04-Vol-2-Material Specification_Electrical

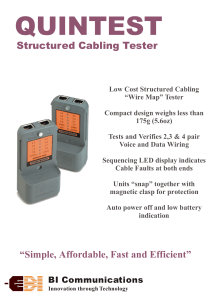

advertisement