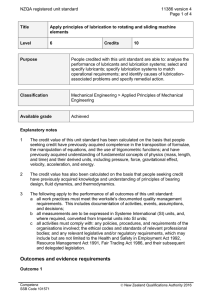

ERIKS Lubrication Essentials

advertisement

ERIKS Lubrication Essentials Your core lubrication range introduction All the lubrication you need? ERIKS Lubrication Essentials is a range of high quality, readily available items designed to meet the most common industrial lubrication and maintenance applications. Why Lubrication Essentials? The Concept Feedback from our customers has With this in mind we set out to define indicated two common problems with a core range of items with excellent lubricant supply:- stock availability, hand picked, by our n The ever expanding plethora of different lubricants, additives and performance claims is becoming impossible to keep up with. Also, it’s easy to become blinded by the “science” of performance claims which sound too good to be true, but how do you cut through the jargon and find out if it is really the right product for your application? lubrication engineers to cover as wide a range of applications as possible while always maintaining the very best in performance and compliance. The Products ERIKS Lubrication Essentials range meets the widest variety of applications imaginable from around 30 core items. These are amongst our most popular products and are proven in hundreds of n When surveying customer stores we regularly encounter several stocked items which all do exactly the same job, multiplying our customers stock values and wasting their time managing excessive inventory. 2 applications across as wide a variety of industrial sectors imaginable. ERIKS LUBRIcATION ESSENTIALS Introduction Products from the leading brands Ambersil Part of the CRC Industries group, a global leader in the chemical industry, Ambersil manufacture and market a wide range of maintenance, repair and overhaul (MRO) products. Castrol One of the most recognised and trusted global lubricant brands, dating all the way back to 1909. Today Castrol forms the main lubricants division of global petrochemical giant BP. OKS Based in Maisach Germany, OKS has engineered and manufactured specialist lubricants to world-class standards for over 30 years. The German MRO market leader, OKS is part of the global Freudenberg Group. Rocol Established in 1882 as Ragosine and Company, Rocol develops and manufactures high quality lubricants and maintenance products in Leeds. ROCOL is part of ITW, a multi-national US owned, Fortune 500 company. The Key Benefits:n Proven performance Hand picked, by our lubrication engineers from the leading brands. All established popular products RX The RX range of products has been developed by ERIKS over many years of practical application engineering and development, this knowledge and understanding is designed into all of our products with the aim to increase your performance and extend reliability. with an impeccable track record of performance and consistency n Simplify and reduce inventory Designed to cover as wide a range of applications as possible with the most manageable number of items n Excellent availability All stocked in volume at the ERIKS National Distribution Centre n Ensure compliance Products from the leading brands with all the relevant certification When you look at it that way, it should be all the lubrication you ever need… smart technologies Simatec An independent Swiss company who for more than 30 years have produced innovative products for the lubrication, fitting, removal and handling of bearings, gears and other mechanical components. Simatec’s market leading products simplify maintenance and ensure safety at all times. Triflow Triflow, a brand of Ronseal, is a market leading high quality maintenance spray used by both consumers and professionals across the UK. WD-40 Developed in 1953 by the Rocket Chemical Company of San Diego, California, it took 40 attempts to get their water displacing formula right and today the WD-40 Company sells to consumers and industrial markets globally. 3 complete ERIKS LUBRIcATION ESSENTIALS RANGE Bearing Greases Multi-Purpose Grease EP2 Wide Temp Range, EP2 Bearing Grease Page 6 Food Grade, EP Bearing Grease Page 7 EP2-400G-RX High Temp, EP2 Bearing Grease Page 8 OKS404-400ML Page 9 OKS479-400ML OKS422-400ML Lubricating Oils Gear Oil Food Grade Gear Oil Hydraulic Oil Page 10 CAS-ALPHASP220-20LTR CAS-ALPHASP320-20LTR Chain Spray Page 11 Page 14 Page 15 OKS3751-500ML Page 18 4 OKS3770-5LTR OKS3770-25LTR Wire Rope Spray Page 16 Page 17 CAS-AIRCOLPD100-20LTR ROC-WIRE ROPE SPRAY Automatic Lubricators Open Gear Dry Film Spray ROC-TUFGEAR SPRAY Page 13 CAS-HYSPINAWS32-20LTR CAS-HYSPINAWS46-20LTR Compressor Oil Open Gear Lubricants Open Gear Grease Spray Page 12 OKS3720-5LTR OKS3720-25LTR Food Grade Chain Spray OKS671-400ML Food Grade Hydraulic Oil Simalube Lubricant Range Page 19 OKS491-500ML Page 20 SIMASL24-125 SIMASL10-125 SIMASL01-125 SIMASL14-125 SIMASL18-125 ERIKS LUBRIcATION ESSENTIALS Work Box Essentials Multi-Purpose Maintenance Oil Multi-Purpose Maintenance Oil with PTFE Page 22 Page 23 WD40-400ML Universal Cleaner Page 26 Page 30 OKS1361-500ML Copper Anti-Seize Paste Fast Drying Cleaner Page 31 Food Grade Anti-Seize Paste Page 34 OKS245-250G Bio-Degradable Cleaner Page 35 OKS252-250G Page 29 AMB-AMBERKLFE10-400ML Cutting Oil OKS1110-100G OKS1110-500G OKS1111-500ML OKS371-500ML Page 28 OKS2621-400ML Silicone Grease Page 25 OKS641-500ML Page 27 OKS2611-500ML Food Grade, Maintenance Spray Page 24 TRIFLOW-500ML Contact Cleaner Silicone Spray (also for mould release) High Performance, Maintenance Spray OKS2650-500ML Leak Detector Spray Page 32 OKS391-400ML Temporary Protective Film, Wax Based Page 36 OKS2101-500ML Page 33 OKS2801-400ML Zinc Galvanizing Spray, Permanent Page 37 OKS2511-500ML 5 Bearing Greases Multi-Purpose Grease EP2 RX Multi-Purpose Grease EP2 is a light brown multi-textured grease utilising a lithium soap base and highly refined mineral oil. In addition, it has been fortified with additives to improve load carrying and corrosion resistance. RX Multi-Purpose Grease is suitable for a wide range of applications within the industrial environment. Its formulation makes it especially suited for slow to medium speed bearings, in addition the incorporation of specially selected additives ensures it will protect equipment even under high loads and where moisture ingress may be a concern. Characteristics Appearance: Light brown Extreme Pressure: Yes Oil: Mineral Soap: Lithium Technical Specification Part No: EP2-400G-RX Also Available: Please check stock availability for additional pack sizes 6 12.5kg EP2-12.5KG-RX NGLI: 2 Temperature: -20°C to 120°C Base Oil Viscosity: 180 mm²/s 4 Ball Weld Load: 2,600N DIN Standard: DIN 51 502: KP2K-20 ERIKS LUBRIcATION ESSENTIALS Bearing Greases Wide Temperature Range, EP2 Bearing Grease OKS 404 is a high performance lubricating grease formulated using a semi-synthetic lubricating oil and a lithium complex soap fortified with extreme pressure additives. This provides OKS 404 with the capability to lubricate medium to high speed friction and roller bearings over a very wide temperature range and under high loads. Characteristics Appearance: Light coloured Extreme Pressure: Yes Oil: Semi-synthetic Soap: Lithium complex Technical Specification NGLI: 2 Temperature: -30°C to +150°C Base Oil Viscosity: 100 mm²/s Four Ball Weld Load: 2,800N DIN Standard: DIN 51 502: KP2P-30 Also Available: Side Lever Grease Gun Suitable for use with 400ml cartridges Part No: OKS5500 Part No: OKS404-400ML Also Available: Please check stock availability for additional pack sizes 1KG OKS404-1KG 5KG OKS404-5KG 25KG 180KG OKS404-25KG OKS404-180KG 7 Bearing Greases Food Grade, EP Bearing Grease OKS 479 is a high performance lubricating grease formulated to lubricate friction and roller bearings operating at medium to moderately high speeds across a very wide temperature range and under high loads. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products, additionally, consistency is NLGI 1 which provides excellent compatibility with centralised lubrication systems. These inherent properties enable OKS 479 to be the ideal product to fulfill the majority of food and beverage manufacturing plant requirements and can therefore significantly reduce the on-site lubricant inventory. Characteristics Appearance: Light coloured Extreme Pressure: Yes Oil: Polyalphaolefin (PAO) Soap: Aluminium complex Technical Specification NGLI: 1 Temperature: -25°C to +160°C NSF Approval: H1 Reg No: 135675 Base Oil Viscosity: 400 mm²/s Four Ball Weld Load: 2,200N DIN Standard: DIN 51 502: KPFHC1P-20 Part No: OKS479-400ML Also Available: Please check stock availability for additional pack sizes 8 1KG OKS479-1KG 5KG OKS479-5KG 25KG OKS479-25KG ERIKS LUBRIcATION ESSENTIALS Bearing Greases High Temperature, EP2 Bearing Grease OKS 422 is a high performance lubricating grease formulated to lubricate friction and roller bearings operating at high speeds and/or high temperatures. The capability to be used as a spindle bearing lubricant and also has the capability to operate at extremely low temperature. Extremely impact and pressure resistant with excellent wear protection. Characteristics Appearance: Light coloured Extreme Pressure: Yes Oil: Polyalphaolefin (PAO) Soap: Barium complex Technical Specification NGLI: 2 Temperature: -40°C to +180°C Base Oil Viscosity: 50 mm²/s Four Ball Weld Load: 4,000N DIN Standard: DIN 51 502: KPHC2R-40 Also Available: Side Lever Grease Gun Suitable for use with 400ml cartridges Part No: OKS5500 Part No: OKS422-400ML Also Available: Please check stock availability for additional pack sizes 1KG OKS422-1KG 5KG OKS422-5KG 25KG OKS422-25KG 180KG OKS422-180KG 9 Lubricating Oils Gear Oil Castrol Alpha SP 220 & 320 are formulated using high quality solvent refined mineral oils, fortified with sulphur-phosphorous compounds to impart anti-wear and extreme pressure properties. These gear lubricants are recommended for the use of industrial gearboxes with forced circulation or splash and oil bath lubrication and meet many major OEM approvals. Characteristics Appearance: Colourless to light amber Extreme Pressure: Yes Oil: Mineral Technical Specification Alpha 220 USED IN FENNER GEARBOXES Alpha 320 ISO VG: 220 320 Temperature: -10°C to +105°C -10°C to +105°C Base Oil Viscosity: 220 mm²/s 320 mm²/s Part No: CAS-ALPHASP220-20LTR CAS-ALPHASP320-20LTR Also Available: Please check stock availability for additional pack sizes 10 208L CAS-ALPHASP220-208LTR CAS-ALPHASP320-208LTR Available in the following viscosity grades: 68, 100, 150, 460, 680. ERIKS LUBRIcATION ESSENTIALS Lubricating oils Food Grade Gear Oil OKS 3720 is a high performance food industry gear oil formulated using synthetic hydrocarbon lubricating oil fortified with extreme pressure additives to impart anti-wear and extreme pressure properties. These gear lubricants are recommended for the lubrication of industrial gearboxes. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Colourless to yellow Extreme Pressure: Yes Oil: Polyalphaolefin (PAO) Technical Specification ISO VG: 220 Temperature: -30°C to +120°C NSF Approval: H1 Reg. No. 135752 Base Oil Viscosity: 220 mm²/s DIN Standard: DIN 51 502: CLP HC 220 USED IN FENNER GEARBOXES Part No: OKS3720-5LTR OKS3720-25LTR Also Available: Please check stock availability for additional pack sizes 200L OKS3720-200LTR Available in the following viscosity grades: 320 - OKS3725 460 - OKS3730 680 - OKS3740 11 Lubricating Oils Hydraulic Oil Castrol Hyspin AWS 32 & 46 premium hydraulic oils are formulated utilising turbine quality solvent refined mineral oils, fortified by an additive package to provide enhanced anti-wear, rust and oxidation properties. Meets the requirements of the majority of hydraulic system original equipment manufacturers. Characteristics Appearance: Colourless to yellow Oil: Mineral Technical Specification Hyspin 32 ISO VG: 32 Hyspin 46 46 Temperature: -10°C to +105°C -10°C to +105°C Base Oil Viscosity: 32 mm²/s 46 mm²/s DIN Standard: DIN 51 502: HLP DIN 51 502: HLP Part No: CAS-HYSPINAWS32-20LTR CAS-HYSPINAWS46-20LTR Also Available: Please check stock availability for additional pack sizes 12 5L CAS-HYSPINAWS32-5LTR CAS-HYSPINAWS46-5LTR 208L CAS-HYSPINAWS32-208LTR CAS-HYSPINAWS46-208LTR Available in the following viscosity grades: 10, 15, 22, 68, 100, 180. ERIKS LUBRIcATION ESSENTIALS Lubricating oils Food Grade Hydraulic Oil OKS 3770 is a high performance hydraulic oil for the food industry formulated using synthetic hydrocarbon lubricating oil fortified with anti-wear additives to impart anti-wear properties. Meets the specifications of the majority of the leading hydraulic system manufacturers. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Colourless Oil: Polyalphaolefin (PAO) Technical Specification ISO VG: 46 Temperature: -40°C to +135°C NSF Approval: H1 Reg. No. 129962 Base Oil Viscosity: 50 mm²/s DIN Standard: DIN 51 502: HLP HC 46 Part No: OKS3770-5LTR OKS3770-25LTR Also Available: Please check stock availability for additional pack sizes 200L OKS3770-200LTR Available in the following viscosity grades: 32 - OKS3725 68 - OKS3730 13 Lubricating Oils Chain Spray OKS 671 is a high performance spray applied lubricating oil formulated with high quality solvent refined mineral oils fortified with extreme pressure and solid lubricant additives. Especially suited for the long term lubrication of chains, guideways, pins, pivots and hinges. Characteristics Appearance: Light-coloured Oil: Mineral Additive Package: Mox-Active* Solid Lubricant: White solid lubricants *OKS developed molybdenum based extreme pressure additive Technical Specification ISO VG: 46 Temperature: -30°C to +80°C Base Oil Viscosity: 42 mm²/s DIN Standard: DIN 51 502: CL F 46 Part No: OKS671-400ML Also Available: Please check stock availability for additional pack sizes 14 5L OKS670-5LTR 25L OKS670-25LTR 200L OKS670-200LTR ERIKS LUBRIcATION ESSENTIALS Lubricating oils Food Grade Chain Spray OKS 3751 is a spray applied high performance chain oil for the food industry, it is formulated using synthetic hydrocarbon lubricating oil fortified with selected additives and PTFE. The additive package enables OKS 3751 to provide excellent high temperature and oxidation stability, excellent wear protection and is very adherent. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Whitish Oil: Polyalphaolefin (PAO) Solid Lubricant: PTFE Technical Specification ISO VG: 100 Temperature: 35°C to +135°C NSF Approval: H1 Reg. No. 124801 Base Oil Viscosity: 110 mm²/s DIN Standard: DIN 51 502: CLF HC 100 Part No: OKS3751-500ML Also Available: Please check stock availability for additional pack sizes 5L OKS3750-5LTR 15 Lubricating Oils Compressor Oil Castrol Aircol PD 100 is a high quality air compressor lubricating oil formulated from high quality solvent refined mineral oils and fortified with additives to impart increased resistance to thermal decomposition and component wear. Characteristics Appearance: Light yellow Oil: Mineral Technical Specification ISO VG: 100 Temperature: 0°C to +110°C Base Oil Viscosity: 100 mm²/s DIN Standard: DIN 51 506: VD-L Part No: CAS-AIRCOLPD100-20LTR Also Available: Please check stock availability for additional pack sizes 16 208L CAS-AIRCOLPD100-208LTR Available in the following viscosity grades: 32, 46, 68 150. ERIKS LUBRIcATION ESSENTIALS Lubricating oils Wire Rope Spray Rocol Wire Rope Spray is a high performance wire rope lubricant formulated from high quality solvent refined mineral oils and fortified with selected performance enhancing additives. It is designed to penetrate wire rope and lubricate the wire strands and core, dewater wet ropes prior to storage plus provide a resilient coating to protect the rope exterior from corrosion. Characteristics Appearance: Grey fluid Extreme Pressure: Yes Oil: Mineral Thickener: Organically modified clay Solid Lubricant: Molybdenum disulphide Technical Specification NLGI: 00 Temperature: -30°C (0 min application temp) to +100°C Base Oil Viscosity: 465 mm²/s Four Ball Weld Load: 3,000N Part No: ROC-WIRE ROPE SPRAY Also Available: Please check stock availability for additional pack sizes 4KG ROC-WIRE ROPE-4KG 5L ROC-WIRE ROPE-5LTR 18KG ROC-WIRE ROPE-18KG 20L ROC-WIREROPE-20LTR 17 open gear Lubricants Open Gear Grease Spray Rocol Tufgear Spray is a high performance heavy duty open gear lubricant formulated utilising a non-melting base with a high viscosity mineral lubricating oil and solid lubricants. It is designed to withstand high loads and provide an almost dry film once cured which will both lubricate and protect the wire rope from corrosion. Characteristics Appearance: Black almost dry film Extreme Pressure: Yes Oil: Mineral Thickener: Organically modified clay Technical Specification NLGI: 2 Temperature: -10°C to +100°C Base Oil Viscosity: >1000 mm²/s Four-ball weld load: 7,845N Part No: ROC-TUFGEAR SPRAY Please check stock availability for additional pack sizes 18 400G Also Available: ROC-TUFGEAR UNI-400G 5KG ROC-TUFGEAR UNI-5KG 18KG ROC-TUFGEAR UNI-18KG ERIKS LUBRIcATION ESSENTIALS open gear Lubricants Open Gear Dry Film Spray OKS 491 is a spray applied high performance open gear lubricant formulated from graphite solid lubricant and resins to produce a dry film. OKS 491 is ideally suited for the lubrication of slow speed open gears which may be subjected to high loads or operating in dusty environments and can also be used for the dry lubrication of wire ropes and springs. Characteristics Appearance: Black Oil: Mineral, solvent Additive Package: Bitumen, natural resins Solid Lubricant: Graphite Technical Specification Temperature: -30°C to +100°C Part No: OKS491-500ML 19 AUTOMATIc LUBRIcATORS Single-point automatic lubricator Simalube is a gas powered single point automatic lubricator filled with 30, 60, 125 or 250 ml of grease or oil. The patented hydrogen producing dry cells drive a piston to dispense lubricant at a consistent rate of between 1 and 12 months, which is adjustable in operation. Gas production is initiated by turning the adjustment disk on the top with a hex key or Allen key. Features / characteristics n 1 to 12 month dispense time n Infinitely adjustable during operation n Patented gas producing dry cell technology means no liquid or dangerous chemicals, no toxic waste n ATEX approval to Zone 2 n Works in any orientation even upside down n Grease or oil filled (oil filled units have a non-return valve) Suitable for the lubrication of rotary bearings, linear bearings, chain, open gears, sprockets etc. Part No. SIMASL24-125 SIMASL10-125 SIMASL01-125 SIMASL14-125 SIMASL15-125 SIMASL18-125 Base oil Thickener/ Soap Description Size Temp range DIN 51502 Multi purpose grease with EP, NLGI 2 125 –30°C to +140°C Mineral oil Li/Comp. KP2N-30 Food industry grease, NSF H1 approved, NLGI 2 125 –30°C to +140°C Synthetic Al/Comp. KPHC2N-30 Water resistant grease, NLGI 2 125 –30°C to +120°C Mineral oil Li/Ca KP2K-30 Chain oil 125 –10°C to +90°C Mineral oil CGLP68 High temperature chain oil 125 –30°C to +250°C Synthetic CGLPE220-320 Food industry oil, NSF H1 approved 125 –15°C to +150°C Synthetic CLPHC220 For other sizes change suffix 125 to relevant size. i.e. SIMASL10-125 becomes SIMASL10-60 Accessories A wide range of accessories are available including; brushes for chain applications, brackets, protectors and remote connection hoses. Bent connection 45° Reducing Nipple ¼” x Extension - 50mm Clamp Ø 50mm Brush 40mm Part No: SIMA2010 Part No: SIMA2035 ¼ Part No: SIMA1001 20 1/8” Part No: SIMA1020 M6 Part No: SIMA1022 Part No: SIMA1041 ERIKS LUBRIcATION ESSENTIALS AUTOMATIc LUBRIcATORS Technical Specification Product: Automatic grease and oil lubricator Power Generation: Hydrogen gas producing dry cells Working Pressure: Max. 5 bar Adjustment: Stepless 1-12 months Dispensing Quantity: 0.08 - 8.3 ml/day Operating Temperature: -20ºC to + 55˚C (unit)* Usage: The lubricator can be installed in any position, even underwater. Attention: do not expose to direct heat. Certifications / Approvals: II 1G Ex ia IIC T6 II 1D Ex iaD 20T 80˚C I M1 Ex ia I Ingress Protection: IP68 (dustproof and waterproof) Water tight to a depth of 10m Usage Period: Within 2 years of filling date Mounting: Works in any orientation, even upside down Sizes: 30 ml 60 ml 125 ml 250 ml Weight Full: 82 g 115 g 190 g 335 g Weight Empty: 55 g 60 g 75 g 111 g * Lubricant fill has a separate operating temperature, please refer to table ø 52 mm (2.05 in.) CalPro App now available! You can use this handy tool to calculate dispense times for simalube at any time when you’re on the move. 193 mm (7.6 in.) Calculation is based on the parameters entered for lubricating bearings, sliding bearings and chains. ø 52 mm (2.05 in.) 100 mm (3.9 in.) ø 52 mm (2.05 in.) R1/4” simalube 30 14 mm (0.55 in.) 14 mm (0.55 in.) 14 mm (0.55 in.) 43 mm (1.7 in.) 14 mm (0.55 in.) 62 mm (2.4 in.) ø 52 mm (2.05 in.) R1/4” R1/4” R1/4” simalube 60 simalube 125 simalube 250 21 MAINTENANcE LUBRIcANTS Multi-Purpose WD Spray WD-40 is the original and most widely used water displacement and maintenance fluid. Formulated from aliphatic hydrocarbons and carefully selected additives, it can be used as a light lubricant, a releasing agent, corrosion preventive cleaner and has many more applications within the workshop environment. Characteristics Appearance: Light amber Oil: Mineral, solvent Additive Package: Corrosion preventative Technical Specification ISO VG: 3 Temperature: -23° to +93°C Base Oil Viscosity: 2.8 mm²/s Salt Spray Test: 0-20% after 72 hours Part No: WD40-400ML Also Available: Please check stock availability for additional pack sizes 22 5L WD40-100ML WD40-600ML WD40-200ML WD40-5LTR 25L 200L WD40-25LTR WD40-200LTR ERIKS LUBRIcATION ESSENTIALS MAINTENANcE LUBRIcANTS Multi-Purpose Maintenance Spray with PTFE Tri-flow is a high performance maintenance fluid formulated using mineral lubricating oil, PTFE solid lubricant and selected additives. The addition of PTFE assists in providing a durable wear reducing lubricating film. Characteristics Appearance: Light amber Oil: Mineral Additive Package: Corrosion preventative Solid Lubricant: PTFE Technical Specification ISO VG: 15 Temperature: -53°C to + 246°C Base Oil Viscosity: 14 mm²/s Part No: TRIFLOW-500ML Please check stock availability for additional pack sizes 200ML Also Available: 4L TRIFLOW-200ML TRIFLOW-4LTR 23 MAINTENANcE LUBRIcANTS High Performance Maintenance Spray Very high performance maintenance fluid for dismantling, lubricating and protecting metal surfaces and machine elements. Excellent cleaning action and temporary protection against corrosion, displaces moisture. Characteristics Appearance: Yellowish-transparent Oil: Mineral, solvent Additive Package: Corrosion preventative Technical Specification ISO VG: 3 Temperature: -50°C to +80°C Part No: OKS641-500ML Also Available: Please check stock availability for additional pack sizes 24 5L OKS640-5LTR 25L OKS640-25LTR 200L OKS640-200LTR ERIKS LUBRIcATION ESSENTIALS MAINTENANcE LUBRIcANTS Food Grade, Maintenance Spray High performance maintenance and lubricating oil. Tasteless and odourless, extremely high creep capacity, enters small gaps, ideal for precise lubrication. Displaces water, dissolves dirt and rust. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Colourless Oil: White Technical Specification ISO VG: 15 Temperature: -10°C to +180°C NSF Approval: H1 Reg. No. 124384 Base Oil Viscosity: 14 mm²/s DIN Standard: DIN 51 502: CL 15 Part No: OKS371-500ML Also Available: Please check stock availability for additional pack sizes 5L OKS370-5LTR 200L OKS370-200LTR 25 Maintenance cleaners Universal Cleaner A solvent degreaser for cleaning machine parts and surfaces with oily or greasy soiling. High cleaning power together with fast evaporation combine to provide residue free surfaces. Short-term corrosion protection due to the incorporation of additives. Commonly used as a solvent cleaner for the removal of excess lubricant from lubrication points and excess adhesive from glueing points. Characteristics Appearance: Colourless Type: Solvent Components: Solvent blend Additive package: Corrosion preventative additive Part No: OKS2611-500ML Also Available: Please check stock availability for additional pack sizes 26 5L OKS2610-5LTR 25L OKS2610-25LTR 200L OKS2610-200LTR ERIKS LUBRIcATION ESSENTIALS Maintenance cleaners Electrical Contact Cleaner A fast evaporating solvent cleaner for the removal of soiling, such as oxide deposits and dust from electrical components that can cause creepage currents. Due to its fast evaporation it does not run and contains no chlorinated hydrocarbons. Excellent for the cleaning of distribution boards, switches, relays, potentiometers, plug-in connections, sliding and screw contacts. Characteristics Appearance: Colourless Type: Solvent Components: Solvent blend Also Available: Multi Foam Cleaner Removes firmly adhering organic soiling such as nicotine, fat and silicone films. Cleans metals, plastics, glass and rubber in the gastronomy, office and vehicle fields gently and without leaving stripes. Ideally suitable for vertical surfaces Part No: OKS2631-400ML Part No: OKS2621-400ML 27 Maintenance cleaners Fast Drying Cleaner A highly effective degreasing agent for all hydrocarbon soiling, including oil, grease, tar and bitumen. A fast and effective cleaning solvent it is an ideal alternative to Trichloroethane. Characteristics Appearance: Colourless Type: Solvent Components: Solvent blend Also Available: Industrial Degreaser Ambersil industrial degreaser FG is a solvent degreasing product formulated from a blend of specially selected solvents. This formulation provides fast drying and high levels of solvency together with sustainability for use within the food and beverage industry. Part No: Part No: AMB-INDDEGREASERFG-500ML AMB-AMBERKLFE10-400ML Also Available: Please check stock availability for additional pack sizes 28 AMB-AMBERKLFE10-1LTR AMB-AMBERKLFE10-5LTR 25L AMB-AMBERKLFE10-25LTR 200L AMB-AMBERKLFE10-200LTR ERIKS LUBRIcATION ESSENTIALS Maintenance cleaners Biodegradable Cleaner Biodegradable aqueous cleaner for removing heavy oily, greasy and sooty soiling from the majority of surfaces. Gentle to delicate surfaces, for universal use in industry, workshops and food processing technology. Depending on the soil to be removed can be diluted with water thereby further enhancing its cost effectiveness. Characteristics Appearance: Red Additive Package: Surface-active agents Type: Water Components: Non-ionic and corrosion protection POSITIVE ENERGY REDUCTION Technical Specification pH Value: 12 Biodegradability: >85% in 28 days Dilution Ratio: 1:5 to a maximum of 1:40 NSF Approval: NSF A1 Reg. No. 129003 POSITIVE POLLUTION REDUCTION ERIKS Planet + Positive Steps for you and the planet Planet + applies ERIKS passion for technology, manufacturing knowhow and innovation in a four part approach to a better planet: reducing energy, pollution, waste and risk. ERIKS aims to achieve the highest manufacturing standard with the lowest levels of pollution, both for ourselves and our customers by purchasing sustainably, eliminating toxic substances, and designing for minimal impact at every stage of the product life cycle. POSITIVE WASTE REDUCTION Part No: OKS2650-500ML Also Available: Please check stock availability for additional pack sizes 5L OKS2650-5LTR 25L OKS2650-25LTR 200L POSITIVE RISK REDUCTION OKS2650-200LTR 29 siliconE LUBRIcANTS Silicone Spray (also for mould release) A colourless silicone spray, chemically neutral, solvent free and also displaces water. An ideal fitting aid for rubber profiles, impregnation and coating of plastic surfaces and textiles. Lubricant for use in processing plastics. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Light-coloured Oil: Silicone Technical Specification Temperature: -50°C to +200°C NSF Approval: H1 Reg. No. 129481 Description: Chemically neutral, solvent free Part No: OKS1361-500ML Also Available: Please check stock availability for additional pack sizes 30 5L OKS1360-1LTR OKS1360-5LTR 25L OKS1360-25LTR ERIKS LUBRIcATION ESSENTIALS siliconE LUBRIcANTS Silicone Grease Market leading silicone grease for fittings, seals and plastic parts. Excellent compatibility to plastics, no drying out or bleeding, tasteless, odourless and highly adhesive. A silicone grease for a broad range of applications, including food processing. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Transparent Oil: Silicone Thickener: Inorganic Technical Specification NLGI: 3 Temperature: -40°C to +200°C NSF Approval: H1 Reg. No. 124381 Base Oil Viscosity: 9,500 mm²/s DIN Standard: DIN 51 502: MSI3S-40 Part No: OKS1110-100G OKS1110-500G OKS1111-500ML Also Available: Please check stock availability for additional pack sizes 10G 500G OKS1110-10G OKS1110-500G 25KG OKS1110-25KG 180KG OKS1110-180KG 31 metal working LUBRIcANTS Cutting Oil A high performance cutting oil suitable for the majority of machining operations on all metals. Excellent metal compatibility and chlorine free. The formulation is suitable for a wide range of cutting speeds and will produce both extended cutting tool life and optimum work-piece surface finish. Characteristics Appearance: Light coloured Extreme Pressure: Yes Oil: Mineral Technical Specification ISO VG: 22 Also Available: Ambersil Tufcut Part No: Ambersil Tufcut spray is a specialist metal cutting lubricant based on a mixture of extreme pressure additives and antioxidants. It has been formulated as an instant, ready to use metal machining lubricant with high film-strength and resistance to extreme pressure. OKS391-400ML Part No: AMB-TUFCUT SPRAY-400ML Also Available: Please check stock availability for additional pack sizes 250 ML OKS390-250ML 32 5L OKS390-5LTR 25L OKS390-25LTR 200L OKS390-200LTR ERIKS LUBRIcATION ESSENTIALS leak detectors Leak Detector Spray Allows the location of leaks on pressurised lines, fittings and containers. For use on pneumatic, oxygen and gas systems as well as refrigeration systems. Formation of bubbles indicates loss of gas. For universal use, non-toxic. When using on polyamide lines, wash off product with water afterwards. Characteristics Appearance: Colourless Base Fluid: Water Additive Package: Surfactant and corrosion protection Technical Specification Temperature: up to + 80°C Part No: OKS2801-400ML 33 anti-seize pastes Copper Anti-Seize Paste For screws, bolts and sliding surfaces subjected to high temperatures, water or salt water. Prevents binding together, rusting and seizing during assembly. Highly adhesive with excellent corrosion protection. Characteristics Appearance: Copper coloured Oil: Synthetic Soap: Lithium Additive Package: Corrosion preventative Solid Lubricant: Copper powder Technical Specification Temperature: -30°C to +150°C / 1,100°C lubrication / separation Press Fit: µ = 0.15 Four-ball weld load: 2,600 N Thread Friction: (M10/8.8): µ = 0.15 Part No: OKS245-250G Also Available: Please check stock availability for additional pack sizes 1KG OKS245-1KG 34 5KG 25KG OKS245-5KG OKS245-25KG ERIKS LUBRIcATION ESSENTIALS anti-seize pastes Food Grade Anti-Seize Paste For screws, bolts and sliding surfaces that are subjected to high pressures, high temperatures at low speeds or oscillating movements. Prevents binding together and rusting. Metal-free, highly adhesive. A universal high-temperature assembly paste, also for use in food processing industry. Certified by NSF as H1 hence suitable for incidental contact with food and beverage products. Characteristics Appearance: Light grey Oil: Polyglycol Thickener: Silicate Solid Lubricant: White solids Technical Specification Temperature: -30°C to +160°C / 1,200°C lubrication / separation NSF Approval: NSF H1 Reg. No. 135748 Press Fit: µ = 0.12 Thread Friction: (M10/8.8): µ = 0.15 Part No: OKS252-250G Also Available: Please check stock availability for additional pack sizes 1KG OKS252-1KG 5KG OKS2452-5KG 35 corrosion protection Temporary Protective Film, Wax Based A temporary wax-based corrosion protection film for storage and shipping of machine parts with bare metal surfaces. Non-tacky transparent film, easy to remove but can be left on due to good compatibility with lubricants. Characteristics Appearance: Light-coloured Oil: Solvent Additive Package: Corrosion preventative Technical Specification Temperature: -40°C to +70°C Salt Spray Test: 1000 hours with 50 µm layer thickness Part No: OKS2101-500ML Also Available: Please check stock availability for additional pack sizes 5L OKS2100-5LTR 36 25L OKS2100-25LTR 200L OKS2100-200LTR ERIKS LUBRIcATION ESSENTIALS corrosion protection Zinc Galvanizing Spray, Permanent Cathodic corrosion protection based on highly pure zinc powder for ferrous metals. For touching up galvanised surfaces, also suitable as adhesive primer for coating systems. Fast-drying, commonly used in steel construction also works in air conditioning technology. Characteristics Appearance: Zinc grey Oil: Solvent Additive Package: Synthetic resin mixture Technical Specification Temperature: up to +400°C Salt Spray Test: 500 hours with 70 µm layer thickness Part No: OKS2511-500ML 37 glossary Additives Animal oil Oil derived from animal material, such as lard oil or lanolin from sheeps wool. Anti-foam additive Chemical added to oils to reduce the foaming that results from aeration. See also Additive. Anti-wear additive Chemical added to oils to reduce friction and excessive wear. Generally acts by reacting with metal surfaces to provide a protective layer. See also Additive. Aqueous cleaner Water based cleaner possibly with active additives / detergents. Base Oil Base oil viscosity 38 Test 2 The load is increased until the rotating ball seizes and welds to the other 3 generating the “weld point”, which is the final load applied. See also EP (Extreme Pressure) Additive. Graphite A common type of lubricant that consists of a form of carbon, which when finely pulverised has lubricating properties either by itself or as a load-carrying component suspended in conventional lubricants. See also solid lubricants. Grease A solid to semi-fluid lubricant consisting of a “thickener” dispersed within a lubricating base oil. The lubricating grease may be the product of a chemical reaction(s) as in soap based greases. Or the result of a more simple mixing process as with non-soap based greases. See also NLGI Grade, Base Oil Viscosity and Thickener. Refer to Oil. Inhibitor Terminology used primarily to reference the viscosity of the lubricating oil component within a grease or paste. See also Viscosity. Controls certain undesirable phenomenon in lubricants or fuels. e.g. oxidation/rust inhibitor. See also Additives. ISO International Organisation for Standardisation. ISO VG grade A system of measuring and standardising viscosity grades for industrial lubricants as determined in ISO Standard 3448. There are 18 ISO VG grades, the higher the number, the more viscous the liquid. Note: As the temperature increases, the viscosity decreases and vice versa. ISO VG Grade Viscosity at 40°C (measured in cSt or mm²/s) ISO VG 2 2.2 ISO VG 3 3.2 ISO VG 5 4.6 ISO VG 7 6.8 ISO VG 10 10 ISO VG 15 15 ISO VG 22 22 ISO VG 32 32 ISO VG 46 46 ISO VG 68 68 ISO VG 100 100 ISO VG 150 150 ISO VG 220 220 ISO VG 320 320 ISO VG 460 460 ISO VG 680 680 ISO VG 1000 1000 ISO VG 1500 1500 Lubricant A substance used to reduce friction and wear between two moving surfaces. A lubricant can be fluid, semi-fluid or solid and depending on specification can: Control friction, control wear, prevent corrosion, transfer heat (cool), seal and keep out contaminants, carry away contaminants, dampen shock, reduce noise levels, transmit power (i.e. hydraulics). Maximum and minimum temperature Total operating window of the lubricant. Consistently operating at the extremities can adversely affect the operating life. See also Operating Temperature. Micro-welding When two metals of similar melting points rub together, hot spots on the two metals will melt together creating a temporary bond. This will then be pulled apart by the relative motion of the two surfaces causing material to break away resulting in surface damage. Mineral Oil Petroleum based, produced by refining crude oil. Molybdenum disulphide (MoS2) A black powder that serves as a dry-film lubricant in certain applications. It is also used as a component of pastes to prevent scoring when Biodegradability Chemical degradation of materials by bacteria or other biological means meaning the substance returns to more basic components. Breakaway torque Rotational force required to begin rotary motion associated with a screwed or threaded connection. See Also White Paste, Press-Fit Test, Thread Friction Coefficient. Cleaners A material which is designed to remove soiling (dirt) from a substrate (surface). Consistency The degree to which grease resists deformation under the application of a force, roughly equates to softness or hardness of the grease. Copper paste Copper powder suspended in a lubricant. Prevents direct metal-to-metal contact and seizing of parts. Corrosion preventative A substance, usually a coating designed to prevent a metallic surface from a corrosive reaction with the surrounding environment. COSHH regulations Control of Substances Hazardous to Health - Legislation requiring employers to control (prevent or reduce workers exposure to) substances that are hazardous to health by:- risk assessment, training, planning for emergencies etc. DIN Standard Deutsches Institut Für Normung, the German Institute for Standardisation. Dry film lubricant A dry lubricant coating applied either directly or suspended in a carrier. The carrier is not intended to have lubricating properties and is purely to facilitate application of the solid lubricant. See also Solid lubricant. EP (Extreme Pressure) additive An additive designed to minimise the tendency of metal surfaces to weld and seize under conditions of extreme localised loads. See also Additives. Film thickness Recommended minimum thickness of coating to give reliable protection. See also Corrosion Preventative. Food grade lubricants In most cases produced from raw materials approved by the Food and Drug Administration (FDA) commonly classified as NSF H1 or H2. See also NSF and NSF Classification. Four-ball test Test 1 A constant load is applied via a rotating ball to 3 static balls for a fixed period of time which are then inspected for the size of “wear scar”. A substance (either soluble or insoluble) added to produce or enhance certain desirable properties of the lubricant. Dry or solid lubricants may be added with the objective to maintain lubrication even when the primary lubricant (oil or grease) had displaced or evaporated. See also Anti-foam additive, Anti-wear additive, EP additive, Inhibitor. Evaluates the load carrying performance of a lubricant via 2 tests. ERIKS LUBRIcATION ESSENTIALS glossary assembling pre-fit parts, and as an additive to provide residual lubrication properties to oils and greases. Molybdenum disulphide is often called moly or moly-di-suplhide. MSDS NLGI Grade Material Safety Data Sheet. A document describing the properties and uses of a chemical product or formulation, including its identity, chemical and physical properties, health hazard information, precautions for use, information on safe handling and disposal, appearance, transport and storage considerations. System for measuring and standardising grease consistency administered by the National Lubricating Grease Institute (NLGI). Different grades have different common application areas. Bearings, for example, would almost always be lubricated by grease with an NLGI Grade of between 1 and 3. NLGI Grade State at room temp 000 Semi fluid 00 Semi fluid 0 Very Soft 1 Soft 2 Medium 3 Firm 4 Very firm 5 Hard 6 Solid Non-soap Non-soap thickeners include; Bentonite, polycarbonate. Also see Thickeners, Soaps. NSF NSF International, formerly National Sanitation Foundation. An independent not-for-profit organisation providing (amongst others) standards development, product certification and auditing in food, water, health and consumer products. NSF Classification “NSF Nonfood Compounds Registration Program Re-introduction (1999) of the authorisation program administered by the U.S. Department of Agriculture (USDA). Products eligible for NSF Registration include all compounds used in and around food establishments (nonfood compounds/non ingredients or cooking oils), including lubricants and cleaners. Registered products carry an NSF Registration Mark on their product label. Commonly; NSF H1 Lubricants which may be used when contact with food cannot be technically excluded (possibility of incidental contact). NSF H2 Applies to lubricants that may be used when contact with food is technically excluded (no incidental contact). NSF A1 General cleaning agents for use on all surfaces (must be washed off, no incidental contact). Oil Operating Temperature A chemical substance that is a viscous liquid at the desired operating temperature and will not form a solution with water, but is soluble in alcohols or ethers. May be animal, vegetable, petrochemical or synthetic in origin. For industrial applications oils are primarily petrochemical or synthetic in origin (base oil) and may also contain selected additives. See also Mineral Oil, Synthetic Oil, Vegetable Oil, Animal Oil. Range of the optimal performance of a lubricant. Operating within this window will cause no accelerated degradation to the lubricant. See also Maximum and Minimum Temperature. lubricant component may have two quoted operating temperatures, one based on the petrochemical components of the lubricant and one (higher) for the dry or solid constituent once the rest of the lubricant has evaporated or is spent. Paste A mixture of lubricating components usually a solid lubricant dispersed in a liquid. Similar in appearance to a grease but can be formed by a simple mixing process. Commonly used on sliding surfaces subjected to high pressures at low speeds such as tightening bolts, to aid subsequent disassembly. See also White Paste, Press-Fit Test, Thread Friction Coefficient, Breakaway Torque. Permanent protective film Intended to remain in place for all or some of the operating life of a product such as paint. Polytetrafluoroethylene (PTFE) A synthetic (man-made) thermoplastic polymer, which is solid at room temperature. Has one of the lowest coefficients of friction of any known solid material. See also solid lubricant. Press-fit test Indicates the lubricating performance of pastes at a very high pressure and low sliding speeds. Properties of oil Refer to; Viscosity, ISO VG Grade. Salt spray test A uniform test method for evaluating the corrosion resistance of coated metallic samples. Soaps Common soap thickeners, include; Calcium, lithium, aluminium-complex, calcuim-complex, lithium-complex. See also Thickeners, Non-Soaps, Soap and Complex Soaps. Solid lubricant A solid substance with a low frictional coefficient intended to act as a lubricant and separate moving parts. Can be applied directly or in a carrier i.e. sacrificial oil (where the solid lubricant operates when the oil has evaporated) or can be an additive to give additional lubrication or load carrying capacity to an oil or grease etc. See also Graphite, Molybdenum disulphide (MoS2), Polytetrafluoroethylene (PTFE). Solvent A liquid capable of absorbing or dissolving another substance, (such as white spirit will dissolve oily deposits). Synthetic Oil “Man made” by chemical reaction rather than refining from crude oil. e.g Polyalphaolefin (PAO), silicone oil. Temporary protective film Used during production, storage and shipping. Intended to be easily removed, often by solvents. Thickener A medium for holding the lubricating base oil. In simple terms, acts as a sponge to hold and then release lubricating oil. See also Soaps, Non-Soap for common types of thickeners. Thread friction coefficient Indicates the lubricating performance of pastes when assembling or disassembling screw threads. See Also White Paste, Press-Fit Test, Breakaway Torque. Torque A turning or twisting force. Vegetable oil Oil derived from plant material, such as castor oil or palm oil. Viscosity Measurement of the resistance to flow of a fluid. In simplified terms, viscosity is essentially thickness, water is low viscosity, honey is high viscosity (more viscous). See also ISO VG Grade. White paste Similar to copper paste but metal-free, uses white solids to prevent metal-to-metal contact. See also white solids. White solids Term used to refer to ceramic solid lubricants. Oils, greases or pastes with a substantial dry or solid 39 Call 0845 006 6000 www.eriks.co.uk ERIKS UK Amber Way, Halesowen, West Midlands, B62 8WG UNREGISTERED