our catalogue - EL.PI. CAST

advertisement

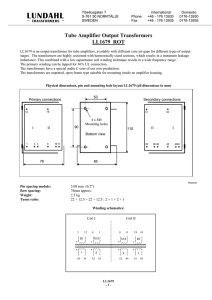

english EL.PI. CAST-RESIN CAST RESIN DISTRIBUTION TRANSFORMERS Stemming from the experience of Elettromeccanica Piossasco, established in 1962, EL.PI. CAST-RESIN, its subsidiary, launched in 2010 the manufacture of cast resin transformers. Thanks to its recent establishment EL.PI. CAST-RESIN can count on state-of-the art machinery to ensure the manufacture of transformers with the highest standards of efficiency. 2 Standard features • • • • • • • • • • • • • • • • • • DATA PLATE JUNCTION BOX PT100 TEMPERATURE SENSORS primary voltage: up to 24kV; secondary voltage: up to kV 0,690; insulation class: up to kV 24; windings configuration (from kVA100 to kVA 3150): delta/star with neutral (other upon request); vector group: Yyn0, Dyn11, Dyn5 (other upon request); frequency: 50Hz; core assembled with layers of grain-oriented steel foil; encapsulated aluminum primary winding; pre-impregnated aluminum secondary winding; primary voltage tap changers; LV terminal plates; bi-directional rollers; lifting lugs; earthing terminal; n. 3 PT100 temperature sensors connected in a junction box; electronic temperature monitoring unit; data plate; protection grade IP 00. NEUTRAL TERMINAL LV TERMINALS LIFTING LUGS MV TERMINALS VOLTAGE REGULATION MV DELTA CONNECTION CORE LV WINDINGS MV WINDINGS BI-DIRECTIONAL ROLLERS EARTHING TERMINAL 3 Core The core is manufactured with first class Carlite insulated grain-oriented magnetic steel foil. Cutting is performed at 45° with CNC machines ensuring precision and quality. Cores are mounted on special benches with STEP-LAP system, through clamps and runners to ensure flawless overlapping of aluminum sheets. Core clamping is ensured by sturdy steel sections. 4 Medium voltage windings Windings feature a circular section and are coaxial to core columns. MV windings are made with an aluminum strip encapsulated in epoxy resin. This process, in addition to its dielectric qualities, ensures excellent fire resistance and immediate self-extinguishing properties as well as high resistance to industrial pollution. Low voltage windings Windings feature a circular section and are coaxial to core columns. LV windings are made with an aluminum conductor strip featuring the same height as the winding and a class F insulation strip, then they are vacuum impregnated in epoxy resin and finally painted with red insulating paint. Terminals are built with extruded aluminum flat bars welded to the conductor along its entire width thus ensuring minimum contact resistance. 5 Epoxy resin encapsulation plant Winding supports and spacers MV and LV windings are secured to transformers’ core frames by special insulating supports and spacers made in PBT and fibreglass. Such supports also ensure windings’ coaxiality in all working conditions. 6 Environmental and climatic classes Dry-transformer environmental working conditions are classified by humidity, condensation, pollution and ambient temperature. These factors are crucial not only once the transformers are operational but also during storage prior to installation. Our transformers are built in compliance with the following environmental standards: E2 Environmental class Transformers withstand a consistent condensation or intense pollution or a combination of both phenomena; C2 Climatic class Outdoor installation (in a protection enclosure) but not under direct weather conditions. Transformers are suitable for operation, transport and storage at ambient temperature down to -25°C; F1 Fire class Transformers subject to fire hazard with reduced flammability with self-extinguishing characteristics. International standards Our transformers are tested in compliance with CEI EN 60076-11. Tests are performed both during and at the end of the production process, according to working instructions and technical department instructions. Before being put on the market all transformers are tested in compliance with CEI/IEC standards and test reports are duly completed. Final tests, performed in our test room, include all compliance tests (routine tests) as per standard CEI EN 60076-11. 7 Tests and trials Our transformers, before being put in the market, are all tested in compliance with CEI EN 60076-11 standard with the following routine tests: • voltage ratio measurement; • polarity and connection group test; • insulation test with applied voltage; • insulation test with induced voltage; • losses and no load current measurement; • winding resistance at room temperature measurement; • measurement of losses and short circuit voltage at required reference temperature; • partial discharge measurement. It is also possible, upon customers’ request (with an extra charge) to run or repeat both routine tests and type tests, in addition to special tests, at accredited external boards facilities (as, for example CESI – Milan Italy). After-sale assistance is also ensured. 8 Customization • • • • • • • • • • • • • • • • • • • primary voltage up to kV36; dual primary voltage; dual secondary voltage; multiple secondary voltage (e.g. for use in photovoltaic systems); copper primary and secondary windings; non-standard losses and voltages (upon request); non-standard connections and vector groups (upon request); 60Hz frequency; electrostatic shield between primary and secondary windings; MV outer cone elastimold type separable connectors; air forced fans; forced air cooling electronic monitoring unit; digital output RS485 module or analog output 4-20mA module; infrared temperature monitoring system (recommended for MV/MV transformers); IP 31 protection grade panel enclosure, mounted on the transformer – RAL 9002 paint; tropicalization up to +55°C (for installation in countries such as United Arab Emirates, African countries etc.); customization for use in arctic weather conditions with temperatures down to -60° C (e.g. Russia); surge protection kit (strongly recommended in case of connection to overhead power lines or lines without surge protection); other features upon request. 9 Tree-phase cast-resin transformers 24 kV Series (Insulation classes: Primary winding 24/50/95 kV - Secondary winding 1,1 - 3 kV) 100 125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 2500 3150 530 580 650 780 880 1000 1200 1320 1650 2000 2400 2750 3000 3900 4400 4200 5000 2,0 1,8 1,6 1,5 1,4 1,2 1,1 1,0 0,9 0,8 0,7 0,6 0,6 0,5 0,4 0,4 0,3 2150 2550 2900 3400 3580 4250 5090 5900 6950 8600 10800 12000 14250 18000 22500 23200 24500 2400 2800 3250 3800 4000 4750 5700 6600 7800 9600 12100 13500 16000 20000 25200 25980 27300 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 8 8 LpA (dB) 48 49 52 53 54 55 56 57 59 60 61 62 63 65 66 65 67 LwA Weight Length Width Height Wheelbase (dB) (Kg) (mm) (mm) (mm) (mm) 55 57 62 63 64 66 67 68 70 71 73 74 75 77 79 78 81 600 700 800 900 1050 1150 1350 1500 1700 2000 2400 2850 3350 4000 5000 4800 5800 1100 1160 1250 1250 1350 1400 1400 1460 1460 1500 1550 1650 1700 1800 2000 2000 2100 600 600 600 600 600 750 750 750 850 850 1000 1000 1000 1300 1300 1300 1300 1200 1260 1320 1340 1360 1450 1560 1600 1680 1800 1910 2040 2200 2300 2350 2310 2370 520 520 520 520 520 670 670 670 670 670 820 820 820 1070 1070 1070 1070 17,5 kV Series (Insulation classes: Primary winding 17,5/38/75 kV - Secondary winding 1,1 - 3 kV) Rated No load No load Losses at Losses at Shortcircuit Power losses current 75° 120° impedance (kVA) (W) % (W) (W) % 100 125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 2500 3150 500 540 620 750 850 920 1150 1200 1550 1850 2200 2550 2850 3700 3800 3700 4900 1,9 1,7 1,6 1,5 1,4 1,2 1,1 1,0 0,9 0,8 0,7 0,6 0,6 0,5 0,4 0,4 0,3 2050 2450 2900 3200 3550 4250 5000 6120 7050 8480 9820 11500 14000 17700 21800 22500 24000 2300 2700 3250 3600 4000 4750 5600 6850 7900 9500 11000 12800 15680 19800 24400 25200 26880 5 6 6 6 6 6 6 6 6 6 6 6 6 6 6 8 8 LpA (dB) 48 49 50 51 53 54 55 56 58 59 60 61 62 64 65 65 67 LwA Weight Length Width Height Wheelbase (dB) (Kg) (mm) (mm) (mm) (mm) 55 56 61 62 64 65 66 67 69 70 71 73 75 77 78 78 81 550 620 720 820 980 1100 1200 1400 1600 1900 2300 2650 3200 3850 4700 4600 5800 1000 1090 1160 1220 1310 1340 1280 1370 1400 1460 1520 1550 1640 1700 1920 1950 2120 600 600 600 600 600 750 750 750 850 850 1000 1000 1000 1300 1300 1300 1300 1180 1240 1280 1300 1320 1410 1520 1540 1640 1790 1910 2000 2180 2270 2290 2270 2350 520 520 520 520 520 670 670 670 670 670 820 820 820 1070 1070 1070 1070 12 kV Series (Insulation classes: Primary winding 12/28/60 kV - Secondary winding 1,1 - 3 kV) Rated No load No load Losses at Losses at Shortcircuit Power losses current 75° 120° impedance (kVA) (W) % (W) (W) % 100 125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 480 530 600 730 800 850 1100 1150 1400 1800 2150 2500 2750 3550 3800 4800 1,9 1,8 1,6 1,5 1,4 1,2 1,1 1,0 0,9 0,8 0,7 0,6 0,6 0,5 0,4 0,3 1960 2460 2960 3210 3480 4100 4900 5980 6950 8480 9820 11150 13900 16100 19650 23200 2200 2750 3300 3600 3900 4600 5500 6700 7800 9500 11000 12500 15600 18000 22000 26000 4 4 6 6 6 6 6 6 6 6 6 6 6 6 6 8 LpA (dB) 46 48 49 51 52 54 55 56 57 58 59 61 62 64 65 66 LwA Weight Length Width Height Wheelbase (dB) (Kg) (mm) (mm) (mm) (mm) 53 55 60 62 63 65 67 67 68 70 71 73 74 76 78 80 500 600 700 760 860 1000 1200 1350 1550 1850 2300 2700 3160 4000 4800 5800 980 1020 1150 1200 1200 1250 1250 1300 1400 1450 1500 1550 1640 1700 1900 2100 DATA VALID FOR ALL SIZES Partial discharges level: Insulation system class – over temperatures: Vector group: Utility frequency: 10 600 600 600 600 600 750 750 750 850 850 1000 1000 1000 1300 1300 1300 1100 1220 1200 1200 1250 1300 1400 1450 1500 1650 1800 1910 2100 2150 2200 2210 520 520 520 520 520 670 670 670 670 670 820 820 820 1070 1070 1070 < 10 pC F / F - 100 / 100 K Dyn11 50 Hz Any technical information detailed in this catalogue is not legally binding. EL.PI reserves the right to amend any specification without prior notice. Rated No load No load Losses at Losses at Shortcircuit Power losses current 75° 120° impedance (kVA) (W) % (W) (W) % Enclosures Cast resin transformers enclosures overall dimensions TYPE EP01 EP02 EP03 EP04 EP05 EP06 A 1550 1750 1850 2000 2200 2500 DIMENSIONS B H 1030 1090 1190 1290 1390 1550 1500 1710 1875 2060 2300 2635 G 520 670 670 820 820 1070 TYPE VALID ISSUE RATED POWER (KVA) PROTECTION GRADE STANDARD PAINT EP01 EP02 EP03 EP04 EP05 EP06 April 2003 April 2003 April 2003 April 2003 April 2003 June 2005 50 - 100 - 125 - 160 - 200 250 - 315 - 400 500 - 630 800 - 1000 1250 - 1600 2000 - 2500 IP31 RAL 9002 11 www.immagine3000.it EL.PI. CAST-RESIN s.r.l. SS 589 dei Laghi di Avigliana, Km 18 10040 CUMIANA (TO) - ITALY Phone +39 011 9042132 / +39 011 9042133 Fax +39 011 9065482 www.elpicastresin.com - info@elpicastresin.com