3M™ Zone Enclosure 8451 Installation

Instructions

Note: Examine box contents and ensure that all necessary

components are present and that they are in a usable and

defect-free condition.

2.0 Kit Contents

• Enclosure assembly

• 13-position module mounting panel

(Factory Installed)

• 2 Heyco metallic liquid tight cordgrips for cable

diameters between .550-.650"

• 2 cable clamps

• 2 keys

• 4 ceiling mount brackets and related hardware

• 4 raised floor mounting brackets and

related hardware.

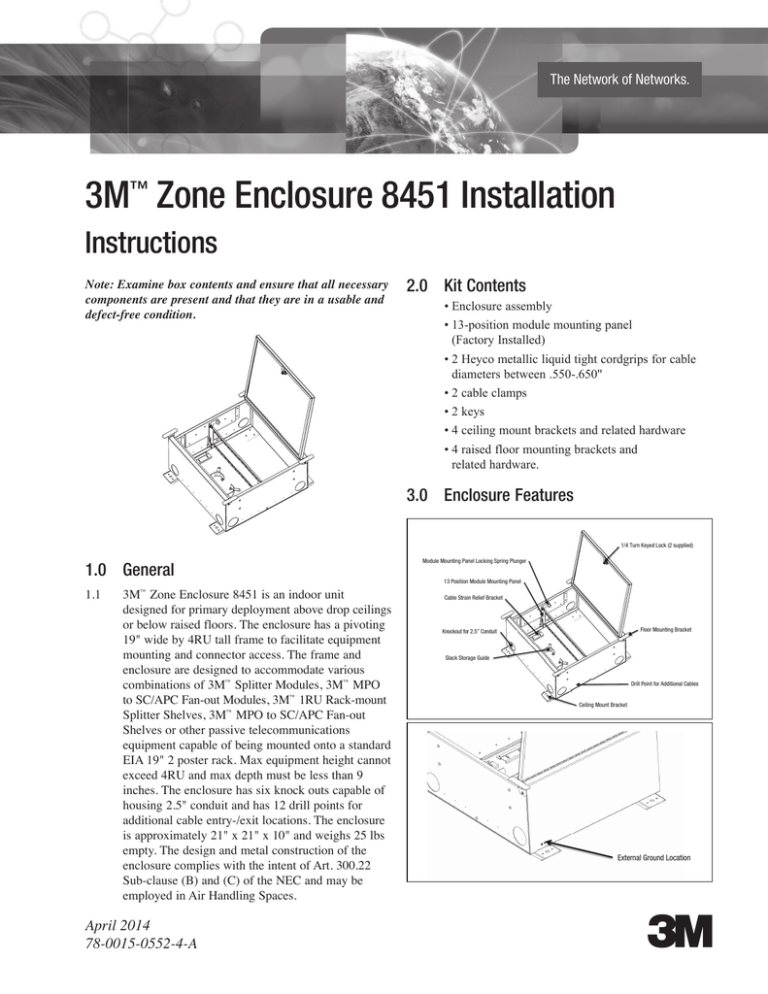

3.0 Enclosure Features

1/4 Turn Keyed Lock (2 supplied)

1.0 General

1.1

3M™ Zone Enclosure 8451 is an indoor unit

designed for primary deployment above drop ceilings

or below raised floors. The enclosure has a pivoting

19" wide by 4RU tall frame to facilitate equipment

mounting and connector access. The frame and

enclosure are designed to accommodate various

combinations of 3M™ Splitter Modules, 3M™ MPO

to SC/APC Fan-out Modules, 3M™ 1RU Rack-mount

Splitter Shelves, 3M™ MPO to SC/APC Fan-out

Shelves or other passive telecommunications

equipment capable of being mounted onto a standard

EIA 19" 2 poster rack. Max equipment height cannot

exceed 4RU and max depth must be less than 9

inches. The enclosure has six knock outs capable of

housing 2.5" conduit and has 12 drill points for

additional cable entry-/exit locations. The enclosure

is approximately 21" x 21" x 10" and weighs 25 lbs

empty. The design and metal construction of the

enclosure complies with the intent of Art. 300.22

Sub-clause (B) and (C) of the NEC and may be

employed in Air Handling Spaces.

April 2014

78-0015-0552-4-A

Module Mounting Panel Locking Spring Plunger

13 Position Module Mounting Panel

Cable Strain Relief Bracket

Floor Mounting Bracket

Knockout for 2.5” Conduit

Slack Storage Guide

Drill Point for Additional Cables

Ceiling Mount Bracket

External Ground Location

3.1

Note: A minimum of one tile location away from walls

or other obstructions is recommended for proper door

operation.

3M™ Zone Enclosure 8451 Access

3.1.1. Insert supplied key and unlock door by

rotating key 1/4 turn counterclockwise to

unlock the enclosure.

Note: If necessary, the enclosure may be installed with

minimal tile removal, removal of adjacent tiles ensures

ease of access and inspection.

3.1.2. Grasp side of the door to open enclosure.

4.1.3. Install the four floor mount brackets as shown

in section 3.0 using the supplied 10-32 screws

and lockwashers. Torque screws to 40-45

in-lbs.

Note: DO NOT use the key to lift door. Doing so may bend

or break key into lock and render the enclosure unusable.

3.1.3 Slowly close door when access is no

longer required.

Floor Mount Brackets

3.1.4. Lock the door using the supplied key by

turning 1/4 turn clockwise.

3.2

Module Mounting Panel Access

3.2.1. To pivot the mounting bracket, pull the spring

plungers on both sides of bracket.

3.2.2. Pivot the bracket to desired location and

release the spring plungers to lock in place.

Note: There are six possible bracket positions indicated

by the holes in the side panel.

4.1.4. Lower enclosure into desired tile location.

Note: Door will not close with Module Mounting Panel

pivoted forward toward the slack storage area. These

locations are for connector access only.

Note: Opening the enclosure door and using the inside

ledge as a handle may make installation easier.

Note: Ability to pivot back will depend on type and size

of equipment mounted into the enclosure.

mWARNING

Do not use door as an installation handle.

3.2.3. The Module Mounting Panel is secured to

the pivot brackets using four 12-24 UNC X

0.5" screws and 12-24 Cage Nuts.

Note: Floor mount brackets should rest on the floor

system posts and not the joists.

4.1.5. Re-install floor tile over enclosure and ensure

that the tile lays flat and that the enclosure

body is not supporting the tile in any way.

Note: Additional hardware will be required to mount

different types of equipment.

3.3

Enclosure Grounding

Note: Variations in raised floor system may result in the

enclosure body supporting the floor tile. The enclosure

is NOT designed to support the weight of individuals or

equipment positioned on the floor for any amount of time.

3.3.1. Enclosure grounding location at rear of box

is designed to accommodate #10-32 UNC

x 0.25" long screws. They are spaced .625"

apart to fit a standard 2 lug ground connector.

Note: If the covering tile does not lay flat or is in

contact with the enclosure, the floor mounting brackets

may be removed and the closure allowed to rest directly

on the subfloor.

4.0 Enclosure Installation

4.1.6. Route and install cables (see section 5

for details) and replace remaining tiles.

To maintain compliance with Art. 300.22, all external cable

must be plenum rated with metal external fittings attached

to the closure, and the enclosure must be fully shut to

protect internal components. You must determine, based on

your use and the components you incorporate, whether the

final system complies with Art. 300.22

4.1

Under a Raised Floor

4.1.1. Select desired installation location.

4.1.2. Remove tile covering location and tiles

adjacent to desired location.

2

78-0015-0552-4-A

4.2.

Suspended Above a Drop Ceiling

Note: The 3M Zone Enclosure 8451 is designed to be

completely hidden behind a ceiling tile for optimal

security and safety.

™

Note: Mounting hardware and supports are not supplied.

Use support struts or NEC compliant support wires.

Support wires must be capable of supporting enclosure

weight, plus populated items. (Total not to exceed 50lbs.)

4.2.1 I nstall the four ceiling mount brackets as

shown in section 3.0 using the supplied

10-32 screws and lockwashers. Torque

screws to 40-45 in-lbs.

Note: Use of Loctite or other thread locking compound

is acceptable. Lock washers MUST still be used.

mWARNING

Warning: Failure to use lock washers and to properly torque bracket

mounting screws may create a safety hazard.

4.2.2. Determine mounting location for the

3M™ Zone Enclosure 8451 and remove

ceiling tiles to aid in installation.

Note: A minimum of two tiles should be removed; however,

the installation process can be simplified with the removal

of the tiles adjacent to the desired location.

Insure all support elements are attached in accordance with applicable

NEC standards and local ordinances.

4.2.4. P

ass the enclosure through the ceiling opening

and rest on suspended ceiling

cross members.

4.2.5. P

ass supporting wires or threaded rod through

mounting bracket holes to support enclosure.

Note: When using support wires pass the wire through

the mounting bracket holes, loop back and make several

wraps around the wire.

mWARNING

Insure all support elements are attached in accordance with applicable

NEC standards and local ordinances.

5.1

4.2. 6. A

djust support elements such that the weight

of the enclosure is evenly supported by all

four units.

Note: Ensure that the enclosure is level and completely

above the suspended ceiling.

4.2.7. E

nsure that the enclosure door can be

accessed and operated safely. Adjust enclosure

position as needed.

4.2.8. Re-install ceiling panels.

4.2.9. N

ote enclosure location per company

standard.

78-0015-0552-4-A3

Using Conduit

mWARNING

Ensure conduit being used is appropriate for use above ceilings or below

raised flooring and is in accordance with all building and fire codes.

Note: In order to maintain a high level of ingress

protection the knock outs are half shear in construction

and may be difficult to remove.

5.1.1. U

sing a hammer or punch remove desired

knockout location.

Note: Knockout locations are designed to accommodate

2.5" conduit and related fittings. Drill point locations can

be used to create openings in the enclosure for conduits

up to 1" in diameter.

Note: DO NOT drill holes larger than 1" in diameter at

drill point locations. Doing so will void UL Certification

as it may create a safety hazard.

Note: For ease of access only use cable entry locations

in front of module locations.

5.1.2. I nstall conduit collars and conduit per

manufacturer’s instructions.

mWARNING

4.2.3. A

ttach the support wires or threaded rod

to the supporting element of ceiling.

mWARNING

5.0 Cable Installation

Insure conduit being used is appropriate for use above ceilings or below

raised flooring is in accordance with all building and fire codes.

5.1.3. P

ull cable through conduit and into enclosure

per company practice.

5.2

Using Liquid Tight Fitting

5.2.1. Drill a 1" hole at the desired cable location.

5.2.2. I nstall liquid tight fitting with knurled nut

toward the outside of the enclosure.

5.2.3. S

ecure to enclosure wall using the supplied

nut.

5.2.4. P

ass plenum rated cable through fitting and

tighten nuts.

5.2.5. S

train relieve cable using the supplied hose

clamp.

Note: Additional fittings and hose clamps must be

purchased separately.

6.0 Grounding

6.1

Using Conduit

mWARNING

Insure all support elements are attached in accordance with applicable

NEC standards and local ordinances.

7.0 Cable Management

7.1

The area in front of the module mounting panel is

intended for slack storage.

Module Mounting Panel

Fiber Guide and Radius Control

External Ground Location

6.2.

Attach grounding hardware to cable armor

according to manufacturer’s instructions.

6.3.

Attach #14 AWG ground wire or equivalent ground

braid to cable grounding hardware and route to

internal ground stud of enclosure. Tighten supplied

locknut to 40 in-lbs.

Cable Strain Relief Bracket

(4 ea)

7.2

To avoid patch cord congestion and aid in

installation the amount of slack stored inside

the zone enclosure should be minimized.

7.2.1. Use of 3M factory-terminated cabling is

recommended.

Internal Ground

Location, 1 each side

7.2.2. When using field-terminated or bulk cabling

slack should be stored outside the enclosure

or inside the closet cabinet.

7.3

Route cabling per company practice.

Note: Do not violate cable minimum bend radius

specified by cable manufacturer.

Note: There are two internal locations for grounding

cables. Consolidate multiple cable grounds as needed.

3M is a trademark of 3M Company. All other trademarks herein are the property of their respective owners.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be reliable, but the accuracy or

completeness is not guaranteed. Before using this product, you must evaluate it and determine if it is suitable for your intended application. You assume

all risks and liability associated with such use. Any statements related to the product which are not contained in 3M’s current publications, or any contrary

statements contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture for a period of one (1) year from the time of purchase. 3M MAKES NO OTHER

WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

If this product is defective within the warranty period stated above, your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product

or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be liable for any indirect, special, incidental or

consequential loss or damage arising from this 3M product, regardless of the legal theory asserted.

Communication Markets Division

6801 River Place Blvd.

Austin, TX 78726-9000

1-800-426-8688

www.3M.com/Telecom

Please Recycle. Printed in USA.

© 3M 2014. All Rights Reserved.

78-0015-0552-4-A