Reliable power

advertisement

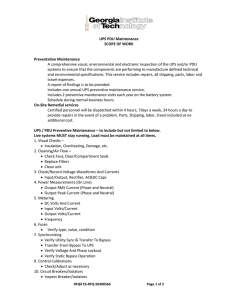

Reliable power for complex installations CP200/CP100 is UPS made for industry, specially designed for the process and petroleum industry to satisfy its stringent demand for operating reliability, monitoring, functions and mechanical resilience. www.siemens.no/pec Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 1 Siemens UPS system CP100/CP200 Siemens Uninterruptible Power System DC UPS CP100 AC UPS CP200 Catalogue October 2005 We reserve the right to do minor changes CONTENTS Contents 2 Applications 3 Qualifications and Experience 4 Main Features for CP100 and CP200 5 Design 6 Main Components 7 CP100 – DC UPS – Single Line Diagram 8 CP200 – AC UPS – Single Line Diagram 9 Function of Main Components – Rectifier 10 Function of Main Components – Inverter (CP200) 11 Function of Main Components – Bypass Circuit (CP200) 12 Function of mains Components – Battery 13 Operating Modes CP100 14 Operating Modes CP200 15-16 Control Panel 17 Alarms and Communication 18 Parallel Operation 19-20 Options 21-22 CP100 Technical Data 23-26 CP100 Electrical Installation Data 27-28 CP200 Technical Data 29-31 CP200 Electrical Installation Data 32 Planning and Installation 33 CP100 Dimention Drawings 34-35 CP200 Dimention Drawings 36-38 Contact Information 39 Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 2 Siemens UPS system CP100/CP200 APPLICATIONS UPS systems provides power to critical loads in case of mains failure and mains disturbances. CP200 and CP100 are especially made to meet the demands when the environments are rough and the total reliability of the UPS system is important. Modern computers and monitoring circuits in poor environments place very high demands on the power supply The CP100 and CP200 UPS systems serve the following purposes: Typical fields of applications for CP100 and CP200: To bridge mains supply failures by using a battery Process control systems in the industry To act as voltage and frequency stabilizers (CP200) To protect the load from mains supply electrical noise and voltage transients Offshore installations Emergency lighting Power supply system controls Telecommunication systems Data processing in banks and insurance companies Hospitals The CP200 unit may also be used as a 50/60Hz or 60/50Hz frequency converter DC UPS CP100 units are delivered in the standard range 50A to 400A (larger as option) with output 24V – 220V DC. AC UPS CP200 units are delivered in the range 30kVA to 120kVA, with three phase input and single phase output. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 3 Siemens UPS system CP100/CP200 QUALIFICATIONS AND EXPERIENCE Siemens has long experience in design and manufacturing of UPS systems. A lot of these systems are delivered according to project specifications for process control and offshore industry. A lot of Siemens UPS systems are in operation on oil platforms in the North Sea where they operate under rough conditions. Sales, engineering, design and production are located in our factory in Trondheim, Norway. This makes very close cooperation in all steps in the process from presales phase – sales phase to engineering and production of the equipment. The factory also manufactures UPS distribution boards and switchboards. This long period has given us very valuable experience and competence in meeting customer and projects demands especially for process- and offshore industry, and other applications where the total reliability of the UPS system is important. Our main features and services: UPS systems with robust mechanical construction Special functions and features as standard or standard options Customized options and design Customer adapted documentation Site projecting for UPS systems; ratings, battery design, installation planning, placing, cabling, distribution boards etc. Installation assistance and/or supervision on site Service, commissioning, maintenance and repair Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 4 Siemens UPS system CP100/CP200 MAIN FEATURES CP100 AND CP200 Galvanic isolation for maximum safety Rectifier isolation transformer Integrated static- and manual bypass switch (CP200) Bypass isolation transformer (CP200) Inverter isolation transformer (CP200) Control panel Safe operation command - Check if your command is safe to execute Soft keys operated LC display Battery care Automatic battery circuit test Informative status information - By LEDs in mimic panel and as text in LC display Battery isolation monitoring Battery capacity test (option) - Check the real battery capacity - Independant of connected load - No need for external test load Temperature compensated charging standard or ex-proof Alarms / Communication Potential free relay contacts (standard 2 pcs) Profibus communication interface (option) Output short circuit capacity CP200 Inverter short circuit current up to 5 x I nominal Increased discrimination in critical situations RS232 to PC Standard options: Manual ”Black start” Battery capacity test CP100 Short circuit capacity is depending on battery short circuit capacity Redundant parallel operation Up to 10 potential free relay contacts Profibus DP communication interface Increased degree of protection Reference marking of internal wiring Cooling CP200 - Natural cooled units: 30kVA, 60kVA and 90kVA - Temperature controlled redundant fans: 40kVA, 75kVA and 120kVA. Isolation monitoring of UPS output Trip battery breaker Panel printer for recording battery test results CP100 - Natural cooled: All standard units 50A – 400A. - Temperature controlled redundant fans: Optional sizes > 400A Mains filter - reduce current harmonics and/or inrush current Other cabinet colours UPS distribution boards in UPS design Common or individual isolation monitoring of output circuits in distribution boards Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 5 Siemens UPS system CP100/CP200 DESIGN CE marking The CP100 and CP200 UPS systems are subject to the Low Voltage Directive and the EMC Directive (chapters III and IV in Regulations for electrical equipment. Battery A battery, connected to the DC link, serves as energy reservoir by mains failures. The battery is installed outside the UPS cabinet. The units complies with the relevant VDE, IEC and DIN regulations and the ”Prevention of Accident regulation VBG4. The units are CE marked. Cabinet The UPS units are built in Siemens cabinet type 8MF. This is a robust steel sheet floor mounted cabinet type. Cooling The UPS units are constructed to be mounted on the floor on detachable legs. The opening between the floor and the cubicle bottom acts as cooling air inlet. The units have open bottom for cooling air inlet. Air outlet is at top of the cabinets. The heat from the power losses from the natural cooled units is dissipated by natural convection. Forced ventilated models have temperature controlled redundant fans which are supplied from the secure bus (UPS output). Each fan is individually monitored. Degree of protection Standard is IP20. As standard options (at the cabinet top) IP21, IP31, IP22 and IP32 are available. Other degree of protection may also be available. Cable entrace The cable entrance for the CP100 and CP200 UPS units is from bottom. If cable entrance from top is required this may be done by one of the following alternatives: An extra cabinet beside the UPS cabinet can be provided and prepared for cable entrance from top. If distribution board is provided beside the UPS cabinet, the distribution board can be prepared for cable entrance from top. The in/out cables to the UPS is run via the distribution board. Siemens AS, E&A, Power Electronics Centre - The UPS units contains: Power circuits - Rectifier - Bi-directional rectifier for battery testing (option) - Inverter (CP200) - Static bypass switch (CP200) - Manual bypass switch (CP200) Necessary auxilaries: - Transformers - Control electronics - Protection and monitoring - Switches / isolators - Display and controls Edition 02, February 2006 Page 6 Siemens UPS system CP100/CP200 MAIN COMPONENTS Rectifier thyristor bridge Bypass thyristor bridge Inverter transistor bridge Control panel Electronics Reversible rectifier (battery capacity tester) DC link capacitors Rectifier input breaker Bypass transformer Bypass input breaker Manual bypass switch Battery breaker Inverter transformer Rectifier transformer Earth bar Rect. input Bypass input Battery Load Test load Alarms/communication External connections / terminals 30kVA / 40kVA CP200 Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 7 Siemens UPS system CP100/CP200 CP100 - DC UPS - SINGLE LINE DIAGRAM Main static components Q11-Q16 Fully controlled thyristor bridge Q101-Q106 Bi-directional rectifier for battery capacity testing (option) Capacitors C21 DC link capacitor C22 Psophometric filter capacitor (option) External connections X11 Rectifier input terminals X21 Battery terminals X53 Output terminals Transformer T11 Rectifier transformer 3-phase Manually operated switches Q17 Isolator at the input to isolate the rectifier from the mains Q21 Battery circuit breaker (MCCB) to isolate the rectifier from the battery. May be located outside the UPS cabinet. Auxiliaries Monitoring and control electronics Control panel with mimic diagram and LC display Surge and EMC protections Output isolation monitoring (option) Q23 Output isolator Fuses F11 Rectifier fuse F101 Bi-directional rectifier fuse (option) Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 8 Siemens UPS system CP100/CP200 CP200 - AC UPS - SINGLE LINE DIAGRAM Main static components Q11-Q16 Fully controlled thyristor bridge Q101-Q106 Bi-directional rectifier for battery capacity testing (option) Q31-Q34 IGBT transistor inverter Q35-Q36 Inverter output static switch Q54/Q55 Static bypass switch Capacitors C21 DC link capacitor C31 Output filter capacitor Transformers T11 Rectifier transformer 3-phase T31 Inverter transformer 1-phase T51 Bypass transformer 1-phase (option) Manually operated switches Q17 Isolator at the input to isolate the rectifier from the mains Q51 Isolator at the input to isolate the bypass circuit from the mains. (option) Q21 Battery circuit breaker (MCCB) to isolate the rectifier from the battery. May be located outside the UPS cabinet. Q52 Manual bypass switch – make before break - to disconnect the UPS without of the power supply to the load. Siemens AS, E&A, Power Electronics Centre - Fuses F11 Rectifier fuse F101 Bi-directional rectifier fuse (option) F31/F32 Inverter fuses F51 Static bypass fuse External connections X11 Rectifier input terminals X51 Bypass supply input terminals X21 Battery terminals X53 Output terminals X54 Test load terminals Auxiliaries Monitoring and control electronics Control panel with mimic diagram and LC display (A15) Surge and EMC protections Output Isolation monitoring (option) Edition 02, February 2006 Page 9 Siemens UPS system CP100/CP200 FUNCTION OF MAIN COMPONENTS Rectifier Rectifier input transformer The rectifier and the battery are galvanically separated from the mains via a transformer, to ensure a higher safety level. The transformer also serves as voltage adaption between mains supply voltage and rectifier. Rectifier The rectifier is a fully controlled 6 pulse thyristor bridge converting AC voltage into DC voltage. It feeds the inverter and charges the battery. The rectifier is supplied from a three phase AC source (mains or standby generator) and is able to charge lead or NiCd batteries. By reactance in the rectifier transformer and the capacitance in the DC link capacitors, the DC voltage is smoothed, so that the ripple is kept within the permitted limits for the inverter and battery. Under normal conditions the rectifier operates automatically. CP200 CP100/ CP200 Mains 1 Mains 2 3ph 1ph CP100/ CP200 Battery discharger Rectifier DC capacitor Battery Inverter Static bypass The following functions are included: Voltage control with tolerance ± 1% Charge automatic for the battery. The output voltage from the rectifier is a regulated DC voltage set to a suitable level for charging the actual connected battery. The battery charging current limit is adjustable to match individual batteries. Manual bypass switch 1 phase 230V Load Charging modus / Current limiting The rectifier is equipped with normal charging mode and boost charging (automatic or manual). In all modes, output rectifier current and charging current will be limited. The rectifier and battery current limits are separate. Battery capacity tester (option) The rectifier can be delivered with bidirectional energy float (reversible rectifier) providing a real battery capacity test. Automatic softstart when mains returns or during standby generator start. The battery capacity can be tested independent of the available load. Temperature compensated charging As option a temperature sensor can be provided at the battery. The battery bank feeds the DC link, and the battery energy is devided between the load and mains supply. Automatic, periodic battery circuit test by decreasing the rectifier voltage The test will proceed with constant current or power (selectable) until the preset discharge end test voltage level is reached. Battery circuit isolation monitoring. The battery insulation level is monitored. An alarm will be initiated in case of failure. Siemens AS, E&A, Power Electronics Centre - The test results will be stored in the rectifier memory, displayed on the UPS display and may as an option be printed out on a panel printer. Edition 02, February 2006 Page 10 Siemens UPS system CP100/CP200 FUNCTION OF MAIN COMPONENTS Inverter (CP200) The inverter produces an alternating voltage of constant amplitude and frequency. The inverter input is permanently connected to the DC link (rectifier output), and takes its power from the rectifier and/or the battery. CP200 Mains 1 Mains 2 CP100/ CP200 3ph 1ph CP200 The main components of the inverter are: Inverter fuses Transistor bridge inverter (IGBT modules) Isolating transformer with built in leakage inductance. Battery discharger Rectifier DC capacitor Battery The inverter has one or more single phase IGBT (isolated gate-base transistor) bridge inverter with 4 IGBT switches (two phase ”branches”). The bridge(s) is/are controlled in a ”sinewave double pulse width modulation mode” with a switching frequency of approx. 8000 Hz. 30kVA and 40kVA UPS units have one transistor bridge. 60kVA and 75kVA units have two bridges. 90kVA and 120kVA units have three bridges. Inverter Static bypass Manual bypass switch The pulse frequency on the inverter transformer primary will be twice the switching frequency and will lie above the audible frequency. The reference curve for the output voltage is generated by an micro controller. The micro controller also contains software for amplitude and frequency control. A special AC controller keeps the filtered output voltage, as far as possible, identical to the reference sine wave. This negative feedback decreases the output impedance for frequencies below 1000Hz. The influence of a non-linear load (particularly 3rd and 5th harmonics) is compensated by the IGBT switches and not in the filter. The input current of the inverter transformer is measured in a DC current transformer. When the current exceeds a pre-set value the modulation stage will go into a current limiting mode, thus keeping the transistor current below their absolute maximum rating. Siemens AS, E&A, Power Electronics Centre - 1 phase 230V Load High overload- and short circuit capability In case of heavy overload or load short circuit, the load is automaticly and without interruption switched over to bypass by the static bypass switch. In case the bypass mains not is available, the overload- or short circuit current is provided by the inverter. The inverter in the CP200 UPS system has a high short circuit capability, which makes it easier to ensure correct selectivity in UPS distribution circuits. For the natural convected units (30kVA, 60kVA and 90kVA) the capacity is: Overload: >150% for 2 minutes Short circuit: 5 x I nominal for 15ms The forced cooled units (40kVA, 75kVA and 120kVA) have the same capacity as the nearest rating below. Edition 02, February 2006 Page 11 Siemens UPS system CP100/CP200 FUNCTION OF MAIN COMPONENTS Bypass circuit (CP200) The main components in the bypass circuit are: Thyristor switch Manual bypass switch Isolator for feeding the static bypass switch Static bypass input fuses and bypass transformer. CP200 Mains 1 Mains 2 CP100/ CP200 3ph 1ph CP200 Battery discharger Rectifier Static bypass switch The static bypass switch connects the load directly to the bypass mains supply if necessary. Switching will take place provided one of the following situations: Battery Severe inverter overload Inverter Inverter failure If the inverter is turned on when the load is supplied from the bypass, the load will automatically be transferred to the inverter. Static bypass Transferring the load from the inverter to the mains before switching the manual bypass on. The thyristor switch acts as an uninterruptible change-over switch. Bypass transformer The bypass transformer is a single phase isolation transformer, providing galvanic isolation between mains supply and the load also i bypass operation. It also provides voltage adaption between bypass supply mains voltage and load voltage (UPS output voltage). Manual bypass switch has make-before-break function. By switching the manual bypass switch, the load will be feed directly from the mains, and the static bypass switch will no longer be operating, and can be isolated for service and test. Selectivity The thyristor switch and its fuse provide selective protection for fuses in the load distribution that are smaller than 30% of the rated current of the UPS. Siemens AS, E&A, Power Electronics Centre - Manual bypass switch 1 phase 230V Load For the control of the static bypass switch following monitoring functions are provided Monitoring of the mains For the condition ”ready to connect” to appear, the following must be fulfilled: - Mains voltage within a tolerance of ±10% - Mains frequency within preset tolerance (programmable up to ±5%) - Mains and inverter output must be synchronous Monitoring of the safe bus voltage Tolerance ±10% If the secure bus voltage goes out of tolerance, the static bypass switch will transfer the load to the mains as long as this is within tolerance. If mains is out of tolerance, different actions are programmable from the parameter list. If the bypass supply is not available the inverter is controlled by its internal quartz oscillator. Edition 02, February 2006 Page 12 Siemens UPS system CP100/CP200 FUNCTION OF MAIN COMPONENTS Battery The battery is an essential component in the UPS system, and serves as an energy reservoir in case of mains supply failure. It is is permanently connected to the UPS DC link via a battery breaker (MCCB). The CP100 and CP200 UPS units can be connected to lead acid, gel or nickel cadmium batteries. Battery location The battery is located outside the UPS cabinet. Valve vented lead acid and gel batteries may be placed in same room as the UPS or in separate rooms. Free vented lead acid batteries and Nickel Cadmium batteries requires separate battery room. Battery function If the mains supply to the rectifier fails, the battery automatically and without interruption takes over the supply to the inverter instead of the rectifier. When the rectifier mains supply returns and are within specified limits, the rectifier automatically takes over the supply to the inverter again, and recharges the battery. Battery backup time depends on the size of the battery (capacity) and size of the UPS load. If the battery is discharged before the mains supply returns, the inverter will be switched off. The inverter is switched off before the battery is completed empty, to protect the battery. If the bypass is supplied by a separate mains supply, and this mains is available, the load will be switched over to the bypass supply without interruption. If bypass supply also is unavailable, the load supply will be interrupted, when the battery is discharged and rectifier mains supply not has returned yet. CP100/ CP200 Mains 1 Mains 2 3ph 1ph CP200 CP100/ CP200 Battery discharger Rectifier DC capacitor Battery Inverter Static bypass Manual service bypass 1 phase 230V Load Battery care Because of the importance of a healthy battery in the UPS system, battery monitoring, regularly capacity testing and maintence is important. Battery life time Different battery types and qualities are available. The expected life time for a battery is depending on the battery type and quality, as well as ambient temperature. The CP100 and CP200 provides the following monitoring and functions for battery care: Battery design/calculation The battery will be designed according to the actual projects requirements regarding battery type, load, system configuration and backup time. Design margins for aging factors, spare capacity and low ambient temperature may be required. Battery capacity test; by backfeeding the battery energy to the mains supply Siemens AS, E&A, Power Electronics Centre - Charge automatic adjusted to the actual battery Battery circuit test; automatic and regularly Battery circuit isolation monitoring Temperature compensated charging Edition 02, February 2006 Page 13 Siemens UPS system CP100/CP200 OPERATING MODES CP100 Normal operation (on-line operation) In normal operation the load is supplied via the rectifier. Option The mains supply voltage is converted to DC in the controlled rectifier. The DC load and the battery are supplied with this DC voltage. The battery is beeing charged. Feeding from battery In case of mains failure or mains disturbance, the rectifier will be switched off. The battery takes automaticly and without interruption over the supply of energy to the DC load. When the mains supply returns, the rectifier will be switched on again and will feed both the battery and the load. The battery will be recharged, and normal operation is re-established. Option Battery discharge test (option) The rectifier can be delivered with bi-directional energy float (reversible rectifier). The battery bank feeds the DC link, and the battery energy is divided between the load and the mains supply. The discharge test is performed with the UPS in normal operation inverter operation. Option The test will proceed until the preset discharge test end voltage level is reached. A battery recharge process is started when the battery is empty. Should there be a mains failure during the discharge test, the test is automatically interrupted, and the battery feeds the inverter only. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 14 Siemens UPS system CP100/CP200 OPERATING MODES CP200 Normal operation (on-line operation) In normal operation the load is supplied via the rectifier and inverter. Option The mains supply voltage is converted to DC in the controlled rectifier. The inverter and the battery are supplied with this DC voltage. The battery is beeing charged. In the static inverter the DC voltage is converted into an alternating voltage with constant voltage and frequency for feeding sensitive loads. Feeding via battery and inverter In case of mains failure or mains disturbance, the rectifier will be switched off. The battery takes automaticly and without interruption over the supply of energy to the inverter. The inverter electronics will keep the alternating voltage constant, even though the battery voltage decreases. Option When the mains supply returns, the rectifier will be switched on again and will feed both the battery and the inverter. The battery will be recharged, and normal operation is re-established. This modus can also be used for testing battery capacity. Then the rectifier is set in standby mode and starts automaticly recharging the battery when the battery is empty, and the capacity is registered. Static bypass operation In case of heavy overload (inrush current or short circuit) or inverter failure, the static bypass switch will automatickly and without interruption transfer the load to the mains. When the overload decreases below 100% of the UPS rated power, the inverter will start up and automatickly take over the load without interruption. Siemens AS, E&A, Power Electronics Centre - Option Edition 02, February 2006 Page 15 Siemens UPS system CP100/CP200 OPERATING MODES CP200 Manual bypass operation By means of isolators in the supplies for rectifier, static bypass switch and the battery circuit, the main parts of the UPS unit can be disconnected and made dead for service work. The manual bypass switch connects the load directly to the mains supply (The active parts which are going to be repaired will be bypassed). Hot standby mode This is an energy saving mode. By choosing this operation mode, inverter hot standby operation, the load will be transferred to the bypass if it can be transferred without interruption. The inverter will continue to run idle in synchronism with the bypass, and will take over the load without interruption if the bypass supply should fail. The rectifier will run as normal and charge the battery and supply the inverter with necessary energy. In this mode, the power loss in the inverter is minimized since it runs in idle. Battery discharge test (option) The rectifier can be delivered with bidirectional energy float (reversible rectifier). Option Option Option The battery bank feeds the DC link, and the battery energy is divided between the load and the mains supply. The discharge test is performed with the UPS in normal operation inverter operation. The test will proceed until the preset discharge test end voltage level is reached. A battery recharge process is started when the battery is empty. Should there be a mains failure during the discharge test, the test is automatically interrupted, and the battery feeds the inverter only. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 16 Siemens UPS system CP100/CP200 CONTROL PANEL The control panel for AC UPS CP200 and DC UPS CP100 contains a mimic diagram and a soft-key operated LC display. Mimic diagram LED fields indicate the energy flow and UPS status. LEDs indicates breaker positions. Rectifier ON/OFF push button Inverter ON/OFF push button Any other operations are done via the display and the soft-keys. Except for manual bypass operation, which is operated from inside the cabinet. Display A 40 x 4 digits alphanumeric display with 5 softkeys is the interface between the UPS and the operator. Electrical measured values, alarms and system status is displayed on the LC display. Battery supply Rectifier supply By means of the soft-keys, it is possible to get useful information: - operation modus - event log - data for the unit - get help with the operation - give commands. Bypass supply Safe operation command The logics controls if your command is safe to execute. All stop commands from the front panel which may cause an interruption on the UPS output, will be checked and need an extra confirmation before they are carried out. Control Panel CP200 (AC UPS) Examples: CP100 The DC UPS CP100 has the same control panel as for the AC UPS CP200, except from all information in the mimic panel and the LC display concerning inverter and static- and manual bypass switch. Siemens AS, E&A, Power Electronics Centre - Inverter off command. Automatic control if bypass can take the load without load disturbances. Rectifier off command. Automatic control if battery can take the load. Edition 02, February 2006 Page 17 Siemens UPS system CP100/CP200 ALARMS AND COMMUNICATION Signal connections All signals to/from the UPS are connected to One or more terminal strips in the bottom of the cabinet. There are terminals for cross section 0,5mm2 – 2,5mm2. Standard provided Relay contacts for common alarms; priority 1 and priority 2. External digital I/O (option) The unit ”External digital I/O” gives access to 4 digital inputs and 4 digital output relays with potential free change-over contacts. Two units External digital I/Os can be provided in each UPS. PC communication (option) By means of the software program CCC all UPS settings / adjustments can be done via a PC. This program is normally used by the service engineers and is normally not to be operated by the customer. Up to 4 (8 with two i/o units) custom specific inputs may be defined. Examples: - Battery room fan control during boost charging / Boost inhibit Input for battery room temperature measurement; Temperature compensated charging. Communication Interface Unit (option) The unit serves two functions: - Bus tie switch position (in a redundant parallel UPS system). Up to 4 (8 with two i/o units) different outputs may be defined. - The outputs are free programmable Remote communication to a control center over Profibus DP protocol. Provided when two or more UPS units are connected in parallel. Over CAN-bus the communication between the UPS blocks is supported. - They may be used as signal / alarm contacts - Gives together with the two standard provided common alarm contacts, totally 6 pcs (10 with two i/o units) free programmable signal/alarm contacts. The interconnection i made by means of a cable with twisted pair plus screen or via fibre optic cable. - One or more signals or alarms may be combined at each output. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 18 Siemens UPS system CP100/CP200 PARALLEL OPERATION Different parallel configurations are possible: 2 units CP100 or CP200 can be connected in redundant parallel configuration to increase reliability or short circuit capacity of the total UPS system. One of the UPS units is directly connected to the output of the other UPS unit. Then a common cable for the two UPS units feeds the load/load distribution board. One should however, be aware of that this common load cable may be a single point of failure. Both units contain full single block monitoring circuits (identical systems with master/slave coordination when swithing on). In normal operation each UPS unit supplies 50% energy to the load. In case of failure in one UPS unit, the other unit takes automatically and without interruption over the load supply alone. If one unit is shut down for service, it can easily be separated while the other is working as a normal single block system with bypass. The UPS units may have a common battery. However, it is recommended that each UPS has its own battery. One common battery can be a common failure point. Each battery can be rated to provide 50% or 100% of the load at specified battery backup time. 100% Battery 100% or 50% rating From each UPS unit, a load cable is wired directly to the load/load distribution board. Then a single point of failure is avoided. The load distribution board input may be a common bus bar for the two UPS units. Each UPS unit feeds its own load distribution board via a load cable connected to each UPS output. A bus tie breaker may be connected between the two distribution boards. This system may be splitted in two separate, independant UPS systems, or opeate as redundant parallel UPS system. 100% Communication 50% load Battery 100% or 50% rating 50% load Load (100%) Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 19 Siemens UPS system CP100/CP200 PARALLEL OPERATION DC UPS CP100 – Parallel operation configuration example. AC UPS CP200 – Parallel operation configuration example. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 20 Siemens UPS system CP100/CP200 OPTIONS Several standard options are available for CP100 and CP200. In addition special customer definied options my be provided. Battery capacity test The rectifier can be delivered with bidirectional energy float (reversible rectifier) providing a real battery capacity test. Panel printer A door panel mounted printer for printing out battery discharge test results and UPS event log. External battery breaker Normally the battery breaker is provided in the UPS cabinet. As an option the breaker can be provided outside the UPS cabinet, eiter in a standard wall box or in an EExd capsule Boost inhibit Boost charging of batteries produces gas. Normally the battery room ventilation fans sucks out the gas and prevent explosive gas in the battery room. The UPS may be provided with a signal input for inhibiting boost charging in case of battery room ventilation failure. Temperature compensated battery charging The life length of lead batteries, and aspecially valve vented lead acid and gel batteries is dending on the battery ambient temperatures. A battery with estimated life length of 10 years at 20oC ambient temperature, will have only 5 years estimated life lenght at 30oC. The life lenght is halved every 10oC above 20oC. Without temperature compensated charging, the loss in life time due to high temperature will be worse for valve vented batteries. Low ambient temperature in the battery room will cause under-charged batteries, and the battery can not be fully charged, if the charge voltage not is adjusted to correct charge voltage depending on ambient temperature. The UPS CP100 and CP200 are provided with temperature compensated battery charging. Siemens AS, E&A, Power Electronics Centre - Typical curve for valve vented lead acid batteries Charge voltage Trip battery breaker The battery breaker (MCCB) can be provided with a shunt trip coil or undervoltage release for emergency shunt down (ESD). Ambient temperature As an option a non-Exd or Exd temperature sensor is placed close to the battery. Via a wire from this sensor the UPS is informed about the battery ambient temperature, and adjust automatically the bcattery charge voltage depending on this temperature. At high temperature, the charge voltage is decreased. At low temperature, the charge voltage is increased Edition 02, February 2006 Page 21 Siemens UPS system CP100/CP200 OPTIONS Manual ”Black start” This function is actual when the UPS system is controlled shut completely down due to a shut down/black-out at for example an oil installation, and UPS power is required before mains supply is re-established. Option Black start means that the inverter is started with energy from the battery only. The load is supplied with battery energy via the inverter. The charger is not running, and the battery isolator is open. Before inverter can be started, the intermediate capacitor have to be charged to prevent inrush current to the capacitor. This is done by a manual operated charge circuit. After charging the capacitor, the battery breaker can be closed and the inverter started and supplied the load with energy. Mains filter – Current harmonics limitation As standard the content of current harmonic feedback to the rectifier mains supply is approx. 30%. For relative small UPS ratings (<100kVA) and a strong mains supply, this is normally no problem. In some cases, where the current harmonic feedback from the UPS is expected to cause disturbances in the mains supply, a mains filter can be provided. The filter is provided in a separate cabinet and will limit the overharmonics to 10%. In special cases the filter can be designed for further overharmonics reduction. When considering if mains filter for the UPS is necessary, the total mains quality and current harmonics contribution from other mains consumers should be taken into consideration. Maybe UPS mains filter will have no positive influence on the mains at all, due to current harmonics from other mains consumers. Siemens AS, E&A, Power Electronics Centre - Option Mains filter – Inrush current limitation The AC UPS CP200 and DC UPS CP100 are provided with a galvanic isolation transformer at the rectifier input. In addition the CP200 is provided with a galvanic isolation transformer at the bypass circuit input. As standard the inrush current from the transformers is approx. 15- 20 times the nominal current. As an option a filter reducing the inrush current to approx. 8 times the nominal current can be provided. The filter is provided in a separate cabinet. Combined mains filter – Current harmonics limitation and Inrush current limitation May be provided in a common cabinet. Edition 02, February 2006 Page 22 Siemens UPS system CP100/CP200 OPTIONS Bypass transformer (CP200) The CP200 AC UPS may be provided with a single phase bypass transformer (T51) at the bypass circuit input. The transformer is installed inside the UPS cabinet. An earthed screen between primary and secondary windings is provided. It serves the following purposes: - Voltage adaption when bypass mains supply is different from UPS output voltage. - Galvanic isolation between mains supply and load. Bypass input breaker (Q51) A non fused load isolator may be provided to isolate the UPS bypass circuit from the bypass mains supply. External I/O Unit. Up to two units may be provided in each UPS. Each I/O unit provides 4 digital inputs and 4 digital outputs for signals and alarms . Communication Interface Unit Profibus / Parallel operation Provides - Profibus DP communication interface - CAN-Bus communication for parallel operation communication between UPS units. Other output voltages for CP200 AC UPS. The standard output voltage for CP200 is single phase 230V 50Hz or 60Hz. As an option 110V, 115V or 120V output is available. Reference marking of internal wiring There is as standard no reference marking on internal wiring in the UPS cabinet. Two optionally levels of wire marking can be provided: - Reference marking only on wiring wired down to external connection terminals - Reference marking on all internal wiring Increased degree of protection As standard the cabinet degree of protection is IP20. The bottom is open for cooling air inlet. As an option higher degree of protection can be provided. Standard options are IP21, IP22, IP31 and IP32. Higher degree of protection may be available on request. Preferably the cabinet bottom is open to secure cooling air inlet. As an option the bottom may be protected IP3x. Lifting lugs As standard no lifting lugs is provided at the UPS cabinet. As an option lifting lugs can be provided at top of the cabinet. Other cabinet colours Standard cabinet colour is RAL 7032 (light grey). As option other RAL colours may be provided. The references will be the same as references in the schematic diagram. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 23 Siemens UPS system CP100/CP200 OPTIONS UPS distribution boards in UPS design AC and DC UPS distribution boards can be provided. The distribution boards are in the same design as the UPS cabinet. Breaker types, rating and number of output circuits to be designed for each case. Breakers can be provided with trip, trip alarm etc. Alarms from the distribution board can be wired directly or via the UPS to a control room. From UPS A output From UPS B Output From UPS output Isolation monitoring of UPS output A common isolation monitoring (earth fault monitoring) for the UPS output can be provided. Make: Bender IRDH series. The isolation monitoring unit will be installed inside the UPS cabinet at the UPS output. Or at the input bus bar in the distribution board if distribution board is to be provided. From UPS output Individual isolation monitoring of output circuits To be provided in the distribution board. Each output circuit can individually be isolation (earth fault) monitored. There is automatically detection of any single output isolation failure. Make: Bender EDS 470 system. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 24 Siemens UPS system CP100/CP200 CP100 TECHNICAL DATA Output rating 50A 100A 150A 200A 300A 400A Rectifier Input Rated voltage V 230, 380, 400, 415, 440, 480, 660 or 690 Number of phases 3 Voltage tolerance % -15/+10 Frequency Hz 50 or 60 Frequency tolerance % ±5 Power factor Input current distortion >0,8 % Standard: 30 Option: 10 4) Inrush current Maximum power incl. battery charging 2) 24V DC output 48V DC output 110V DC output 220V DC output 1) Standard: Option: Approx. 20 x In Approx. 8 x In 4) kVA kVA kVA kVA 2 4 8,5 17 4 7,6 17 33,6 V 24, 48, 110 or 220 6 11,5 25,5 50,5 8 15,2 34 67,2 12 23 51 5) 16 30,5 68 5) DC output Nominal output voltage Min. / max. output voltage Ripple voltage without battery Depending on connected battery charge voltage and end discharge voltage. % 1 Short circuit current Nominal output rating/ max. rectifier current 3) 1) Depending on actual battery short circuit current A 50 100 150 200 300 400 1) Other voltages on request 2) At rated load 3) Load current + battery charge current 4) Other factors on request 5) Available as special option only Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 25 Siemens UPS system CP100/CP200 CP100 TECHNICAL DATA Output rating 50A 100A 150A 200A 300A 400A UPS unit Cooling Natural convection Ambient temperature oC 0 – 40 Derating factor at 45oC ambient temperature % 12 RFI Suppression EN 55011 Group 1, Class A Degree of protection (EN60529) Standard: IP20 Standard options: IP21, IP22, IP31, IP32 Colour RAL 7032 (light grey) Cable entry Below Acostic noise (DIN 45635) 1) dB(A) <60 <60 <60 <60 <60 <60 kW kW kW kW 0,3 0,4 0,5 0,7 0,5 0,6 0,8 1,6 0,6 0,8 1,1 1,9 0,8 1,0 1,7 2,4 1,1 1,6 2,2 1,4 2,0 2,7 24V DC output 48V DC output 110V DC output 220V DC output % % % % 86 89 94 95 86 91 94 95 88 91 95 95 88 92 95 96 88 91 95 89 93 95 Heigt mm 1900 1900 1900 1900 1900 1900 Lenght 24V outp. 48V outp. 110V outp. 220V outp. mm mm mm mm 620 620 620 620 620 620 620 620 620 620 620 920 620 620 620 920 920 920 920 920 920 920 Depth mm 634 634 634 634 634 634 Increase in height at IP21-IP32 mm 160 160 160 160 160 160 Weight (approx.) kg kg kg kg 400 420 450 520 420 440 520 560 440 480 540 650 460 500 560 700 480 500 650 500 550 700 Power losses (at rated load) 24V DC output 48V DC output 110V DC output 220V DC output Efficiency (at rated load) Dimentions 1) 2) 24V DC output 48V DC output 110V DC output 220V DC output 2) 2) 2) 2) 2) 2) 2) 2) Other colours on request Available as special option only Standards The low voltage directive; EN 50178, EN 60439-1 Product standard/EMC EN 50091-2 Immunity; EN 50082-2 Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 26 Siemens UPS system CP100/CP200 CP100 ELECTRICAL INSTALLATION DATA Output rating 50A 100A 150A 200A 300A 400A Rectifier Input (3 phase) - 230V mains supply Input current 24V DC output A 5 48V DC output A 10 110V DC output A 21,4 220V DC output A 43 10 19 43 85 15 29 64 127 20 38 86 169 30 58 128 40 77 171 Recommended minimum fuse 1) in mains supply 24V DC output 48V DC output 110V DC output 220V DC output A A A A 16 25 40 100 25 40 100 160 35 63 125 225 40 80 160 315 63 125 225 80 160 315 Terminals for max. cable cross section 24V DC output 48V DC output 110V DC output 220V DC output mm2 mm2 mm2 mm2 35 35 35 70 35 35 70 95 35 35 70 240 35 70 95 240 70 95 240 70 95 240 Rectifier Input (3 phase) - 380V-415V mains supply Input current 24V DC output A 3 6,1 48V DC output A 6,1 11,6 110V DC output A 13 26 220V DC output A 26 51 9,1 17,5 39 77 2) 2) 2) 2) 2) 2) 12,2 23 52 102 18,2 35 78 24,3 47 104 2) 2) Recommended minimum fuse 1) in mains supply 24V DC output 48V DC output 110V DC output 220V DC output A A A A 10 16 25 50 16 25 50 100 25 40 80 160 25 50 125 200 40 80 160 50 100 200 Terminals for max. cable cross section 24V DC output 48V DC output 110V DC output 220V DC output mm2 mm2 mm2 mm2 35 35 35 35 35 35 35 70 35 35 70 95 35 35 70 240 35 70 95 35 70 240 2) 2) 2) 2) 1) Slow action 2) Available as special option only Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 27 Siemens UPS system CP100/CP200 CP100 ELECTRICAL INSTALLATION DATA Output rating 50A 100A 150A Rectifier Input (3 phase) – 440V-480V mains supply Input current 24V DC output A 2,7 5,3 48V DC output A 5,3 10 110V DC output A 11,2 22,3 220V DC output A 22,3 44 7,9 15 34 67 200A 300A 400A 11 20 45 89 16 30 67 19 36 82 2) 2) 40 80 160 Recommended minimum fuse 1) in mains supply 24V DC output 48V DC output 110V DC output 220V DC output A A A A 10 16 25 50 16 25 50 100 20 35 80 125 25 40 100 160 35 63 125 Terminals for max. cable cross section 24V DC output 48V DC output 110V DC output 220V DC output mm2 mm2 mm2 mm2 35 35 35 35 35 35 35 70 35 35 70 70 35 35 70 95 35 70 95 35 70 95 2) 2) 5,3 10 22,3 45 7 13,3 30 59 10,5 20,2 45 14 27 60 Rectifier Input (3 phase) – 660V-690V mains supply Input current 24V DC output A 1,8 3,5 48V DC output A 3,5 6,7 110V DC output A 7,5 15 220V DC output A 15 30 2) 2) 2) 2) Recommended minimum fuse 1) in mains supply 24V DC output 48V DC output 110V DC output 220V DC output A A A A 6 10 16 35 10 16 35 63 16 25 50 100 20 35 63 125 25 40 100 Terminals for max. cable cross section 24V DC output 48V DC output 110V DC output 220V DC output mm2 mm2 mm2 mm2 35 35 35 35 35 35 35 35 35 35 35 70 35 35 35 70 35 35 70 Battery (DC) Terminals for max. cable cross section mm2 50 95 240 240 240 2x240 Output (DC) Terminals for max. cable cross section mm2 50 240 240 240 2x240 Max. recommended distribution fuse 1) 2) 95 2) 35 63 125 2) 35 35 95 2) 2) Depending on actual battery short circuit current Slow action Available as special option only Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 28 Siemens UPS system CP100/CP200 CP200 TECHNICAL DATA 30 kVA 40 kVA 60 kVA 75 kVA 90 kVA 120 kVA Rectifier Input Number of phases 3 Rated voltage V 230, 380, 400, 415, 440, 480, 660 or 690 Voltage tolerance % -15 / +10 Frequency Hz 50 or 60 Frequency tolerance % ±5 Power factor Input current distortion 1) >0,8 % Standard: 30 Option: 10 Inrush current Standard: Option: 4) Approx. 20 x In Approx. 8 x In 4) Rated power without battery charging 2) kVA 36 48 72 90 108 144 Maximum power with battery charging 2) kVA 42 56 84 105 126 168 V 436 Min. output/end discharge voltage V 316 Ripple voltage without battery % 1 Inverter input voltage range V 316 – 436 Max. rectifier current 3) A 68 91 136 170 204 272 Max. inverter input current at 316V A 79 106 158 198 237 316 Inverter input power 2) 26 35 52 65 78 103 DC-link / Battery Max. output/max. charge voltage 1) Other voltage on request 2) At rated load, cos φ=0,8 3) Inverter input current + battery 4) Other factors on request kW charge current Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 29 Siemens UPS system CP100/CP200 CP200 TECHNICAL DATA 30 kVA 40 kVA 60 kVA 75 kVA 90 kVA 120 kVA Inverter / Output Number of phases 1 Rated voltage V 230 Power factor range 1) 0,9 kap. - 0,7 ind. Frequency Hz 50 or 60 Frequency deviation % ± 1 self controlled ± 0,1 – 5,0 (selectable) mains controlled Static voltage tolerance in inverter operation % ±1 Voltage tolerance in in bypass operation % As for mains up to ± 10 Dynamic voltage tolerance % Better than ± 5 (40ms) at 100% load change Distortion at linear load % <3 total <2 single harmonic Rated power at cos φ=0,8 (40oC ambient temperature) kVA 30 40 60 75 90 120 Max. active power kW 24 32 48 60 72 96 130 173 261 326 391 522 5 4 5 3,75 Rated current at 230V, cos φ=0,8 A Crest factor Ipeak/IRMS Overload (IEC 146 cl.II) 2 min % A >150 >195 113 195 >150 >391 120 391 >150 >586 112 586 Short circuit current peak 15ms % A 500 650 333 650 500 1305 400 1305 500 1955 375 1955 Short circuit current 2s % A >200 >260 >150 >260 >200 >522 >160 >522 >200 >782 >150 >782 Short circuit current 20s % A 180 234 135 234 180 470 144 470 180 704 135 704 A 35 35 63 63 125 125 Recommended max. distribution fuse (MCB C) 2) 1) 2) 5 3,33 Other voltages on request For other type of protection, different values may be valid Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 30 Siemens UPS system CP100/CP200 CP200 TECHNICAL DATA 30 kVA 40 kVA 60 kVA 75 kVA 90 kVA 120 kVA UPS unit Ambient temperature oC 0 – 40 Derating factor at 45oC ambient temperature % 12 RFI Suppression EN 55011 Group 1, Class A Degree of protection (EN60529) Standard: IP20 Standard options: IP21, IP22, IP31, IP32 Colour RAL 7032 (light grey) Cable entry Below 1) Power losses At rated load kW 3,2 4,3 6,4 8,0 10,0 13,8 Efficiency At rated load % 89 88 89 88 89 88 Efficiency At 50% load % 89 88 89 88 89 88 Cooling Natural convection x Forced ventilation x x x x x Acostic noise (DIN 45635) dB(A) 60 63 60 63 60 63 Dimentions Heigt mm 1900 1900 1900 1900 1900 1900 Lenght mm 920 920 1820 1820 2720 2720 Depth mm 634 634 634 634 634 634 Increase in height at IP21-IP32 mm 160 160 160 160 160 160 Weight Kg 750 850 1370 1520 2190 2430 Approx. 1) Other colours on request Standards The low voltage directive; EN 50178, EN 60439-1 Product standard/EMC EN 50091-2 Immunity; EN 50082-2 Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 31 Siemens UPS system CP100/CP200 CP200 ELECTRICAL INSTALLATION DATA 30 kVA 40 kVA 60 kVA 75 kVA 90 kVA 120 kVA A A A A 105 64 55 37 158 96 83 55 211 128 110 74 NA 160 138 92 NA 191 165 110 NA 255 220 147 Recommended minimum fuse 1) in mains supply 230V 380V - 415V 440V - 480V 660V - 690V A A A A 160 100 100 63 250 160 125 100 355 200 200 125 NA 250 225 160 NA 315 250 200 NA 400 355 225 Terminals for max. cable cross section 230V 380V - 415V 440V - 480V 660V - 690V mm2 mm2 mm2 mm2 95 50 50 50 150 95 95 50 2x240 240 240 95 NA 240 240 240 NA 240 240 240 NA 2x240 2x240 240 A A A A A 143 143 83 72 48 215 215 124 107 72 286 286 166 143 96 258 358 207 179 119 430 430 249 215 143 573 573 332 286 191 Recommended minimum fuse 1) in mains supply 230V 2) 230V 3) 380V - 415V 440V - 480V 660V - 690V A A A A A 250 160 160 125 100 400 250 225 200 125 500 315 315 250 200 630 400 355 315 225 800 500 425 400 250 1000 630 630 500 350 Terminals for max. cable cross section 230V 2) 230V 3) 380V - 415V 440V - 480V 660V - 690V mm2 mm2 mm2 mm2 mm2 240 240 95 95 50 2x240 240 240 240 95 2x240 2x240 240 240 240 2x240 2x240 2x240 240 240 2x240 2x240 2x240 2x240 240 2x240 2x240 2x240 2x240 2x240 A 79 119 158 198 237 316 mm2 50 95 240 240 240 240 A 130 196 261 326 391 522 mm2 95 240 240 2x240 2x240 2x240 A 35 35 63 63 125 125 Rectifier Input (3 phase) Input current 230V 380V - 415V 440V - 480V 660V - 690V Bypass Input (1 phase) Input current 230V 2) 230V 3) 380V - 415V 440V - 480V 660V - 690V Battery (DC) Max. Battery current Terminals for max. cable cross section Output (1 phase) Output current Terminals for max. cable cross section Max. recommended distribution fuse 1) Slow action 2) With bypass transformer Siemens AS, E&A, Power Electronics Centre - 3) without bypass transformer Edition 02, February 2006 Page 32 Siemens UPS system CP100/CP200 PLANNING AND INSTALLATION When planning a new UPS installation, or replacing an old UPS installation, it is of highly importance to plan the installation properly. In this way the UPS system will be designed to fit the needs and demands for each installation. Siemens Power Electronics Centre can provide well qualified teams for: Sales Engineering, also for special applications Studies and projecting of UPS systems and planning of installation. Both new installations and replacements. Installation supervising and assistance. Service Aspects to be considered when planning an UPS installation: Regulations Safety regulations Local and international standards Load Size and type of load Voltage and number of phases Importance of load Sensitivity System configuration Importance of load Single or parallel redundant UPS system If parallel UPS system; Which parallel configuration to choose? Operation safety Life time of UPS and battery to be considered in conjunction to expected life time of overall installation. Functional and monitoring/alarm requirements UPS load distribution Number and size of output circuits Selectivity – Breaking capacity – breaking time Type of output circuists – MCBs, MCCBs or fuses Trip monitoring of output circuits Isolation monitoring – common or individual Siemens AS, E&A, Power Electronics Centre - Battery Autonomy time Type of battery - Valve vented or gel – can be placed in UPS room or in separate room - Free vented lead acid and NiCd battery requires separate battery room Requirement to battery life life time Available space for batteries Ventilation requirements and possibilities Temperature control – optimal is 20oC For parallel operation UPS systems; 2x100% or 2x50% batteries? This is often a question about costs, available space and load safety requirements. 1x100% battery is normally not recommended due to safety reasons and to avoid single point of failure. Installation planning Available space – space requirements Ventilation – cooling requirements IP protection Cabling and connections - cable routing, cable size and type - signal cabling Any physical limitation Local Loading and transport routing possibilities and limitations Weight and size of equipment HMS When replacing old UPS systems Change in load size, type and requirements ? New system philosophy ? Placing - New UPS larger or smaller than existing - Need new foundation ? Change in IP protection Cabling – To be replaced or additional cabling required ? Remote alarms and monitoring philosophy to be evaluated / changed Battery – Evaluation – Same battery type as before – Change in battery type – change in backup time – available space Sequence of disconnection and deinstallation of old system in relation to installation and commissioning of new system. Edition 02, February 2006 Page 33 Siemens UPS system CP100/CP200 CP100 DIMENTION DRAWINGS Dimentions with IP 21 / IP31 Distribution board is optional DC UPS CP100 ratings with cabinet width 600mm Output current 50A 100A 150A 200A Output voltage (DC) 24V – 220V 24V – 220V 24V – 110V 24V – 110V Distribution board Distribution board for approx. 24 output circuits. More circuits: Extension in number of cabinets. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 34 Siemens UPS system CP100/CP200 CP100 DIMENTION DRAWINGS Dimentions with IP 21 / IP31 DC UPS CP100 ratings with cabinet width 900mm Output current 150A 200A 300A 400A Output voltage (DC) 220V 220V 24V – 220V 24V – 220V Higher output current: Forced vented cabinets. Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 35 Siemens UPS system CP100/CP200 CP200 DIMENTION DRAWINGS Dimentions with IP 21 / IP31 Switches Transformers Etc etc CP200 30kVA (natural convection) 40kVA (forced vented) Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 36 Siemens UPS system CP100/CP200 CP200 DIMENTION DRAWINGS Dimentions with IP 21 / IP31 CP200 60kVA (natural convection) 75kVA (forced vented) Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 37 Siemens UPS system CP100/CP200 CP200 DIMENTION DRAWINGS Dimentions with IP 21 / IP31 CP200 90kVA (natural convection) 120kVA (forced vented) Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 38 Siemens UPS system CP100/CP200 CONTACT INFORMATION Company name and adress Contact persons: Siemens AS Energy & Automation Division Power Electronics Centre Heidi Rø Tel.: + 47 73 95 94 14 Fax.: +47 73 95 90 22 E-mail: heidi.roe@siemens.com Post adress: N-7493 Trondheim Norway Visit adress: Bratsbergvn. 5 N-7037 Trondheim Norway Alf Olav Valen Tel.: +47 73 95 94 92 Fax.: +47 73 95 90 22 E-mail: alf.valen@siemens.com Telephone: +47 73 95 90 00 Telefax: +47 73 95 90 22 Siemens AS, E&A, Power Electronics Centre - Edition 02, February 2006 Page 39