Critical Shortages of Precision Machining and Industrial

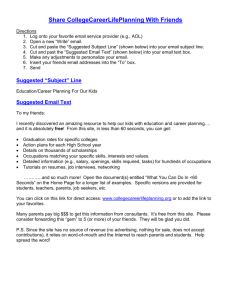

advertisement