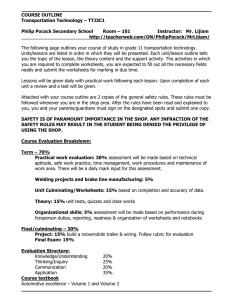

Operator`s Service Book

advertisement