Electronic V-belt monitoring device EKW 2.3.x.x / EKW 2.3.x.xA

advertisement

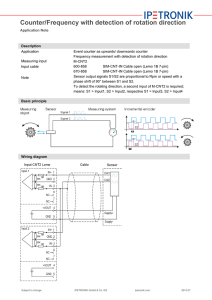

Electronic V-belt monitoring device EKW 2.3.x.x / EKW 2.3.x.xA Areas of application These devices are used in ventilation and air conditioning systems for the reliable monitoring of V-belts. DDC control technology and intelligent control systems have meanwhile become standard. Therefore, the demand for more opera­ tionally reliable and modern belt monitoring has become more urgent. Especially with speed-controlled fans, there is no better monitoring for V-belts. Principle of operation Technical data Housing: Mounting rail attachment: Terminals: Ambient temperature: Dimensions: Protection class: Ambient humidity: High impact polystyrene for TS 32 and TS 35 pluggable to the base plate 0 °C to + 40 °C 96 x 48 x 60 mm (L x W x D) IP 40 Class F according to DIN 40040 for components Working range: 100 – 9.000 rpm Setting range: 100 – 6.000 rpm Operating principle: lower deviation Voltage: EKW 2.3.1 230 V 10 %, 50 – 60 Hz EKW 2.3.2 24 V 10 %, 50 – 60 Hz Current consumption: 50 mA, including sensor External fuse protection: max. 1 A Switching hysteresis: 5% Breaking capacity: Relay 3 A 250 V, AC-1 Outputs: 2 changeover contacts Supply voltage: 15 – 18 V DC Sensor: between terminal 14 and 16 Analog output: EKW 2.3.1..A1: 0 – 10 V, max. 2 mA EKW 2.3.2..A2: 4 – 20 mA An electronic proximity sensor mounted on the fan housing sensor detects the rotation of the fan shaft through the detection of a retaining screw mounted on the fan shaft by means of a tension band. When a metal part (tensioning screw) passes by the sensor face, the electromagnetic field is broken and an impulse is created. These are analyzed in the control unit. If the rotation speed falls below the set value, the relay drops out. For use in explosion-risk areas, Namur sensors are used, whose signals are delivered via an additional Ex-amplifier to the electronic V-belt monitor. The device is ready for operation when the voltage is applied, and the relay is energized. In parallel to the fan, the release contact is opened and the control unit starts. First the startup bridging takes place for 60 seconds, the relay is forcibly energized, contacts 4 – 5, 7 – 8 are closed. After the start-up bridging sequence, the relay remains energized as long as the rotation speed exceeds the limit, and drops out if the speed falls below it. Then a compulsory interlock takes place as long as and until the fault is eliminated and the release is carried out on the device with the key button , or externally either individually or centrally. Sensor ventilation air conditioning | Data sheet No. 10102 | Version 07-2008_1 | 1 Electronic V-belt monitoring device EKW 2.3.x.x / EKW 2.3.x.xA Analog output Installation Only for models with the suffix “A”. Bring the fan with a secure V-belt to full rotation speed. Then adjust “Anpassung” with the potentiometer 10 V or 20 mA. A clockwise rotation of the 12-gang-shaft potentiometer causes a decreasing signal. With a multimeter’s probes the measuring signal is easy to tap at the terminals. Behind the front panel is a green LED , that glows lighter or darker according to the output signal. The switching device is to be snapped on mounting rails in a switching cabinet in the equipment room with its click-in base. The distance from device to device and to heat-emitting relays etc. must be at least 2 mm. The back-of-hand-proof connection terminals are to be inserted from top to bottom in the housing socket board and therefore provide adequate protection against contact. Since the devices are installed in a dust-proof cabinet, they do not require cleaning. Should it still be necessary, it should be carried out with a dry brush. The operating license is valid only if the above mentioned operating instructions are followed. Opening the housing or damaging the warranty seal will void the warranty. Note: The analog output is only adjustable at speeds of 100 – 1000 rpm. Higher ranges on request. Dimensional drawing Dimensions in mm Adjusting the threshold With the DIP switches , which are accessible behind the open­ ings in the front panel, the rotation speed range is preselected (View is with the company logo at the top): DIP-switch left: down, right: down Range 1: 100 – 1000 rpm DIP-switch left: down, right: up Range 2: 1000 – 2000 rpm DIP-switch left: up, right: down Range 3: 2000 – 4000 rpm DIP-switch left: up, right: up Range 4: 4000 – 6000 rpm LED Functions Yellow LED : Start-up bridging Green LED : Flashes with the impulse of the sensor, as long as the set rotation speed is too low. Green LED : Continuous, set speed is exceeded, operating state. Red LED : Fault, rotation speed is too low. If the red and green LEDs light up together, the fan shaft is positioned with the hose clamp’s screw directly over the front surface of the sensor. If the yellow and green LEDs light up together, the shut-down speed has already been exceeded during the start-up phase. With this it is clearly recognizable that the transfer from the sensor to the controller is functioning properly. If during the start-up phase the green LED does not flash in time with the impulse frequency, there is a communication problem between the sensor and control unit, or the fan is not running. The adjustment potentiometer is located behind the front panel (marked “Schwellwert”) with a 340° rotation. The slot in the shaft is easily accessible through the hole with a 3 mm screw­driver. The left position corresponds to the upper threshold of the preselected range; the right position corresponds to the lower threshold (lower deviation functional principle). Factory setting: Range 1, right position, 100 rpm. 2 | Sensor ventilation air conditioning | Data sheet No. 10102 | Version 07-2008_1 Electronic V-belt monitoring device EKW 2.3.x.x / EKW 2.3.x.xA Connection diagram Specification text Only insulated circuits may be connected, i.e. only devices may be connected which do not have any accessible energized parts. The devices to be switched must be consolidated in a switching cabinet. When connecting the terminals, the stranded wires must be provided with ferrules so that no stranded wire ends can touch terminals with different polarity. Electronic V-belt monitor for monitoring the V-belt fan drive shaft. Built-in time-delay relay (60 s) for start-up bridging of the drive motor. Visual indication of operating conditions (start-up, operation, fault) with light emitting diodes (LEDs). With adjustable shut-down speed (100 – 6000 rpm). In case of a fault, a shut-down of the motor and self-interlock takes place. Release is possible with a reset button on location and/or internally. With click-in base for mounting on DIN rail. Dimensions: 96 x 48 x 60 mm (L x W x H). Output: 1 relay with 2 changeover contacts. Supply voltage 230 V ± 10 %, 50 – 60 Hz, EKW 2.3.1 24 V ± 10 %, 50 – 60 Hz, EKW 2.3.2 With additional analog output: If the rotation speed drops below 100 rpm, the analog output abruptly goes to 0 V or 0 mA. 230 V ± 10 %, 50 – 60 Hz, 0 – 10 V, EKW 2.3.1.A1 24 V ± 10 %, 50 – 60 Hz, 0 – 10 V, EKW 2.3.2.A1 230 V ± 10 %, 50 – 60 Hz, 4 – 20 mA, EKW 2.3.1.A2 24 V ± 10 %, 50 – 60 Hz, 4 – 20 mA, EKW 2.3.2.A2 Complete with accessories. Brand: Oppermann Regelgeräte GmbH Supply voltage NC NO 1 2 3 C 4 5 NC NO 6 7 O 8 K = Release contact from the motor contactor with 2-speed fan contacts in series S = reset button, only if desired 9 10 11 12 13 14 15 16 S Analog output with version “A” K blue black brown Sensor black black Sensor Connections interchangable Contact depictions are with the power off – relay de-energized. Operational readiness after voltage is applied – relay energized. Oppermann Regelgeräte GmbH | Im Spitzhau 1 | 70771 Leinfelden-Echterdingen, Germany Phone +49 711 72723560 | Fax +49 711 7280527 | info@oppermann-regelgeraete.de | www.oppermann-regelgeraete.de Specifications subject to change. Sensor ventilation air conditioning | Data sheet No. 10102 | Version 07-2008_1 | 3