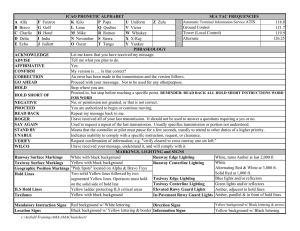

2012 Updated Airfield Inspection Report

advertisement