D Series Maintenance Manual

Date: January, 2010

Page:

3C2-4

MAINTENANCE

EXTERIOR CLEANING

Regular washing to remove accumulated dust and dirt

is recommended. Do not use alkaline cleaners on

aluminum parts; corrosion could result. Use only mild

detergent and a soft brush. Do not use abrasive cleaners,

polish, or steel wool, which can remove the protective

coating and may scratch and discolor the finish.

New Finishes

The exterior of the coach requires special attention

during the first 60 days after it is painted. During this time,

the paint is still curing and hardening.

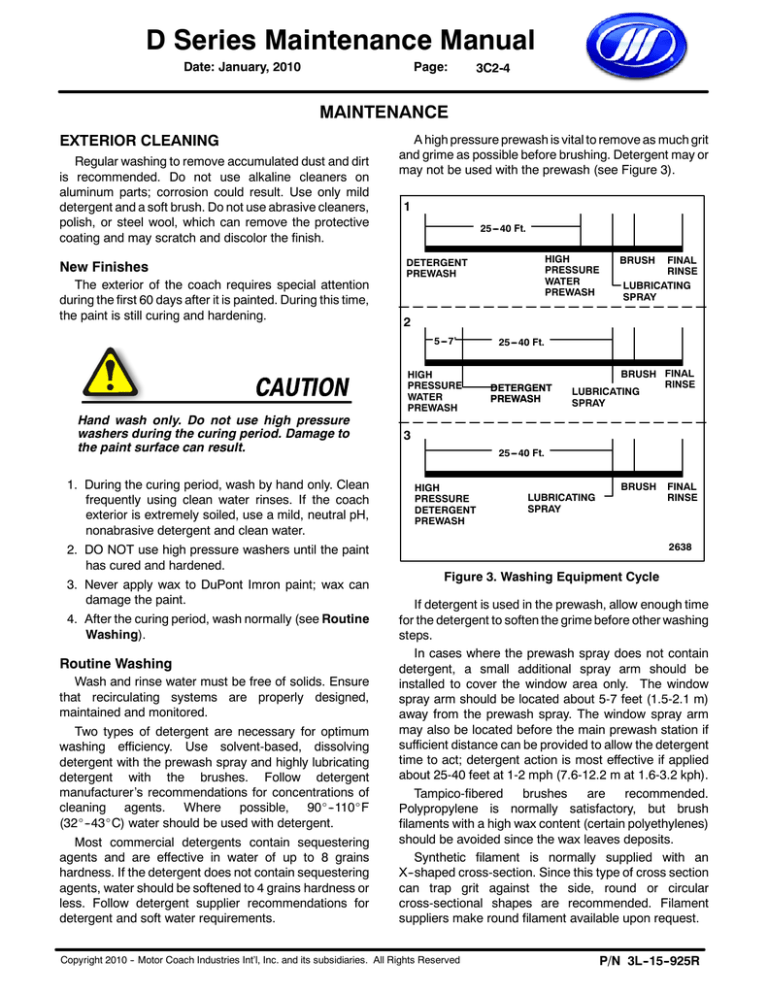

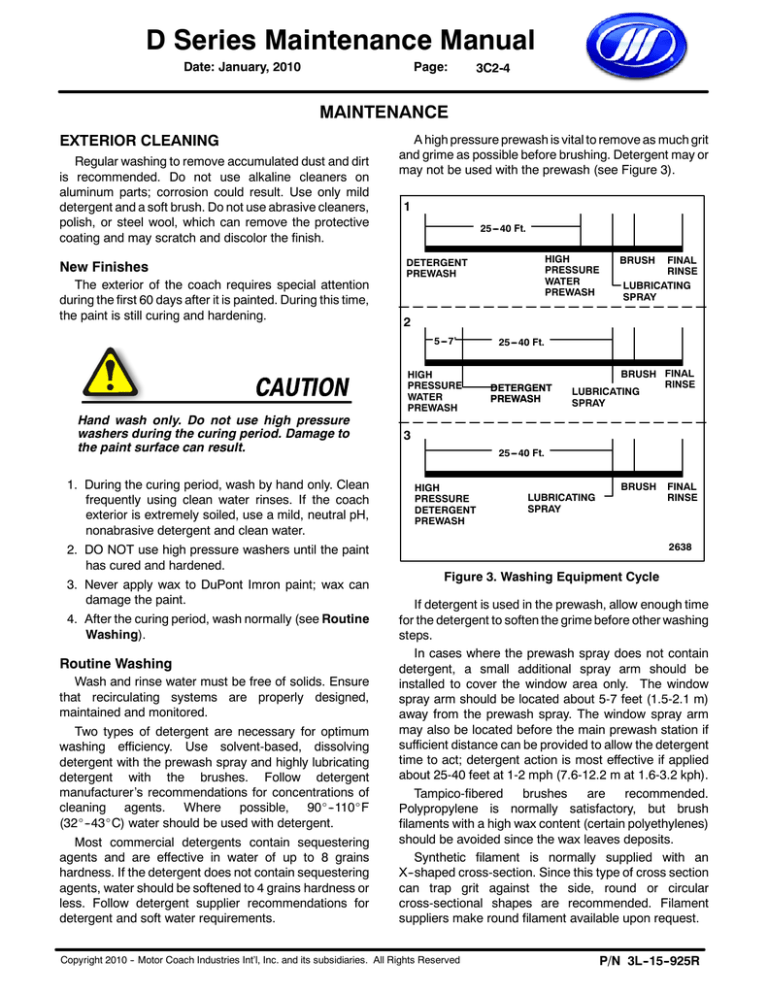

A high pressure prewash is vital to remove as much grit

and grime as possible before brushing. Detergent may or

may not be used with the prewash (see Figure 3).

1

25---40 Ft.

1. During the curing period, wash by hand only. Clean

frequently using clean water rinses. If the coach

exterior is extremely soiled, use a mild, neutral pH,

nonabrasive detergent and clean water.

2. DO NOT use high pressure washers until the paint

has cured and hardened.

3. Never apply wax to DuPont Imron paint; wax can

damage the paint.

4. After the curing period, wash normally (see Routine

Washing).

Routine Washing

Wash and rinse water must be free of solids. Ensure

that recirculating systems are properly designed,

maintained and monitored.

Two types of detergent are necessary for optimum

washing efficiency. Use solvent-based, dissolving

detergent with the prewash spray and highly lubricating

detergent with the brushes. Follow detergent

manufacturer’s recommendations for concentrations of

cleaning agents. Where possible, 90_--110_F

(32_--43_C) water should be used with detergent.

Most commercial detergents contain sequestering

agents and are effective in water of up to 8 grains

hardness. If the detergent does not contain sequestering

agents, water should be softened to 4 grains hardness or

less. Follow detergent supplier recommendations for

detergent and soft water requirements.

FINAL

RINSE

LUBRICATING

SPRAY

BRUSH

2

5---7’

Hand wash only. Do not use high pressure

washers during the curing period. Damage to

the paint surface can result.

HIGH

PRESSURE

WATER

PREWASH

DETERGENT

PREWASH

HIGH

PRESSURE

WATER

PREWASH

25---40 Ft.

DETERGENT

PREWASH

BRUSH FINAL

RINSE

LUBRICATING

SPRAY

3

25---40 Ft.

HIGH

PRESSURE

DETERGENT

PREWASH

LUBRICATING

SPRAY

BRUSH

FINAL

RINSE

2638

Figure 3. Washing Equipment Cycle

If detergent is used in the prewash, allow enough time

for the detergent to soften the grime before other washing

steps.

In cases where the prewash spray does not contain

detergent, a small additional spray arm should be

installed to cover the window area only. The window

spray arm should be located about 5-7 feet (1.5-2.1 m)

away from the prewash spray. The window spray arm

may also be located before the main prewash station if

sufficient distance can be provided to allow the detergent

time to act; detergent action is most effective if applied

about 25-40 feet at 1-2 mph (7.6-12.2 m at 1.6-3.2 kph).

Tampico-fibered

brushes

are

recommended.

Polypropylene is normally satisfactory, but brush

filaments with a high wax content (certain polyethylenes)

should be avoided since the wax leaves deposits.

Synthetic filament is normally supplied with an

X--shaped cross-section. Since this type of cross section

can trap grit against the side, round or circular

cross-sectional shapes are recommended. Filament

suppliers make round filament available upon request.

Copyright 2010 -- Motor Coach Industries Int’l, Inc. and its subsidiaries. All Rights Reserved

P/N 3L--15--925R

D Series Maintenance Manual

Date: January, 2010

Many washers are designed with more than one set of

side brushes. Since abrasion occurs when brushes

contact the coach, it is important to minimize the

exposure of windows to brush contact. One set of

brushes should be deactivated from the side washing

function. Where two sets of side brushes are deemed

necessary, it is especially important that the brushes be

properly adjusted and maintained to minimize abrasion.

Brush pressure should be as low as possible. Do not

allow more than 6 inches of filament to overlap the coach

as the brush turns. The coach should travel through the

prewash, wash and rinse at 1-2 mph (1.6-3.2 kph). Never

stop the coach while it is in contact with the brushes.

Many washers include a rinse spray to clean grit from

the brush. This should be retained and its position

optimized. The final rinse should be high pressure and

high volume, with a minimum delivery of 125 GPM.

Cleaning Magnesium Chloride and Calcium

Chloride

When operating in areas where snow is present, extra

care in cleaning must be taken. Ice and snow treatments

like calcium chloride add a more severe degree of

corrosion if left unchecked.

When it comes to maintenance, washing vehicles to try

to keep the chemicals off the metal is important. There is

no clear answer to the question of what washing

strategies are best. Pressure washing may only push the

chemical mixture further into tiny cracks and crevices. In

addition, the new chlorides tend to stick to surfaces more

than traditional road salt, and may need physical action to

get them off rather than just spraying them with wash

water. Keep in mind that more cleaning liquid is not

necessarily better--in some cases, an over--concentration

of washing compound may actually attack some of the

plastics that are there to provide corrosion resistance.

Electrical connectors and systems must be inspected

weekly. Foam socket inserts that slide over the pins in

seven--way connector sockets, go into the base to seal

out moisture, and are effective to prevent corrosion. Any

time a tractor or trailer is repaired, use a heat shrink

terminal that seals out moisture. The old nylon and PVC

terminals are unsealed, easily allowing contaminants

inside.

Brakes need special attention when inspection and

routine maintenance are done to inspect for corrosion.

Using gladhand seals with dust flaps, which keep

contaminants out of the air system when the trailer is

unthethered, is recommended. It is very easy for

Page:

3C2-5

rainwater to become contaminated with the chlorides on

the trailer surfaces and creep into the air system.

Corrosive material can get inside the air lines and air

tanks. It is more critical than ever to maintain the air driers

and keep water drained from the air system.

CORROSION PREVENTION

The entire underside of the coach is sprayed with a

heavy application of tectyl undercoating. All fasteners are

corrosion resistant.

The coach operating environment determines the

amount of dirt and corrosion that will accumulate over any

given period. Corrosion can be controlled by preventive

maintenance. As part of regular service, inspect all coach

structures that are likely to corrode.

Road splash affects the body and causes moisture, dirt

and road salt to accumulate in crevices and on flanges

causing corrosion. Wash frequently, depending on

operating conditions. Wash daily when the coach is

exposed to road salt.

IMPORTANT: Failure to properly maintain the

body surfaces and structural components of the

coach affects the coach warranty.

Certain areas of the coach are more susceptible to

corrosion than others and must be inspected more

frequently.

Preventive Maintenance: Seasonal Inspection

Before and after the winter, thoroughly inspect the

coach exterior body and understructure for corrosion.

1. Wash the coach body, undercarriage, and cavities to

remove all accumulated dirt and salt.

2. Inspect for signs of corrosion or bare metal (see

Exterior Body Inspection, Understructure

Inspection).

Exterior Body Inspection

1. Remove the bumpers. Clean thoroughly and remove

corrosion; apply paint as required.

2. Remove the sash and belt moldings from the coach

body (see Figure 4), Remove accumulated dirt and

inspect sealant between sidewall panels and lower

body panels for signs of decay and cracks. Apply

Sikaflex sealant as required. Inspect for loose rivets

and replace as necessary. Reinstall moldings.

3. Loosen the rub rail molding and clean behind it.

Inspect for corrosion. Clean thoroughly and remove

corrosion; apply paint as required. Reinstall rub rail.

Copyright 2010 -- Motor Coach Industries Int’l, Inc. and its subsidiaries. All Rights Reserved

P/N 3L--15--925R

D Series Maintenance Manual

Date: January, 2010

Page:

3C2-6

5. Remove the fenders (see Figure 6). Clean

thoroughly and remove corrosion; apply paint as

required. Reinstall the fenders.

Figure 4. Molding and Rub Rail Inspection

4. Inspect the entrance doors and moldings (see

Figure 5). Clean thoroughly and remove corrosion;

apply paint as required.

Figure 6. Fender Inspection

6. Inspect all panels, seams and fasteners. Clean

thoroughly and remove corrosion; apply paint as

required.

7. Inspect the window sashes, frames and moldings

(see Figure 7). Clean thoroughly and remove

corrosion; apply paint as required.

Figure 7. Window Frame and Molding Inspection

Figure 5. Entrance Doors Inspection

8. Inspect the drip moldings (see Figure 8), roof cap,

and panel seams. Check for loose rivets. Replace as

required.

Copyright 2010 -- Motor Coach Industries Int’l, Inc. and its subsidiaries. All Rights Reserved

P/N 3L--15--925R

D Series Maintenance Manual

Date: January, 2010

Page:

3C2-7

Baggage Compartment Floor Inspection

1. Clean thoroughly and remove corrosion from

baggage compartment floors, flanges, bulkheads,

beams and fasteners (see Figure 9).

2. Apply undercoat as required.

D00167

Figure 8. Drip Molding Inspection

Understructure Inspection

Any damaged paint, undercoating or corrosion must

be repaired immediately as follows:

1. Remove dirt, grease and oil (See Surface

Preparation).

2. Remove corrosion and loose Tectyl coating with a

wire brush or by other means such as sandblasting.

Figure 9. Baggage Compartment Floor Inspection

Rear Bogie Area Inspection

1. Clean thoroughly and remove corrosion from

flanges, seams, bulkheads, the bogie, all air lines

and components, electrical harnesses, connectors,

and fasteners (see Figure 10).

2. Replace corroded lines, connectors and fasteners.

3. Apply undercoat as required.

Sandblasting can be used for cleaning

bulkheads, brackets and other structural

members. Do not sandblast exterior side

paneling. Do not sandblast excessively.

Follow

safe

shop

practices

when

sandblasting. Wear hearing protection, a face

shield, gloves, protective clothing and

respiration equipment.

D00168

Figure 10. Rear Bogie Area Inspection

Copyright 2010 -- Motor Coach Industries Int’l, Inc. and its subsidiaries. All Rights Reserved

P/N 3L--15--925R

D Series Maintenance Manual

Date: January, 2010

Engine / Tire Compartments Inspection

1. Clean thoroughly and remove corrosion from

flanges, seams, bulkheads, the engine and tire

compartments, all air lines and components,

electrical harnesses, connectors, and fasteners.

2. Replace corroded lines, connectors, and fasteners.

3. Apply undercoat as required.

STRUCTURAL WELDING

NOTE: Refer to the welding Caution in the

introductory pages of this manual before starting any

welding operation.

NOTE: Refer to Specifications: Welding Rod

Applications. Welding must conform to American

Welding Society specification D1.1 Structural Welding

Code -- Steel.

The frame structures are welded steel. The

high-strength Corten steel front and rear bogie

assemblies are jig welded to ensure proper alignment of

the main radius rod attaching points.

All of the lower frame components, including truss

frames, are manufactured from stainless steel.

PANEL REPLACEMENT

Metal or fiberglass body panel replacement requires

removal of rivets, metal screws or capscrews. Aluminum

rivets can be removed by drilling out the rivet with a drill

slightly smaller than the body of the rivet. When drilling out

pop rivets, always push out the stem first.

Page:

3C2-8

NOTE: Only drill 4 or 5 holes at one time. Do not drill

all the holes and then rivet. Prior to riveting, ensure

correct alignment.

Hand-operated guns and lazy tongs for pulling Cherry

rivets, Imex rivets, and Pop rivets are available from MCI.

Contact MCI Service Parts for information.

NOTE: Most panel repairs or replacements will

require a sealant. Refer to the Parts Manual for

appropriate materials.

Fiberglass Panel Repairs

Fiberglass repair generally consists of reinforcing

cracked or broken areas. Application of fiberglass to the

back or underside of a damaged panel may allow it to be

refinished and painted. Large holes, torn sections, and

separated joints require layed-up cloth and resin repair.

Small exterior depressions, scratches or pits can be

repaired using body putty.

Always use rubber gloves and a mask when

working with resins. If resin contacts skin,

wipe with denatured alcohol or clean thinner.

Protective hand creams are available and their

use is recommended.

3. Drill holes through the panel from the underside of

the channel.

If disc grinding or sanding, wear a respirator

and goggles. Resin dust is combustible; do

not use an electric sander. To sand resin, use a

low- speed, air- driven sander with water flush

attachment; a dry sander with a vacuum bag

attachment may also be used.

The following tools and materials will assist in making

repairs. Hacksaw blade, assorted files, emery paper or

cloth (No. 150 grit or finer), scissors or tin snips, wax

paper or cellophane sheets, small 3 inch (76.2 mm)

grooved roller, paint brush, putty knife, acetone and one

or more heat lamps. For best results the ambient

temperature should be 70-75_F (21-24_C) when making

repairs.

1. Remove all loose particles or damaged material

using a power sander or rasp. Where necessary,

sand paint away.

2. Grind or file the damaged area to form a V--shaped

notch at the broken or cracked portion. Sides of the

notch should have a shallow pitch for maximum

bonding area.

NOTE: Existing holes in the roof bow channel may

be used as a template.

NOTE: Roughening the surface improves adhesion

of resin.

If replacement of fiberglass roof or front lower cap

panels is required, fit the old panel to the underside of the

new panel and mark the locations of rivet holes.

1. If the roof bow channels are bent or damaged, they

should be repaired or replaced in order to match the

contours of the fiberglass panel. Some areas may

require shims. Mark the location and thickness of

each shim.

2. Remove the panel and sand the marked areas to

roughen the mounting surfaces. Apply Dolphinite

sealer to the channel mounting surface and the

sanded area. Clamp the panels and shims in place.

Inspect the panel for proper fit.

Copyright 2010 -- Motor Coach Industries Int’l, Inc. and its subsidiaries. All Rights Reserved

P/N 3L--15--925R