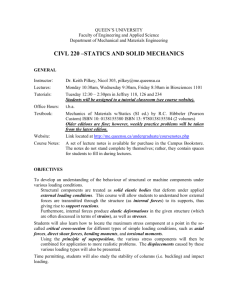

Single cell rectangular conduits - Association of State Dam Safety

advertisement