Enhancing the Functionality of Delactosed Whey

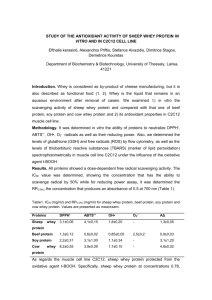

advertisement