873444

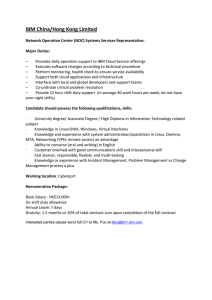

advertisement