Reliability of CMOS Integrated Circuits

advertisement

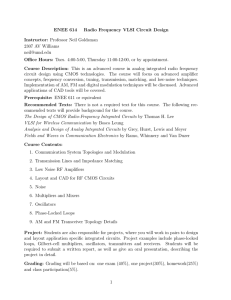

CMOS ICs are being produced using a variety of processes, and considerable data is now available on their reliability and failure mechanisms. Reliability of CMOS Integrated Circuits There are basic differences between MOS and bipolar digital integrated circuits, and between CMOS and other digital MOS technologies. Some of those differences have an impact on the reliability of the various types of digital integrated circuits. Accelerated-life tests and field use, along with other available data on CMOS reliability, indicate that CMOS devices, properly made, are equal in reliability to bipolar digital circuits of equal complexity. In this article, we look at CMOS packaging, circuit complexity, and electrostatic gate protection and compare CMOS to other types of digital IC technology. CMOS IC Technology The basic building block for CMOS integrated circuitry1-4 is shown in Figure 1. In contrast to other types of MOS integrated circuits, the CMOS circuits contain no load resistors; this results in very low quiescent dissipation. The voltage transfer characteristics of a basic CMOS inverter are shown in Figure 2, and typical curves of dynamic dissipation versus frequency in Figure 3. CMOS ICs were originally produced in volume in 1968. The technology has evolved from that used for the original RCA CD4000 series' devices (6-15 volts) to the CD4000A series (3-15 volt) devices2 in 1971, and to the 4000B series (3-20 volt) devices 3,6 in 1974. The introduction, in 1970, of plasticencapsulated devices5 was instrumental in achieving even wider acceptance of the popular 4000 series. CMOS ICs are being produced by a number of manufacturers using a variety of different processes.2'2w5-'9 Ion implantation is being used to form p-wells, 3,20 to adjust thresholds,6 and to avoid field inversion. Metallization materials have included aluminum, polycrystalline silicon, and titaniumpalladium-gold or titanium-platinum-gold.52'2 Tech6 0018-9162/78/1000-0006$00.75 O 1978 IEEE niques for attaching the die to the substrate have in- cluded gold-silicon eutectic bonding and epoxy attachment.' Although most CMOS ICs being manufactured today are bulk silicon types, devices fab'ricated on thin-film silicon-on-sapphire substrates are being produced.3'7"1'9-1419 At present, 4000A series CMOS ICs are commercially available from more than 10 suppliers, and standardized 4000B series devices22 are or will be available from at least nine. Devices qualified to MIL M-38510, Class A are also commercially available.4 The packages used for CMOS devices are similar to those used for other types of MOS devices and for bipolar devices. The same potential failure mechanisms apply to chip-to-substrate bonds, wire bonds, and packages.2 All MOS devices are, however, more surface-sensitive than digital bipolar devices, and higher voltages are applied to MOS devices than to digital bipolar devices. MOS vs. bipolar ICs MOS ICs have had a major impact on the digital electronics industry. Not only have they displaced bipolar ICs for many applications, but they have also made possible a large number of totally new applications. As a result, they are now being produced in volumes roughly comparable to those of bipolar devices. Because bipolar devices antedate MOS devices, more information has been published on the reliability of bipolar circuits than on the reliability of MOS circuits. Also, bipolar circuits were initially used to a large extent in high-reliability military and aerospace applications, whereas' MOS circuits have been used principally in consumer and commercial applications. Also, while most early MOS devices were hermetically packaged, a large portion of all MOS ICs produced today are encapsulated in plastic.1,13 COMPUTER + VDD VDD SUBSTRATE VOUT INPUT Q- GATES G 0 OUTPUT l_n p - WELL -vss Figure 1. The basic building block for CMOS integrated circuits. The first commercially available MOS devices based on p-channel enhancement-mode MOS transistors with aluminum gates. Accordingly, considerable information is available on the reliability of this type of device, and on possible failure mechanisms.ss-27 Devices that have since become commercially available include CMOS, silicon-gate, n-channel, depletion-mode, floating-gate, CCD, and CMOS/SOS devices. Considerable data is now available on the reliability and possible failure mechanisms of CMOS devices, on ICs containing silicon-gate transistors,51-" and on devices based on n-channel transistors.55-" A number of fundamental differences between MOS and bipolar devices have an impact on reliability. The principal differences are that MOS ICs have a higher substrate resistivity and use higher applied voltages, and the properties of the gate oxide of MOS devices are more important. The process of MOS fabrication is simpler than bipolar fabrication.5,23 Accordingly, it is easier to attain higher chip complexity with MOS, and thus higher gate-to-pin ratios. Since wire-bond failures are a significant factor in limiting the reliability of small-scale ICs, MOS can significantly improve reliability by reducing the number of wire bonds and external interconnections. Moreover, with MOS technology, there is lower power dissipation per function, which improves reliability by lowering chip temperatures. In typical bipolar ICs (TTL), device dissipation is significant. MOS, particularly CMOS, also has an advantage over bipolar devices in that the high impedance of MOS devices does not result in high current densities in the metal interconnections, and thus electromigration (current-induced mass transport) is not a common problem in MOS devices. Problems of high current density at metal-silicon contacts are also less frequent. The high impedance of MOS devices also makes multilevel interconnections feasible in complex arrays without significantly were October 1978 VIN Figure 2. Voltage CMOS inverter. transfer characteristics of a basic compromising circuit properties. Diffused crossunders in the single-crystal silicon are effective, and if another level of interconnections is required in addition to that provided by the metallization layer, polycrystalline silicon, deposited as part of the silicon-gate process, is quite effective as an interconnection level. By contrast, an additional level of interconnections. in bipolar arrays means use of metal-over-metal 'crossovers, which requires additional technology and introduces possible new failure mechanisms. Since localized defects in silicon are a factor in IC reliability, one advantage of MOS compared to bipolar circuits is that no epitaxial layer is required for conventional monolithic MOS devices. MOS devices are thus fabricated in silicon of better AMBIENT TEMPERATURE (TA) - 250C POWER DISSIPATION P = CVDD2f + PQUIESCENT 103 104 105 106 107 INPUT FREQUENCY (fl) - Hz Figure 3. Typical relationship between dynamic dissipation of CMOS integrated circuits and frequency. 10 7 crystallographic perfection, with no possibility of epitaxial stacking faults or of epitaxial spikes that cause device problems and damage the masks used for photolithography. Finally, since MOS processing is simpler than bipolar processing and requires fewer steps, fewer manufacturing errors are possible. Failure rates for devices of various complexities are often lumped together and reported as a failure rate for a particular device family. Since MOS devices tend to be more complex than bipolar devices, equal reported failure rates per packaged part actually represent lower failure rates per gate. MOS ICs use many of the same materials and processes that bipolar ICs and small-signal transistors do. Accordingly, improvements in silicon materials,'9 oxidation,65-69 photolithography,50'70-7' diffusion,20'72 metallization,7' passivation,78'" and plastic encapsulation,"23"3'97-79 and also in device physics, design, process control,'8 automation,80 and electrical characterization have resulted in substantial improvements in the reliability of both types of devices. Reliability advantages of CMOS CMOS technology provides a number of reliability advantages over other MOS technologies, 34,7-9,14,21,28 For example, since both p-type and n-type diffusions are part of the normal process, both are available to use as channel stoppers or as part of a more effective input protection circuit. The low dissipation of CMOS ICs results in lower chip temperatures, which substantially improve reliability. The wide range of CMOS operating voltages permits greater reliability of operation, including allowing functional testing at voltages substantially _above and below the ultimate operating voltage. Moreover, because of low dissipation per gate, CMOS can be used to fabricate very complex chips without introducing reliability problems resulting from excessively high chip temperatures."'0"4 By contrast, power dissipation in large chips is a problem with TTL integrated circuits and, to some extent, PMOS and NMOS circuits. Finally, CMOS technology represents a mature, high-volume technology with an extensive history of reliability. Potential failure mechanisms are well understood, and production processes and process controls have been specifically selected to ensure against the possibility of manufacturing errors that might adversely affect reliability. Other factors of importance to the reliability of CMOS ICs include device and design features >(dielectric thickness and quality, design rules, device complexity, in-process controls), specifications (maximum and minimum operating voltages, operating temperature range), electrical testing (tests performed on the wafer and on packaged devices), and screening (amount of burn-in or other screens applied). Operating conditions of impor-, tance include chip temperature, applied voltage, 8 voltage transients, moisture content of the ambient, and exact circuit usage.5 CMOS packaging CMOS ICs are available in all of the common package configurations. The conventional hermetically sealed ceramic package containing a cavity filled with dry gas is generally used for highreliability military and aerospace applications. The frit or Cerdip package, with the final seal made by fusion of a devitrifying solder glass, is the least expensive hermetic package for high-volume commercial application. Beam-lead sealed-junction devices may also be considered hermetically sealed devices in that the silicon nitride provides junction hermeticity. The use of a gold-based metallization system and an overlying amorphous inorganic passivation layer provides additional protection against possible deleterious reactions over the life of the device. Most ICs being manufactured in 1978, including CMOS as well as other MOS and bipolar types, are encapsulated in plastic rather than in hermetic packages. Plastic encapsulation provides a number of significant advantages, including lower product cost, freedom from potential problems with loose particles (in molded devices), mechanically strong dual-in-line packages, good resistance to- shock and vibration, no leak-test requirement, and possibility of small packages. A number of possible limitations of plasticencapsulated integrated circuits were identified",2"28 in studies of early plastic encapsulation systems applied to both bipolar and MOS ICs. These included moisture penetration effects, effects due to mismatches between the coefficients of linear thermal expansion of plastics and those of silicon and the various interconnect metals, and the presence of ionic materials and other contaminants in certain plastics. The knowledge of potential limitations of certain plastics has led to the use, in recent years, of vastly improved materials and processes for fabricating plastic-encapsulated devices.5,2",36"37'41,48,76 An example is the use of high-purity novolac epoxy plastics with high glass transition temperatures.23'7' Modifications in assembly techniques have also been made. As a result of these changes, plasticencapsulated devices manufactured in the 1976 to 1978 period have been significantly more reliable than devices fabricated a number of years ago. Humidity levels above 85 percent can greatly accelerate 'possible failure mechanisms in plasticencapsulated silicon devices."523,""i7'41,48.76'78 Consequently, high-humidity tests, particularly under bias conditions, have been used to quantitatively assess the integrity of IC passivation and encapsulation systems, and have been the basis for process improvements as well as quality control tests. The effect of high humidity in accelerating failure mechanisms has been the basis for a number of detailed studies."37'48,64 COMPUTER CMOS failure modes and mechanisms temperature-deposited glass-like inorganic passivation materials can be very effective in reducing the possibility of aluminum corrosion. Specific factors that can result in chemical corrosion of aluminum and electrochemical corrosion at cathode and anode regions have been identified. Failures in plastic-encapsulated devices are frequently attributable to penetration of moisture or other iohic impurities along the chip-plastic interface. Figure 4 shows a cross-section of a typical dual-in-line plastic package. The two paths by which water vapor can enter such packages are through the plastic and along the leads.' Pl:astic devices rarely fail in normal field use unless the wrong package is selected for the system environment.' Gate oxide breikdown may be due to localized breakdown at defects or to intrinsic breakdown of thin oxides at input circuits. Breakdown at inputs is principally attributable to overstress from static electricity discharges, particularly when the devices are mishandled. While virtually all MOS ICs contain an input protection circuit, such circoits vary considerably in design, principle of operation, and effectiveness.",990-96 The susceptibility of silicon devices to static electricity effects is not unique to MOS circuits; it has also been reported to occur with bipolar integrated circuits"""'97-" and with other electronic components. Improved input protection circuits in CMOS integrated circuits have been shown to provide additional protection against static electricity discharges.446',8 " Figure 5 shows the improved input protection network" being used on all new CD4000B devices. Some information has been published on the reliability of silicon-on-sapphire CMOS ICs, and on possible failure mechanisms for that type of construction.88'89'42 While new failure mechanisms are possible with CMOS/SOS, the principal failure mechanisms are frequently similar to those observed with bulk CMOS devices. MOS failure modes can be classified into the categories of shorts, opens, and degradations. Shorts are most commonly due to dielectric failure of the gate (thin) oxide. Dendrite formation in goldmetallized devices can ilso result in resistive shorts. Electrical opens may be due to microscopic cracks in the metallization at topographic steps-, to photolithography problems, to corrosion of metallization, to fusion of metal due to overstress, or to open wire bonds. Degradation effects are attributable to the motion of ions (such as Na+) in the silicon dioxide, or to surface-charge-spreading effects and consequent inversion. Considerable information is available on the distribution of failure mechanisms in CMOS devices that failed during accelerated-life stress tests or field use. The principal failure mechanisms in CMOS are due to parameter changes caused by motion of charge in or on oxides, and to shorts through gate oxides. (The relative distribution of CD4000A CMOS field failure mechanisms6 is shown in Table 1.) These failure mechanisms are similar to the principal failure mechanisms of other MOS device types. There is,- however, a considerable variance in the distribution of mechanisms: depending on the source issuing the informatioii The -reports of users, who include electronic equipment manufacturers as well as government agencies and industrial organizations performing government-funded reliability studies, tend to indicate that there are large, variations between products from different suppliers. Several forms of alkali ion migration are possible, including the commonly reported transverse Na+ ion movement in an electric field at an elevated temperature, and lateral Na + ion movement followed by transverse movement. The net result of alkali ion migration is to increase the threshold voltage of p-channel transistors, to decrease the threshold of n-channel transistors, or to decrease the field inversion voltage'of n-type regions. Because MOS structures have proven an excellent tool for Data on CMOS Reliability the study of silicon-silicon dioxide interface properVarious sources of data on the reliability of CMOSties, a vast amount of information has been available to- apply to the improvement of the pro- -integrated circuits exist, including data generated cess, as well as to the design and control of device by device manufact-urers,"4"59,8,283,29,0,"6,"7,89,4041,48 by users, and by government agencies and fabrication.8' Aluminum metal corrosion in integrated circuits has been the subject of considerable study in recent TRANSFER MOLDING years."'9,23,48,'-89 It has been shown that low1/4" e MATERIAL NOVOLAC EPOXY Table 1. DIstrIbutIon of mechanisms that normally occur In field failures. FAILURE MECHANISM FALSE PULLS GATE OXIDE SHORTS (HANDLING) BLOWN METAL (OVERCURRENT STRESS) QUALITY RELATED (SCRATCHED METAL, BONDING, WRONG PELLET-OR PACKAGE). MOISTURE (PLASTIC USED IN WRONG APPLICATION) October 1978 GOLD 1.0 MIL WlRES T.C. BONDED STEEL LEAD FRAME PERCENT 35 25 20 DEPRESSED EPOXY MOUNT PAD DIE ATTACH SPOT GOLD FRAME SOLDER COATED 15 Figure 4. Cross-sectlonal:vlew of a typical dual-In-lIne 5 plastic-encapsulated Integrated circult. 9 operating-life tests of devices from five manufac- VDD turers.9 IN *INTRINSIC DIODES Figure 5. Improved input protection network for new CD4000B Integrated circuits. Specific types of CMOS devices that have been evaluated include standard A-series,products in hermetically sealed ceramic packages,4'""80 B-series devices,"5""""'" beamlead contractors."""""""'""2 sealed-junction devices,9 CMOS/SOS devices,'339"2 and others. s~ CC Results of accelerated-life stress tests. A considerable amount of data has been generated during qualification and conformance testing of CD4000A series CMOS devices for MIL-M-38510, Class A. These data indicate excellent package integrity lone failure in a total of 729 devices tested to Group B qualification tests) and excellent stability4"9"45 (only one failure in a total of 1504 devices tested to Group C qualification tests). Conformance test data on more than 2.3 million device-hours of accelerated-life stress testing at 125 OC on a wide variety of circuits, from gates to MSI devices, show only five degradational failures and three inoperable failures, which corresponds to a functional failure rate at 125 IC of 0.14 percent per 1000 hours, at a 60-percent confidence level.9 Much of the available data on CMOS reliability has been generated by accelerated-operating-life stress tests. A typical figure for reliability of hermetically sealed CMOS devices (ceramic packages) is on the order of 0.1 percent per 1000 hours at a 60-percent confidence level) for devices operated at 1250C with VDD of 10 volts. This is based on more than 9 million device-hours of Table 2. Effect of activation energies on extrapolated failure rates. ACTIVATION ENERGY 0.3 eV 1.3 eV 10 FAILURE RATE (%/1000 hours) VERSUS TEMPERATURE 1250C 550C 250C 0.1 0.1 0.02 0.00004 0.005 0.0000005 Reliability effects of operating temperature. Since the thermal activation energy for failure of MOS devices by the more prevalent failure mechanisms, such as alkali ion migration in the thermally grown gate oxide in an electric field, -is relatively high, the overall thermal activation energy for failure of MOS ICs, including CMOS devices, tends to be high. Reported thermal activation energies for CMOS IC failure rates range from 0.3 eV to 1.3 eV; In some cases, a low acceleration factor is used to extrapolate results of accelerated tests, and it is pointed out that the actual acceleration factor is believed to be higher. Where experimental data is presented to support an activation energy, the value arrived at is frequently on the order of 1 eV. The implications of these various activation energies are apparent in Table 2, which shows the effect6 of extrapolating the extremes reported in activation energies, 0.3 eV and 1.3 eV. Both have been taken as 0.1 percent per 1000 hours at 125 IC. Reliability effects of operating voltage. A number of manufacturers have shown increases in failure rates of CMOS products as a result of increasing operating voltage under accelerated stress conditions in operating-life tests.""9,23'29"36'37"41 Possible effects of higher operating voltage, on MOS ICs include increased chip temperature, accelerated motion of alkali ions, increased susceptibility to surface-charge spreading and to field inversion, and' increased incidence of oxide breakdown. Oxide breakdown in MOS structures has been studied by a number of investigators, and has been considered by some to follow Peek's law in that the time to failure is inversely related to the fourth power of the applied voltage.23 The effect of operating voltage on relative failure rate of CD4000A series and CD4000B series devices is shown in Table 3. The higher reliability of B series devices at higher voltages is attributed to the ability to electrically test devices at higher voltages, and to operation at a smaller percentage of actual device breakdown voltage.3 Functional and DC parameter testing on CD4000B series parts is performed at RCA at 2.8 volts and at 22 volts, whereas CD4000A series devices are tested at 2.8 volts and at 17 volts. Failure rates of plastic-encapsulated CMOS ICs. Some data is available on comparative reliability of Table 3. Relative failure rates at 1250C at virious applied voltages. APPLIED VOLTAGE 5 CD4000 A SERIES 1 B SERIES - 10 3 1 15 10 3 20 - 6 CD4000 COMPUTER similar devices in hermetic versus plastic packages. In general, operating-life failure rates are reported to bq several times higher for devices in plastic as for those that are hermetically sealed. It is generally not possible, hoWever, to take the available data and make specific quantitative conclusions about the effect of plastic encapsulation on the reliability of a given type of MOS IC. One reason why this cannot be done, even though the same wafer processing is applied to both plastic-encapsulated and hermetically sealed devices, is that there are many differences in the assembly and test sequences other than the packaging. For example, devices intended for highreliability applications may be subjected to more stringent visual inspection criteria, may be assembled under very closely controlled conditions with considerable documentation, may be electrically tested under wide ranges of conditions (such as temperature ranges between -55 OC and 125 0C), and may be subjected to various screens, electrical tests, burn-ins, and lot-acceptance criteria. Obviously, such techniques, while more costly, are effective in eliminating a certain number of potentially less reliable (freak) devices from the main population. The failure rate of plastic-encapsulated MOS devices can be considered to be the sum of the specific failure rates of the total system, including failure mechanisms occurring on the chip, in the interconnection system external to the chip, and in the package. While unsuitable plastics can adversely affect the reliability of susceptible chips, plastic encapsulation cannot provide a chip reliability in excess of that which would be encountered in a dry, inert ambient. Accordingly, the reliability of many plastic-encapsulated devices, particularly under lower humidity conditions, is limited by the reliability of the encapsulated chip, rather than by any reliability limitations imposed by the plastic. A failure rate on the order of 0.1 percent per 1000 hours at 850C, at the 60 percent upper confidence level, can be expected for high-quality plasticencapsulated commercial-type MOS ICs prepared by a mature, well-controlled process.23 Figure 6 shows the failtre rate of plasticencapsulated CMOS devices as a function of ambient water-vapor pressure, and indicates the degree of improvement in packaging attained in recent years.5 Reliability effects of device complexity. A number of authors have dealt with the effect of chip complexity on failure rate. It is now generally agreed that increasing chip complexity increases the failure rate per packaged part, but reduces the failure rate per gate or per function accomplished. The overall failure rate may be considered as the sum of the failure rates due to wire bonds, to failures that would occur with a chip of any size, and to chip failures at localized defects, which is an areadependent factor.5'28 The failure rate due to wire bonds is simply the product of the failure rate per wire, such as 0.0001 percent per 1000 hours, times the number of wires. The failure rate of chips due to October 1978 20. / 0 , __1- a- I.) C.) 1 0.5__ 100 2 4 6 8 _ 1,000 2 AGE AT FAILURE-HOURS Figure 6. Weibull plot of results of 85°C185% relative humidity test on CMOS devices. localized defects increases with increasing chip area but is not linearly dependent on the area of the chip; it is considered to increase less rapidly than chip size, owing to the tendency of localized defects to cluster rather than to occur at random. (The considerations here are somewhat similar to those that have been shown to apply to the effect of chip size or circuit complexity on IC yield.)100°104 Complex ICs are thus more reliable per gate, and the use of complex ICs in electronic equipment to perform the same functions as a larger number of less complex devices will in general result in substantially im-proved equipment reliability. Field failure rates. Failure rates under field-use conditions are much lower than failure rates under accelerated stress conditions typically used by device manufacturers to evaluate reliability. The prediction of failure rates under field conditions requires the use of an acceleration factor to extrapolate high-temperature accelerated-stress reliability data. Frequently, the acceleration factors selected have been excessively conservative, with some based on very low activation energies that represent early bipolar IC reliability experience. In general, the Arrhenius equation continues to be considered appropriate for expressing the effect of temperature on failure rates. Recent data on the reliability of CMOS ICs in satellites105 includes a total of over 100 million device-hours of operation of CD4000A series devices at 25-125 OC with no failures, which corresponds to a failure rate of 0.0009 percent per 1000 hours at a 60 percent confidence level.104 Field failure rates for plastic-encapsulated CMOS ICs, at operating temperature up to 550C, can be considered to be on the order of 0.001-0.01 percent per 1000 hours at a 60 percent confidence level. Obviously, variations will occur depending upon type, design, process, 11 manufacturer, screens applied, voltage, and severity of the ambient conditions. Radiation hardening. Ionizing radiation is a specific type of environmental stress that can produce severe degradation in the electrical properties of silicon ICs. Early MOS devices were sensitive to ionizing radiation, with degradation occuring at a level as low as 103 rads. Recent studies have generated a considerable amount of information concerning the effect of the thermally grown oxide purity, growth conditions, and annealing conditions on susceptibility to radiation damage. As a result of these studies, it is now possible to modify the processing conditions to produce CMOS integrated circuits with considerably improved radiation hardness.4,9106-12 CMOS ICs guaranteed (by testing) to withstand 1 X 106 rads became commercially availablels in early 1978. Reliability effects of process technology trends A number of trends in CMOS fabrication technology affect IC reliability. Important recent trends include increased chip complexity (more functional devices per chip), 01-I5,20,801141-122 use of devices with smaller geometries,123-128 and increased use of automation and of better process-monitoring techniques.129'31 Wafer processing trends include use of improved materials.132'13 improved photolithography and etching techniques,134'135 increased use of ion implantation, 1.137 improved metallization, and more effective passivation layers.'38-140 Process moodifications have also been devised to substantially improve the radiation hardness of MOS oxides. Advances have also been made in encapsulation techniques, in plastic materials,141 and in testing of completed devices. Ion implantation provides a high-purity, veryclosely controlled source of dopant atoms. This, in turn, permits tighter distributions of the electrical characteristics of transistors. High chip complexity makes possible higher gate-to-pin ratios, decreasing the probability of failure due to wire bonds, packages, or external interconnections of various types, such as. soldered conffections in electronic equipment. Moreover, with chips of high complexity, the failure rate per logic gate tends to be lower than that of gates on chips of low complexity. These and other advantages, plus immunity to noise, have resulted in very wide use of CMOS ICs in electronic systems, with predictions of even wider use in the next several years.142-147 A number of authors have indicated that CMOS/SOS is particularly well suited to fabrication of VLSI circuits.10"4'4 The reliability of MOS IC chips is not at present limited by the inherent properties of silicon, silicon dioxide, aluminum, or thin-film polycrystalline silicon; further improvements being made in chip design and processing will continue to increase the reliability of MOS ICs in all types of packages. 12 The net result of MOS process changes made in recent years has been to lower costs of all types, to permit more complex circuits to be fabricated economically, and to produce products with substantially improved reliability, both in plastic and in hermetic packages. Reliability of CMOS vs. other MOS devices Data on comparisons of the reliability of CMOS ICs with that of other MOS technologies, such-as p-channel or n-channel MOS circuits, or with that of bipolar ICs such as TTL circuits, indicates that when circuits of equal complexity, prepared by mature, well-controlled processes are compared at the same operating temperature, there are no systematic differences among devices incorporating the major MOS technologies, between MOS devices with aluminum and polycrystalline silicon gates, or between MOS and bipolar ICs."99,23,30148149 The most reliable integrated circuits are those specifically designed for high reliability; fabricated by mature, well-controlled processes; and screened at all stages to remove freak devices that deviate from the main population and are susceptible to early failure. Even the most reliable devices available today are not limited in reliability by the properties of materials; further substantial improvements in CMOS device reliability are possible and are being made by improvements in CMOS circuit design, processing, packaging, and testing. Conclusion The reliability of CMOS ICs is equal to that of bipolar ICs of equal complexity, when each type is prepared by a well-controlled process and operated at the same temperature. The reliability of CMOS ICs in plastic depends on the design, process, circuit, manufacturer, degree of testing and screening, and on the application, as well as on packaging. Plastic packages are satisfactory for the majority of all MOS IC applications. No major differences in the reliability of products of equal functional complexity, made with the major MOS technologies (PMOS, CMOS, or NMOS), or of products made with aluminum or silicon gates, are evident in the available reliability data. Furthermore, the reliability of MOS devices can be considered to be equal to that of bipolar digital circuits of equal complexity when each type is prepared by a well-controlled process and operated at the same temperature. The potential failure mechanisms of CMOS devices are now well understood, and CMOS devices are being made by processes that minimize susceptibility of those devices to electrical degradation or catastrophic failure. Process changes made in recent years have lowered costs as well as substantially improved the reliability of CMOS ICs. M COMPUTER References 1. R. W. Ahrons and P. D. Gardner, "Interaction of Technology and Performance in Complementary Symmetry MOS Integrated Circuits," IEEE J. Solid-State Circuits, VoL SC-5, Feb. 1970, pp. 24-29. 2. T. G. Athanas, "Development of COS/MOS Technology," Solid-State Technology, Vol. 17, No. 6, June 1974, pp. 54-59. 3. G. B. Herzog, et al., "COS/MOS Product Design," RCA Engineer, Vol. 21, No. 4, Dec. 1975/Jan. 1976, pp. 35-59. 4. "High-Reliability Devices," SSD-230, RCA Solid State Division, Somerville, N.J., Aug. 1976. 5. L. J. Gallace, H. L. Pujol and G. L. Schnable, "CMOS Reliability," ST-6561, RCA Solid State Division, Somerville, N.J., Sept. 1976; also in Proc. 27th Electronic Components Conf, May 1977, pp. 496-512. 6. E. C. Douglas and A. G. F. Dingwall, "Ion Implantation for Threshold Control in COS/MOS Circuits," IEEE Trans. Electron Devices, Vol. ED-21, June 1974, pp. 324-331. 7. S. S. Eaton, "Sapphire Brings out the Best in C-MOS," Electronics, Vol. 48, No. 12, June 12, 1975, pp. 115-120. 8. R. S. Ronen and F. B. Micheletti, "Recent SOS Technology, Advances and Applications," Solid State Technology, Vol. 18, No. 8, Aug. 1975, pp. 39-46. 9. G. L. Schnable, E. M. Reiss, and M. Vincoff, "Reliability of Hermetically-Sealed CMOS Integrated Circuits," EASCON '76 Record, Sept. 1976, pp. 143A to 143-G. 10. J. Borel, "Advanced MOSFET Technologies: A Review," Solid State Circuits 1976 (ESSCIRC, Toulouse), Editions du Journal de Physique, Paris, 1977, pp. 69-87. 11. Y. Nishi, "Silicon on Sapphire Technology," ibid., pp. 89-116. 12. A. Capell, D. Knoblock, L. Mather, and L. Lopp, "Process Refinements Bring C-MOS on Sapphire into Commercial Use," Electronics, Vol. 50, No. 11, May 26, 1977, pp. 99-105. 13. R. A. Bishop, "L. S. I. CMOS Applications," Microelectron. and Reliab., Vol. 16, No. 4, Apr. 1977, pp. 461-475. 14. J. Hilibrand, "LSI Technology Choices," RCA Engineer, Vol. 23, No. 1, June/July 1977, pp. 14-19. 15. A. G. F. Dingwall and R. E. Stricker, "CIL: A New High-Speed High-Density Bulk CMOS Technology," IEEE J. Solid-State Circ., Vol. SC-12, Aug. 1977, pp. 344-348. 16. W. H. White, "Versatile Bulk CMOS," EASCON 77 Record, Sept. 1977, pp. 30-5A to 30-5D. 17. A. C. Ipri and J. C. Sarace, "Integrated Circuit Process and Design Rule Evaluation Techniques," RCA Rev., Vol. 38, Sept. 1977, pp. 323-350. 18. A. Aitken and P. Kung, "The Influence of Design and Process Parameters on the Reliability of CMOS Integrated Circuits," Microelectron. and Reliab., Vol. 17, Jan. 1978, pp. 201-210. 19. N. Snyderman, "Seniconductor Materials," Electronic News, Mar. 20, 1978, pp. 86-88. 20. M. Lassus and J.-P. Founaud, "Modern Physics Brings Semiconductor Technology to a Turning Point," Microelectron. and Reliab., Vol. 16, No. 4, 1977, pp. 367-387. 21. H. Khajezadeh and A. S. Rose, "Reliability Evaluation of Trimetal Integrated Circuits in Plastic Packages," 15th Ann. Proc. Reliab. Phys., 1977, pp. 244-249. October 1978 GOOD SIMULATION BEGINS WITH THE RIGHT TOOLS With the increased availability of SIMSCRIPT, developing a new model in FORTRAN makes as much sense as eating a meal with construction tools. The results are probably going to be unsatisfactory. Just as FORTRAN was designed to solve computational problems efficiently, SIMSCRIPT was designed to help the model-builder succeed at every stage of model development. SIMSCRIPT is a method of modelling, not just a language. Because SIMSCRIPT models clearly reflect the organization and logic of the system, the design, programming, checkout, evolutionary changes, maintenance and documentation are greatly simplified. The terminology and notation provide an effective vehicle for communication and understanding among all involved: programmer, analyst, and manager. Everyone comes out ahead. SIMSCRIPT II.5TM is available for the large-scale computers produced by CDC, Honeywell, IBM, Univac, and we are working on the PDP-11 version. Let us tell you about our world-view. Write or call Joe Annino, Manager of CACI's Systems Development Department, for Free Trial information, a copy of "A Quick Look at SIMSCRIPT II.5, and new course dates. C.A.C.I. 12011 San Vicente Boulevard Los Angeles, California 90049 (213) 476-6511 ©COPYRIGHT, CACI, INC.-FEDERAL 22. D. Blandford, "Industry Standard for B-Series CMOS," Microelectron. and Reliab., Vol. 16, No. 4, 1977, pp. 449-460. 23. G. L. Schnable, "Reliability of MOS Devices in Plastic Packages," Proc. of the Tech. Program Intern'l Microelectronics Conf, 1976, pp. 82-91. 24. W. Eccleston and M. Pepper, "Modes of Failure of MOS Devices," Microelectron. and Reliab., Vol. 10, No. 10, Oct. 1971, pp. 325-338. 25. G. L. Schnable and R. S. Keen, "On Failure Mechanisms in Large-Scale Integrated Circuits," in Advances in Electronics and Electron Physics, Vol. 30, L. Marton, Editor, Academic Press, New York, 1971, pp. 79-138. 26. G. L. Schnable, H. J. Ewald, and E. S. Schlegel, "MOS Integrated Circuit Reliability," IEEE Trans. Reliab., Vol. R-21, Feb. 1972, pp. 12-19. 27. E. D. Colbourne, G. P. Coverley, and S. K. Behera, "Reliability of MOS LSI Circuits," Proc. IEEE, Vol. 62, Feb. 1974, pp. 244-259. 28. D. J. Burns and V. C. Kapfer, "A Comparative Reliability Evaluation of C/MOS-A Maturing Technology," Proc. 1975 Ann. Reliab. and Maint. Symp., Jan. 1975, pp. 354-359. 29. J. Kinney, "Solid Statements from Solid State Scientific, Inc.," Reliability Bulletin No. 25, Solid State Scientific, Inc., Montgomeryville, Pa., Sept. 1975. 30. M. N. Vincoff and G. L. Schnable, "Reliability of Complementary MOS Integrated Circuits," IEEE Trans. Reliab., Vol. R-24, Oct. 1975, pp. 255-259. 31. L. Mattera, "Component Reliability, Part I: Failure Data Bears Watching," Electronics, Vol. 48, No. 20, Oct. 2, 1975, pp. 91-98; "Reliability Revisited: Failure-Rate Comparisons are Given a Second Look," Electronics, Vol. 48, No. 26, Dec. 25, 1975, pp. 83-85. 32. M. Stitch, G. M. Johnson, B. P. Kirk, and J. B. Brauer, "Microcircuit Accelerated Testing Using High Temperature Operating Tests," IEEE Trans. Reliab., Vol. R-24, Oct. 1975, pp. 238-250; "Addendum," IEEE Trans. Reliab., Vol. R-25, No. 2, Apr. 1976, p. 62. 33. J. S. Smith and D. D. Talada, "A CMOS/SOS Reliability Study," 14th Ann. Proc. Reliab. Phys., 1976, pp. 23-32. 34. T. J. Kobylarz and A. J. Graf, "Long Term Dormant Storage Testing, Initial Results," Proc. 1976 Ann. Reliab. and Maint. Symp., Jan. 1976, pp. 176-181. 35. R. P. Schuster and R. D. Fischer, "Analysis of Electronic Component Screening Programs and Their Cost Effectiveness," IEEE Trans. Mfg. TechnoL, Vol. MFT-5, June 1976, pp. 37-43. 36. "Reliability Report-1976 CMOS Life Stress Testing," Motorola Semiconductor Products, Inc., Austin, Tex., June 1976. 37. "Reliability Report-1976 CMOS Plastic IC Packaging System," Motorola Semiconductor Products, Inc., Austin, Tex. June 1976. 38. G. M. Johnson, "Accelerated Testing Highlights CMOS Failure Modes," EASCON '76 Record, Sept. 1976, pp. 142-A to 142-I. 39. G. Caswell and S. Cohen, "A Reliability Study of CMOS/SOS Technology," GOMAC '76 Proceedings, Nov. 1976, pp. 84-87. 40. S. Kumar, "Failure Mechanism in MOS Devices versus HC1 Gettering," Proc. Advanced Techniques in Failure Analysis Symp.-1976, Feb. 1976, pp. 104-109. 14 41. "Semiconductor Data Library/CMOS," Vol. 5, Series B, Motorola Semiconductor Products, Inc., Austin, Tex., 1976, pp. 3-2 to 3-3, 6-2 to 6-20. 42. W. E. Ham, M. S. Abrahams, J. Blanc, and C. J. Buiocchi, "The Study of Microcircuits by Transmission Electron Microscopy," RCA Rev., Vol. 38, Sept. 1977, pp. 351-389. 43. M. E. Levy, "An Investigation of Flaws in Complex CMOS Devices by a Scanning Photoexcitation Technique," 15th Ann. Proc. Reliab. Phys., 1977, pp. 44-53. 44. G. M. Johnson and M. Stitch, "Microcircuit Accelerated Testing Reveals Life Limiting Failure Modes,'" 15th Ann. Proc. Reliab. Phys., 1977, pp. 179-195. 45. B. Maximow, E. M. Reiss, and S. Kukunaris, "Accelerated Testing of Class A CMOS Integrated Circuits," 15th Ann. Proc. Reliab. Phys., 1977, pp. 212-216. 46. A. Shumka, E. L. Miller, and R. R. Piety, "Failure Modes and Analysis Techniques for CMOS Microcircuits," Proc. ATFA-77, Sept. 1977, pp. 75- 87. 47. J. M. Patterson, "Failures Due to Pinholes in Polysilicon Conductors on CMOS Memory Devices," Proc. ATFA-77, Sept. 1977, pp. 60-63. 48. M. J. Fox, "A Comparison of the Performance of Plastic and Ceramic Encapsulations Based on Evaluation of CMOS Integrated Circuits," Microelectron. and Reliab., Vol. 16, No. 3, 1977, pp. 251-254. 49. "Memory/LSI, 1977," Second Edition, MDR-7, Reliability Analysis Center, Rome Air Development Center, 1977. 50. T. T. Sheng and R. B. Marcus, "Gate Oxide Thinning at the Isolation Oxide Wall," J. Electrochem. Soc., Vol. 125, Mar. 1978, pp. 432-434. 51. R. J. Mattauch and W. M. Howle, Jr., "Field Strength Degradation in Si-SiO2-Polycrystalline Si Structures," IEEE J. of Solid-State Circ., Vol. SC-11, Oct. 1976, pp. 732-735. 52. M. R. Child, D. W. Ranasinghe, and D. White, "Applications of the Scanning Electron Microscope in the Development of Microtechnology," Proc. ATFA-77, Sept. 1977, pp. 323-344. 53. R. M. Anderson and D. R. Kerr, "Evidence for Surface Asperity Mechanism of Conductivity in Oxide Grown on Polycrystalline Silicon," J. Appl Phys., Vol. 48, Nov. 1977, pp. 4834-4836. 54. H. M. Naguib and L. H. Hobbs, "The Reduction of Poly-Si Dissolution and Contact Resistance at Al/nPoly-Si Interfaces in Integrated Circuits," J. Electrochem. Soc., Vol. 125, Jan. 1978, pp. 169-171. 55. R. Allan, "The Failure Tracers," IEEE Spectrum, Vol. 13, No. 10, Oct. 1976, pp. 33-39. 56. E. R. Hnatek, "Semiconductor Memory Attrition Summary," IEEE 1976 Semiconductor Test Symposium Digest, Oct. 1976, pp. 35-40. 57. C. R. Barrett and R. C. Smith, "Failure Modes and Reliability of Dynamic RAMs," System Design-A Discipline in Transition, COMPCON 77 Spring Digest, Feb. 1977, pp. 179-182. 58. J.C. McDonald and P. T. McCracken, "Testing for High Reliability," ibid., pp. 190-191. 59. E. R. Hnatek, "Microprocessor Device Reliability," Microprocessors, Vol. 1, June 1977, pp. 299-303. 60. D. S. Peck, "Current Status of Integrated-Circuit Reliability," Proc. Int. Conf. on Thin- and ThickFilm Technology, Augsburg, Germany, Sept. 1977, pp. 223-228. COMPUTER 61. C. H. Sie, R. A. Youngblood, J. H. Liao, and A. Turk, "Soft Failure Modes in MOS RAMs," 15th Ann. Proc. Reliab. Phys. 1977, pp. 27-32. 62. R. V. Pappu, E. Harris, and M. Yates, "Screening 63. 64. 65. 66. 67. 68. 69. Methods and Experience with MOS Memory," Microelectron. and Reliab., Vol. 17, Jan. 1978, pp. 193-199. B. Hall, "The Microprocessor Failure Rate Predictions," Microelectron. and Reliab., Vol. 17, No. 1, Jan. 1978, pp. 211-221. J. W. Peeples, "Influence of Electrical Bias Level on 85/85 Test Results of Plastic Encapsulated 4K RAMs," 16th Ann. Proc. Reliab. Phys., 1978. B. E. Deal, "The Current Understanding of Charges in the Thermally Oxidized Silicon Structure," J. Electrochem. Soc., Vol. 121, June 1974, pp. 198C-205C. R. Williams, "Properties of the Silicon-SiO2 Interface," J. Vac. Sci. Technol., Vol. 14, Sept./Oct. 1977, pp. 1106-1111. E. H. Nicollian, "Electrical Properties of the SiSiO2 Interface and its Influence on Device Performance and Stability," J. Vac. Sci. TechnoL, Vol. 14, Sept./Oct. 1977, pp. 1112-1121. P. Solomon, "Breakdown in Silicon Oxide-A Review," J. Vac. Sci. Technol., Vol. 14, Sept./Oct. 1977, pp. 1122-1130. B. R. Singh and P. Balk, "Oxidation of Silicon in the Presence of Chlorine and Chlorine Compounds," J. Electrochem. Soc., Vol. 125, Mar. 1978, pp. 453-461. 0 SofttWV; Texas Instruments has immediate openings for highly motivated, talented individuals in their Central Research Laboratories. In this highly visible and dynamic organization you will be a member of a team whose function is to evaluate emerging technologies, design and implement prototype systems, and develop stateof-the-art tools and procedures for software development, computer system design and new product development. If you are a computer professional with an MS or PhD and are looking for a challenging opportunity, we have positions for experienced individuals with records of achievement in: * Software engineering methodology* Software verification * Computer architecture * Machine intelligence * Natural language understanding * Computer-aided instruction * Speech research * Image understanding * Computer graphics * Seismic data processing If you qualify, send your resume in complete confidence to: Staffing Manager/P. 0. Box 225474, M.S. 217/Dallas, TX 75265. 70. W. S. DeForest, Photoresist, McGraw-Hill Book Co., New York, 1975. 71. E. I. Gordon and D. R. Herriott, "Pathways in Device Lithography," IEEE Trans. Electron. Devices, Vol. ED-22, July 1975, pp. 371-375. 72. K. A. Pickar, "Ion Implantation in Silicon-Physics, Processing and Microelectronic Devices," in Applied Solid State Science, Vol. 5, edited by R. Wolfe, Academic Press, New York, 1975, pp. 151-249. 73. E. Philofsky and E. L. Hall, "A Review of the Limitations of Aluminum Thin Films on Semiconductor Devices," IEEE Trans. on Pts. Hbr. Pkg., Vol. PHP-11, Dec. 1975, pp. 281-290. 74. A. J. Learn, "Evolution and Current Status of Aluminum Metallization," J. Electrochem. Soc., Vol. 123, June 1976, pp. 894-906. 75. P. B. Ghate, J. C. Blair, and C. R. Fuller, "Metallization in Microelectronics," Thin Solid Films, Vol. 45, Aug. 15, 1977, pp. 69-84. 76. G. L. Schnable, W. Kern, and R. B. Comizzoli, "Passivation Coatings on Silicon Devices," J. Electrochem. Soc., Vol. 122, Aug. 1975, pp. 1092-1103. 77. W. Kern and R. S. Rosler, "Advances in Deposition Processes for Passivation Films," J. Vac. Sci. TechnoL., Vol. 14, Sept./Oct. 1977, pp. 1082-1099. 78. J. M. Lock, et al., Proc. Symp. Plastic Encapsulated Semicond. Dev., (symposium held at the Royal Signals and Radar Establishment, Malvern, England, May 1976), pp. 1-13 /17. 79. C. H. Taylor, "Plastic Encapsulated Semiconductor Devices-A Bibliography," Microelectron. and Reliab., Vol. 16, No. 6, 1977, pp. 701-704. 80. J. Lyman, "Demands of LSI are Turning Chip Makers Towards Automation, Production Innovations," Electronics, Vol. 50, No. 15, July 21, 1977, pp. 81-92. TEXAS INSTRUM ENTS INCORPORATED An equal opportunity employer M/F Iq - 8L A. H. Agajanian, "Semiconducting Devices: A Bibliography of Fabrication Technology, Properties, and Applications," IFI/Plenum Data Co., New York, 1976. October 1978 15 82. R. C. Olberg and J. L. Bozarth, "Factors Contributing to the Corrosion of the Aluminum Metal on Semiconductor Devices Packaged in Plastics," Microelectron. and Reliab., Vol. 15, No. 6, 1976, pp. 601-611. 83. R. B. Comizzoli, "Aluminum Corrosion in the Presence of Phosphosilicate Glass and Moisture," RCA Rev., Vol. 37, Dec. 1976,- pp. 483-490. 84. B. Reich, "Bias Influence on Corrosion of Plastic Encapsulated Device Metal Systems," IEEE Trans. on Reliab., Vol. R-25, Dec. 1976, pp. 296-298. 85. E. P. G. T. van de Ven and H. Koelmans, "The Anodic Corrosion of Aluminum," J. Electrochem. Soc., Vol. 123, Jan. 1976, pp. 143-144. 86. W. M. Paulson and R. P. Lorigan, "The Effect of Impurities on the Corrosion of Aluminum Metallization," 14th Ann. Proc. Reliab. Phys., 1976, pp. 42-47. 87. F. Neighbour and B. R. White, "Factors Governing Aluminum Interconnection Corrosion in Plastic Encapsulated Microelectronic Devices," Microelectron. and Reliab., Vol. 16, No. 2, 1977, pp. 161-164. 88. A. Quach and W. L. Hunter, "A Study of Properties of Plastics Used for Semiconductor Encapsulation," J. Electronic Mtls., Vol. 6, May 1977, pp. 319-331. 89. N. L. Sbar and R. P. Kozakiewicz, "New Acceleration Factors for Temperature, Humidity, Bias Testing," 16th Ann. Proc. Reliab. Phys., 1978, pp. 161-178. 90. M. Lenzlinger, '-'Gate Protection of MIS Devices," IEEE Trans. Electron Devices, Vol. ED-18, Apr. 1971, pp. 249-257. 91. L. W. Linholm and R. F. Plachy, "Electrostatic Gate Protection Using an Arc Gap Device," 11th Ann. Proc. Reliab. Phys., 1973, pp. 198-202. 92. C. E. Jowett, Electrostatics in the Electronics Environment, Halstead Press, New York, 1976, pp. 55-70, 107-113, 117-128. 93. "RCA COS/MOS Integrated Circuits," SSD-250, RCA Solid State, Sommerville, N.J., July 1977. 94. F. S. Hickernell and J. J. Crawford, "Voltage Breakdown Characteristics of Close Spaced Aluminum Arc Gap Structures on Oxidized Silicon," 15th Ann. Proc. Reliab. Phys., 1977, pp. 128-131. 95. R. K. Pancholy, "Gate Protection for CMOS/SOS," 14th Ann. Proc. Reliab. Phys., 1977, pp. 132-137. 96. L. J. Gallace and H. L. Pujol, "The Evaluation of CMOS Static-Charge Protection Networks and Failure Mechanisms Associated with Overstress Conditions as Related to Device Life," 15th Ann. Proc. Reliab. Phys., 1977, pp. 149-157. 97. T. S. Speakman, "A Model for the Failure of Bipolar Silicon Integrated Circuits Subjected to Electrostatic Discharge," 12th Ann. Proc. Reliab. Phys., 1974, pp. 60-69. 98. A. C. Trigonis, "Electrostatic Discharge in Microcircuits," Proc. 1976 Annual Reliab. and Maint. Symp., Jan. 1976, pp. 162-169. 99. R. L. Minear and G. A. Dodson, "Effects of Electrostatic Discharge on Linear Bipolar Integrated Circuits," 15th Ann. Proc. Reliab. Phys., 1977, pp. 138-143. 100. E. I. Muehldorf, "Fault Clustering: Modeling and Observation on Experimental LSI Chips," IEEE J. Solid-State Cir., Vol. SC-10, Aug. 1975, pp. 237-244. 101. C. H. Stapper, "LSI Yield Modeling and Process Monitoring," IBM J. Res. Develop., Vol. 20, May 1976, pp. 228-234. 16 102. G. E. Moore, "The Cost Structure of the Semiconductor Industry and Its Implications for Consumer Electronics," IEEE Trans. Cons. Electr., Vol. CE-23, No. 1, pp. x-xvi, Feb. 1977. 103. 0. Paz and T. R. Lawson, Jr., "Modification of Poisson Statistics-Modeling Defects Introduced by Diffusion," IEEE J. Solid-State Circ., Vol. SC-12, Oct. 1977, pp. 540-546. 104. L. J. Gallace, H. L. Pujol, E. M. Reiss, G. L. Schnable, and M. N. Vincoff, "CMOS Reliability," RCA Engineer, Vol. 23, No. 2, Aug./Sept. 1977, pp. 61-69. 105. G. J. Brucker, R. S. Ohanian, and E. G. Stassinopoulos, "Successful Large-Scale Use of CMOS Devices on Spacecraft Traveling Through Intense Radiation Belts," IEEE Trans. on Aerosp. and Electron. Syst., Vol. AES-12, Jan. 1976, pp. 23-29. 106. W. R. Dawes, Jr., G. F. Derbenwick, and B. L. Gregory, "Process Technology for RadiationHardened CMOS Integrated Circuits," IEEE J. Solid-State Circ., Vol. SC-li, Aug. 1976, pp. 459-465. 107. E. M. Reiss, "Radiation-Hardened CMOS," 1976 Govt. Microcirc. Appl. Conf (GOMAC) Digest, Nov. 1976, pp. 154-157. 108. C. W. Gwyn, "Radiation Effects in the Insulator Region of MOS Devices," in Oxides and Oxide Films, Vol. 4, edited by J. W. Diggle and A. K. Vijh, Marcel Dekker, Inc., New York, 1976, pp. 99-168. 109. H. Borkan, "Radiation Hardening of CMOS Technologies-An Overview," IEEE Trans. Nucl. Sci., Vol. NS-24, Dec. 1977, pp. 2043-2046. 110. A. Pikor and E. M. Reiss, "Technological Advances in Manufacture of Radiation-Hardened CMOS Integrated Circuits," IEEE Trans. Nucl. Sci., Vol. NS-24, Dec. 1977, pp. 2047-2050. 111. T. J. Sanders, "CMOS Hardness Assurance Through Process Controls and Optimized Design Procedures," IEEE Trans. Nucl Sci., Vol. NS-24, Dec. 1977, pp. 2051-2055. 112. A. London, D. A. Matteucci, and R. C. Wang, "Establishment of a Radiation-Hardened CMOS Manufacturing Process," IEEE Trans. Nucl. Sci., Vol. NS-24, Dec. 1977, pp. 2056-2059. 113. B. LeBoss, "News Update," Electronics, Vol. 51, No. 4, Feb. 16, 1978, p. 8. 114. D. A. Hodges, "A Review and Projection of Semiconductor Components for Digital Storage," Proc. IEEE, Vol. 63, Aug. 1975, pp. 1136-1147. 115. J. Cunningham and J. Jaffe, "Insight into RAM Costs Aids Memory-System Design," Electronics, Vol 48, No. 25, Dec. 11, 1975, pp. 101-103. 116. J. Luecke, "Overview of Semiconductor Technology Trends," Computers... by the Millions, for the Millions, COMPCON 76 Fall Digest, Sept. 1976, pp. 52-55. 117. R. J. Koppel and I. Maltz, "Predicting the Real Costs of Semiconductor-Memory Systems," Electronics, Vol. 49, No. 24, Nov. 25, 1976, pp. 117-122. 118. L. Altman, "Five Technologies Squeezing More Performance from LSI Chips," Electronics, Vol. 50, No. 17, Aug. 18, 1977, pp. 91-112. 119. R. Falkenberg, "Future Semiconductor Memories-A System Designer's View," WESCON/77 Record, Sept. 1977, pp. 17/2-1 to 17/2-4. 120. A. G. F. Dingwall, R. E. Stricker, and J. 0. Sinniger, "A High Speed Bulk CMOS- C2L Microprocessor," IEEE J. Solid-State Circ., Vol. SC-12, Oct. 1977, pp. 457-462. 121. R. G. Stewart, "High-Density CMOS ROM Arrays," ibid., pp. 502-506. COMPUTER 122. G. Kasouf and S. Mercurio, "Evaluation of LSI/MSI Reliability Models," Proc. 1978 Ann. Rel. Maint. Symp., Jan. 1978, pp. 443-446. 123. R. W. Keyes, "Physical Limits in Digital Electronics," Proc. IEEE, Vol. 63, May 1975, pp. 740-767. 124. G. Meusburger and R. Sigusch, "Scaling of n-MOS Devices: Experimental Verification of an LSI Concept," Siemens Forsch. u. Entwickl Ber., Vol. 5, No. 6, 1976, pp. 332-337. 125. D. Widman and K.-U. Stein, "Semiconductor Technologies with Reduced Dimensions," Solid State Circuits 1976 (ESSCIRC, Toulouse), Editions du Journal de Physique, Paris, 1977, pp. 29-49. 126. G. R. Madland, "The Future of Silicon Technology," Solid State Technol., Vol. 20, No. 8, Aug. 1977, pp. 91-99. 127. K.-U. Stein, "Noise-Induced Error Rate as Limiting Factor for Energy per Operation in Digital IC's," IEEEJ. Solid-State Circ., Vol. SC-12, Oct. 1977, pp. 527-530. 128. W. Myers, "The Limits of Silicon," Computer, Vol. 11, No. 4, Apr. 1978, pp. 79-80. 129. P. Wang, "An IC Factory in the New Age-An Overview," in Semiconductor Silicon 1977, edited by H. R. Huff and E. Sirtl, The Electrochemical Society, Inc., Princeton, N.J., 1977, pp. 932-943. 130. P. Wang, "A LSI Factory of the New Age," Japan. J. AppL Phys., Vol. 17, Suppl. 17-1, 1978, pp. 3-7. 131. "Harris Wafer Fab: Automation Boosts Yields in 4-Inchers," Electronics, Vol. 51, No. 8, Apr. 13, 1978, pp. 80-81. 132. B. E. Deal, "New Developments in Materials and Processing Aspects of Silicon Device Technology," Japan. J. Appl. Phys., Vol. 16, Suppl. 16-1,1977, pp. 29-35. 133. Semiconductor Silicon 1977, edited by H. R. Huff and E. Sirtl, The Electrochemical Society, Princeton, N.J., 1977. 134. "Projection Printing and Product Mix will Transform Masking Needs by 1980," Electron. Pkg. and Prod., Vol. 16, No. 2, Feb. 1977, p. 11. 135. J. B. Houston, Jr., et al., "Developments in Semiconductor Microlithography II," Proc. of the Soc. of Photo-Optical Inst. Eng., Vol. 100, Apr. 1977, pp. 1-174. 136. J. L. Stone and J. C. Plunkett, "Recent Advances in Ion Implantation-A State of the Art Review," Solid State Technol., Vol. 19, No. 6, June 1976, pp. 35-44. 137. R. J. Duchynski, "Ion Implantation for Semiconductor Devices," Solid State Technol., Vol. 20, No. 11, Nov. 1977, pp. 53-58; Western Electric Eng., Vol. 21, No. 2, Apr. 1977, pp. 59-66. 138. R. Reichelderfer, et al., "Plasma Technology," Solid State Technol., Vol. 21, No.4, Apr. 1978, pp.87-121. 139. A. K. Sinha, H. J. Levinstein, T. E. Smith, G. Quintana, and S. E. Haszko, "Reactive Plasma Deposited Si-N Films for MOS-LSI Passivation," J. Electrochem, Soc., Vol. 125, Apr. 1978, pp. 601-608. 140. M. Shibagaki, Y. Horiike, and T. Yamazaki, "Low Temperature Silicon Nitride Deposition Using Microwave-Excited Active Nitrogen," Japan. J. AppL Phys., Vol. 17, Suppl. 17-1, 1978, pp. 215-221. 141. Proc. ERADCOM Symp. on Plastic Encapsulated/Polymer Sealed Semiconductors for Army Equipment, Symposium held at Fort Monmouth, N.J., May 1978. 142. B. LeBoss, "C-MOS Gets a Rise Out of LSI," Electronics, Vol. 50, No. 21, Oct. 13, 1977, pp. 65-66. October 1978 143. "Worldwide Equipment Sales to Top $100 Billion," Electronics, Vol. 51, No. 1, Jan. 5, 1978, pp. 125-148. 144. M. Gold and D. Hanson, "C/MOS MPU Applications Spur RCA Deal with Intel," Electronic News, Vol. 23, No. 1179, Apr. 10, 1978, pp. 22, 26. 145. "RCA to Make Intel Parts Using SOS," Electronics, Vol. 51, No. 8, Apr. 13, 1978, pp. 41-42. 146. W. F. Arnold, "SOS Pact has 'em Guessing," Electronics, Vol. 51, No. 9, Apr. 27, 1978, pp. 94-95. 147. Y. Nishi and H. Hara, "Physics and Device Technology of Silicon on Sapphire," Japan. J. Appl Phys., Vol. 17, Suppl. 17-1, 1978, pp. 27-35. 148. L. C. Hamiter, Jr., "How Reliable are MOS IC's? As Good as Bipolars, Says NASA," Electronics, Vol. 42, No. 13, June 23, 1969, pp. 106-110. 149. D. A. Hodges, "Components for Semiconductor Memories," 1973 IEEE INTERCON Technical Papers, Solid State, Mar. 1973, pp. 2/1-1 to 2/1-2. George L. Schnable is head of solid state process research in RCA Laboratories' Integrated Circuit Technology Center. He has been involved in electronic materials and process technology R&D for 25 years, both at RCA and at Philco-Ford. He is the author or coauthor of more than 50 publications and holds 20 US patents. He is a member of a number of societies, including the American Chemical Society and the IEEE. He received a BS degree in chemistry from Albright College and holds MS and PhD degrees from the University of Pennsylvania. Larry J. Gallace is manager of the Reliability Engineering Laboratory in RCA's Solid State Division in New Jersey. He joined RCA in 1958 and has t: f g'l0worked predominantly in the area of -0 \% !wreliability ft a engineering. Since 1972, he has been heavily involved in developing test methods for characterizing * £g;g l the reliability of CMOS devices. He has been a recipient of RCA team awards for silicon power transistor engineering. He holds a BS degree in mathematics and an MS degree in applied and mathematical statistics, both from Rutgers University. Henry L. Pujol is manager of engineering, assembly, and test at RCA's Solid State Division in West Palm Beach, Florida. He joined RCA in 1969 and has been responsible for the design of many standard CD4000 series circuits. He has been responsible for worldwide market planning of CMOS standard parts and for the application engineering of MOS logic products, including custom-circuit support, product specifications, and test specifications. He holds a BSEE from City College of New York and an MSEE from Rutgers University. 17