LED AGL - ADB Airfield Solutions

advertisement

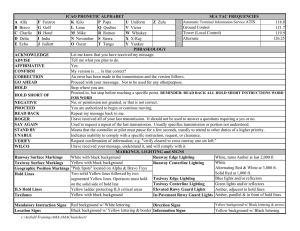

Leading the way to more cost effective, efficient and environment-friendly airfields Why LEDs are the future of Airfield Ground Lighting Summary The use of Light Emitting Diode (LED) technology for Airfield Ground Lighting (AGL) dates back to just over a decade when ADB Airfield Solutions first introduced its Elevated Taxiway Edge LED (ETEL) lights in 2002. With the benefits of LED AGL coming to light over the years, these products are fast becoming the technology-of-choice at airports looking for higher energy savings, lower maintenance costs and a reduced carbon footprint. This whitepaper aims to trace the journey of LED AGL, from its origin until today, understand the clear benefits this technology offers, and also explain why LED is seen as the future of AGL. ADB Airfield Solutions I www.adb-air.com A brief history of LED AGL The early days While the world’s first LED was reportedly created as far back as the early 1900s, it was only in the 1960s that this technology found its way into practical applications. Over the next few decades, the light output, efficiency and reliability of this technology improved. By the late 1990s, LED lamps came to the fore as a more energy-efficient alternative to traditional incandescent lighting. LED lighting was still expensive but its long-term benefits far outweighed the initial acquisition costs. The practical applications of this technology were increasing by the day and in 1999, engineers at ADB Airfield Solutions began to explore the use of LEDs in airfield lighting. Their quest led to the development of the world’s first LED AGL – inset and elevated LED lighting, which was launched commercially in 2002. With this, the journey of the LED AGL had begun. Growing acceptance as AGL: The new millennium Initially the use of LEDs was limited to low intensity fittings as they lacked the brightness and power to be used in high intensity runway AGL. In the decade since 2002, LED AGL design has seen some significant developments which have addressed the power output, brightness, performance and reliability issues. Today, LED light fittings are commercially available across the spectrum of AGL applications. To understand market perception of LED technology, ADB Airfield Solutions surveyed about 1400 customers in a 2013 study titled ‘Innovating the Airside’1. The findings speak volumes: • Nearly 90% of respondents agree that energy-efficient LED AGL will emerge the winner and gradually replace traditional halogen AGL in the coming years. • About 59% are fully convinced of the energy savings and Total Cost of Ownership (TCO)2 benefits of LED technology, while 30% partially agree. Studies by other AGL manufacturers and aviation authorities also reiterate the growing demand for LED AGL. The FAA’s Airport Cooperative Research Program notes in its report on LED AGL that use of LED technology for airfield lighting is growing at airports in the United States and abroad.3 1 http://www.adb-air.com/media/16875/Innovating-the-Airfield-Survey_consolidated_20131220.pdf 2 Total Cost of Ownership: The purchase price of an asset plus its operational costs. When choosing between alternatives, buyers should not just consider the initial investment but the long-term price including operations and maintenance, which is its total cost of ownership. 3 ACRP Synthesis 35 – Issues with use of Airfield LED Light Fixtures - Preface 2 | LED AGL Whitepaper Regulatory standards and approvals The premier regulatory bodies for civil aviation – ICAO and FAA – do not specify what kind of lighting technology should be used. However, in countries like the UK, the Civil Aviation Authority (CAA) has approved use of LED AGL on the runway and taxiway. Its policy on the replacement of traditional lights with LED AGL and obstacle lighting systems at UK licensed aerodromes is detailed in NOTAL 2005/06. LED applications already permitted include runway lead-off, runway guard lights, taxiway centerline and edge, and obstacle lighting. To reflect the rapid development of LED AGL technology, the CAA, in conjunction with the Airport Operators Association, conducted a trial of inset high intensity white and red runway centerline lights within a CAT II/III system. The result – LED lighting is not limited to taxiway use only; the CAA has approved the use of inset LED fixtures on runways4. In Australia, the move to replace existing halogen 4 for LED at civil airports is mandatory. The country is targeting to reduce emissions considerably by 2020 and it is government policy to reduce greenhouse gases. Airports are making the switch, convinced that LED offers better clarity and spectrum emission, as well as constant photometric emission at any steps of light intensity without losing chromaticity. Reduction of operating costs from energy savings and high Mean Time Between Failures (MTBF) are huge benefits. ICAO: While ICAO Annex 14 outlines requirements with respect to the maintenance and serviceability of AGL, it does not specifically delve into what kind of lighting technology or equipment should be used. ICAO only specifies what the light intensity should be and how it should be distributed. FAA: FAA Advisory Circular 150/5345-46D specifies the FAA requirements for runway and taxiway elevated and inset lighting, but it does not make any specific difference regarding the lighting technology used (LED or http://www.airportsinternational.com/2013/01/let-there-be-leds/13200 3 | LED AGL Whitepaper Tungsten Halogen). However, it is interesting to note that the color boundaries in FAA are different for LED and non-LED. FAA has issued specific requirements for LED lights in Engineering Brief 67D to make sure that LED lights will present the same kind of behavior as halogen lights in the same situation. The definition of the dimming curve (light output in function of the input current) is part of this document. Advisory Circular 150/5345-30H also states that “LED light fixtures must not be interspersed with incandescent lights of the same type”. What this means is that one should not mix both technologies that have the same function, such as straight or curved sections of taxiway edge or runway edge. This is due to the difference in the color perception; LED whites stay within the color boundaries for aviation white in all intensity steps. Tungsten-Halogen lamps become yellowish-white in the lower intensity steps. The absence of a clear endorsement of LED AGL by the international regulatory bodies does not in any way indicate a lack of confidence in the reliability and performance standards of LED AGL technology. When the ICAO Annex 14 requirements were defined, TungstenHalogen (TH) AGL was the prevalent technology and the performance standards are therefore suited to TH lighting. LED AGL installations have the potential to meet these standards to a much greater degree than comparable TH installations. It is only a matter of time before regulatory bodies start to frame standards around the superior performance of LED AGL. An example of this is the new Canadian Draft regulatory document ‘Aerodrome Standards and Recommended Practices’ TP312 which states: “This document has been updated to harmonize, where possible with... Advances in lighting technology such as those related to the introduction of Light Emitting Diodes (LEDs).” Why switch to LED Industry professionals and experts believe LED is the future of AGL. There are many reasons why it makes sense to switch from traditional lighting, but broadly they fit into the following areas: Safety: Traditional incandescent AGL is prone to shift color at lower intensity settings and wide angles, especially in case of Stop Bars and Runway Guard Lights. In order to minimize this effect, FAA Advisory Circular 150/5345-46D5 requires that the color of these fixtures must meet Traffic Signal red (for Stop Bar) and Traffic Signal yellow (for RGL). Traffic signal colors are more limited to pure red or yellow and help to minimize the effect of color shift when these fixtures are viewed at wide angles or lower intensity steps. Fig. 1 5 http://www.faa.gov/documentLibrary/media/advisory_circular/150-5345-46D/150_5345_46d.pdf 4 | LED AGL Whitepaper With LEDs, color saturation variation is minimized with intensity step - in effect, they essentially stay the same color. Plus, LEDs switch on instantly unlike traditional AGL which takes some time to warm up. This Instant On capability improves conspicuity and enhances safety. Let’s look at how these characteristics would work to a pilot’s advantage: A.Better differentiation between the white runway centerline and yellow rapid exit taxiway centerline lights as shown in the illustration below (Fig. 1) B.Last 600 meter (2000 feet) of the runway: White LED AGL on the runway edge maximizes discrimination with the yellow lights that may be used on the last 600 meter (2000 feet). C.Runway Guard Lights are often continuously operated nowadays and LED RGL with Instant On are more conspicuous and enhance safety. D.LED Runway Status Lights (RWSL) with Instant On are seen much quicker than incandescent (especially in the lower steps), improving safety by limiting the likelihood of an incursion. E.Discrimination between the white and red parts of the PAPI beam becomes much better at low brightness steps, thanks to the absence of color shift from white to yellow. Let’s consider LED apron floodlighting. A precise and accurate area is illuminated, and all energy is converted to effective light on the ground. The bright white color temperature of the emitted light shows the true colors on the markings used on the apron or of the warning symbols on the aircraft. All colors are presented precisely and accurately. As this increases the safety on the apron, it is becoming a legal requirement in certain 5 | LED AGL Whitepaper countries. White light from LEDs compared to the orangewhite light emitted by high pressure sodium is perceived as brighter. Furthermore, apron floodlights from ewo use multilayer illumination - all individual LEDs or luminaires illuminate the same area, so the effect of one LED or luminaire failing is limited as it only reduces the general illumination level. These features eliminate the risk of dark areas or ‘black spots’ in case of light failure, and improve safety. The Instant On feature allows for full or partial dimming of individual apron parking positions. Because there is no waiting time before full brightness is reached, the illumination of individual parking positions is much more dynamic and on demand. The capability for dimming implies further and significant energy savings and increases the life time of the luminaires. Increased life time reduces the installation cost of the floodlights and more importantly, the maintenance cost. Masts without lowering system can be considered and replacing lamps becomes virtually unnecessary. In other applications such as airfield signs, runway end identifier lights and wind cones, the safety benefits of LED make it the ideal choice. Lesser maintenance, more safety and more air traffic capacity: LED lighting is longer lasting and requires lesser maintenance. Incandescent lamps typically last 4,0006,000 hours and need to be replaced once or twice a year. For LEDs, the MTBF in the same operational conditions is more than 200,000 hours. The annual failure rate of 100% to 200% for incandescent lamps falls to just 1% to 2% with LED. Fewer lamp replacements free up maintenance resources for other duties and reduce maintenance vehicle fleet costs. Lesser maintenance translates to reduced movement of maintenance technicians and vehicles on the airfield, and infrastructure remains open to air traffic. This lowers the risk of runway incursions, and increases operational safety and aircraft movements. With fewer interruptions needed for airfield lighting maintenance, airport downtime is reduced. This also results in fewer unexpected delays and overall, airports are better able to address growing passenger demand and improve profitability. 6 | LED AGL Whitepaper Lighting application Halogen light LED light* Taxiway Center Line 40 – 100 W 20 W Stop Bar 40 – 105 W 10 W Runway Center Line 96 W 30 W Touchdown Zone 48 W 15 W Taxiway edge light (elevated) 30 – 45 W Table 1 Cost-efficiency: With LED AGL, energy consumption is reduced anywhere between 50% to 90% without heating. LED lighting is more long lasting than incandescent. Plus, end-to-end power train savings - from the input supply from the electric company all the way to the fixture - need to be factored in. LED lighting reduces load on the power management systems – this translates to a smaller CCR, smaller isolation transformers, a smaller engine generator, and smaller circuit protection devices, among others. Also, voltage powered LED fixtures consume much less power and operate on a wide voltage range. Electrical supply equipment (such as intermediate step-up and stepdown voltage transformers) can therefore be eliminated or made much smaller. 11 W *Minimum Power Factor of 0.9 With LED apron floodlighting, airports can reduce energy consumption – the average reduction across projects is about 50%. Furthermore, by using the dimming feature which allows dimming of individual parking positions by up to 50% at night, it is possible to achieve more savings even while complying with ICAO requirements. Take for example, the benefit of using LED fixtures when implemented with old series circuit wiring that has reduced insulation resistance. Substituting LED lighting on a circuit with using all LED lights reduces the maximum CCR output voltage and allows the airport to extend the life of older, degraded Series Circuit components. Operational costs are optimized as the use of LEDs in AGL fixtures translates to fewer man-hours due to reduced maintenance, in addition to fewer lamp replacements and disposals over the life-cycle of the product. While the initial investment in LED AGL might seem higher than traditional AGL, it is important to note than this investment can be recovered anywhere from two to four years, and in some cases, as low as six months. Typical LED Return on Investment Total LED Benefits 43.2% 40.7% Capital Equip (Ex: CCR + Transformer) Lamp Replacement Labor Lamp Replacement Cost 12.6% Energy Cost 3.5% Note: The above illustration is from an actual installation at a US airport Fig. 2 Cost comparison: LED versus Halogen 350% 300% Comparison made on the cost of the light only: purchase price, installation, maintenance costs, energy costs. All the remaining components (CCR, cables, transformers) are excluded from this calculation 250% 200% 150% 100% 50% LED Halogen Fig. 3 0% Reduced environmental impact: Low energy consumption leads to reduced carbon emissions. Furthermore, long light engine life in case of LEDs translates to fewer failed lamps needing disposal. Additionally, LED lighting fixtures require lesser maintenance, which means lower vehicle fuel consumption due to fewer AGL maintenance trips, further reducing carbon 7 | LED AGL Whitepaper emissions. LED apron floodlighting is more environmentally friendly - all light is oriented downward; the ULR (upward light ratio) is zero at a horizontal positioning of the lights, and this eliminates glare to pilots and ATC controllers. The environmental advantage has been noted as a legal requirement in some countries. Reaping the benefits of LED AGL Thousands of airports around the world are making the switch to LED AGL. To gain a better understanding of what benefits are derived by choosing LED over traditional halogen lighting, let’s consider two examples of LED installations by ADB - the first a trial at Manchester Airport and the second, an installation of AGL at Xi’an Xianyang Airport in China. Case #1: Evaluating LED high intensity runway centerline lighting at Manchester6 Background: When high intensity LEDs became available in late 2010, an evaluation trial of LED runway centerline lighting was commissioned by the Aerodrome Operators Association (AOA) Technology Working Group with facilities provided by Manchester Airport and supported by the CAA. Objective: Demonstrate that LEDs can be used as a light source in high intensity (HI) runway light units. Trial: Prior to the trial, the lights were photometrically tested and found compliant to ICAO standards. The trial was split into two phases – the first which used pre-production lights and ended in 2011, and the second which used final 6 production lights supplied by the same manufacturer, ADB Airfield Solutions. The complete centerline of runway 05L/23R and touchdown zone lighting was changed to LEDs with similar checks, measurements and inspections repeated as per the first phase. To address concerns about the perceived brightness of these light fixtures, ADB created what was described as a human perception dimming curve. The trial established that the dimming curve was as close as possible to that of the corresponding ADB model “FRC” halogen light. Note that this curve is also compliant to today’s FAA Engineering Brief 67D requirements (even for the lowest two brightness steps on a 5-step CCR). Results: In both phases, it was clear that HI inset red AOA TECHNOLOGY WORKING GROUP – Evaluation report of LED high intensity runway centerline lights – Manchester Airport, May 2012 8 | LED AGL Whitepaper and white LED light units can be installed in an operational environment and meet photometric requirements satisfactorily. The AOA Technology Working Group submitted their report together with supporting evidence and a draft Information Notice to replace NOTAL 2005/6 requesting a change of policy to permit their introduction. On the basis of the submission, Aerodrome Standards (ASD) is content that these inset LED light units are compliant with the requirements set out in CAP 168 Chapter 6 demonstrate an equivalent level of safety, and dependable serviceability to that provided by similar incandescent sourced light units. Furthermore, no unintended consequence arose as a result of the trial nor any failure modes were found to exhibit an unsafe condition.7 Other observations: There was a high degree of acceptance by aircrew that saw both sets of LED light units. This underlines the progress made in harmonizing the brightness with TH lamps at lower intensity settings. LED lights are not brighter than halogen. In fact, there were no reported instances of pilots being dazzled by glare from LED lights at any brilliancy levels. Pilots were asked to complete a short questionnaire and 60 responses were received and are recorded. 86% of pilots rated the clarity and color definition of the LED light units as ‘Excellent’ and 93% reported the overall balance of AGL systems to be ‘Good’. Overall, 85% reported the LED lights were an improvement over the conventional TH light units in providing visual references to pilots. Main benefits expected in high intensity runway services are improved serviceability levels, reduced maintenance and operating costs, and a reduction in an airport’s carbon footprint while maintaining existing levels of safety. In addition, here is a summary of what Manchester Airport achieved in savings by opting for LED8, clearly demonstrating that LED AGL brings about huge savings in carbon emissions. Runway AGL Installation: Halogen and LED lighting comparison Table 2 200 x Rwy C/L Lights 240 x Rwy TDZ Lights 100 x Rwy Inset Edge Lights Halogen 200 x 0.096 kW x 8 hrs/day x 364 days p.a. = 55,910 kWh x 0.5246 = 29,330 Kg CO2e 240 x 0.048kW x 8hrs/day x 364 days p.a. = 33,546 kWh x 0.5246 = 17,598 KgCO2e 100 x 0.15kW x 8hrs/day x 364 days p.a. = 43,680 kWh x 0.5246 = 22,915 Kg CO2e LED 200 x 0.02 kW x 8 hrs/day x 364 days p.a. = 11,648 kWh x 0.5246 = 6,110 Kg CO2e 240 x 0.010 kW x 8hrs/day x 364 days p.a. = 6,989 kWh x 0.5246 = 3,666 Kg CO2e 100 x 0.065kW x 8hrs/day x 364 days p.a. = 18,928kWh x 0.5246 = 9,930 Kg CO2e* Halogen Total Rwy C/L Rwy TDZ Rwy Inset Edge Total = 29,330 Kg CO2e = 17,598 Kg CO2e = 22,915 Kg CO2e = 69,843 Kg CO2e Grand Total Savings = 50,137 Kg CO2e LED Total Rwy C/L Rwy TDZ Rwy Inset Edge Total = 6,110 Kg CO2e = 3,666 Kg CO2e = 9,930 Kg CO2e* = 19,706 Kg CO2e * Estimated energy consumption if Manchester replaces the Halogen Edge lights when LED versions are available Note: This was calculated at100% power output. In practice, 100% output is rarely the case, and this illustration depicts the maximum savings possible. 7 http://www.airportsinternational.com/2013/01/let-there-be-leds/13200 8 Source: ADB study 9 | LED AGL Whitepaper Case #2: Xi’an Xianyang International Airport’s LED Taxiway Lighting installation Comparison of actual energy savings: LED Vs Halogen 1600 Background: To meet growing passenger throughput and air traffic, Xi’an Xianyang International Airport embarked on a Phase II expansion project to build a 3,800-meter (12,470-feet) long and 60-meter (200-feet) second runway. In 2014, the airport handled 29 million passengers, making it the ninth busiest airport in China. Fig. 4 1479.5 1400 1192.7 1200 Results: The Taxiway LED lighting has been running more than a year. From an 672.1 800 600 400 200 0 Taxiway Centerline light Application/ Area Taxiway Edge (Elevated) Savings 19.38% 40.77% Maintenance: The airport has two runways and the operating time per-day is more than 16 hours. After deducting the time taken for all internal processes, preparation and driving, this leaves only about 4.5 hours for maintenance and repair. Runway 1 (Halogen Lighting) Runway 2 (LED Lighting) Need ≥5 hours for troubleshooting Less than 1 hour A minimum of 4 technicians for AGL 2 technicians for AGL inspection inspection Pressure on repair time, to ensure airport normal operation Table 4 12 | LED AGL Whitepaper LED Light (kwh) 1000 Taxiway Centerline light Objective: At the beginning of the project, Xi’an airport Elevated Taxiway edge lights management received a Table 3 mandate from the Civil operational perspective, Aviation Administration of the airport is achieving China, the government of significant savings on energy, Shaanxi Province, Xi’an City maintenance time and Hall and Xi’an Airport Group cost. From a sustainability to build a greener and safer, more environment-friendly and perspective, the taxiway uses a greener, more efficient efficient airport. lighting source, and this helps Installation: In a bid to choose the airport reduce carbon footprint. more environment-friendly technology, Xi’an Airport’s second runway expansion project thus saw the selection and installation of LED light fixtures for the entire taxiway. Halogen light (kwh) 1134.8 Unlikely to encounter failure on LED light, less maintenance needed • Considering the actual lamp life cycle and Xi’an airport’s AGL usage, approach lighting and runway (halogen) lighting needs preventive maintenance twice a year while taxiway (LED) lighting needs only one preventive maintenance session a year. • With its longer life cycle, LED lighting consumes low energy, and offers additional savings on maintenace cost and time. Annual Preventive Maintenance time Fig. 5 2.5 2 2 2 1.5 1 1 0.5 0 0 Approach Light Runway Light Halogen Taxiway light Taxiway Light LED A comparison of north runway and the new south runway equipment at Xi’an according to current AGL usage Parameters Runway 1 Taxiway Light (Halogen + LED) Lighting Inset Taxiway Centerline Elevated LED Taxiway Edge Light Inset LED Taxiway Centerline Elevated LED Taxiway Edge Light Light Quantity 1096 ±450 2792 880 Power 48W 7W 2×8W(Bi- directional) 8W(Uni-directional) 7W Operation Hours 15 hours (Average) Life Cycle 1500 hours 56000 hours 56000 hours 56000 hours Light Source Replacement (annual) 2 times per year LED light engine will continue up to 7 years Cost of replacement of Light Source about 300K (RMB) Will not need to replace within 7 years Annual power consumption (Including the loss of other powered devices) 374.4 KWH 17.2KWH 244.5 KWH 398.8 KWH The annual consumption of electricity More than 200K (RMB) ±10K (RMB) 120K (RMB) ±20K (RMB) Required for maintenance personnel 4 people (replacement of light and accessories) 2 person (inspection) Labor costs 4 people * 5000 RMB * 12 months+ other = about 300K (RMB) 2 people * 5000 RMB * 12 months+ other = about 150K (RMB) Total annual operation cost 900K (RMB) 300K (RMB) Table 5 13 | LED AGL Whitepaper Runway II Taxiway Lighting (LED) Failure Rate: Total AGL lighting failure per year is around 6.7%. For halogen lighting, it’s 11.77% and LED lighting is about 0.68%. LED AGL has lower failure rate compared to halogen lighting, and this helps save maintenance costs and also ensures safer operation. Annual Maintenance Times (in man hours) 600 500 Fig. 6 513 400 300 200 100 0 Halogen light: Lamp replacement 19 6 LED light failure Elevated LED Txy Edge light frangible coupling broken LED is the future Fig. 7 14 | LED AGL Whitepaper A comparison of LED AGL and traditional AGL installations clearly shows that there is no confusion with regard to the function of LED fixtures. As of October 2014, it has been estimated that there are nearly 1.3 million LED AGL fixtures installed at more than 600 airports around the world. Current trends indicate LED is here to stay and will replace traditional lighting. The technology continues to evolve with manufacturers like ADB introducing the second generation of LEDs. With better output and energy efficiency, these products offer a compelling proposition. Adoption of LED AGL for various lighting functions within the airport is expected to grow further. Airports and aviation authorities are also cognizant of the fact that technology used in these installations will have to be consistent; they will need to choose one light source (LED or incandescent) per function; for e.g. if they switch to LED for one runway, the entire runway will need LED AGL. Given LED’s many advantages – safety, low maintenance, visibility and energy savings which lead to a greener carbon footprint, experts believe that this technology has a bright future. Even so, LED technology for AGL is relatively new, and there is a lack of clarity on LEDs and their capabilities. Greater awareness and ongoing research on LED AGL is imperative. Initiatives like the Airport Cooperative Research Program (ACRP) sponsored by the FAA, which are working to solve the challenges of the aviation industry, regularly publish reports on current best practices. One of its reports ACRP Synthesis 35 Issues with Use of Airfield LED Light Fixtures, reiterates the technology’s benefits – “the study findings confirm that LED airfield light fixtures reduce energy use and maintenance requirements, compared with conventional airfield lighting technologies. LED airfield lighting systems have been in use for a number of years, and most feedback on their visibility and performance is positive.”9 9 FAA Research on new LED PAPI The FAA continues to research usage of LEDs in the pursuit of AGL technology that can save energy. It is planning to convert from incandescent lights to light-emitting diodes (LEDs) in precision approach path indicator (PAPI) systems. More recently, the FAA conducted a study on the usability of LED PAPIs in individuals with marginal color vision. This was a follow up study to preliminary work on the usability of LEDs by color vision-waivered pilots (Bullough, Skinner, & Milburn, 2012) which indicated that red weak (protan) individuals made a few errors identifying red. The new study explored whether clustering LEDs of different chromaticities of the same hue would aid users with color vision deficiencies (CVD). Participants, aged 18 to 33 years, included those with normal color vision and others with varying deficiencies in color vision - deutans (greenweak), protans, tritans (blueyellow weak), and subjects evidencing both red-green and yellow-blue deficiencies. In addition to a primary color blindness test, participants undertook the Signal Light Gun Test (the secondary test for issuing color vision waivers), the Cone Contrast Test, and a simulation of the PAPI system. Analysis did not indicate any significant differences between the incandescent, monochromatic, and heterochromatic conditions. Furthermore, the study revealed that color visionwaivered pilots will perform the same on red and white LED PAPI systems as with the current incandescent system.10 SYNTHESIS 35 - ACRP http://onlinepubs.trb.org/onlinepubs/acrp/acrp_syn_035.pdf 10 FAA DOT/FAA/AM-14/6 - Usability of Light-Emitting Diodes in Precision Approach Path Indicator Systems by Individuals With Marginal Color Vision 15 | LED AGL Whitepaper The aviation industry ecosystem – regulatory bodies, manufacturers, airports, consultants and engineers among others must continue to study LED technology so the industry is better equipped with knowledge to make informed decisions. A collaborative approach can ease the transition to what is a far better technology on various parameters – safety, cost, environmental impact and maintenance. ADB and LED AGL: 800,000 and counting As a pioneer, ADB is committed to leading innovation in LED AGL. Since our first product in 2002, we have introduced a steady stream of new products to our LED offering and offer one of the most comprehensive LED AGL portfolios in the industry. Not only have we been at the forefront of promoting LED adoption in the industry, we continue to drive innovation in LED AGL and have many industry firsts to our credit on the product front. We were the first to introduce second ADB Airfield Solutions Leuvensesteenweg 585 B-1930 Zaventem Belgium Phone: +32 (2) 722 17 11 Fax: +32 (2) 722 17 64 marketing@adb-air.com www.adb-air.com generation LEDs, and also the first to offer a complete LED portfolio in both the normal and low protrusion inset light range. Airport more than a decade ago, to today where our LED products are installed at leading airports around the world. Three basic principles guide our LED strategy. London’s Heathrow Airport, the world’s busiest international airport has recently selected ADB’s LED lights for its southern and northern runways. In the US, Chicago O’Hare Airport has more than 10,500 elevated taxiway LED fixtures (ETES), and Denver International Airport has close to 7,000 inpavement taxiway LED fixtures from ADB. Other notable references include Charles De Gaulle Airport in France, Manchester Airport, UK, Frankfurt Airport in Germany and Treviso Airport, Italy. A.Build a complete LED AGL portfolio for all applications including flashing lights B.Offer airports ‘halogen free’ areas where they can get the full benefit of LED reliability C.Apply ICAO & FAA (future) recommendations to avoid mixing technologies on the same function ADB is recognized as a pioneer and expert in LED AGL – from our first LED trials at Brussels ADB Airfield Solutions LLC 977 Gahanna Parkway Columbus, OH 43230 USA Tel: +1 (614) 861 1304 Fax: +1 (614) 864 2069