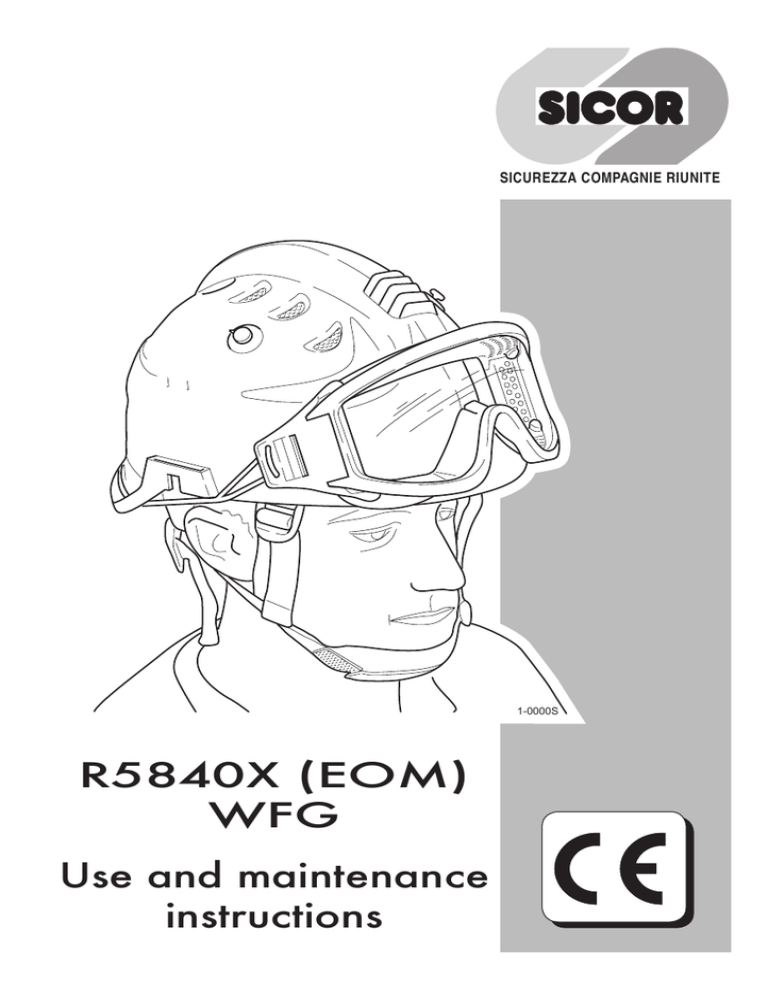

R5840X (EOM) WFG Use and maintenance instructions - Sicor

advertisement

SICUREZZA COMPAGNIE RIUNITE 1-0000S R5840X (EOM) WFG Use and maintenance instructions SICUREZZA COMPAGNIE RIUNITE Copyright by SICOR S.p.A. Via C. Pisacane 23/A - 20016 Pero (MI) Italy Printed in Italy Printed 05/10 - 2^ Edition 07/2012 0.2 EOM - WFG EOM - WFG SICUREZZA COMPAGNIE RIUNITE SICUREZZA COMPAGNIE RIUNITE These are the instructions for use of the R5840X hardhat, hereinafter called EOM, and the WFG goggles. These instructions were very carefully drawn up in accordance with UNI 10913:2001. Nonetheless, the editor cannot be held responsible for any errors and/or the possible consequences. We would welcome any suggestions regarding the product or the manual and will implement them if they would be a real improvement. SICOR S.p.A. reserves the right to make any modifications without prior notice to the product and its accessories as well as their technical features. Sincerely SICOR S.p.A. 0.3 SICUREZZA COMPAGNIE RIUNITE 0.4 EOM - WFG EOM - WFG SICUREZZA COMPAGNIE RIUNITE CHAPTER INDEX INTRODUCTION CHAPTER 1 General regulations 1 CHAPTER 2 Use and adjustments 2 CHAPTER 3 Maintenance 3 CHAPTER 4 Accessories 4 CHAPTER 5 Technical data 5 CHAPTER 6 Warranty 6 CHAPTER 7 Declaration of conformity 7 0.5 SICUREZZA COMPAGNIE RIUNITE 0.6 EOM - WFG EOM - WFG General regulations SICUREZZA COMPAGNIE RIUNITE Chapter 1 GENERAL REGULATIONS CONTENTS 1.1 - INTRODUCTION.........................................................................1.2 1.1.a - How to consult the manual................................................1.2 1.1.b - Component identification...................................................1.3 1.1.c - Reference standards.........................................................1.4 1.1.d - Spare parts and accessories.............................................1.4 1.1.e - Storage..............................................................................1.4 1.1 EOM - WFG General regulations SICUREZZA COMPAGNIE RIUNITE 1.1 - INTRODUCTION - This manual must be carefully read by the persons that will be wearing the hardhat and the goggles and those that will be carrying out the maintenance operations. - The hardhat and the goggles guarantee the performance for which they were designed only if they are properly used and maintained according to the instructions in this manual. Otherwise the protective features cannot be guaranteed. - The warranties on these products shall become invalid if the warnings, precautions and instructions contained in this manual are not followed. - Should you have any doubts about the conditions of use or the maintenance procedures after reading this manual, please do not hesitate to contact: SICOR S.p.A. Via C. Pisacane n. 23/a 20016 PERO (MI) Tel. +39 02 3539041 Fax. +39 02 3539060 e-mail info@sicor-sureco.it internet:http://www.sicor-sureco.it 1.1.a - How to consult the manual - This manual must be kept for the entire lifetime of the PPD used - This manual is divided into chapters covering different topics. An index is given at the beginning of each chapter for easier consultation. The chapter number is shown at the bottom left or right of each page and at the top of the page the topic dealt with in the chapter. - The following symbols are used in this manual to point out safety messages: RISK TO PERSONS Partial or total inobservance of the rules pointed out with this symbol may cause serious risks to the health of the user of the hardhat and the goggles. IMPORTANT INFORMATION This symbol indicates important communications for proper use or maintenance of the hardhat and the goggles. 1.2 EOM - WFG General regulations SICUREZZA COMPAGNIE RIUNITE 1.1.b - Component identification 1= Cap exterior 1.a = Ventilation system 1.b = Adapters 2= Protective goggles (optional) 2.a = Cord 3= PU cap interior 4= Anti-shock straps 5= Harness: 5.a = Front fasteners 5.b = Band 5.c = Suspension mesh 5.d = Size adjustment system 5.e = Rear fastener 5.f = Rear adjusters 6 = Retention system 6.a = Chin-strap 6.b = Anti-creep system 6.c = Anti-creep adjuster 6.d = Rectangular ring 6.e = Quick-release buckle 6.f = Anti-stretch strap 7= Nape guard (optional) 8= Comfort piece 8.a = Front comfort piece 8.b = Rear comfort piece 2a 1a 1b 6f 6b 2 6f 1 6d 3 6c 6a 6e 4 5c 7 5b 5a 5e 8a 8b 5f 5d 1-0064S 1.3 EOM - WFG SICUREZZA COMPAGNIE RIUNITE General regulations 1.1.c - Reference standards Hardhat: EN 397: 2001 EN 443: 1997 Points 5.6 - 5.7 - 5.8.1 - 5.8.3 EN 12492: 2003 1.1.d - Spare parts and accessories IMPORTANT Only original spare parts and accessories authorised and certified by the manufacturer must be used and fitted Using non-original spare parts and unauthorised accessories will invalidate the warranty conditions and relieve SICOR S.p.A. of all responsibility. WARNING - Never apply decals and/or identification labels less than 25 mm from the edges of the cap; do not use paints, petrol or solvents to clean the hardhat. Inobservance of these rules may reduce the levels of protection and/or the dielectric properties. - Do not modify or remove any of the constituent components of the hardhat. 1.1.e - Storage IMPORTANT • The hardhat must be stored in a clean, dry, dark place away from sources of heat and at a temperature between +10°C (50°F) and +40°C (104°F). • The hardhat and its accessories must be stored in the bag provided. • Never leave the hardhat in a vehicle if not in its bag to prevent needless exposure to the sun (UV rays). 1.4 EOM - WFG Use and adjustments SICUREZZA COMPAGNIE RIUNITE Chapter 2 USE AND ADJUSTMENTS CONTENTS 2.1 - INTRODUCTION.........................................................................2.2 2.2 - HEIGHT ADJUSTMENT.............................................................2.2 2.3 - CIRCUMFERENCE ADJUSTMENT...........................................2.3 2.4 - RETENTION SYSTEM ADJUSTMENT......................................2.4 2.4.a - First use.............................................................................2.4 2.4.b - Regular use.......................................................................2.4 2.5 - HARDHAT USE..........................................................................2.5 2.5.a - Ventilation system use.......................................................2.5 2.1 EOM - WFG SICUREZZA COMPAGNIE RIUNITE Use and adjustments 2.1 - INTRODUCTION - - - - Any improper use not in compliance with the reference standards shall make the user solely responsible for any personal harm and invalidate the warranty conditions. In order to provide adequate protection, this hardhat must be adjusted to the head size of the user. The hardhat has been designed to absorb the energy of an impact by destroying or partially damaging the cap and the harness; even if this damage may not immediately be visible, any hardhat that has been subjected to strong impact must be replaced. For your own safety it is advisable to familiarise yourself with the adjustment systems before using the hardhat. Make several adjustments and fasten and unfasten the retention system several times so that these actions become instinctive. 2.2 - HEIGHT ADJUSTMENT Adjust the hardhat in height by changing the depth of the suspension mesh as follows: Release the rear tabs of the mesh fastened with Velcro and slide them in the slots on the harness. 1-0004S 2.2 EOM - WFG Use and adjustments SICUREZZA COMPAGNIE RIUNITE 2.3 - CIRCUMFERENCE ADJUSTMENT IMPORTANT The hardhat is supplied with the size adjustment band fully extended. For proper adjustment follow the sequence described below. - Put on the hardhat and then adjust the size using the wheel (1). - For optimal adjustment it is advisable to push down on the hardhat with one hand and then make the adjustment with the other hand. - The size adjustment system also acts on the anti-creep system. - Pull the two straps (2) that join the chinstrap to the adjustment system only during the first adjustment. 1-0003S 2 1-0002S 2.3 EOM - WFG Use and adjustments SICUREZZA COMPAGNIE RIUNITE 2.4 - RETENTION SYSTEM ADJUSTMENT 2.4.a - First use Chin-strap: - Adjust in height as described in Chapter 2.2. - Put on the hardhat. - Adjust the size (as described in Chapter 2.3) - Fasten the buckle. - Slide the adjustment strap (1) in the adjustment crosspiece of the system (2). - Again pull the strap (1) so that the system adjusts correctly. - Should you be unable to achieve the correct adjustment, act on the adjusters (point 3) positioned on either side of the chin-strap and lengthen or shorten the strap as shown in the image. 1-0007S 2.4.b - Regular use Chin-strap: - Fasten the chin-strap with the buckle. Size and anti-creep adjustment: - Adjust as described in Chapter 2.3. 1-0008S 3 3 1-0006S 2.4 1 1-0062S EOM - WFG Use and adjustments SICUREZZA COMPAGNIE RIUNITE 2.5 - HARDHAT USE 2.5.a - Ventilation system use The hardhat ventilation system can be adjusted to prevent rainwater and fire-extinguishing water from penetrating. Operate the sliding lever on the top of the hardhat with one hand. Position 1 = Closed Position 2 = Open 2 1 1-0009S WARNING Despite the steel spark protection mesh, we advise you to completely close the ventilation system during fires, near fires or when there is a strong wind. 2.5 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE Chapter 3 MAINTENANCE CONTENTS 3.1 - HARDHAT DISASSEMBLY .......................................................3.2 3.2 - HARDHAT ASSEMBLY .............................................................3.7 3.3 - HARDHAT CLEANING AND CARE......................................... 3.11 3.4 - INSPECTION PROCEDURE.................................................... 3.11 3.5 - GOGGLES CLEANING............................................................3.12 3.6 - HARDHAT LIFE........................................................................3.12 3.7 - GOGGLES LIFE.......................................................................3.12 3.8 - DISPOSAL................................................................................3.12 3.1 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE 3.1 - HARDHAT DISASSEMBLY WARNING It is recommended to read through each single paragraph before proceeding with the disassembly operations. To proceed with disassembly, place the hardhat upside down on an uncluttered surface in order not to lose any components. During the disassembly procedures, position all the parts removed in an orderly way. - Pull the strap (1) out of the adjusters (2) and out of the anti-creep system. 1-0010S - Release the rear part (3) of the protective mesh (4). 3 4 1-0011S 3.2 1-0012S EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Release the two tabs (5) of the harness (6). 6 5 5 1-0013S 5 1-0014S - Release the rear of the harness (6) by pulling upwards so that the clips are released from the cap. 6 1-0015S 3.3 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Release the front part (7) of the harness (6) and pull it upwards so that the clips are released from the cap, then remove the harness (6) from the hardhat. 7 6 1-0016S 1-0017S - Remove the polyurethane cap interior (8). - Release the retention system by pushing the fasteners (9) downward and remove the harness with the retention system. 8 9 1-0018S 3.4 1-0019S EOM - WFG Maintenance - Unfasten the clips (10) from the harness (turn and remove). SICUREZZA COMPAGNIE RIUNITE 10 1-0020S - Remove the mesh (4) releasing it from the respective fastening pins. 4 1-0021S 3.5 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Release and remove the rear comfort piece (11) by unfastening the Velcro tabs. - Remove the front fasteners (12). - Remove the front comfort piece by unfastening the Velcro tabs (13). 11 1-0022S 12 13 1-0023S 3.6 1-0024S EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE 3.2 - HARDHAT ASSEMBLY - Refit the fasteners (1) of the retention system from the bottom to the top. - Fit the polyurethane cap interior (2). 2 1 1-0061S 1-0025S 3 - Fit the clips (3) of the anti-shock straps (4) making sure that the strap passes between the clips and the external shell and refasten the clips (5). 3 4 1-0027S 5 1 3 3 1 1-0028S 1-0029S 3.7 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Fit the front comfort piece (6) on the retention system. - Refit the front fasteners (7) on the harness. 7 6 1-0024S 1-0023S - Refit the mesh (8) on the harness. - Refit the rear comfort piece (9) using the Velcro tabs. 9 1-0021S 1-0022S 3.8 8 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Refit the harness complete with mesh and comfort piece on the hardhat and fasten the rear and front fasteners. 1-0031S 1-0032S 11 - Fit the retention system inserting the front straps (10) in the adjusters (11) and the rear straps (12) in the anti-creep system (13). 10 13 12 1-0033S 3.9 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE - Fit the anti-stretch strap (14) of the retention system using the anti-creep adjuster (15). The anti-stretch strap (14) stays positioned underneath the protective mesh (16). 15 14 14 16 1-0063S 3.10 EOM - WFG Maintenance SICUREZZA COMPAGNIE RIUNITE 3.3 - HARDHAT CLEANING AND CARE After each use, put the hardhat in its bag or in a closed place (e.g. locker) away from light and humidity. Clean the hardhat as follows: - - - - - - - Never clean the hardhat in the sun. Disassemble the hardhat as described in Chapter 3.1 Clean all the parts inside and out using only neutral soap and lukewarm water. Leave to dry at room temperature. DO NOT USE DRYERS. Before reassembling the hardhat, check that all the parts are completely dry. Never use abrasive or strong alkaline detergents. When the hardhat is completely dry, reassemble it as described in Chapter 3.2 IMPORTANT Never use solvents or organic liquids such as petrol or alcohol! 3.4 - INSPECTION PROCEDURE Inspect the hardhat before and after each use, paying particular attention to all the fastening points (harness and retention system). Immediately replace any worn and/or damaged parts, exclusively using spare parts supplied by Sicor S.p.A., since only the original spare parts are homologated and guarantee conformity of the hardhat. - Check that there are no colour changes and/or cracks on the cap and harness. - Check that there are no cuts and/or breakage at the edges and the holes - Check that the suspension system is intact by checking the seams. 3.11 EOM - WFG SICUREZZA COMPAGNIE RIUNITE Maintenance 3.5 - GOGGLES CLEANING Clean the goggles as follows: - - - - - Never clean the hardhat in the sun. Remove the goggles as described in Chapter 4.1. Use a normal detergent for glasses. Dry with a soft smooth cloth preferably in microfiber.. Never use abrasive or strong alkaline detergents. IMPORTANT Never use solvents or organic liquids such as petrol or alcohol! 3.6 - HARDHAT LIFE If properly stored, the EOM hardhat has a lifetime of about 8 years. Depending on the conditions of use, the lifetime may vary considerably. IMPORTANT The hardhat must be replaced after every significant event. 3.7 - GOGGLES LIFE If properly stored, the WFG goggles have a lifetime of about 8 years. Depending on the conditions of use, the lifetime may vary considerably. Replace the goggles or the filters if there is evident surface damage, such as scratches, cuts or marks. IMPORTANT The hardhat must be replaced after every significant event. 3.8 - DISPOSAL Strictly comply with the disposal regulations in force. 3.12 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE Chapter 4 ACCESSORIES CONTENTS 4.1 - GOGGLES..................................................................................4.2 4.2 - LAMP..........................................................................................4.4 4.3 - SAFETY EARMUFFS.................................................................4.6 4.4 - MESH FACE SCREEN / TRANSPARENT FACE SCREEN.......4.7 4.5 - NAPE GUARD............................................................................4.8 4.5.a - Fitting / Removal...............................................................4.8 4.5.b - Use..................................................................................4.10 4.1 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE WARNING Only accessories and PPDs authorised and certified by the manufacturer must be used and fitted. Using unauthorised accessories: 1 Makes the hardhat not conform to the current regulations. 2 Leads to forfeiture of the warranty. 3 Makes the user responsible for any accidents. 4.1 - GOGGLES - Insert one of the ends of the silicone cord into the hole (1) and make a single knot (detail A). - Run the cord through the cavity (2) and insert it in the holes on the goggle supports (3). Check that the goggles are correctly positioned. 3 5 4 2 1 1-0034S - Run the cord through the cavity (2) to the outside of the cap and insert it in the cavity (4). - Run the cord through the holes in the goggle supports (3) and then through the cavity (4). - Finally, run the cord through the hole (5) and securely fasten it by making a single knot (detail A). 4.2 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE - Once secured with the cord, the goggles can be used. If you do not want to use the goggles, push them up onto the hardhat. You can adjust the goggle pressure on the face by adjusting the cord length. 1-0035S 1-0037S 1-0036S 4.3 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE 4.2 - LAMP 1 - The lamp holder is fitted on the left or right of the external shell on the dedicated adapters. - To use the lamp, fit the holder (1) in the appropriate slide (2). 2 1-0173S - Once fitted, slide the holder (1) along the slide to stabilise its position. 1 1-0174S 4.4 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE - Fit the lamp (3) in the holder (1). 1 3 1-0175S The lamp can be used in four positions: facing down (A) or facing up (B). A B 1-0176S 1-0177S 4.5 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE 4.3 - SAFETY EARMUFFS 2 - To fasten the safety earmuffs, fit the fastening supports (2) on the connectors (1) provided on the external shell. 1 1-0054S - Pull the earmuffs down over the ears to use them or push them up if you do not want to use them. - To push the earmuffs up onto the cap, first pull them off your ears until you hear a click and then turn them upward and lock them into place by pressing on the earmuffs. 1-0049S 4.6 1-0050S 1-0051S EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE - To remove the earmuffs, press on the locking point (3) of the fastening support (2). 3 4.4 - MESH FACE SCREEN/TRANSPARENT FACE SCREEN IMPORTANT To fit these accessories, you must have fitted the safety earmuffs or the relative supports. The face screen is fitted on the external shell by clipping it onto the fastening clips (1) in the fastening supports (2). Once fastened, the face screen (3) can be adjusted to two positions: up (A) or down (B). 2 1-0055S 2 1 To remove the face screen, unclip it from the fastening clips (1) by pulling outwards. IMPORTANT This accessory is not compatible with the goggles. B 1-0044S A 3 3 1-0045S 1-0046S 4.7 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE 4.5 - NAPE GUARD 4.5.a - Fitting/removal - Release the two tabs (1) of the harness (2). 1 1 1-0013S - Release the rear of the harness (2) by pulling upwards so that the clips are released from the cap. 1 1-0014S 2 1-0015S 4.8 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE - Insert the two central straps (3) in the tabs of the two released clips (4) and refit them in their seats. 3 4 1-0056S 1-0057S - Refit the rear harness (2) 5 - Fit the two side straps (5) on the harness band. 4 - For removal work in reverse order. 5 4 3 1-0058S 4.9 EOM - WFG Accessories SICUREZZA COMPAGNIE RIUNITE 4.5.b - Use The nape guard can be used in two different ways: 1) Nape and shoulder protection Position the nape guard (6) behind the nape and on the shoulders with the side pieces folded back. 2) Nape, shoulder and neck protection. Position the nape guard (6) behind the nape and on the shoulders with the side pieces (7) tied around the neck. 6 1-0059S 6 7 4.10 1-0060S EOM - WFG Technical data SICUREZZA COMPAGNIE RIUNITE Chapter 5 TECHNICAL DATA CONTENTS 5.1 - DIMENSIONS AND WEIGHTS...................................................5.2 5.2 -MARKINGS................................................................................5.2 5.1.a - Hardhat..............................................................................5.2 5.1.b - Goggles.............................................................................5.3 5.1 EOM - WFG Technical data SICUREZZA COMPAGNIE RIUNITE 5.1 - DIMENSIONS AND WEIGHTS Hardhat weight...........................................................................................................806 g Goggles weight...........................................................................................................116 g Width......................................................................................................................240 mm Height.....................................................................................................................295 mm Length....................................................................................................................193 mm 5.2 - MARKINGS 5.2.a - Hardhat Reference standards: UNI EN 397:2001 “Protective hardhats for the industry” UNI EN 443:1999 “Hardhats for firefighters” points 5.6 “Flame resistance” and 5.7 “Radiating heat resistance” UNI EN 12492:2003 “Hardhats for mountaineers” 3 4 1) 2) 3) 4) 5) Manufacturer Reference laboratory CE marking Reference standards Sizes 5.2 EN 397:01 - EN 12492:02 EN 443:97 (p.ts 5.6 - 5.7) 2 CE 0497 1 5 10 SICOR SICUREZZA COMPAGNIE RIUNITE Größen - Taglie Size - Tamanhos Tamaños - Tailles 52~64 cm -30°C LD 9 xxxxxxxxxxxxxxxx 8 YYYYYY Bergsteigerhelme - Casco per Alpinisti Helmet for mountaineer Casque d’Alpinistes Capacetes para alpinistas Cascos para montañeros Helm für Waldbrand - Casco per AIB Helmet for forest fire Casque pour les incendies de forêt Capacete para incêndio florestal Casco de incendios forestales MADE IN ITALY 7 DD-MM-YY 6 6) Optional requirements 7) Country and date of manufacture 8) Product description 9) Product name 10) Product identification EOM - WFG Technical data SICUREZZA COMPAGNIE RIUNITE 5.2.b - Goggles Reference standards: EN166:2004 “Personal eye protection - Specifications” EN167:2004 “Personal eye protection – Optical test methods” EN168:2004 “Personal eye protection – Non-optical test methods” GLASSES 2-1.2 SICOR 1 B 3 K N CE 0497 Scale number SICOR S.p.A. identification Optical class Resistance to high velocity particles – average impact energy Resistance to molten metal and hot solid metal projections Resistance to fine dust particle damage Resistance to misting CE marking Notified Body identification (Art.13 89/686/EEC amendment 93/68/EEC) FRAME SICOR B 9 K CE 0497 SICOR S.p.A. identification Resistance to high velocity particles – average impact energy Resistance to molten metal and hot solid metal projections Resistance to fine dust particle damage CE marking Notified Body identification (Art.13 89/686/EEC amendment 93/68/EEC) 5.3 EOM - WFG Technical data SICUREZZA COMPAGNIE RIUNITE SPARE PART REFERENCES AND CODING Ref. Fig. 1 1 2 1 1 1 1 1.a 1.b 3 4 6 5.c 5.d - 5.b 8.a 8.b - 2 2.a - - - - - - - - - - Description Cap with ventilation system and adapters - Red Cap with ventilation system and adapters - White Cap with ventilation system and adapters - Yellow Cap with ventilation system and adapters - Blue Cap with ventilation system and adapters - Black Cap with ventilation system and adapters - Luminescent Complete ventilation system Adapters PU internal shell Anti-shock straps + clips Retention system Suspension mesh Size adjustment system Rear adjuster Front band Front comfort piece Rear comfort piece IT information note Two-lens safety goggles Silicone fastening device Reflecting bands - Red Reflecting bands - White Reflecting bands - Grey Lamp holder Earmuff adapter cones Mesh face shield with adapters Polycarbonate face shield with adapters Polycarbonate face shield (resistant to electric arcs) with adapters Nape guard in fireproof fabric Hardhat bag = The highlighted parts are optional 5.4 Code R58407 R58408 R58409 R58410 R58411 R58412 R58413 R58414 R58415 R58416 R58417 R58418 R58419 R58420 R58421 R58422 R58423 549310000 R58424 R58425 R58426 R58427 R58428 R58429 R58430 R58431 R58432 R58433 R58434 5223200000 EOM - WFG Warranty SICUREZZA COMPAGNIE RIUNITE Chapter 6 WARRANTY CONTENTS 6.1 - WARRANTY................................................................................6.2 6.1 EOM - WFG SICUREZZA COMPAGNIE RIUNITE Warranty 6.1 - WARRANTY The product is guaranteed according to the legislation in force on the date of purchase. 6.2 EOM - WFG Declaration of conformity SICUREZZA COMPAGNIE RIUNITE Chapter 7 DECLARATION OF CONFORMITY CONTENTS 7.1 - DECLARATION OF CONFORMITY...........................................7.2 7.1 EOM - WFG Declaration of conformity SICUREZZA COMPAGNIE RIUNITE 7.1 - DECLARATION OF CONFORMITY The manufacturer: Sicor S.p.A. Via Pisacane 23/a 20016 Pero (MI) declares that the PPD described below: HARDHAT FOR FOREST FIRE-FIGHTERS AND MOUNTAINEERS (R5840X) is in conformity with the provisions set out in Directive 89/686/EEC and with the national regulations that implement the harmonised standards EN397:2001 and EN 443:1997 (points 5.6 - 5.7) and EN12492:2003. It is identical to the PPD as certified in the CE certificate issued by: CSI S.p.A. Viale Lombardia 20 - 20021 Bollate (MI) owner of the identification number 0497 dated 21-01-2008. In witness whereof SICOR S.p.A. ❉❉❉ The manufacturer: Sicor S.p.A. Via Pisacane 23/a 20016 Pero (MI) declares that the PPD described below: PROTECTIVE GOGGLES (WFG) is in conformity with the provisions set out in Directive 89/686/EEC and with the UNI EN 166:2004 standards. It is identical to the PPD according to the test reports nos. 0036/ME/DPI/07A and 0036/ ME/DPI/072 issued by: CSI S.p.A. Viale Lombardia 20 - 20021 Bollate (MI) owner of the identification number 0497. In witness whereof SICOR S.p.A. 7.2