LI-ARP 120/277 Installation Instructions

advertisement

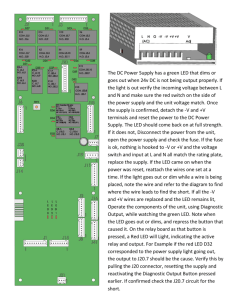

Automatic Relay Pack for the Lighting Integrator Panel Installation and Operation SPECIFICATIONS: Voltage ........................................... 120/277VAC, 60Hz Load rating for relays @120/277VAC, 60Hz...............................20A ballast @120VAC, 60Hz ........................... 20A incandescent @ 120/250VAC, 60Hz .........................................1 hp Auxiliary relay contacts ................ 1A@24VDC, form C Pilot light output............................. 24VDC each relay Auxiliary power................................... 200mA@24VDC Network dataline........... one pair twisted, 1500’ max, free topology Enclosure mounting ..........................1/2” pipe thread NEMA 1, approved for use in return air plenum Dimensions ..........................6.63”h x 6.13”w x 2.13”d FCC Compliant Part 15, subpart J for commercial and residential UL and CUL listed Three year warranty DESCRIPTION INSTALLATION The Automatic Relay Pack is a distributed control device. It is designed for networked operation with the Lighting Integrator Complete Control series lighting control panel, or it can be used in stand-alone mode. For an overview of the entire system, refer to the Lighting Integrator Installation and Operation Manual. With the LI-ARP, load control relays can be located in the space where the control is required rather than clustered in the lighting control panel. Further, all of the low voltage Class 2 connections associated with the space including wall switches, occupancy sensor and daylight sensor, are terminated at the LI-ARP. Up to 48 LI-ARP units may be connected on a single digital dataline for system wide lighting control and monitoring. This greatly reduces home run wiring requirements for the installation while maintaining capability for advanced system wide lighting control functionality. If you have any questions, call our Service Team at: 800.879.8585. General Installation Information • All power must be turned off prior to installation or service. • More than one disconnect may be required to deenergize power to the LI-ARP. • External circuit protection to the LI-ARP is required (e.g., circuit breaker). • Installation shall be in accordance with all applicable regulations, wiring practices, and codes. • Care should be taken to separate high voltage power from low voltage (Class 2) control wiring. Location Planning The LI-ARP is often installed above the finished ceiling. Therefore, be consistent in choosing the location for the LI-ARP. This will help locate the LI-ARP units in the future if they require service or adjustment. A good location choice is directly above the wall switch(s) that are connected to the LI-ARP. In a school, a good choice is in the hall directly above the door to each classroom, to give easy access to the unit without disrupting classroom activities. Please Recycle Santa Clara, CA 95050 www.wattstopper.com Call 800.879.8585 for Technical Support 08513r2 9/2008 Installation Instructions LI-ARP 120/277 Line Voltage Wiring CAUTION Make line voltage connections to the flying leads inside the J-box using the color code provided on the label. Note that the LI-ARP is a dual voltage capable device. Both brown (277 volt) and black (120 volt) leads are provided. Cap off the unused power lead with a wire nut. RISK OF ELECTRIC SHOCK. DISCONNECT POWER AT THE CIRCUIT BREAKER BEFORE INSTALLING OR SERVICING THE LI-ARP OR WORKING ON ANY CIRCUIT. Control power to the LI-ARP may be shared with the controlled loads. It is acceptable for the control power voltage to be different than the controlled load's voltage. Mounting The LI-ARP is provided with a standard ½” threaded conduit nipple to facilitate mounting to any standard J-box (not supplied). The LI-ARP has two electrically independent load control relays. Connect one switched load to the red wires (Load #1) and one switched load to the orange wires (Load #2). These connections are not line/load sensitive. High voltage power wiring Daylighting: If the LI-ARP will be equipped with a daylight sensor, load #2 (orange wires) must be connected to the lights that will be shed by the daylight sensor. Low voltage switch and signal wiring Low voltage section Figure 1: Mounting Offset or flex fitting Model #: LI-ARP 120/277 Low Voltage Wiring Remove the LI-ARP's cover to access the connections and configuration switches in the low voltage section. If the low voltage wire will be run in conduit, connect the LI-ARP to the low voltage wiring through a junction box. High Voltage Wiring Automatic Relay Pack Common Terminals for Low Voltage Devices Input Rating 120/277VAC, 60Hz 8W Maximum Load Output Rating 20A Tungsten,120VAC, 60Hz 20A Ballast, 120/277VAC, 60Hz 1hp, 120/250VAC, 60Hz Auxiliary Output Rating 1A, 24VDC Type 1 enclosure Acceptable for use in plenum For operation within a Maximum Ambient of 60°C 08511r1 Configuration Switches for Override Switch Options and StandAlone Mode Options: Relay and Blink Warning BLK (120V) BRN (277V) WHT GRN RED RED ORG ORG Output 2, Load & Line Network Address and StandAlone Mode Time Delay Setting Technical Support: 800.879.8585 Dataline Network Terminals 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 OPEN OPEN Factory Use Only Override Switch Terminals Technical Support 800.879.8585 Output 1, Load & Line Industrial Control Equipment 83AJ Designed and Manufactured in USA Figure 2: Low Voltage Section Power, cap unused wire Neutral Ground Pilot Light Terminals page 2 Do not connect conduit runs directly to the low voltage section of the LI-ARP. Make all splices in the junction box, not in the LI-ARP. Do not run low voltage wiring with line voltage or power wiring. Wiring for Pilot Light Switches Prepare low voltage wires Low voltage wire used to connect the switches, occupancy sensor, or daylight sensor is not required to be either twisted or shielded. Use any appropriate stranded 18 gauge wire. Terminals PILOT 1 and PILOT 2 supply 24VDC when the corresponding relay is ON and can be used with appropriate lamps to provide pilot status indication for the load relays. Since in most LI-ARP installations the switches will be in close proximity to the controlled lighting, the use of pilot light switches is normally not necessary. Wiring for Low Voltage Switches Properly strip and crimp low voltage wires onto the 0.25" quick connect lugs provided (use T&B crimp tool #WT145C, WT2000, ERG2001, ERG2003 or WT1455). Lugs must be UL listed, T&B #RA250 (22-18AWG) or equivalent to maintain spacings on the circuit board. Terminate the lugs to LI-ARP terminals as directed in this manual as described for the device you are connecting. Low voltage wiring should be stranded,18 gauge, plenum rated wire. Switch 1 controls load relay #1 (red power wires) and switch 2 controls load relay #2 (orange power wires). See figure 2 on page 2. Consult the graphic for location of these terminals for OVERRIDE SWITCH 1 and OVERRIDE SWITCH 2. LOW VOLTAGE SWITCHES Three Wire Momentary Switch (factory default) The LI-ARP is factory configured to use three wire, momentary type low voltage switches such as Watt Stopper LVS-1 or RS2-3. However, any center loaded double throw toggle switch will work. Factory default operation provides individual control of each load relay by separate switches labeled OVERRIDE SWITCH 1 and OVERRIDE SWITCH 2. Both switches provide manual ON operation; the lighting in the sensor-controlled space will not come ON automatically. The user must operate the switch to turn ON the lights. If this is the desired switch operation, no further adjustments are required. If other than default switch operation is desired, see Alternate Switch Operation below. Set the configuration switches in the low voltage section of the housing prior to closing up the housing and the ceiling. Connect the common connection from the three wire momentary switch to one of the terminals labeled COMMON in the LI-ARP. Connect the ON connection from the switch to the terminal labeled A(ON) and the OFF connection from the switch to the terminal labeled B(OFF). LVS-1 momentary toggle switch Single switch OVERRIDE SWITCH 1 CONFIG. SETTINGS: SW1T2 SW1T1 SW1T2 SW1T1 OFF OFF OFF ON A(ON) Common B(OFF) or Multi-way Override Switch Terminal On Off To other switches as needed Two Wire Momentary Switch Connect the common from the two wire momentary switch to one of the terminals labeled COMMON in the LI-ARP. Connect the other wire to the A(ON) terminal in the LI-ARP. Three wire momentary (default) Two-wire switch Three wire maintained SW1T2 SW1T1 ON OFF Two wire maintained SW1T2 SW1T1 ON ON Two wire momentary Single switch SW2T2 SW2T1 OFF OFF Three wire momentary (default) SW2T2 SW2T1 OFF ON Three wire maintained SW2T2 SW2T1 ON OFF Two wire maintained SW2T2 SW2T1 ON ON Two wire momentary On LI-ARP Low voltage wiring A(ON) Common Off or Multi-way On Override Switch Terminal Off OVERRIDE SWITCH 2 CONFIG. SETTINGS: www.wattstopper.com LI-ARP Low voltage wiring Off Alternate Switch Operation OVERRIDE SWITCH 1 and OVERRIDE SWITCH 2 can be individually be configured for different switch types by changing the position of the configuration DIP switches. The tables below show the alternate configuration settings. On To other switches as needed Once the switches are connected and power is applied to the LI-ARP, the switches will control the loads. page 3 NETWORK CONFIGURATION Network Wiring When used as part of the Lighting Integrator Complete Control series lighting control panel network, up to 48 LI-ARP units may be connected on a single digital dataline for system wide lighting control and monitoring. Network wire should be Watt Stopper HDLW4 or HDLW4P (plenum rated) as required for the site conditions. This wire has two independent unshielded, 18 gauge twisted pairs. The red/black pair is used for the LI-ARP network connection. The blue/white pair should not be connected to the LI-ARP. This pair is used only when HDLS series dataline switches are part of the installation. See the HDLS installation instructions for more information on installing these switches. Network Address Set the network address of the unit using the ADDRESS switches in the low voltage section of the LI-ARP. See figure 2 on page 2. Each LI-ARP in the network must have a network address in the range of 1-48. This information is provided in the submittal documents that came with your system. Set the DIP switches according to the illustrations provided for each LI-ARP in the submittal documents. Connect the red/black pair to the NETWORK terminals A and B using the push on connectors supplied. This connection is not polarity sensitive. Either the red or black wire may be connected to the A or B terminal. For installations where factory submittal documents are not supplied, it will be necessary to set the LI-ARP addresses in the range of 1–48. In this case, the individual settings are not important. However, each LI-ARP must have a unique (relative to the panel it is attached to) network address in order for the system to function properly. Network Address Switches Network Wiring 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 OPEN OPEN The DIP switch address is set using a binary numbering scheme where each DIP switch has a numeric value. The address is determined by totaling the switch value for each switch that is set to ON. Switch number Value when ON 1 2 3 4 5 6 Total 1 2 4 8 16 32 Example The network wire need not be run in a daisy chain or any other particular topology. Star, T-tap or other configurations are permitted provided the total network wire length of the segment does not exceed 1500 feet. 1+ 2+ 8+ If the installation requires more than 1500 feet of wire to complete the segment, the wire must be run in a daisy chain (linear) topology and termination resistors should be installed at both ends of the segment. Contact Technical Support for details or if the segment wire length will be greater than 4000 feet. A network repeater will be required. 11 For example, with switch #4, switch #2, and switch #1 set to ON, the address for this LI-ARP is 11. This is determined by adding the switch values of 8 + 2 + 1 = 11. Note: if the LI-ARP is to be used stand-alone (not on a network), the ADDRESS must remain set at the factory default of 0 (all address switches set to OFF). See the section on Using the LI-ARP in Stand-alone Mode. Technical Support 800.879.8585 page 4 OPTIONAL OCCUPANCY SENSOR OPTIONAL DAYLIGHT SENSOR The LI-ARP is designed to work seamlessly with Watt Stopper 24VDC occupancy sensors. The sensor will provide local overrides to the LI-ARP based on detection of movement within the controlled space. The actual function of the sensor depends on how it is configured in the WinControl software. In all cases, the occupancy sensor will always affect both load relays in the LI-ARP. The LI-ARP is designed to work seamlessly with Watt Stopper 24VDC daylight sensors such as the LS-100 and the LS-101. The sensor provides a signal to either hold OFF or shed load relay #2 when sufficient daylight is present. Default operation for the occupancy sensor is manual ON/automatic OFF. In this mode, the lighting is turned ON manually using the low voltage wall switch connected to the LI-ARP. The occupancy sensor will keep the lighting ON as long as it senses motion. When the sensor times out and turns OFF the lighting, an integral timer in the LI-ARP provides a 5 minutes grace period during which a detected motion will turn the lighting back ON. After the 5 minute grace period expires, the manual ON feature is reset and the wall switch must be used to turn ON the lights. Wiring the Daylight Sensor All connections to the daylight sensor are through the low voltage section of the LI-ARP. 1. 2. 3. 4. Wiring the Occupancy Sensor Connect the red lead from the daylight sensor to the terminal labeled +24VDC (RED). Connect the black lead to COMMON. Connect the blue lead to CTRL-24V (BLUE) on the DAYLIGHT SENSOR terminal bank. Adjust the daylight sensor as directed in the installation instructions supplied with the sensor. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 OPEN OPEN 4. OPEN Control (24VDC) Out Black Common 1 2 3 4 5 6 7 8 OPEN Blue 1 2 3 4 5 6 7 8 Isolated Relay Outputs 24VDC Sensor www.wattstopper.com Red +24V (In) Daylight Sensor Relay Common Common Normally Open Contact N.O. N.C. Normally Closed Contact page 5 Blue Control (24VDC) Out 2. 3. Connect the red lead from the occupancy sensor to the terminal labeled +24VDC (RED). Connect the black lead to a COMMON terminal. Connect the blue lead to CTRL-24V (BLUE) on the OCCUPANCY SENSOR terminal bank. Alternatively, if the sensor provides a dry contact relay instead of a 24V signal, then connect the relay to the COMMON and CTRL terminals. Adjust the occupancy sensor as directed in the installation instructions supplied with the sensor. Black Common 1. Red +24V (In) All connections to the occupancy sensor are through the low voltage section of the LI-ARP. USING THE LI-ARP IN STAND-ALONE MODE Stand-alone Mode Functions The LI-ARP may be used in stand-alone mode (not connected to a Lighting Integrator panel network). In this mode, the LI-ARP typically receives a signal from an external system such as a BAS or simple time clock switch to toggle the operation of the LI-ARP between normal mode and “after hours” mode of operation. To use the LI-ARP in stand-alone mode, all of the ADDRESS switches must be set to OFF. In stand-alone mode, all of the special functions of the LI-ARP must be set using configuration switches in the low voltage compartment of the housing. These include a selection for Auto On or Manual ON for each relay, enabling Blink Warn, and setting a Time Delay duration for after hour overrides. The tables below show the special functions that must be programmed with the configuration switches. In stand-alone mode, the DAYLIGHT SENSOR input terminals are used to provide the after hour mode signal to the LI-ARP. A daylight sensor can not be used with the LI-ARP when it is used in stand-alone mode. An externally maintained contact closure between COMMON and CTRL (on the bottom right corner of the low voltage section – what would otherwise belong to the daylight section) will place the LI-ARP into the after hour mode of operation. An open condition between the COMMON and CTRL terminals places the LI-ARP in normal operating mode. The time delay setting will be in effect during after hour periods and will be disabled during normal operating periods. Relay 1 Switch Settings: RL1AON RL1AON OFF ON Manual ON (factory default) Automatic ON Relay 2 Switch Settings: RL2AON RL2AON OFF ON Manual ON (factory default) Automatic ON Blink Warn Switch Settings: BLKWRN OFF BLKWRN ON No blink warn (factory default) Blink warn enabled Time Delay Switch Settings: TO1 TO2 ON OFF .5 hour (30 minute) time delay TO1 TO2 OFF ON 1 hour time delay TO1 TO2 OFF OFF 2 hour time delay (factory default) TO1 TO2 ON ON 4 hour time delay FCC NOTICE This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Caution: Any changes or modifications to this device not explicitly approved by Watt Stopper/Legrand could void your authority to operate this equipment. WARRANTY INFORMATION Watt Stopper/Legrand warranties its products to be free of defects in materials and workmanship for a period of three (3) years. There are no obligations or liabilities on the part of Watt Stopper/Legrand for consequential damages arising out of, or in connection with, the use or performance of this product or other indirect damages with respect to loss of property, revenue or profit, or cost of removal, installation or reinstallation. Technical Support 800.879.8585 2800 De La Cruz Boulevard, Santa Clara, CA 95050 Technical Support: 800.879.8585 www.wattstopper.com 08513r2 11/2008 page 6 Please Recycle