Micro-scanning Mirrors for High-power Laser Applications in Laser

advertisement

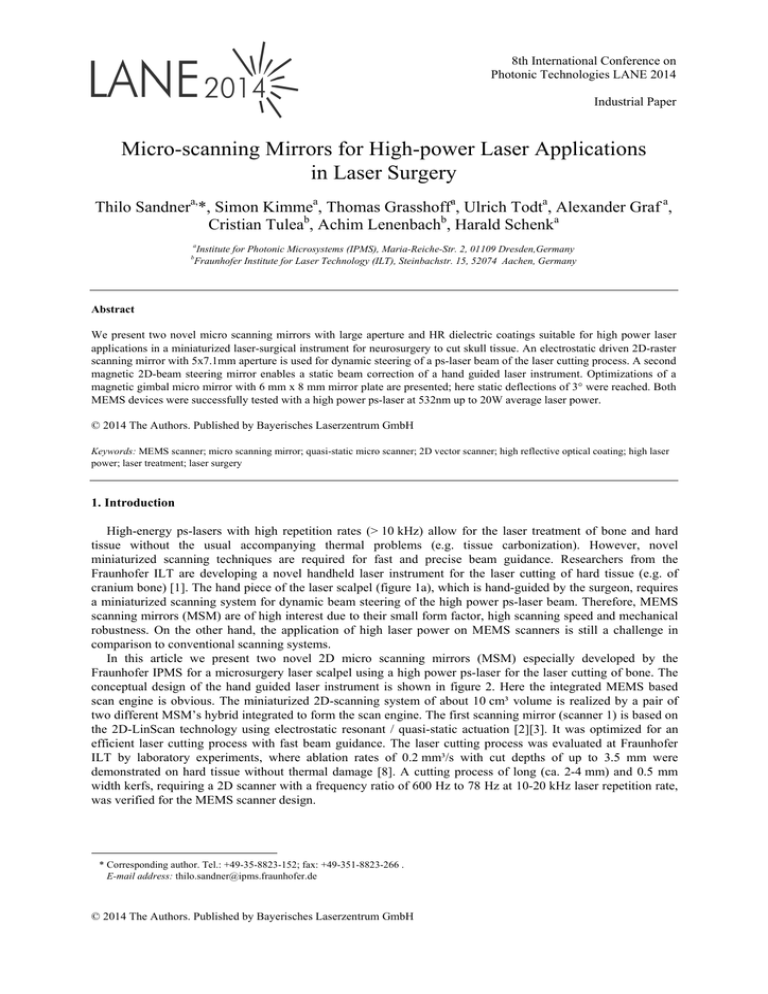

8th International Conference on Photonic Technologies LANE 2014 Industrial Paper Micro-scanning Mirrors for High-power Laser Applications in Laser Surgery Thilo Sandnera,*, Simon Kimmea, Thomas Grasshoffa, Ulrich Todta, Alexander Graf a, Cristian Tuleab, Achim Lenenbachb, Harald Schenka a b Institute for Photonic Microsystems (IPMS), Maria-Reiche-Str. 2, 01109 Dresden,Germany Fraunhofer Institute for Laser Technology (ILT), Steinbachstr. 15, 52074 Aachen, Germany Abstract We present two novel micro scanning mirrors with large aperture and HR dielectric coatings suitable for high power laser applications in a miniaturized laser-surgical instrument for neurosurgery to cut skull tissue. An electrostatic driven 2D-raster scanning mirror with 5x7.1mm aperture is used for dynamic steering of a ps-laser beam of the laser cutting process. A second magnetic 2D-beam steering mirror enables a static beam correction of a hand guided laser instrument. Optimizations of a magnetic gimbal micro mirror with 6 mm x 8 mm mirror plate are presented; here static deflections of 3° were reached. Both MEMS devices were successfully tested with a high power ps-laser at 532nm up to 20W average laser power. © 2014 The Authors. Published by Bayerisches Laserzentrum GmbH Keywords: MEMS scanner; micro scanning mirror; quasi-static micro scanner; 2D vector scanner; high reflective optical coating; high laser power; laser treatment; laser surgery 1. Introduction High-energy ps-lasers with high repetition rates (> 10 kHz) allow for the laser treatment of bone and hard tissue without the usual accompanying thermal problems (e.g. tissue carbonization). However, novel miniaturized scanning techniques are required for fast and precise beam guidance. Researchers from the Fraunhofer ILT are developing a novel handheld laser instrument for the laser cutting of hard tissue (e.g. of cranium bone) [1]. The hand piece of the laser scalpel (figure 1a), which is hand-guided by the surgeon, requires a miniaturized scanning system for dynamic beam steering of the high power ps-laser beam. Therefore, MEMS scanning mirrors (MSM) are of high interest due to their small form factor, high scanning speed and mechanical robustness. On the other hand, the application of high laser power on MEMS scanners is still a challenge in comparison to conventional scanning systems. In this article we present two novel 2D micro scanning mirrors (MSM) especially developed by the Fraunhofer IPMS for a microsurgery laser scalpel using a high power ps-laser for the laser cutting of bone. The conceptual design of the hand guided laser instrument is shown in figure 2. Here the integrated MEMS based scan engine is obvious. The miniaturized 2D-scanning system of about 10 cm³ volume is realized by a pair of two different MSM’s hybrid integrated to form the scan engine. The first scanning mirror (scanner 1) is based on the 2D-LinScan technology using electrostatic resonant / quasi-static actuation [2][3]. It was optimized for an efficient laser cutting process with fast beam guidance. The laser cutting process was evaluated at Fraunhofer ILT by laboratory experiments, where ablation rates of 0.2 mm³/s with cut depths of up to 3.5 mm were demonstrated on hard tissue without thermal damage [8]. A cutting process of long (ca. 2-4 mm) and 0.5 mm width kerfs, requiring a 2D scanner with a frequency ratio of 600 Hz to 78 Hz at 10-20 kHz laser repetition rate, was verified for the MEMS scanner design. * Corresponding author. Tel.: +49-35-8823-152; fax: +49-351-8823-266 . E-mail address: thilo.sandner@ipms.fraunhofer.de © 2014 The Authors. Published by Bayerisches Laserzentrum GmbH 2 Auuthors name / LANE L 2014 b) b a) c) Fig. 1. Microsurgery laaser scalpel [1]: (aa) hand piece of llaser scalpel; (b) laser cut in hard tissue; t (c) high-po power picosecond d laser. Pa arameter Unit Inneer axis Qs frame 1) Electrostatic 2D-raster scannner (scanner 1) 1 Mirrorr aperture mm 5.0 x 7.1 dyn. deef. σRMS (σmax) nm 20 (1110) @ 2.5° Eigen frequency Hz 600 DC… …250 MSAnoom ° 2.5 0.5 @ DC 2) Electromagneetic 2D-vector scanner (scann ner 2) Mirrorr aperture mm 6.0 x 8.0 Hz 200 200 Eigen frequency ° 2@D MSAnoom DC 2 @ DC D 3) Optical requirements for hiigh power ps-laser Averag ge laser power W 20 Spectraal reflectance % 2 nm ≥ 99.99 @ 45° & 532 Radiuss of curvature m ≥4 Fig. 2. Concceptual design off the hand guided laser instrument with integrated MEMS M scan engin ne (left); requirem ments of MEMS scan engine consisting oof two 2D MEMS S scanning mirrorrs (right). The seecond scannerr is required for f 2D-beam ssteering to compensate geo ometrical misaalignments off the handguided laaser scalpel caaused by the surgeon. s Therrefore, an elecctro-magnetic actuated 2D--vector scanniing mirror was deveeloped by IPM MS to allow tw wo-dimensionnal static defleections up to ± 2° and thus,, in effect, alllows static and dynaamic correctioons of the lasser beam possition. For reaal-time assistaance the handd piece involv ves a 2Dimaging ssystem to autoomatically anaalyse the cuttiing process an nd deliver the feedback signnal for beam correction. c In additioon, an OCT syystem is coupled parallel too the cutting laaser beam to measure m the re residual thickn ness of the laser-cut hard tissue. Inn order to be able to use thhe micro scann ners at a high h laser power ((Paverage = 20 W, power density ≥ 200 kW/cm m²) it was neccessary to usee large mirrorr apertures (≥ ≥ 5 mm), high gh reflective and a robust optical cooatings (R ≥ 99.9%) enablin ng large laser damage threshold and high h optical planaarity of < λ / 10 1 even on top of a fragile silicoon mirror plaate of only 775 µm thickn ness. Thereforre, MSM’s w with large apertures of 5 × 7.1 m mm² and 6 × 8 mm², coated with stress annd thermally compensated c dielectric Braagg coatings (R R > 99%, 532 nm, 220 W) were developed. d The main param meters required d for the MEM MS scanning ssystem are su ummarized in figure 2. 2. Electrostatic Raster Scanning The 2D D-raster scannning mirror (ssee figure 3) w was especially y developed for fo raster scann nning at 78 Hzz / 610 Hz required bby the ps-laseer cutting process using 200 kHz laser reepetition rate. The 2D-MEM MS device con nsists of a resonant inner mirror (5 ( × 7.1 mm² elliptic) gimbbal suspended within a quassi-static actuaated frame. Whereas the inner mirrror is actuateed in paramettric resonancee by conventional in-plane vertical com mb drives [4], staggered vertical ccomb (SVC) drives, d based on o the LinScaan-technology developed at IPMS [3], aree used for non n-resonant (quasi-staatic) actuationn of the outer frame. In figuure 3a details of the 3D verrtical comb drrives, activateed by WLbonding oof a cover subbstrate, are sh hown. A microoscopic photo ograph of the 2D-MEMS 2 sccanner (capturred via the free apertture of the coover wafer) is shown in figgure 3b (bello ow). For real time t feedbackk driving conttrol piezo- 3 Auuthors name / LANE L 2014 resistive (PZR) positioon sensors aree integrated onn chip for botth scanning ax xis. Thereforee, two bendin ng beams used as mechano-elecctrical transdu ucers and wir ired to form a resistive Wheatstone W haalf bridge - are added symmetriically to the annchor point off the torsionall string suspen nsions (see figure 3c). Fig. 3. Phottographs of quasi-static / resonant 2D-MEMS rasteer scanning mirrorr: (a) details of qu uasi-static drive uusing staggered vertical v comb (SVC) electtrodes; (b) MEMS chip layout (above) and after W WL-bonding of cov ver wafer (below)) and (c) details oof integrated piezo-resistive (PZR) posittion sensors. 2.1. MEM MS Design andd Fabrication The toorsional sprinng suspension of the quasi--static frame was designed d for the quaasi-static equillibrium of spring torrque and elecctrostatic driviing torque gennerated by thee SVC driving g electrodes tto guarantee a static tilt angle off MSA = ± 0.5° at limited d DC voltagee of 150 V. The frame suspension reesults in relaative high eigenfreqquency of 2622 Hz enabling mechanical rrobustness with high mechanical shock rresistance of ≥ 2500 g. Results oof the FEA moodal analysis are a exemplarilly shown in fiigure 4a. The resonant inneer axis was designed for 629 Hz eigenfrequencyy, where a scaan angle of MS SAnom = ±2.5°° is required by b the laser scaalpel, but it caan provide larger scaan angles of at a least MSA = ± 5° (see figgure 4c). The hand piece, shown s in figurre 2, needs an n effective aperture oof 5 mm at 455° angle of in ncidence for sscanner 1, resu ulting in a larrge elliptical m mirror aperturre of 5.0 x 7.1 mm². To guaranteee ≤ λ/10 opticcal flatness evven for this large mirror wiith 75µm SOII thickness an advanced mirror suuspension withh distributed spring s [4] wass used to miniimize the dyn namic mirror ddeformation to o ≤ 20 nm (rms at M MSA = ±2.5°, see s figure 4b),, which is suffficient for the ps-laser beam m of λ = 532 nnm. a) b) c) Fig. 4. FEA A simulation resullts of MEMS desiign of electrostatiic 2D-raster scann ning mirror: (a) modal m analysis; (bb) dynamic mirro or deformationn and (c) dynamicc behaviour of inn ner axis, shown aare the frequency response curves in parametric ressonance. 4 Authors name / LANE 2014 The electrostatic 2D-raster scanning mirrors were fabricated based on the LinScan technology, described in [2] and [3], using a doped SOI-layer of 75 µm thickness. The basic LinScan process was modified by (i) implantation of on-chip integrated piezo-resistive position sensors, (ii) modification of the cover wafer fabrication process using DRIE etching of the open aperture instead of the previous wet chemical TMAH etching and (iii) backend integration of high reflective dielectric coatings replacing the metallic Al mirror coating, using an ion assisted deposition technique combined with shadow masking for structured deposition on the silicon mirror aperture. 2.2. Experimental Results The frequency response characteristics of the inner (resonant) mirror - measured in parametric resonance for varied pulse driving voltages (30…80 V) and 50 % duty cycle - are exemplary shown in figure 5a. Here the scan angle was limited by the experiment to MSA = 5° to avoid any mechanical over load of the torsional springs. From the frequency response curves a frequency band width of 33 Hz is obvious for the nominal scan angle of MSAnom = ± 2.5°, sufficient to adjust the scan pattern of the laser cutting process. In addition, the dependency of mechanical deflection and pulse driving voltage was measured in synchronized operation mode (see figure 5b). Here a maximal mechanical angle of up to MSAnom = ± 10.7° was measured at 113 V, before a first mechanical failure of the torsional springs occurred. This demonstrates the potential of this scanning mirror with large aperture of D = (5x7.1) mm². The static deflection characteristic of the quasi-static frame - i.e. the mechanical tilt angle versus DC driving voltage – was measured in static equilibrium of electrostatic and mechanical torque. A maximal static deflection of MSA = ± 0.52° @ 180 V DC driving voltage was measured. For the laser cutting process only a small scan angle of MSA = ± 0.2° is needed for the frame at 78 Hz scan frequency corresponding to 95V AC (sinusoidal) drive voltage. 11 HC02_04_14_30V 5 HC02_04_14_25V 9 HC02_04_14_20V 8 HC02_04_14_40V HC02_04_14_45V Amplitude / ° Amplitude / ° 4 HC02_04_14_50V 3 HC02_04_14_55V HC02_04_14_60V HC02_04_14_65V 2 Resonant operat ion In synchronized m ode 10 HC02_04_14_35V HC02_04_14_70V HC02_04_14_75V MSAmax = +/-10,7° 7 6 5 4 3 HC02_04_14_80V 1 2 HC02_04_14_CL_maximal 1 0 600 a) 0 620 640 660 680 700 720 740 Frequency / Hz 18 b) 28 38 48 58 68 78 88 98 108 118 Voltage / V Fig. 5. Experimental results of inner resonant axis; (a) Frequency response in parametric resonance for varied driving voltages and (b) amplitude vs. driving voltage in synchronized (resonant) operation mode. 3. Vector Scanning Mirror with Magnetic Actuation To enable a static two-dimensional beam steering – required for correction of mechanical misalignments of the hand-guided laser scalpel – an electro-magnetic 2D-MEMS mirror (see figure 6) has been developed at Fraunhofer IPMS [5]. On the backside of the gimbal mounted silicon mirror four permanent NdFeB magnets with 1 mm diameter and 1 mm height are precisely (hybrid) assembled and adhesive- fixed by glue. The MEMS scan engine needs a 2D-vector scanning mirror (scanner 2, shown in figure 2) with enlarged aperture of 6 × 8 mm² aperture. The mirror plate consists of 75 µm thick silicon coated with a high reflective dielectric coating. The magnetic forces are generated by stationary electromagnetic coils placed underneath the moving magnets. To enhance the magnetic forces flux guiding materials (FGM) are used [5]. The schematic setup of the hybrid assembled magnetic scanner is shown in figure 6b & c. 5 Auuthors name / LANE L 2014 a) b) c) Fig. 6. 2D-vvector scanner wiith electro-magneetic actuation; (a) Finite element model m of gimbaled d 2D-MEMS mirr rror with mounted d permanent magnets andd (b) photograph of the assembled d electromagneticc 2D vector scann ner with 6 × 8 mm m² mirror plate, acctuated in x (b) an nd y (c). 3.1. Expeerimental Resuults Examiined are two actuator a confiigurations witth and withou ut FGM. The characteristicss of static defflection of the devicces are shown in figure 7. The T target of static deflectiion is MSAnom ± 2 ° for both th scan directiions. With the use oof FGM signifficant higher deflection d anggles (about 50 0 % increased d) can be reach ched at identiccal current density. T This enables to optimize th he magnetic scanner desig gn to (i) realizze larger defllections or (iii) increase spring stiiffness and meechanical reliaability at the ssame scan ang gle and (iii) to reduce parasiitic thermal drrift effects of the staatic deflection angle induced d by Joule heaating of the eleectro-magnetiic coils. The coombined defleection of both h scan axes is shown in figu ure 7c. Here no n coupling beetween the sccan axes is visible. T The measured deviations aree less than thee measuremen nt accuracy (cca. 0.04°). Thee thermal drifft behavior of the staatic deflectionn angle induceed by Joule heeating of the electro-magne e etic coils was measured forr a sample without F FGM for varieed current den nsities. A tem mperature increease within th he coils of up to 45 K was measured for 300 m mA driving cuurrent, resultin ng in a maxim mal thermal in nduced drift of the static deeflection of 6% % over 1h observation time. (d) Fig. 7. Charracteristics of stattic deflection of the t magnetic mirrror with and with hout FGM in all quadrants (a); detaail of the hybrid assembled a magnetic sccanner with FGM M (b); two dimensional static deflecctions by simultaneous actuation of o both scan axes (c); dynamic beh haviour (d). The dyynamic charaacterization off the magneticc scanner was performed using u a 2D poosition sensitiive devise (PSD) foor measurement of free damped oscillattion (see figu ure 7d). In ad ddition, the reesonant frequeencies are shown foor both axis ussing samples with w and withhout FGM. A decrease of th he resonant frrequencies is visible v for the magnnetic scanner with FGM. This T effect is attributed to current-indep pendent magnnetic forces, which w take effect like a negative magnetic m stifffness [5]. Obvvious from thee decreasing vibration v (seee upper graphss of figure 7d) is a hhigher dampinng coefficient for the sampples with FGM M. This higherr damping is ccaused by edd dy current occurringg in the FGM due d to the moving magnetss. 4. Opticaal Scanner Prroperties for High Laser P Power Both m micro scannerr devices - prresented beforre - have to withstand w high h ps-laser pow wer of Paveragee = 20 W, which iss a challengee for small and a fragile M MEMS scann ning mirrors in contrast tto conventional bulky galvanom meter scannerss. Typically, a thin metalllic coating off aluminum is used for opptical coating g of micro scanning mirrors at IPM MS, which is unfeasible foor pulsed high power laser sources. s To exxtend the micrro scanner technologgy to high pow wer laser appllications the uuse of high reflective opticaal coatings haave been investigated at IPMS in the past [6][[7]. Besides teechnological challenges off process inteegration of abbsorption freee and high reflectivee optical coatiings into the MEMS scannner process flo ow, the main challenge forr MSM is to guarantee 6 Auuthors name / LANE L 2014 high optiical planarity of the HR coated c thin annd fragile mirrror plate. In [6] high refllective dielecttric Bragg coatings on MSM – deposited d by Magnetron M spputtering - haave been investigated for a pulsed Nd:Y YAG-laser (λ = 10644nm). Even for fo a high refllectance of R ≥ 99.9° thesse sputtered Bragg-coating B gs failed at pu ulsed laser irradiationn due to locaal defects of the t dielectric layers. In [7] micro scann ning mirrors hhave been su uccessfully tested forr the first tim me at pulsed laser l radiationn of a Nd:YA AG-laser (λ = 1064nm) up to 100 MW//cm² pulse power deensity. In [7] the HR coatings were evaaporated using g a hybrid op ptical coating design, consiisting of a metallic ((Ag) reflectorr enhanced by y an evaporateed dielectric Bragg-coating B g to reduce thhe overall thicckness and mechaniccal stress of the t optical co oating. In adddition, a symm metric coating design wass successfully y tested to achieve a sufficient sttress and tem mperature com mpensation and d mirror plan narity of the H HR coated 30 0µm thick silicon m mirror plate. For thhe MEMS scaanning mirrors reported in this article we w used dielectric Bragg ccoatings deposited by a commerccial ion assisted depositio on technique. To decouple the HR co oating deposiition from th he CMOS compatibble MEMS scaanner process we use a backkend integratiion of the Bragg coating onn the final waffer bonded silicon M MEMS scanneers. For patteerning the Brragg-coating locally on th he mirror apeerture a shad dow mask techniquee was used. The T scanning g mirrors werre coated from m both sidess to allow a stress and temperature compensaation of the 75µm 7 thick siilicon mirror plate. Photog graphs of dielectric HR coaated electrosttatic raster scanning mirrors are shhown in figuree 8. An equal incidence ang gle of 45° wass chosen for bboth scanning mirrors of the miniaaturized MEM MS scan enginee shown in figgure 2, enabling to use an identical i Braggg coating dessign for all MEMS sccanners. This simplified thee developmennt efforts for stress s and temp perature comppensated high h reflective Bragg coatings significcantly. The op ptical coating design of thee dielectric Bragg mirror waas optimized to t achieve a high reeflectance of R ≥ 99.9% with w a broad spectral and angular plateau at 45° inncidence anglle and the wavelenggth of ps-laserr (λ = 532 nm m; selected byy ILT to enab ble a laser cu utting of hard tissue under continues water flow to remove debris). In ad ddition, the B Bragg coating was designed d also for a seecond plateau u of higher reflectancce (R > 90%) above 900 nm m required forr the OCT sysstem used to measure m in situ tu the residuall thickness of the cuttted cranial boone. a) b) Fig. 8. Phottographs of dielecctric HR coated electrostatic e scannning mirror (a) fro ont side of MEMS chip with activvated SVC drive & HR coating; (b)) backside of MEM MS chip with streess & temperaturre compensation coating. c 4.1. Expeerimental Resuults on Dielectric HR Coatiings a) Specctral and angulaar reflectance In figuure 9 the meassured spectrall reflectance oof the dielectriic Bragg coatiings depositedd on a MEMS S scanning mirror - uusing shadow masks for patterning – is sshown. For th hese measurem ments a spectraal (VASE) elllipsometer setup was used enablinng to vary the wavelengthh and the anglle of incidencce within the required rang ges. Broad angular aand spectral pllateaus are obvious from figgure 9a for bo oth spectral op peration pointts of the high power pslaser at λ = 532 nm andd the OCT-sy ystem λ > 900 nm. In figuree 9c the spectrral reflectancee around the wavelength w of the higgh power ps-laaser with λ = 532 nm is shoown, measured d for an incideence angle off 45°. A high reflectance r R ≥ 99.9% % is obvious, the measuring g date above R > 100% are interpreted within w the unceertainty of measurement of the elliipsometer cauused by the tem mporal stabilitty of the lightt source baseliine used for caalibration of reflectance r measurem ment. In addittion, the influ uence of shaddow masking on spectral reflectance r waas investigateed, for the relevant m mirror aperturres of D = (5 x 7.1) mm no pparasitic effeccts were found d by experimeent. 7 Auuthors name / LANE L 2014 Fig. 9. Specctral reflectance of o HR coated MS SM; measured loccally at the HR co oated mirror plate e for varied anglee of incidence using a spectral ellipsometeer setup; (a) specctral reflectance for f extended wavvelength region λ = (300-1000) nm; n (b) spectral rreflectance λ = (4 400-750) nm centered to 532nm of ps-laseer; (c) detail of sp pectral reflectancee at operation poiint of ps-laser (λ = 532nm, 45°). b) Statiic mirror deform mation The sttatic mirror deformation d of o HR coatedd MEMS scan nning mirrorss was measurred using a white w light interferom meter (WLI). The experimeental WLI ressults are show wn in figure 10 0a & b for HR R coated samp ples of the electrostaatic scanning mirror and in n figure 10c for the magn netic vector scanner. s The influence of the stress compensaated HR coatting design iss obvious from m figure 10a & b. The staatic mirror deeformation prrofile of a MEMS scanner samplee with non-strress compensaated HR coatiing, where thee Bragg coatinng is depositeed only on one surfaace of the siliicon mirror pllate, is shownn in figure 10 0a. For the no on-stress comp mpensated HR coating a significannt convex mirrror deformatio on with a radiius of curvatu ure |R| = 0.3 m is visible, whhich would bee unusable for the laaser scalpel. In figure 10b b the mirror ddeformation of o an optimizzed MEMS sscanner with stress and temperatuure compensaated Bragg coating is show wn. For the strress compensaated coating ddesign the staatic mirror deformatiion is significantly reduceed to |R| > 5 m radius off curvature, en nabling goodd optical planarity. The magnetic scanning mirrrors were co oated with thee identical Braagg coating design, d resultinng also in good optical mirror planarity with radius r of curv vature |R| > 5 m (see figure 10c). Due to the permanennt magnets gllued under the mirroor plate the static mirror deeflection is sliightly depend ding on the static tilt anglee, because thee magnetic driving fo forces of the inner i mirror are a direct couupled to the mirror m plate. Nevertheless, N the radius off curvature remains aalways abovee 5.7 m withiin the specificcation (see fiigure 2). Hen nce, this mechhanical coupling is not crucial foor the optical performance. p a) b) c) Fig. 10. Plaanarity of electrosstatic scanner with high reflective dielectric (Bragg g) coatings, measu ured with white llight interferomettry; a) mirror with HR coating without streess compensation n; (b) mirror with stress and tempeerature compensated HR (Bragg) ccoating. 4.2. Laser Irradiation Test The H HR coated ME EMS mirrors were w tested inn a laser irrad diation experiment at ILT uusing a high power pslaser of ssimilar parameeters of laser power and beeam profile reelevant for thee future laser scalpel. The schematic experimeental setup of the t laser irrad diation test is sshown in figurre 11, where all a relevant lasser and beam parameter are summ marized in the table. In a fi first experimennt the dielectric HR coatinngs deposited d on MSM weere tested to withstand thee maximal power off the ps-laser. The average--laser power w was varied beetween 5W, 10W and 22W W at the maxim mum. The repetitionn rate was chaanged from 20 0 kHz to 35 kH Hz, and the diiameter (1/e²) of the collimaated laser beaam was set to 2 mm. To detect a laser l damage of o the HR coaatings the straay light of the mirror surfacce was measured with a photodiodde. In additioon, a power meter m was useed to monitorr the reflected d laser power and a CCD camera to 8 Auuthors name / LANE L 2014 analyze th the beam proffile after opticcal reflection at the dielectrric mirror sam mple. The surfface temperatture of the irradiatedd MEMS sam mples was meeasured with a pyrometer. In the first laser test thee MEMS sam mples were irradiatedd 15-30 min equal e to maxim mal 65 millioon pulses. How wever, only 10 pulses are ddefined by thee standard ISO 112554 to test the laser l damage threshold. Noo single failurre occurred for all tested sam amples. Hencee, the laser damage tthreshold of thhe HR coated d MEMS scannner was not reached and a significant m margin for hiigher laser power is expected. Thhese results deemonstrate thee high potentiial of MSM for f miniaturizeed scanning systems s in future higgh power laserr applications. In thee second laseer irradiation test, full funnctional HR coated MEM MS scanner ddevices were tested in electromeechanical actuuation (scanniing operation)) at their operration points relevant r for thhe laser cutting process. A two dim mensional PSD D was used to o monitor the ccontinuous 2D D oscillation of o the electrost static raster scaanner. Laser param meter Sym mbol Valuee Unit Pavverage 20 Hz @ 20 kH W τ 25 ps Pulse energy H max < 0.01 1 J/cm² Repetition ratte fppulse 20 kHz Pulse power density d Pppulse 410·10 05 W/cm² Dx,y @ 1/e² 2.1 (1.6 6) mm Raylay length h in x (y) L 3.9 (3.0 0) m Test time t ≥ 60 min Nppulse ≥ 120·106 - NISOO-11254 10 - Average laserr power Pulse time Beam diamete er No. of pulses Standard ISO 11254 Figg. 11. Experimenttal setup (left) and d laser parameterr (right) of laser irrradiation tests on n HR coated MEM MS scanning mirrors. In the experiment thhe electromagnetic scanner was statically y actuated at small s angles (cca. MSA = 0.5 5°) in twodimensionns to avoid any a parasitic thermal t drift caused by thee Joule heatin ng of the elecctromagnetic coils. The temporal drift of the sttatic tilt deflecction – resultiing of mirrorss heating by absorbed a laserr power - was measured with a CC CD based autoocollimator to achieve a higgh angular resolution. Severral samples w were tested, eacch over 1h irradiationn time using the t laser param meter summarrized in figuree 11. Experim mental results aare exemplary y shown in figure 12. To meeasure the absolute temperrature of the irradiated ME EMS mirror the t pyrometerr was calibraated to the optical prroperties of thhe HR coated d MEMS sampples using a hotplate h for caalibration at ttwo temperatu ure points. The meassured temporaal behavior off laser power, temperature of o MEMS mirror and scannner actuation parameters p (e.g. scann angle) is shoown for the ellectrostatic miirror in figure 12a and for the t electromaggnetic scanner in figure 12b. A sm mall increase of MEMS tem mperature of about 14 K and a 6 K was measured m for tthe irradiated 2D raster scanner ((see figure 122a) and the magnetic m vecttor scanner (see figure 12 2b), respective vely. The laseer induced temperatuure increase iss smaller for the t magnetic scanner. This can be explained by their bbetter thermaal coupling to the heat sink due too broader spriings compare d to the electtrostatic 2D raaster scanner,, obvious also o from the shorter tim me constant too reach the th hermal equilibrrium. For the magnetic scanner small anngular drifts ΔM MSA < 10 arcsec weere measured for 1h irradiattion time. Alsso for the electtrostatic rasterr scanner no nnoticeable parasitic drift of the scaanner oscillattion was found (see figure 12a). The no oise visible in the optically measured daata of scan position iis caused by stray s light of the t high poweer ps-laser settup. In summary, both HR coated MEM MS scanner devices w were successfu fully tested in the laser irraadiation test at a operations points p of elecctro-mechanicc scanning and laser parameters off the ps-laser relevant r for thhe laser scalpeel. 9 Authors name / LANE 2014 0 1000 2000 3000 22,5 0 4000 Device electrostatic 3-10#1 Electrostatic scanner 1332,11 1331,98 1331,85 Amplitude Phase temperature MEMS [°C] MSA [a.u.] 1000 1500 2000 2500 3000 3500 Magnetic scanner 20,0 17,5 15,0 34,2 0,00126 500 laser power Freqency Frequency laser power [W] 2 frequency [Hz] 1332,24 0,00084 0,00042 temperature MEMS temperature intern 30,4 ΔT ca. 6K 26,6 22,8 0,00000 Y-axis X-axis 20 31,5 18 27,0 16 X-axis [arcsec] 36,0 ΔT ca. 12K 10 9,6 laser power [W] temperature [°C] 22 ΔM SA <10 arcsec 4,8 8 6 0,0 4 -4,8 Y-axis [arcsec] Laser Power Temperature 2 22,5 0 a) 1000 2000 time [s] 3000 0 4000 0 b) 500 1000 1500 2000 2500 3000 3500 time [s] Fig. 12. Experimental results of laser irradiation of HR coated MEMS scanning mirrors in electromechanical operation; shown is MEMS behaviour over 1h irradiation time for the electrostatic scanner (left) and the magnetic scanner (right). 5. Conclusion In this article we presented two novel micro scanning mirrors with large aperture (≥ 5 mm) and HR dielectric coatings especially developed for a miniaturized microsurgical laser instrument using a high power ps-laser for cutting of hard tissue. An electrostatic driven 2D-raster scanning mirror with (5 x 7.1) mm aperture was designed for dynamic steering of the ps-laser beam to control the laser cutting process. A second 2D-beam steering mirror was designed for static beam correction within a hand guided laser instrument. Here, an electro-magnetic actuation was used to allow a dynamic vector scanning of the 6 mm x 8 mm mirror plate. By optimization of the magnetic drive using flux guiding material (FGM) static deflections of ± 3° were reached for the magnetic vector scanner. To use the MEMS scanning mirrors for high power laser applications we deposited stress and thermal compensated dielectric Bragg coatings on MEMS mirror, where a reflectance of R ≥ 99.9% at 532 nm wavelength was measured on the HR coated MEMS mirrors. Due to the stress compensated HR coating design a high optical planarity with R > 5 m radius of curvature was measured for the 75 µm thin silicon mirror plate. In a laser irradiation test both MEMS devices were successfully tested in electro-mechanical operation to sustain high power ps-laser irradiation 532 nm up to 20 W average laser power. This demonstrates the feasibility and high potential of MEMS scanning mirrors for high laser power applications, enabling miniaturized scanning systems required for future medical laser instruments e.g. for microsurgery. References [1] Lenenbach, A., Noll, R., 2011. Microsurgery laser scalpel with real-time assistance system. Annual report, Fraunhofer ILT, pp. 120. [2] Sandner, T., Jung, D. et al., 2011. Microscanner with Vertical out of Plane Combdrive. Proc. Optical MEMS & Nanophotonics, 33-34. [3] Jung, D., Sandner, T. et al., 2012. Vertical comb drive microscanners for beam steering, linear scanning, and laser projection applications. Proc. SPIE 8252, 82520U. [4] Schenk, H., Sandner, T. et al., 2009. Single crystal silicon micro mirrors. Phys. Status Solidi C 6(3), 1-8. [5] Kimme, S., Sandner, T. et al 2013. ... Two-Dimensional Quasistatic Micro Scanning Mirrors. Proc. of AMA - OPTO, Nürnberg, Germany, 22-27. 10 Authors name / LANE 2014 [6] Sandner, T., Schmidt, J.-U., Schenk, H., Lakner, H., Braun, S., Foltyn, T., Leson, A., Gatto, A., Yang, M., Kaiser, N., 2005. Micromechanical Scanning Mirrors with Highly Reflective NIR Coatings for High Power Applications MOEMS. Proc. SPIE 5721, 3442. [7] Sandner, T., Schmidt, J.-U., Schenk, H., Lakner, H., Yang, M., Gatto, A., Kaiser, N., Braun, S., Foltyn, T., Leson, A., 2006. Highly Reflective Optical Coatings for High Power Applications of Micro Scanning Mirrors in the UV-VIS-NIR Spectral Region. Proc. SPIE 6114, 61140H-1-15. [8] Tulea, C., Caron, J., Wahab, H., Gehlich, N., Hoefer, M., Esser, D., Jungbluth, B., Lenenbach, A., Noll, R., 2013. Highly efficient nonthermal ablation of bone under bulk water with a frequency-doubled Nd:YVO4 picosecond laser, Proc. SPIE 8565, 85656E1-11.