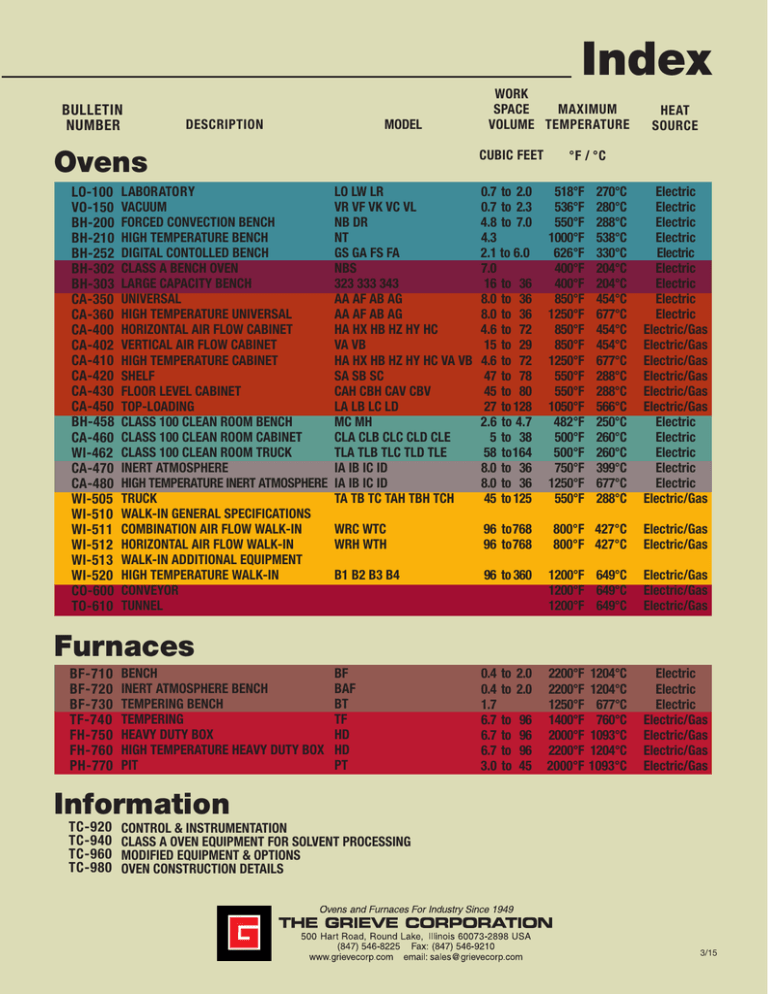

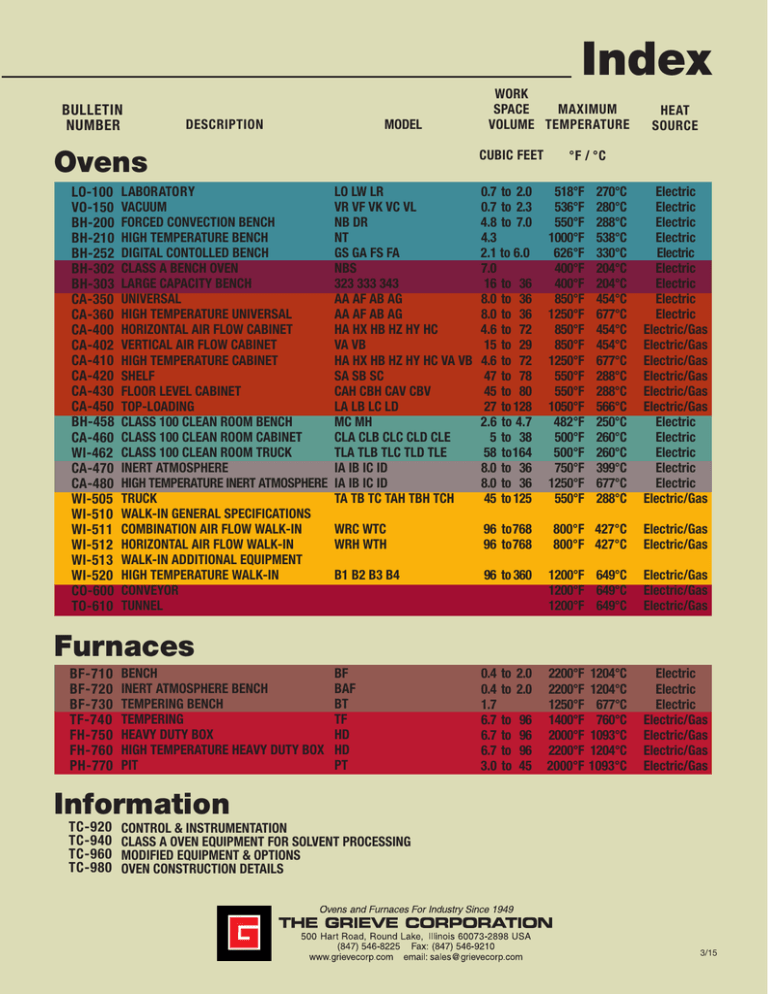

Index

BULLETIN

NUMBER

DESCRIPTION

MODEL

CUBIC FEET

Ovens

LO-100

VO-150

BH-200

BH-210

BH-252

BH-302

BH-303

CA-350

CA-360

CA-400

CA-402

CA-410

CA-420

CA-430

CA-450

BH-458

CA-460

WI-462

CA-470

CA-480

WI-505

WI-510

WI-511

WI-512

WI-513

WI-520

CO-600

TO-610

LABORATORY

VACUUM

FORCED CONVECTION BENCH

HIGH TEMPERATURE BENCH

DIGITAL CONTOLLED BENCH

CLASS A BENCH OVEN

LARGE CAPACITY BENCH

UNIVERSAL

HIGH TEMPERATURE UNIVERSAL

HORIZONTAL AIR FLOW CABINET

VERTICAL AIR FLOW CABINET

HIGH TEMPERATURE CABINET

SHELF

FLOOR LEVEL CABINET

TOP-LOADING

CLASS 100 CLEAN ROOM BENCH

CLASS 100 CLEAN ROOM CABINET

CLASS 100 CLEAN ROOM TRUCK

INERT ATMOSPHERE

HIGH TEMPERATURE INERT ATMOSPHERE

TRUCK

WALK-IN GENERAL SPECIFICATIONS

COMBINATION AIR FLOW WALK-IN

HORIZONTAL AIR FLOW WALK-IN

WALK-IN ADDITIONAL EQUIPMENT

HIGH TEMPERATURE WALK-IN

CONVEYOR

TUNNEL

WORK

SPACE

MAXIMUM

VOLUME TEMPERATURE

LO LW LR

VR VF VK VC VL

NB DR

NT

GS GA FS FA

NBS

323 333 343

AA AF AB AG

AA AF AB AG

HA HX HB HZ HY HC

VA VB

HA HX HB HZ HY HC VA VB

SA SB SC

CAH CBH CAV CBV

LA LB LC LD

MC MH

CLA CLB CLC CLD CLE

TLA TLB TLC TLD TLE

IA IB IC ID

IA IB IC ID

TA TB TC TAH TBH TCH

0.7 to 2.0

0.7 to 2.3

4.8 to 7.0

4.3

2.1 to 6.0

7.0

16 to 36

8.0 to 36

8.0 to 36

4.6 to 72

15 to 29

4.6 to 72

47 to 78

45 to 80

27 to 128

2.6 to 4.7

5 to 38

58 to164

8.0 to 36

8.0 to 36

45 to 125

WRC WTC

WRH WTH

HEAT

SOURCE

°F / °C

518°F

536°F

550°F

1000°F

626°F

400°F

400°F

850°F

1250°F

850°F

850°F

1250°F

550°F

550°F

1050°F

482°F

500°F

500°F

750°F

1250°F

550°F

270°C

280°C

288°C

538°C

330°C

204°C

204°C

454°C

677°C

454°C

454°C

677°C

288°C

288°C

566°C

250°C

260°C

260°C

399°C

677°C

288°C

Electric

Electric

Electric

Electric

Electric

Electric

Electric

Electric

Electric

Electric/Gas

Electric/Gas

Electric/Gas

Electric/Gas

Electric/Gas

Electric/Gas

Electric

Electric

Electric

Electric

Electric

Electric/Gas

96 to768

96 to768

800°F 427°C

800°F 427°C

Electric/Gas

Electric/Gas

B1 B2 B3 B4

96 to 360

1200°F 649°C

1200°F 649°C

1200°F 649°C

Electric/Gas

Electric/Gas

Electric/Gas

BF

BAF

BT

TF

HD

HD

PT

0.4

0.4

1.7

6.7

6.7

6.7

3.0

2200°F

2200°F

1250°F

1400°F

2000°F

2200°F

2000°F

Electric

Electric

Electric

Electric/Gas

Electric/Gas

Electric/Gas

Electric/Gas

Furnaces

BF-710

BF-720

BF-730

TF-740

FH-750

FH-760

PH-770

BENCH

INERT ATMOSPHERE BENCH

TEMPERING BENCH

TEMPERING

HEAVY DUTY BOX

HIGH TEMPERATURE HEAVY DUTY BOX

PIT

to 2.0

to 2.0

to

to

to

to

96

96

96

45

1204°C

1204°C

677°C

760°C

1093°C

1204°C

1093°C

Information

TC-920

TC-940

TC-960

TC-980

CONTROL & INSTRUMENTATION

CLASS A OVEN EQUIPMENT FOR SOLVENT PROCESSING

MODIFIED EQUIPMENT & OPTIONS

OVEN CONSTRUCTION DETAILS

3/15

REQUEST FOR QUOTATION

DATA SHEET

We will be pleased to review your heat processing application. Please photocopy this form,

fill in the appropriate information and send to us by mail or fax.

COMPANY NAME

ADDRESS

CITY

ATTENTION

COPY TO

REFERENCE

PHONE (

FAX

(

STATE

TITLE

TITLE

)

)

ZIP CODE

1. PROCESS

2. MATERIAL

***Size

Weight

Condition of pieces (wet) (oily) (dry)

Thickest cross section

3. FLAMMABLE SOLVENTS OR VAPORS INVOLVED IN PROCESS

Amount

gallons per batch (or per hour for continuous processing)

4. INERT ATMOSPHERE (Nitrogen) (Argon)

5. TEMPERATURE

Operating temperature

***Required dwell time at operating temperature

Maximum temperature

(Include time for parts to heat up; assume preheated equipment)

Required uniformity within workspace

6. MATERIAL HANDLING

BATCH (Shelf) (Tray) (Basket) (Fixture)

(Provide sketch & description if we are to quote on this equipment.)

Quantity of parts per batch or production rate

CONTINUOUS (Belt Conveyor) (Rotary Hearth) (Roller Hearth)

Length Load Zone

***Production Rate

Length Unload Zone

Length Cooling Zone

Pass Line

Exit Temperature from Cooling Zone

7. CLEAN ROOM/PHARMACEUTICAL

backwelded seams

front welded ground seams 1/2" radius interior corners

#4 brushed stainless steel exterior

door at both ends for pass through

door locks/interlock

HEPA fresh air inlet

HEPA exhaust filter

HEPA recirculation filter

alarms for filters/temperature

pressurizing blower

motorized intake and exhaust dampers

automation depyrogenation cycle

one pass granulation drying

8. DESIGN

Type of equipment

Similar to standard model

Work space size

Air flow (horizontal) (combination) (vertical up) (vertical down)

Special features

wide x

9. SPECIFICATIONS APPLICABLE (JIC) (FM) (IRI) (Military Specification#

deep x

high

)

10. SERVICES

Electrical Service

Volts

Phase

Hz

To be heated by (Electric) (Natural Gas) (Propane) (Steam)

11. EQUIPMENT TO BE INCLUDED IN BASE PRICE

12. EQUIPMENT TO BE INCLUDED AS OPTIONS

13. BUILDING DATA

Smallest opening through which unit must pass

wide x

high

(Don’t forget doorways, elevators & existing machinery, pipes, or ducts.)

Floor space limitations

wide x

deep

Headroom limitations

Floor or elevator load limitations

***Information which must be supplied for continuous processing such as belt conveyor or rotary hearth.

Copyright The Grieve Corporation All Rights Reserved Printed in U.S.A.

INDEX

3/15