SUCCESS

STORY

Improved quality with proper

validation of all master data

Project background

The successful collaboration between Roche and Rockwell Automation’s

Propack Data specialists has more than 10 years of history. Based on

many successful joint projects in several plants in Germany, Switzerland,

and England, Laboratoires Roche Nicholas S.A. (Roche) decided in favor

of Propack Data PMX MESTM as the most suitable solution for updating

and extending the existing manufacturing execution system (MES). This

decision was reached after an intensive evaluation phase in search for

a global MES supplier. Important factors for Roche’s decision were, e.g.,

- the completeness of Propack Data PMXTM which supports the entire

pharmaceutical life-cycle from goods receipt through the production

process to the finished product,

- the benefit of a single-source, prevalidated system, and

- the confidence in a partner offering dependable system support

following the productive start.

■

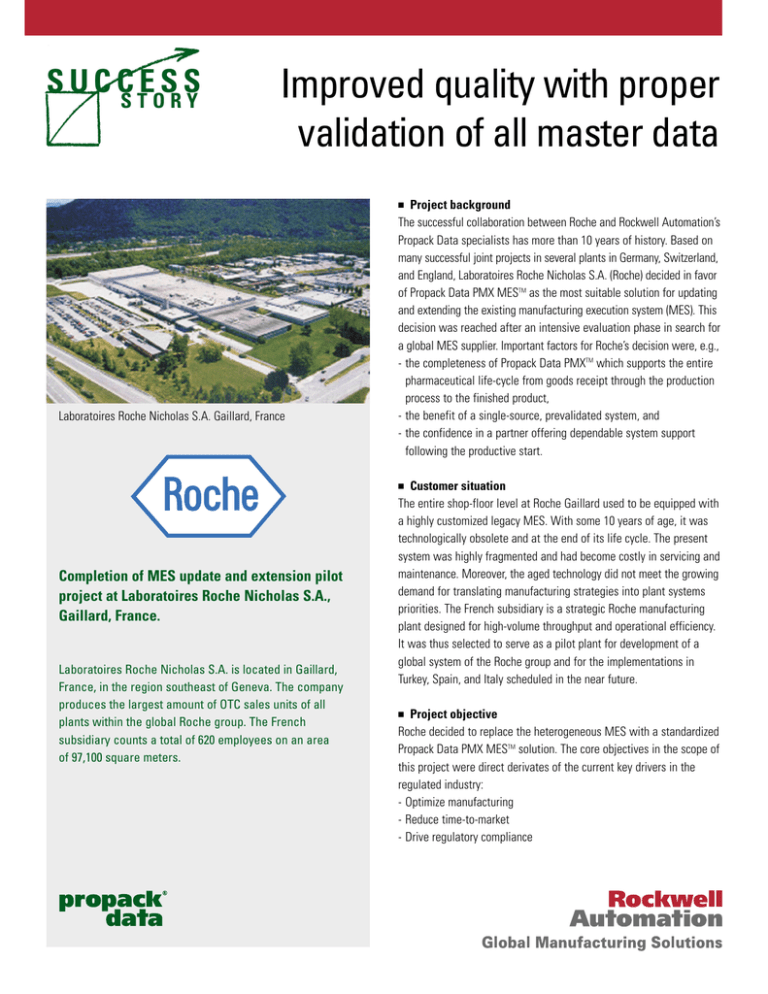

Laboratoires Roche Nicholas S.A. Gaillard, France

Customer situation

The entire shop-floor level at Roche Gaillard used to be equipped with

a highly customized legacy MES. With some 10 years of age, it was

technologically obsolete and at the end of its life cycle. The present

system was highly fragmented and had become costly in servicing and

maintenance. Moreover, the aged technology did not meet the growing

demand for translating manufacturing strategies into plant systems

priorities. The French subsidiary is a strategic Roche manufacturing

plant designed for high-volume throughput and operational efficiency.

It was thus selected to serve as a pilot plant for development of a

global system of the Roche group and for the implementations in

Turkey, Spain, and Italy scheduled in the near future.

■

Completion of MES update and extension pilot

project at Laboratoires Roche Nicholas S.A.,

Gaillard, France.

Laboratoires Roche Nicholas S.A. is located in Gaillard,

France, in the region southeast of Geneva. The company

produces the largest amount of OTC sales units of all

plants within the global Roche group. The French

subsidiary counts a total of 620 employees on an area

of 97,100 square meters.

Project objective

Roche decided to replace the heterogeneous MES with a standardized

Propack Data PMX MESTM solution. The core objectives in the scope of

this project were direct derivates of the current key drivers in the

regulated industry:

- Optimize manufacturing

- Reduce time-to-market

- Drive regulatory compliance

■

With the new integrated system, Roche Gaillard aimed at automated

planning, management, and traceability support in the manufacturing

area. Y2000 and GMP compliance were important issues as well as

version control, configurable access, and audit trail. A complete

interface to SAP R/3 as well as to the existing production facilities

was also planned to be implemented in the course of the project.

Project Procedure

The general project started in 2000. After Roche had submitted the

general requirements, a detailed conception was developed in close

cooperation with Propack Data specialists. The general project

schedule was subdivided in two stages starting in April 2001 and

ending in November 2002.

■

Stage I: Rockwell Automation’s Propack Data specialists started the

project with the preparation of appropriate user requirements specifications and the general project plan. Further documents such as detailed

procedures and reports for system tests and acceptance followed.

These documents provided a solid basis for targeted execution of the

individual implementation steps and reliable validation of the system

components.The following functionalities were realized during stage I:

- Complete SAP interface with the support of the IT department

- Propack Data PMX Recipe MESTM for version-controlled management

of pharmaceutical recipes and the complete master data on

shop-floor level

- Propack Data PMX Schedule MESTM for comfortable support of

SAP R/3 rough-cut capacity planning as a basis for finite scheduling

along the entire production chain from weighing through packaging

With the approval of the functional and technical specifications (FTS)

including the entire software qualification, stage I was completed.

Operation started in January 2002.

Stage 2: The second project stage focused on the implementation of

process-related functionality. The following function sets were

integrated during this stage:

- Propack Data PMX Warehouse MESTM for material handling and

warehouse control with an interface to warehouse automation

which processes transportation, storage, and removal orders.

- Propack Data PMX Dispense MESTM for weighing and dispensing

- Propack Data PMX Visual MESTM for evaluating all production data,

creating batch documents, for order processing and line monitoring

www.propack-data.com

with an interface to the automated production facilities

- Deviation handling

- GMP-compliant material flow control (MFC)

In addition to the technological solutions and the validation services, the

Propack Data team provided continuous onsite support, e.g., knowledge

transfer, key user training, and data migration. Prior to commissioning

of the general system in November 2002, the Propack Data team

conducted accurate system tests and acceptance procedures in order

to secure a successful start.

Project Success

Throughout the entire project, the Propack Data team collaborated closely

with the responsible Roche staff and carefully considered the actual

and planned system states in order to develop the most suitable solution.

Since commissioning on Nov. 12, 2002, the new Propack Data PMX MESTM

is running without any major bugs at Roche Gaillard. According to the

Roche Global Global MES steering committee meeting and the Roche

Global MES Manager Mr. Robert Fretz, Roche is very satisfied to have

achieved almost 100% of the former delivery capability after only

10 weeks. “The new system has helped improve our workflow considerably", says Mr. Michel Doucet, Production Manager at Laboratoires

Roche Nicholas S.A., Gaillard. “Management of user access, general

planning, and the traceability of actions, for example, have become

much easier. The project was very complex taking into account the

switch from our existing MES system to Propack Data PMX MESTM,

the validation according to the Computer System Validation (CSV)

guidelines, and the training of more than 200 people. The keys of

success of this project were the high level of professionalism of

Propack Data, the experience of Gaillard concerning MES, and the team

spirit between Propack Data and Roche Gaillard to drive this project.

Furthermore, we expect that the enhanced functionality, the possibility

of evolution, and regulatory consistency will not increase total IT costs”.

■

Summary

As a result of this extensive MES pilot project in Gaillard and the MES

implementation in Turkey scheduled for completion in Sep. 2003, Roche

has selected Rockwell Automation as global MES vendor.

■

Authors:

Michel Doucet, Production Manager, Lab. Roche Nicholas S.A.

Fred Schiffmacher, Director Services EMEA, Propack Data GmbH

www.rockwellautomation.com

Corporate Headquarters:

Rockwell Automation, 777 East Wisconsin Avenue, Suite 1400, Milwaukee, WI, 53202-5302 USA, Tel. (1) 414 212 5200, Fax (1) 414 212 5201

Headquarters for Allen-Bradley Products, Rockwell Software Products and Global Manufacturing Solutions

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel. (1) 414 382 2000, Fax (1) 414 382 4444

Headquarters for Dodge and Reliance Electric Products

Americas: Rockwell Automation, 6040 Ponders Court, Greenville, SC 29615-4617 USA, Tel. (1) 864 297 4800, Fax (1) 864 281 2433

Headquarters Worldwide for Propack Data, A Rockwell Automation Business

Propack Data Gmb, Vincenz-Priessnitz-Str. 1, 76131 Karlsruhe, Germany, Tel. (49) 721 9650-6, Fax (49) 721 9650-888, contact@propack-data.com

Headquarters for Americas

2000 Regency Parkway, Suite 675, Cary, NC 27511 USA, Tel. (1) 919 465 1741, Fax (1) 919 465 1742, contact.us@propack-data.com

Headquarters for Asia Pacific

Rockwell Automation, 55 Newton Road, #11/02 Revenue House, Singapore 307987, Tel. (65) 6356 9077, Fax (65) 6356 9011,

contact.asia@propack-data.com

© Propack Data 0013-1503-ROCHE-0703US All rights reserved. Printed in Germany