profinet - Siemens

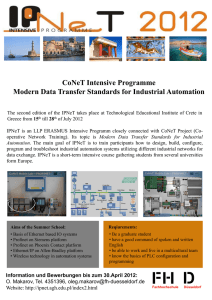

advertisement