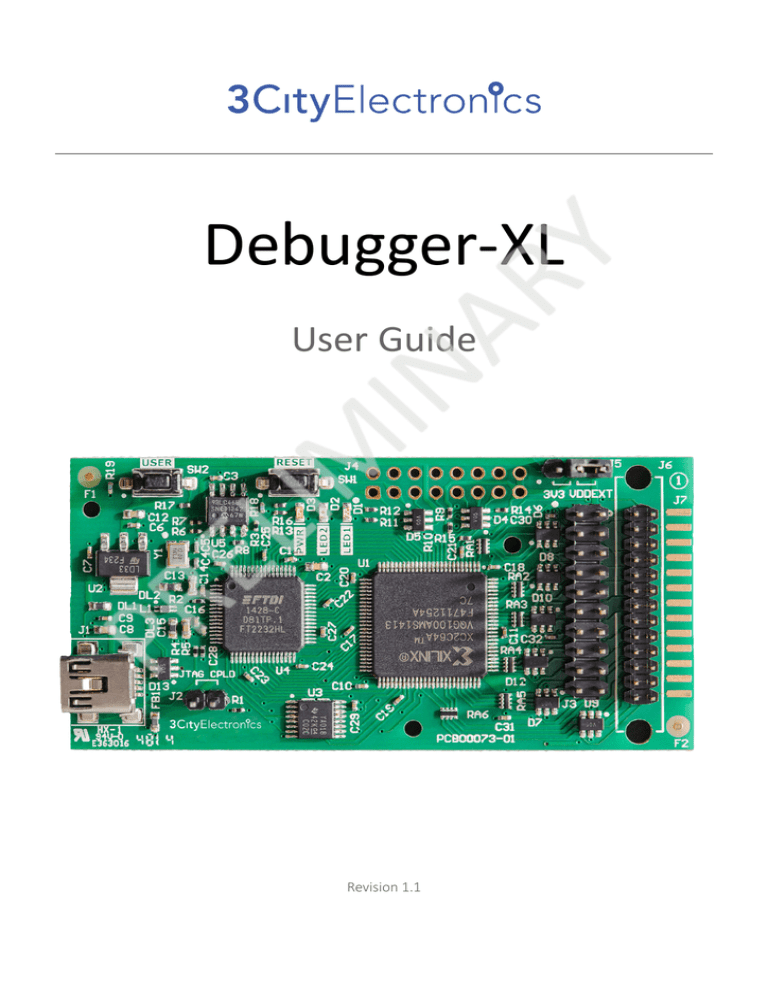

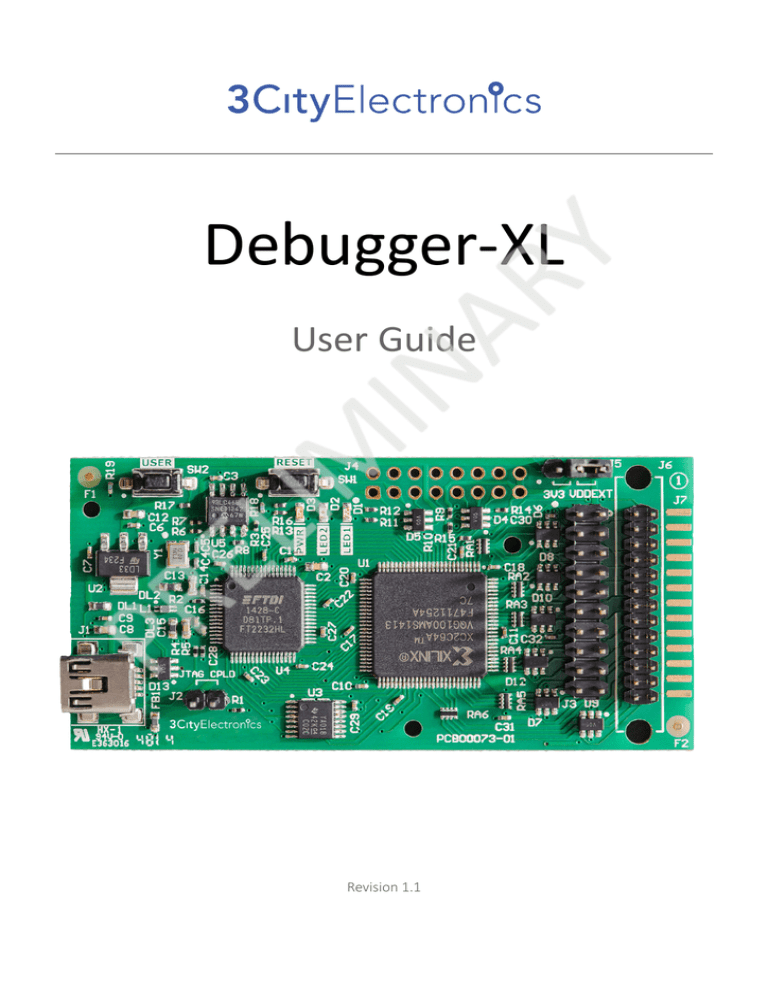

Debugger-XL

User Guide

Revision 1.1

Table of contents

1. Introduction...........................................................................................................................4

2. Product specifications...........................................................................................................5

2.1. Block diagram.................................................................................................................. 5

2.2. CPLD................................................................................................................................ 5

2.3. FT2232H.......................................................................................................................... 6

2.4. Power............................................................................................................................. 6

2.5. Protection features......................................................................................................... 6

2.6.Temperature..................................................................................................................... 6

2.7.Other................................................................................................................................ 7

3. Connectors.............................................................................................................................7

3.1. Connector J1................................................................................................................... 8

3.2. Connector J2................................................................................................................... 9

3.3. Connector J3................................................................................................................. 10

3.4. Connector J4................................................................................................................. 11

3.5. Connector J5................................................................................................................. 12

3.6 Connectors J6 and J7..................................................................................................... 13

4. Mechanical..........................................................................................................................14

5. Additional information........................................................................................................15

5.1. Copyright notice............................................................................................................ 15

5.2. Trademarks.................................................................................................................... 15

5.3. Warranty....................................................................................................................... 15

5.4. Certification................................................................................................................... 15

5.5. RoHS.............................................................................................................................. 15

5.6. Technical support ......................................................................................................... 16

List of pictures

Picture 1:Block diagram......................................................................................................................................5

Picture 2:Connector placement (top).................................................................................................................7

Picture 3:Connector placement (bottom)..........................................................................................................8

Picture 4:Overall board size [mm]....................................................................................................................14

List of tables

Table 1: Connector J1..........................................................................................................................................8

Table 2: DEBUGGER-XL operating mode............................................................................................................9

Table 3: Connector J3........................................................................................................................................10

Table 4: Connector J4........................................................................................................................................11

Table 5: Connector J5........................................................................................................................................12

Table 6: Connector J6 and J7............................................................................................................................14

1. Introduction

DEBUGGER-XL is a multifunctional device, helpful for embedded systems developers, electronic

engineers and programmers. By using the popular chip FT2232H, the device provides functionality of

GPIO, parallel ports and supports basic serial ports including: UART/USART, SPI, JTAG, SWD. The USB

protocol allows to communicate with the PC and support basic functions on most operating systems

without additional drivers installation.

A lot of Open Source projects support FT2232H as a communication interface. Therefore, DEBUGGER-XL

can be used (with no additional action) to:

•

programming/debugging many devices JTAG/SWD (OpenOCD),

•

reading/programming flash memory SPI (flashrom).

Due to the CPLD usage, the range of possible functions is expanded. It is possible for user, to program

board according to his needs. All of 32 functional pins, available on FT2232H, can be configured to

provide user defined functions and may change dynamically during device runtime. It is possible to

manage some tasks or preliminary data processing using internal CPLD's resources.

Voltage of all available signals can be customized to external device voltage (1.8 – 3.3V).

DEBUGGER-XL can be used as standalone Xilinx XC2C64A CPLD development (evaluation) board. User

can make use of available buttons, LED diodes and many I/O pins.

Board was designed with ESD protection consideration. Special anti-ESD diodes was used to protect

devices from both sides: developed system (target) and developer system (PC). Top surface is protected

from mechanical destructions by plexiglass.

Fermio-EM: Datasheet

4/16

2. Product specifications

2.1. Block diagram

Picture 1:Block diagram

2.2. CPLD

Xilinx XC2C64A is a logic buffer situated on the board. It can be program by any logic created by the user,

making it suitable as an educational platform.

For more information go to: http://www.xilinx.com/support/documentation/data_sheets/ds090.pdf.

Fermio-EM: Datasheet

5/16

2.3. FT2232H

FT2232H manages the interface between development environment (PC) and external device

(developed environment). This device has two channels using MPSSE (Multi-Protocol Synchronous Serial

Engine) that supports most popular serial protocols such as UART/USART, SPI, I2C, JTAG. Chip can also

support custom user's protocols. High-Speed USB interface enable high data throughput and efficient

work.

As an alternative, the FT4232H chip can be used. It can be mounted on the board instead of FT2232H.

FT4232H has two addition channels with reduced functionality.

For more information go to: http://www.ftdichip.com/Support/Documents/DataSheets/ICs/DS_FT2232H.pdf and

http://www.ftdichip.com/Support/Documents/DataSheets/ICs/DS_FT4232H.pdf.

2.4. Power

DEBUGGER-XL is powered from USB. With the ability to change the CPLD logic voltage of communication

levels, DEBUGGER-XL is compatible with devices powered by lower voltage (from 1.8 to 3.3 V).

2.5. Protection features

Connectors J3, J6, J7 and USB port are secured from ESD. Additionally, on some lines, there are mounted

protections in order to limit the current. Top surface is secured from mechanical destructions by

plexiglass.

2.6.Temperature

Safety temperature range for DEBUGGER-XL is from 0°C to 85°C.

Fermio-EM: Datasheet

6/16

2.7.Other

There are 2 buttons and 3 diodes. Diode PWR inform about the power. LED1, LED2, USER button and

RESET button can be programmed by the user.

Note: Button RESET is not used to reset FTDI or CPLD, but may be used to reset external devices.

3. Connectors

There are, on the board, a miniUSB connector (J1), 5 header pins: 2 single-pin (J2, J5), 3 double-pin (J3,

J4, J6) and one edge socket (J7).

Picture 2:Connector placement (top)

Fermio-EM: Datasheet

7/16

Picture 3:Connector placement (bottom)

3.1. Connector J1

J1 connector is an USB 2.0 port (miniUSB connector TYPE B). It is used to supply power and for the

communication between DEBUGGER-XL and a computer. Pin specification is presented in Table 1.

Pin

Pin name

Functional description

1

5V

POWER

2

U_N

USB DATA -

3

U_P

USB DATA +

4

ID

NOT CONNECTED

5

GND

GROUND

Table 1: Connector J1

Fermio-EM: Datasheet

8/16

3.2. Connector J2

J2 connector (header, 2-Pin, Raster 2.54mm) is used to change DEBUGGER-XL operating mode.

Description of the modes is presented in table 2.

Note: For CPLD reprogramming, there is a jumper needed.

Jumper

Functional description

OFF

TARGET PROGRAMMING

ON

CPLD PROGRAMMING

Table 2: DEBUGGER-XL operating mode

Fermio-EM: Datasheet

9/16

3.3. Connector J3

J3 connector (Header, 2x10-Pin, Raster 2.54mm) consist of I/O pins from CPLD. Their functionality

depend on loaded logic. It is possible to use it to communicate with external devices. Pin specification is

presented in table 3.

Pin

Pin name

Functional description

1

VDD_EXT

EXTERNAL POWER SUPPLY SOURCE

2

VDD_EXT

EXTERNAL POWER SUPPLY SOURCE

3

IO_17

CPLD I/O 3 (GTS0)

4

GND

GROUND

5

IO_18

CPLD I/O 1 (GTS2)

6

GND

GROUND

7

IO_19

CPLD I/O 97

8

GND

GROUND

9

IO_20

CPLD I/O 92

10

GND

GROUND

11

IO_21

CPLD I/O 90

12

GND

GROUND

13

IO_22

CPLD I/O 81

14

GND

GROUND

15

IO_23

CPLD I/O 78

16

GND

GROUND

17

IO_24

CPLD I/O 76

18

GND

GROUND

19

IO_25

CPLD I/O 71

20

GND

GROUND

Table 3: Connector J3

Fermio-EM: Datasheet

10/16

3.4. Connector J4

J4 connector (Header, 2x8-Pin, Raster 2.54mm) consist of the following CPLD outputs: RESET button,

USER button, LED1, LED2, PWR diode and three configuration signals. J4 connector can be used to read

those signals or to make tests. CONF1, CONF2 and CONF3 have pull up resistors and can be connected

to the ground by a jumper. Configuration signals can be used to change configuration of the CPLD. Pin

specification is presented in table 4.

Pin

Pin name

Functional description

1

RESET BUTTON

CPLD I/O 13

2

GND

GROUND

3

USER BUTTON

CPLD I/O 12

4

GND

GROUND

5

LED1

CPLD I/O 11

6

GND

GROUND

7

LED2

CPLD I/O 10

8

GND

GROUND

9

CONF1

CPLD I/O 9

10

GND

GROUND

11

CONF2

CPLD I/O 8

12

GND

GROUND

13

CONF3

CPLD I/O 7

14

GND

GROUND

15

VDD_IO_TARGET

CPLD POWER SUPPLY

16

VDD_IO_TARGET

CPLD POWER SUPPLY

Table 4: Connector J4

Fermio-EM: Datasheet

11/16

3.5. Connector J5

J5 connector (Header, 3-Pin, Raster 2.54mm) is used to select voltage level of communication logic. It is

essential to use DEBUGGER-XL with devices working on lower voltage levels. Jumper between pin 1 and

pin 2 select 3.3 V (DEBUGGER-XL supply), jumper between pin 2 and pin 3 select external supply (from

1.8V to 3.3V). Pin specification is presented in table 5.

Pin

Pin name

Functional description

1

3V3

MAIN POWER SUPPLY SOURCE

2

VDD_IO_TARGET

CPLD POWER SUPPLY

3

VDD_EXT

EXTERNAL POWER SUPPLY SOURCE

Table 5: Connector J5

Fermio-EM: Datasheet

12/16

3.6 Connectors J6 and J7

J6 (Header, 2x13-Pin, Raster 2mm) and J7 (Socket, 2x13-Pin, Raster 2mm) connectors are pin outputs

from the CPLD and can be used to communicate with external devices. These connectors are doubled –

have the same connections and the same pin configuration - so user can choose how to connect device

with DEBUGGER-XL (e. g. with no ribbon). Additional, while working, one of these connector can be used

to observe signals. Pin specification is presented in table 6.

Pin

Pin name

Functional description

1

VDD_EXT

EXTERNAL POWER SUPPLY SOURCE

2

IO_1

CPLD I/O 6

3

GND

GROUND

4

IO_2

CPLD I/O 4

5

GND

GROUND

6

IO_3

CPLD I/O 2

7

GND

GROUND

8

IO_4

CPLD I/O 99

9

GND

GROUND

10

IO_5

CPLD I/O 94

11

GND

GROUND

12

IO_6

CPLD I/O 91

13

GND

GROUND

14

IO_7

CPLD I/O 89

15

GND

GROUND

16

IO_8

CPLD I/O 79

17

GND

GROUND

18

IO_9

CPLD I/O 77

19

GND

GROUND

20

IO_10

CPLD I/O 74

21

IO_11

CPLD I/O 71

Fermio-EM: Datasheet

13/16

22

IO_12

CPLD I/O 70

23

IO_13

CPLD I/O 68

24

IO_14

CPLD I/O 67

25

IO_15

CPLD I/O 64

26

IO_16

CPLD I/O 61

Table 6: Connector J6 and J7

4. Mechanical

Device dimensions are 76x39 mm.

Picture 4:Overall board size [mm]

Fermio-EM: Datasheet

14/16

5. Additional information

5.1. Copyright notice

Copyright© 2015 3City Electronics Sp. z o.o. All rights reserved. No part of this document may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise), without the express written permission of 3City Electronics Sp. z o.o.

5.2. Trademarks

All products and trademarks mentioned in this manual are trademarks of their respective owners.

5.3. Warranty

For this 3City Electronics Sp. z o.o. product warranty for defects in material and workmanship exists as

long as the warranty period, beginning with the date of shipment. During the warranty period, 3City

Electronics Sp. z o.o. will decide on its discretion if defective products are to be repaired or replaced.

Within the warranty period, the repair of products is free of charge as long as warranty conditions are

observed. Warranty does not apply for defects resulting from improper maintenance or handling by the

buyer, unauthorized modification, as well as the operation outside of the product´s environmental

specifications and improper installation and maintenance. 3City Electronics Sp. z o.o. will not be

responsible for any defects or damages to other products not supplied by 3City Electronics Sp. z o.o.

that are caused by a faulty 3City Electronics Sp. z o.o. product.

5.4. Certification

3City Electronics Sp. z o.o. is certified ISO 9001 and ISO27001 Standards.

5.5. RoHS

All 3City Electronics Sp. z o. o. designs and products are created from lead-free components and are

completely RoHS Directive compliant.

Fermio-EM: Datasheet

15/16

5.6. Technical support

3City Electronics Sp. z o. o. engineers are committed to provide the best possible technical support for

our customers so that our products can be easily used and implemented. We request that you first visit

our website at www.3cte.com for the latest documentation, utilities and drivers, which have been made

available to assist you. If you still require assistance after visiting our website then contact with our

specialist by email at support@3cte.com

Fermio-EM: Datasheet

16/16