theory unit standards

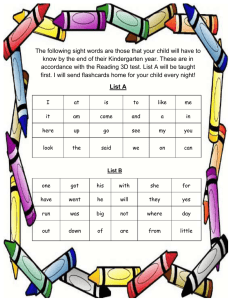

advertisement