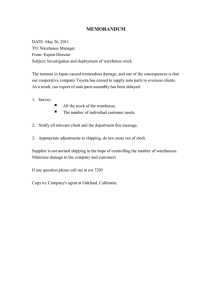

User`s manual and Construction Requirements for WareHouses in

advertisement