Talk sessions on the 2015 BC Electrical Code is scheduled to begin this fall. BCSA provided training for electrical safety officers in September. Certification FSR Class A 22 FSR Class B 56 FSR Low Energy Systems 7 FSR Refrigeration Mechanic 5 FSR Security Alarms Installer 2 FSR Underground Raceway Installer 2 Provincial Electrical Safety Officer 2 Licences Active licences 5131 Enforcement Warning notices issued 13 Compliance order issued 11 Sanctions issued 0 Monetary Penalties issued 2 Quarterly Report to Electrical Technology Advisory Committee October -2015