Achieve Maximum Efficiency and Stable Operation with Combustion

advertisement

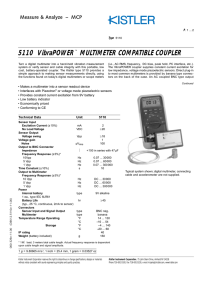

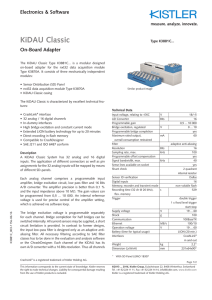

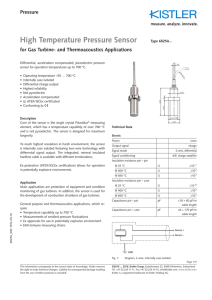

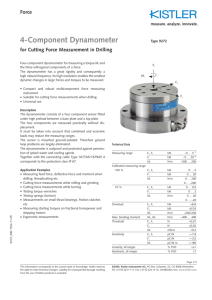

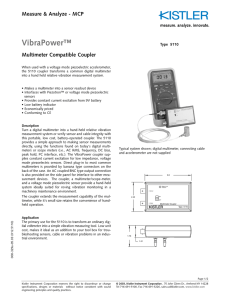

Achieve Maximum Efficiency and Stable Operation with Combustion Dynamics Monitoring. Thermoacoustics Measuring Combustion Dynamics in High Temperature Environments www.kistler.com www.kistler.com Gas turbine combustors Reliable Gas Turbine Monitoring in Environments up to 700 °C. Today's gas turbines must meet ever increasing demands. Among them are high fuel efficiency, fuel flexibility and optimal partial load behavior while complying to increasingly stringent emissions standards. This leads to combustion processes that need to be monitored and controlled within small margins. Pressure pulsations in the combustors play a prominent role. Excessive pulsations caused by instabilities could potentially damage the equipment. To avoid unstable conditions and maintain safe operation, the pulsations must be continuously monitored using the industry's state-of-the-art measurement solutions. Kistler high-temperature pressure sensors are designed for use in gas turbine combustors. Because of their outstanding high-temperature capability, they can be used without a 'long tube' and, if desired, placed in very hot locations. This simplifies the system and delivers more accurate pressure measurements. Ground isolated differential designs, robustness against electromagnetic interference, long lifetime and approvals for operation in hazardous areas are among the features of this measuring system. 2 Pressure pulsation monitoring Benefits of Kistler Pressure Pulsation Monitoring • • • • • • • • Increased fuel efficiency Reduced emissions Enable flexible operation Reduced operating costs Enhanced engine lifetime Prevention of downtime/outage Operation in hazardous areas Retrofitting existing engines www.kistler.com One Portfolio – Many Applications. Kistler high-temperature pressure sensors can be applied to many applications other than gas turbine combustion monitoring. Wherever pressure pulsations in extremely hot environments needs to be measured, our sensors will do the job, be it for R&D projects or for monitoring applications with the sensor permanently installed to protect expensive capital equipment. Application Objective Benefits – Measuring dynamic pressures in turbo – machinery (compressors, propellers, – steam turbines, etc.) for R&D and – continuous monitoring purposes – Measurements at optimal locations – Optimize performance – Improve efficiency – Reduce emissions – Protect equipment – Measuring dynamic pressures on – aircraft-, helicopter- or rocket engines – for R&D purposes – Investigations on continuous pulse – detonation engines – Increased power and efficiency – Help reduce emissions – Improve performance and reliability – Investigation of pressure pulsations in – piping systems for hot media – Identification of excitation mechanisms – R&D and continuous monitoring – purposes – No cooling adapters needed – Protect equipment – Avoid fatigue stress and improve – lifetime – Determine two dimensional temperature – profiles using acoustical methods – Measure temperature distribution in – power plant boilers, blast furnaces and – other large industrial furnaces – Efficient plant operation – Meet emissions regulations – High accuracy; no heat radiation error – Temperature measurements exceeding – 1 000 °C Turbo Machinery Turbine Engine R&D Vibration in Piping Systems Acoustic Thermometry www.kistler.com 3 Main Components. High-temperature pressure sensors, differential charge amplifiers and high-temperature cables are the main elements to configure measuring chains for a large spectrum of thermoacoustics applications. Our components are available in a great variety of versions and have been designed to guarantee seamless interoperability. Ex-certified components for applications requiring explosion protection (installation in hazardous areas) complete the portfolio. Component Features Benefits – Several sensor envelopes – Hardline cable length (1, 2, 5 m) – Various terminations – Ex-Certification (Ex-nA, Ex-ia) – Continuous operating temperature – –55 … 650 °C, short term up to 700 °C – Integrated mineral insulated hardline cable – Differential signal output, 2-wire system – Internally case isolated – Acceleration compensated – High natural frequency – Cable length (5, 10 and 20 m) – Various cable terminations – (LEMO, Fischer, 7/16"-27, open leads) – Operating temperature – –55 … 200 °C / 390 °F – 2-core twisted pair – Low noise design, individually shielded – Steel overbraid – Locking connectors – Aluminum die-cast housing – DIN Rail mounting – Ex-certification (Ex-ia, Ex-nA) – Wide sensitivity range – 0,25 ... 20 000 mV/pC – Various signal output options – Voltage, single ended or differential – Current, 3- or 2-wire loops – Programmable low and high pass filters High Temperature Pressure Sensors Two-wire Softline Cables Differential Charge Amplifiers Typical Measuring Chain p Q Sensor Type 6021A... , 6023A... , 6025A... 4 Softline Cable Type 1652A... Differrential Charge Amplifier Type 5181A... Control Cable 3rd Party DAQ System 3rd Party www.kistler.com Features and Benefits. The proprietary single crystal PiezoStar® sensing elements are the foundation of our superior performance, ultra-high-temperature pressure sensors. They have been thoroughly tested at well over 700 °C. Unlike ceramic-based sensor elements, they are not pyroelectric and show no popcorn effect. The differential measuring system guarantees accurate high-quality signals and is ideally suited for harsh environments. Features Benefits Unique Crystal for Ultra-High Temperature Environments – Proprietary PiezoStar® sensing element Outstanding high-temp. performance: – Operating temperature up to 700 °C – Excellent long-term stability – High sensitivity – Not pyroelectric – No popcorn effect – Highly Accelerated Lifetime Testing – (HALT) under defined conditions – Beta testing over years under various – conditions – Reliability – Repeatability – Long lifetime – Modular portfolio design – High flexibility – Flexible configuration of sensor and – measuring chain – Small number of components Long-term Durability Testing Modular Portfolio that Meets Your Needs Diff. Ladungsverstärker, Typ 5183A Sensor Typ 6021A Softline-Kabel Typ 1652A Sensor Typ 6023A Softline-Kabel Typ 1652A Übergangs-Box Typ _ _ _ _ Softline-Kabel Typ 1652A Sensor Typ 6025A Diff. Ladungsverstärker, Typ 5183A Diff. Ladungsverstärker, Typ 5183A Immune against Electromagnetic Interference Sensor + Sensor – – Internally ground isolated two-wire – design – Truly differential measuring chain – Robust against electromagnetic – interferences – Effective interruption of ground loops – All components are optionally available – in Ex-nA and Ex-ia – Matched components – Efficient implementation for applications – in hazardous environments GND Explosion Protection www.kistler.com 5 Learn More. Kistler measurement technologies cover a wide range of applications beyond Thermoacoustics. Find out more about our offering for acoustic emission, predictive maintenance and many others by visiting our website www.kistler.com. T F A R D Thermoacoustics Technical Brochure For more in-depth information on our Thermoacoustics portfolio, please refer to our technical brochure available at www.kistler.com/thermoacoustics. Discover examples of measuring system configurations for typical application scenarios, including installations in hazardous areas requiring explosion protection. Here you can also find the latest product data sheets and manuals. Product Line for Combustion Dynamics on Gas Turbine www.kistler.com www.kistler.com In the field of Gas Turbine, Kistler offers also acoustic emissions (AE) sensor solutions (ATEX) for: • diagnostics of combustion oscillation • diagnostics of fatigue damage of gas turbine engine blades • general condition monitoring For more information, please visit our website www.kistler.com/acoustic-emission. On our website www.kistler.com, you can find a wealth of information on Kistler's solutions and technologies – not only for Thermoacoustics, but also for many other applications. Please visit our website to find dedicated brochures on other specific measuring technologies and systems. PiezoStar® is a registered trademark of Kistler Holding AG. 6 www.kistler.com About us. Sales Center Tech Center Production Center The Swiss-based Kistler Group is one of the world's leading providers of dynamic technology for measuring pressure, force, torque, and acceleration. Kistler technology is used to analyze physical processes, control industrial processes, and optimize product quality. Kistler offers a comprehensive range of sensors, electronics, and systems for engine development, engine monitoring, plastics processing, metalworking, assembly engineering, and biomechanics. Because of Kistler's 30 Sales and Production Centers, three Tech Centers, as well as more than 30 agencies, the Group is present on every continent. This allows customers to benefit from local contacts as well as application support tailored to their needs. The Kistler Group employs more than 1,400 people worldwide. www.kistler.com 7 ©2015, Kistler Group 960-200e-12.15 Kistler Group Eulachstrasse 22 8408 Winterthur Switzerland Tel. +41 52 224 11 11 Kistler Group includes the Kistler Holding AG and all its subsidiaries in Europe, Asia, Americas and Australia. Find your local contact at www.kistler.com