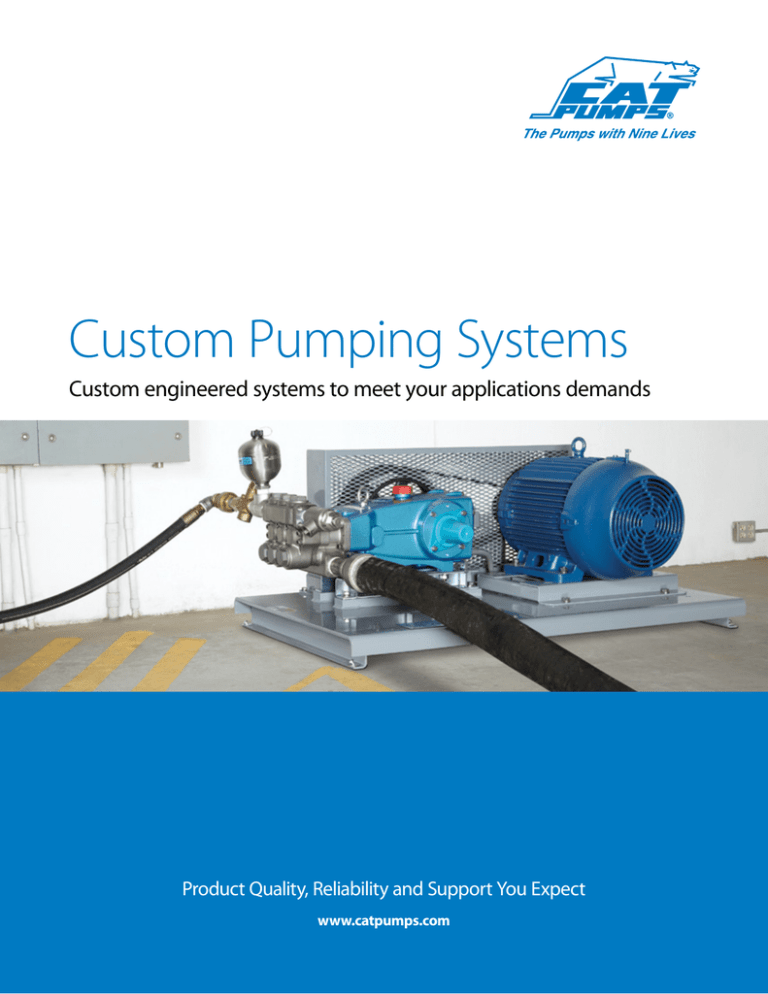

Custom Pumping Systems

Custom engineered systems to meet your applications demands

Product Quality, Reliability and Support You Expect

www.catpumps.com

Pumping System Solutions

For over 25 years, Cat Pumps has been the industry leader in providing

customers with quality custom-engineered pumping systems to meet a wide

range of application needs. Each custom system is built to meet the needs of

the individual customer with the assistance and expertise from our technical

sales and engineering team. They will assist in all phases of the build including

gathering application information, component/configuration selection,

building and testing as well as aftersales support. This includes installation,

operation, maintenance and troubleshooting support. All systems are

designed, built and pressure tested in Cat Pumps’ Minneapolis location, and

typically ship in two to eight weeks. Each system includes an owner’s manual

with start-up and maintenance information.

Purchasing a custom system from Cat Pumps offers more benefits than

simply providing a high quality pumping system. By choosing Cat Pumps for

your next custom system need you can greatly save time and expenses of:

•

•

•

•

•

Initial Design

Multiple Source Buying

Fabrication

Assembly

Testing

Our custom pumping systems are the quickest way to get up and running

with the proper equipment. Each system includes all the required safety and

pressure regulation valves to assure optimum performance and safety. Our

technical sales staff will provide you with industry leading after sale support

for assistance with installation, operation and maintenance.

With thousands of installations running around the world, choose Cat Pumps

for your next custom pumping system.

Custom Engineered to Meet your Application Demands

Applications

With experience in hundreds of different applications around the globe, we have built custom systems that can be configured to

meet even the most challenging application demands. Applications served include:

• Ag Fertilizer/Pesticide Injection

• Ham, Chicken, Turkey Deboning

• Paint and Rust Removal

• Airplane De-icing

• Pesticide Injection

• Arch Misting Systems

•H

eavy Equipment Drive-thru

Arch Cleaning

• Bakery Sanitizing

• Homogenization

• Pulp and Paper

• Barnacle Removal

• Hydraulic Powered Cleaner

• Reclaim Vehicle Washing

• Barrel Cleaning

• Hydro-evacuation

• Screen Cleaning

• Boiler Feed

• Hydrostatic Testing

• Seawater Reverse Osmosis

• Butter/Margarine Processing

• Industrial Cleaning

• Secondary Recovery

• Central Cleaning Systems

• Label Removal

• Sewer and Pipe Cleaning

• Compressor Cleaning

• Laser Cutting

• Slaughter and Smoke House Cleaning

• Conveyor Cleaning

• Laundry Moisture Extracting

• Swimming Pool Cleaning

• Drain, Pipe, Sewer Cleaning

• Liquid CO2

• Temperature Control - Hen Houses

• Equestrian Misting

• Lumber Humidity Control • Train Washing

• Exposed Aggregate

• Machining Flushing and Cooling

• Turbine Mist Cooling

• Fire Suppression

• Mining Dust Suppression

• Waste Water Re-injection

• Fish Scale Removal

• Mold and Casting Cleaning

• Wet Sandblasting

• Food Processing

• Moss and Mildew Treatment

• Window Awning and Blind Cleaning

• Glycol/Methanol Injection

• Odor Control

• Underground Boring

• Golf Course Injection/Aeration

• Oil, Gas Process Systems

• Underground Tank Cleaning

• Gypsum Cutting

•O

utdoor Cattle, Swine & Horse

Cooling System

• Portable Rubber Remover

“We have used Cat Pumps customized pumping system over the years

because they know how to get the job done right. From the beginning

of the process to the completion, Cat Pumps has provided a quick

turnaround and a very professional looking piece of equipment that

meets our customer needs.”

Michael Brown

President • Georgia Chemical

Base

Configuration

System design starts with choosing the base

that best fits your application. Numerous base

configurations are available to meet space,

portability, sound and material demands.

Popular configurations include:

Standard

Our standard base configuration is constructed of heavy duty steel, epoxy coated for added

protection and available in a variety of sizes. Includes heavy-duty shock mounts for easy leveling and

shock absorption. Drive guard also included for proper ventilation and operator safety. Aluminum

and stainless steel models available by request.

Stacked

For compact installations, we offer a variety of vertically stacked options that provide smaller footprint,

yet still provide easy accessibility for maintenance.

Portable

We offer a wide variety of portable base configurations to suit any portable application. Wheels and

handle can be added to our standard base package or we can design a custom base to better meet

your requirements. Carrying handles, carts, fork lift slots, lifting lugs and truck mount bases are popular

configurations.

Enclosed

For installations that require extra protection or lower sound, we have designed fully enclosed bases to

best suit your application needs. Enclosed bases still provide easy accesibility for routine maintenance.

Multiple Pump

For applications that require a higher flow or pressure rating than a single pump can achieve, we have

special configurations designed to hold multiple pumps to meet your application demands.

Power

Source

Evaluate which power source will best fit the

needs of your installation. A qualified and

proven staff with extensive experience can

assist in recommending the correct product

for any power source available.

Popular configurations include:

Electric

Our most popular power source is electric motors. There are number of options that we offer

but are not limited to, such as: Horsepower range - 1/4 to 200; RPM – 1800 or 3600; Phase - single

or three; Enclosure – TEFC, ODP, explosion proof; Frequency - 60Hz or 50Hz; Nema frame styles –

56C to 449T; Voltages - 115 to 575.

Gas

For portable applications or installations that do not have an electric motor source available,

we offer a variety gas engine options: Horsepower range – 3.5 to 40; 3600 rpm; 4 stroke OHV;

horizontal shaft; electric or manual start; cyclonic air cleaner; muffler.

Diesel

For portable applications or higher horsepower installations that do not have an electric motor

source available, we offer variety of diesel engine options: Horsepower range 9.9 to 80; RPM –

2600 to 3600; four stroke; electric start; manual clutch; air or liquid cooled.

Hydraulic

For custom systems being installed where hydraulics are available, we offer three types of

hydraulic motor options: SAE “A”, 2 bolt mount, 12 SAE side ports, dual rotation, 3000rpm, up

to 17.5 gpm, 3000psi, in a variety of displacement sizes or SAE “B”, 2 bolt mount, 16 SAE side

ports, dual rotation, 3000rpm, up to 44.0 gpm, 3000psi, in a variety of displacement sizes or

SAE “C”, 2 bolt mount, dual rotation, 400 to 2500rpm, 14 to 50gpm, up to 3500psi, in a variety of

displacement sizes.

Pneumatic

For explosive environments or where an air source is plentiful, we have a variety of lubricated

pneumatic (air-driven) motors with and without gearboxes available. We can cover a variety

of mounting configurations from hub, foot, face, NEMA C-flange to metric D series. Clockwise,

counter-clockwise or reverse rotations. Horsepower up to 9.5, and rpm ranges from 300 to 10,000.

Drive

Packages

A wide variety of drive packages are available

to compliment your power source of choice.

Popular drive packages include:

Belt

Our most common drive package gives you the flexibility to run pump at different performances

based on set up. Anti-static, synchronized, and v-belt options available.

Direct

For lower flow applications, we have a variety of compact, direct-drive pumps available. These

models bolt directly to your electric motor or gas engine for simple installation and space saving.

Flex Coupling / Bell Housing

Another space saving direct-drive option is a flex coupling and/or bell housing. Options available

from small 3CP models to our large frame models. This configuration provides a simpler, more

compact design while eliminating belt maintenance.

Gearbox

For gas engine installations, we offer a variety of gearbox models that provide the ability to directly

mount as well as reduce the pump speed to correct RPM. Available for 3/4”, 1” and 1-1/8” shaft sizes.

Clutch

For applications where the pump will run in by-pass for extended time, we have a variety of clutches

available that provide the ability to remotely engage/disengage the pump, extending life.

Accessories

Choose from hundreds of high-quality

genuine Cat Pumps accessories to ensure

optimum system performance and life.

Popular accessories include:

Regulator/Unloader

Relief / Pop-off Valve

A pressure regulator is used to accurately

set and maintain consistent system pressure.

For trigger gun applications, an unloader

is recommended which reduces load on

the pump and motor when the system is

in by-pass.

A relief or pop-off valve provide your system

with an accurate and reliable secondary

pressure relief to protect your pump and

system from damage caused by overpressurization.

Pressure Gauge

Pulsation Dampener

A pressure gauge is used to accurately

monitor pump pressure. All models are

glycerine filled for consistent and accurate

pressure readings with brass and stainless

steel options available. We also offer a variety

of panel mount options.

A pulsation dampener is used to help provide

smooth and consistent flow as well as increase

overall system life. Most models available are

rechargeable and are available in steel

or stainless steel.

Oil Level Indicator

Captive Acceleration Tube (C.A.T.)

Our oil level indicators can be installed

in a variety of locations for convenient

monitoring of crankcase oil levels. Kits are

also equipped with oil drain plugs for fast

and convenient oil changes.

A captive acceleration tube or C.A.T. is used to

stabilize and maintain consistent inlet pressure

when dealing with high temperatures, booster

pump feed, long inlet lines or pressure spikes

caused by regulating valves.

Inlet Filter / Strainer

LPS Monitor

Inlet filters or strainers are used to catch

standard water particles and debris from

reaching and causing damage to your pump.

Removable bowl permits easy cleaning

without removing filter or plumbing.

A low pressure seal monitor can be added

to your system to alert you when the low

pressure seals are worn and need

replacement. Either PLC or lighted versions

are available to signal maintenance personnel

the seals need to be replaced.

Quality Service

and Support

Advanced

Control Options

Ask about Cat Pumps’ wide variety of advanced control options which is designed

to help ensure maximum system performance, as well as provide maximum system

protection. Some options include:

•

•

•

•

•

Variable Frequency Drives

PID Loop (varies speed of pump to maintain system pressure)

Multiple Pump Systems

Low-Pressure Seal Monitors

Auto Shutdowns (Temperature and Low Inlet Pressure)

Other control options to suit your application needs are available upon request.

Cat Pumps has partnered with

many leading manufacturers in

many industries. You can expect

responsive service and technical

support, as well as, the reliability

and durability you demand from

your equipment.

Product Availability

You can count on quick turnaround

times for equipment with our 99%

fill and accuracy rate and over 95%

of orders shipped within 24 hours

(U.S. and Canada).

Distributor Partners

Our global distributors represent

the very best in our industry and

can provide local after-market

support for parts, accessories,

and technical expertise.

Technical Support

We have a seasoned technical

sales and support staff to answer

your application questions. Many

of our sales and engineering team

members have over 25 years of

experience. Live technical support

is available Monday-Friday,

7:30 a.m. to 5:00 p.m. CST.

Ask about Cat Pumps’ wide variety

of advanced control options which is

designed to help ensure maximum

system performance.

CAT PUMPS

1681 - 94th Lane N.E. Minneapolis, MN 55449-4324

Phone (763) 780-5440 — FAX (763) 780-2958

e-mail: techsupport@catpumps.com

www.catpumps.com

For International Inquiries go to www.catpumps.com and navigate to the “Contact Us” link.

©2012 Cat Pumps All rights reserved. 992260 Rev. B 5/12