Tenant Design Standards

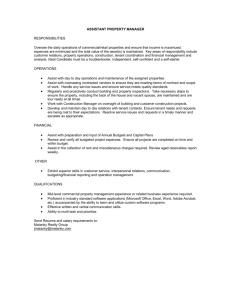

advertisement