Quantum O+M Manual

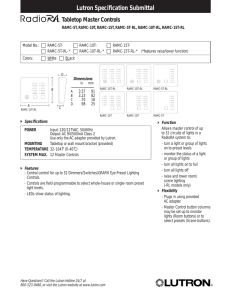

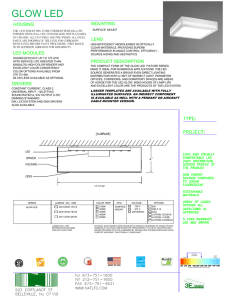

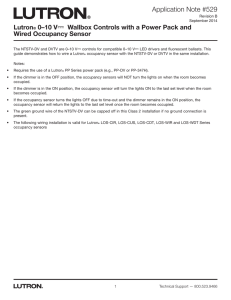

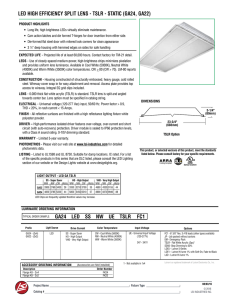

advertisement