QDHP Bid Spec - Air Energy Air Compressors

advertisement

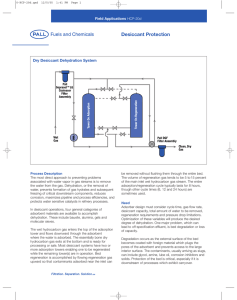

quincycompressor.com 701 North Dobson Avenue Bay Minette, AL 36507 Phone: 251.937.5900 Fax: 251.937-1457 BID SPECIFICATION QHP SERIES HEATED REGENERATIVE AIR DRYER 1. SCOPE The specification outlines the requirements for the design, fabrication and supply of a dual tower, automatic, externally heated compressed air or gas dryer completely piped, wired, shop assembled and test run as a single unit. 2. GENERAL REFERENCE SPECIFICATIONS The air/gas dryer system shall be designed, fabricated and assembled in accordance with the applicable sections of the following codes, standards, and specifications: A. ASME Boiler and Pressure Vessel Code – Latest Edition, Section VIII, Division 1 of unfired pressure vessels. B. ASME Boiler and Pressure Vessel Code – Latest Edition, Section IX (Welding Qualification). C. NEMA Standard governing auto-cycling equipment and electrical components. D. National Electrical Code E. ANSI B31.1 Code for Power Piping F. ANSI B16.5 Code for Forged Steel Flanges. G. ANSI B16.9 & ASTM SA-234 for fittings. H. ANSI B16.3 Class 150 Threaded Iron Fittings. I. Customer Specification J. ISA – Instrument Society of America 3. PERFORMANCE REQUIREMENTS The dryer shall be designed to handle the following operating conditions: Fluid Capacity: Operating Pressure Design Pressure: Inlet Temperature: Moisture Content: Electrical Classification: Power Supply: Outlet Dew Point: Compressed Air Flow in SCFM rated @ 14.7 PSIA and 680F. 100 PSIG (Normal) 150 PSIG. (Standard) 100° F (Normal) Saturated NEMA Class 4 115V-1PH-60HZ (35cfm to 100cfm) 460/480V-3PH – 60HZ (150 cfm and larger) -40F CONSTANT at the operating pressure. 1 4. SPECIFICATIONS Input Power: 120VAC or 230VAC, Single Phase Frequency: 50 or 60 Hertz Operating Temperature: 32° F to 122° F (0°C to 50°C) Time Delays Type: Digital Integrated Circuitry NEMA Cycle: 8 hours 1% Thermocouple Inputs: Three (3) Type ‘K’ Temperature measurement range: 50° F to 500° F (10°C to 260°C) Mechanical: Control unit with molded housing and encapsulated circuitry. Remote I/O Module is open circuit board construction. 5. Basic Design The dryer shall be dual tower, fully automatic regenerative type. The dryer shall be assembled on a heavy-duty steel base. The dryer shall be furnished with all the necessary components, equipment and accessories for continuous, fully automatic operation for drying the in coming air with simultaneous reactivation of the idle desiccant bed. The air dryer system shall be fabricated with dual desiccant chambers. Inlet switching valves shall be two 2way non-lube, diaphragm, pilot air operated, normally open (up through and including 2600 cfm).The air outlet valves shall be soft seated, silent check The purge valves shall be air operated, normally closed, so that in case of power failure or when the unit is de-energized, both the inlet valves open, and the purge valves close to avoid any air loss. The dryer unit shall be completely prepiped, prewired and test run before shipment. Dryers up to 1500 SCFM are shipped with a full charge of desiccant. Dryers 1800 SCFM and larger shall be shipped with loose desiccant supplied in 50 lb. bags to be filled on site by the customer. High performance switching valves with integrally mounted double acting rack and pinion actuators with permanent lubrication and a 5 year valve warranty shall be available on all models up through 3,100 cfm. The valves shall be carbon steel valve body with offset shaft design to eliminate wear points at top and bottom of the seats for higher cycle life. The purge check valves shall be stainless steel for high temperature operation. The outlet check valves shall be high temperature silent seated check valves. The air dryer assembly shall not use any Silicone based Material. The gaskets shall be designed for high temperature service and user friendly. 6. Cycle The dryer shall be designed to operate on NEMA 8 hour time cycle. This 8 hour cycle is the time required for the desiccant bed to be in drying service, regenerated and returned to drying service. The Sequence of Operation is divided into: Drying- 4 Hours, Heating – 2½ Hours, Cooling – 1 Hr.20 Min. Re-pressurizing – 10 Min. 7. Q Sorb The desiccant used shall be Q $orb an enhanced formula of activated alumina that improves adsorption, reduces channeling, reduces pressure drop, lasts longer than ordinary desiccants and is suitable for the operating conditions and the dew point specified. The desiccant fill shall comprise of active buffer desiccant at the top and bottom to safe guard the desiccant from being fluidized, minimize the pressure drop and reactivation air/gas distribution. The contact time of the air/gas with the desiccant bed shall be greater than or equal to 5.0 seconds which provides for a velocity less than that which would disrupt, upset or fluidize the desiccant bed. 8. Vessels: The desiccant towers shall be supplied with removable stainless steel screens. The screens shall be designed to distribute the air/gas flow evenly through the desiccant bed and disperse the hot air/gas for desiccant regeneration. Each desiccant bed shall be supplied with separate desiccant fill and drain ports. Desiccant vessels shall be designed, fabricated, tested and code stamped according to the latest edition of ASME Section VIII, Division I Code for Unfired Pressure Vessels. The desiccant vessels shall be designed with 1/16” corrosion allowance. All vessels above 6" diameter are constructed and code stamped to ASME Sec. VIII, 2 1989 edition and its addenda. The towers shall be free standing and installed with stainless steel desiccant retainer and air diffuser screen for even distribution of air. 9. Velocity: The desiccant chambers shall be designed to maintain maximum velocity of 50 F.P.M. and contact time of 5.5 seconds for drying of air at optimum design conditions with minimum pressure drop and extended desiccant life. The towers shall have desiccant fill and drain ports, and shall be assembled with pressure relief valve and tower pressure gauge. Each tower shall contain sufficient desiccant to account for effects of desiccant aging. 10. PIPING AND FITTINGS: Standard dryers shall be constructed with SA53B, black steel pipe Schedule 40 conforming to ANSI B36.10. Pipe fittings shall be black malleable iron fittings conforming to ASTM A197 specification. The fittings 1/4” to 2” size shall be Class 150 threaded, designed to conform to ANSI B16.3. All piping and fittings 2-1/2” and larger shall be buttweld SA234WPB with SA105 slip-on or weld neck flanges conforming to ANSI B31.3. 11. HEATER: The heater shall be mounted externally in a dedicated chamber. The element shall be a low watt density, stainless steel type that provides extended heating surface and is sheathed to prolong life. There shall be heater control, over heat protection, and desiccant regeneration sensors. 12. INSULATION: The externally mounted heater shall be insulated with 2” insulation made from glass fibers bonded with a thermosetting resin. It shall be jacketed with a reinforced vapor retarder facing. ½” ceramic fiber insulation shall be applied to hot purge piping. 13. REGENERATION SYSTEM 1. Standard (fixed cycle mode) Regeneration of the desiccant shall be carried out by means of External Heater and 7% of dry process air. The regeneration flow shall be in the opposite direction to the process drying flow. 2. Regeneration of the desiccant in the off line tower shall be accomplished at atmospheric pressure. The tower to be reactivated shall be depressurized to ambient conditions by blowing down the tower through the purge valves and exhaust mufflers. The air required for desiccant reactivation shall be supplied from the dry process side. The dry air for desiccant regeneration shall be regulated and passed through a heater chamber that is external to the desiccant bed. 3. The hot and dry air at almost atmospheric pressure shall pass through the saturated desiccant bed. The dry, hot air shall desorb the moisture from the desiccant beads and purge it out into the atmosphere through the exhaust mufflers. The heating period shall last for nominal two and one-half hours. At this time the heater shall be de-energized or bypassed. The Heater Control Thermostats shall terminate the heating cycle when the desiccant bed is heated to the full regeneration temperature. This will prevent overheating of the desiccant and allow the desiccant to cool down. 4. The hot desiccant bed shall be cooled down by passing the dry process air through the desiccant bed at near atmospheric pressure. The cooling flow helps to sweep out the last traces of moisture while the desiccant is being cooled. The cooling flow also maintains the low dew point performance and normal discharge temperature. 14. DEW POINT PERFORMANCE: Dryer shall be designed to provide a constant dew point of -40F at line pressure with no spike at tower shift. 15. CONTROLS 1. An electrical control panel shall be furnished and mounted on the dryer assembly. The panel shall consist of digital microprocessor controller to sequence the desiccant tower switch over and regeneration automatically. A sequence annunciator shall use LED’s to indicate drying status, regeneration status, alarms, and demand cycle indicator (optional). The digital microprocessor control and all electricals shall be mounted in a NEMA-4 electrical enclosure. 2. Only dry, filtered air may be used for pilot or control air necessary for the operation of the dryer. 3. Heater Temperature shall be controlled by a thermocouple located in the heater chamber to monitor the temperature of the reactivation air. This will cycle the heater and reduce the utility cost. 4. A low pressure switch shall be provided to monitor the loss of air flow through the dryer. The low pressure switch shall shut down the system when it senses low pressure due to the loss of air flow. The system shall be shut down in the fail-safe mode. The system shall automatically start up as the air starts to flow and the pressure is restored. This mode of control helps to safe guard the electric heater. 3 5. In the case of loss of power or low pressure shut down, the air dryer shall be placed in the fail-safe mode. Both the inlet valves shall fail in the normally open position and the purge valves shall fail in the normally closed position. When the power is restored, the operation shall commence from where it had stopped. 6. Thermocouples shall be located in the desiccant beds to shut off the heater when the desiccant bed is heated to the full regeneration temperature. This will save on utility cost during periods of low moisture loading and prevent the desiccant from over heating and causing dewpoint spikes. It will also help to extend the desiccant life. The dryer shall be equipped with a re-pressurizing circuit to allow gradual rise of regenerating tower to full line pressure prior to switch-over. 16. LOW PRESSURE All heated regenerative dryers shall be supplied with Low Pressure Switch Inhibit. When the low pressure is detected; all timing functions stop and all loads are de-energized. A red LED on the remote I/O module will light up and “LOW PRESSURE” shall be displayed on the LCD screen. This function will put dryer operation in the fail-safe mode. Both the inlet valves shall fail OPEN and the purge valves fail CLOSED. As soon as the pressure is restored the normal functions will resume. The Low Pressure inhibit is set to operate when the pressure in the dryer drops to 50 PSIG (3.4 Bar G) 17. DEW POINT DEMAND SEQUENCE CONTROL (OPT.) The demand cycle inhibit function switch will be operational if there are 5 minutes before the end of the drying cycle and the dew point is below the preset level. During dew point demand cycle, all the timing functions stop. The yellow LED on the remote I/O will light up and “DEMAND CYCLE “ will be displayed on the LCD screen. As soon as the dew point reaches the preset dew point level the towers will switch and the normal cycle will commence. The dew point demand inhibit function will be disabled if the dew point is above the preset level. 18. HIGH HUMIDITY (OPT.) The high humidity inhibit shall be indicated by a red LED on the remote I/O module. The high humidity relay will energize for remote annunciation. All the normal functions will be maintained. 19. FAILURE TO SWITCH (OPT.) The failure to switch inhibit shall be energized if the inhibit switch remains closed for 30 minutes beyond the normal cycle. Failure to switch inhibit will be indicated by the red LED on the remote I/O module and the failure to switch relay will be energized for remote annunciation. The failure to switch inhibit is an indication of a malfunction of the tower switching valves or the purge exhaust valves. 20. RELAY OUTPUTS (DRY CONTACTS) There shall be two relay outputs for remote annunciation. The output shall be normally open rated for 10 AMPS resistive at 125VAC, 5 AMPS resistive at 30VDC. The outputs are for the inhibit Failure to Switch and High Humidity. If one or both inhibits are made, the relays will be energized and the LED on the remote I/O will light up. 21. INSTRUMENTATION The dryer assembly shall include the following instrumentation as minimum. 1. 2. 3. 4. 5. 6. 7. Full size Pressure Relief Valve on each tower. Pressure indicator locally mounted on each tower. Regeneration temperature controller in the heater chamber outlet. Desiccant bed temperature control. Heater over temperature protection. Indicating lights showing: Control Power On, Heater On, Low pressure, Tower status. Pilot air control filter 22. ELECTRICAL 1. In the case of power supply over 120V, the panel shall include control transformer with primary and secondary circuit fuses. 4 2. The controls shall operate on 120 volts, 60 hertz, and 1 phase power. 3. Electric heater shall be activated by a heavy duty contactor sized for the heater load. 4. Electrical construction shall be in accordance with NEMA area classification and shall be wired in accordance with NEC requirements. 5. All the wiring shall be numbered and end in terminal block. Splicing of the wires shall be avoided. Each terminal shall hold only two wires. 6. Provide the Digital Microprocessor Controller with Master Advance Switch to manually advance through the sequence and help in trouble shooting. FINISHING AND PAINTING The finishing and painting shall be according to the manufacturer standard procedure. 1. 2. 3. 4. 5. 6. 7. Remove grease, dirt and dust from steel and iron surfaces by cleaning with solvents or inorganic detergents. Remove rust, scales and heavy coatings of paint by wire brushing or sanding. Remove all weld spatters by dipping or grinding. Immediately prime any bare metal Prime all welds as soon as it is cool to prevent any rust formation on the bare metal. Prime all the bare metal with red primer. Finish Paint with standard hammertone gray enamel. 23. INSPECTION AND TESTING The completed dryer assembly shall be Inspected and tested according to the Inspection and Test Procedures. 1. The air dryer assembly shall be leak tested pneumatically at 1.25 times the normal operating pressure with soap bubble pressure test. 2. The dryer shall be tested at no load through its complete sequence of operation. 3. All the alarm conditions shall be tested for their function. 4. All the control settings shall be tested and recorded. 5. The completed shop test report shall be submitted with the dryer. 24. SHIPMENT The Manufacture shall provide the following minimum for Shipment. 1. All the nozzles shall be plugged or sealed with protective covers. 2. Place a small bag of desiccant in the enclosure. 3. Place the Installation, Operation and Maintenance Manual with the shop test report in the Enclosure or strapped to the dryer. 4. Wrap the entire dryer package with polyethylene shrink film for protection. 5. Desiccant for dryers 1800 SCFM and larger is shipped separately in sealed 50 LB. bags on a separate skid. 5