I2C manual

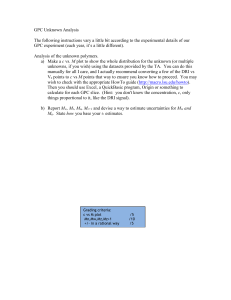

advertisement