Type W Round 3/C Mold-cured Jacket • 2000 Volts

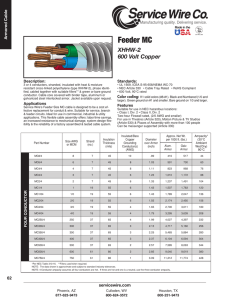

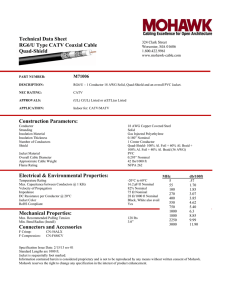

advertisement

Index 36-311 Type W (Flat) 2/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 36-314 Type W (Flat) 4/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 36-320 Type G (Flat) 2/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7 36-322 Type G-GC (Flat) 3/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9 36-431 Type W (Round) 3/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11 36-432 Type W (Round) 4/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13 36-442 Type G-GC (Round) 3/C 2kV . . . . . . . . . . . . . . . . . . . . . . . . 14-15 36-503 Type SHD-GC (Round) 3/C 2kV . . . . . . . . . . . . . . . . . . . . . . 16-17 36-504 Type SHD-PCG 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19 36-505 Type SHD-CGC 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21 36-506 Type SHD-CGC 5kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23 36-510 Type SHD (Flat) 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25 36-515 Type SHD-GC 5kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27 Type SHD-GC (Round) 3/C 2300V . . . . . . . . . . . . . . . . . . . . . . 27 36-516 Type SHD-PCG 5kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29 36-601/602/604 Type MP-GC 3/C 5-15kV (EP/CPE) . . . . . . . . . . . . . . . . . . . . 30-31 36-621/622/624 Type MP-GC 3/C 5-15kV (XLP/PVC) . . . . . . . . . . . . . . . . . . . 32-33 36-202-018 Longwall Signal Cable 2-9/C 50 Volts . . . . . . . . . . . . . . . . . . . 34 36-202-118 Underground Lighting Cable 2-9/C 110 Volts . . . . . . . . . . . . . . 35 37-119 DLO 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-37 36-501 VFD 2kV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-39 Tiger Stripes – Reflective and Standard . . . . . . . . . . . . . . . 40-41 Jacket Materials – CPE, TPU and Orange XL . . . . . . . . . . . . . . 42 El Dorado, Arkansas Made in America Safety, Training and Education . . . . . . . . . . . . . . . . . . . . . . . . 43 Cable Assemblies and Refurbishing . . . . . . . . . . . . . . . . . . 44-45 Nexans AmerCable believes the information presented throughout this catalog to be reliable and current. All information is subject to change without notice. The information listed is sapproximate, and is presented only as a guide for product selection. We make no claims or warranties for the suitability of any product for any particular application. © 2012, AmerCable Incorporated Committed to Safer, More Productive Mining Since the electrification of mines, Nexans AmerCable’s core business has been powering mine equipment. Surface or underground – Nexans AmerCable has a cable productivity solution for you. Our innovatively engineered and manufactured Tiger® Brand cable line is designed for your toughest conditions. As the leading producer of mining cables in North America, Nexans AmerCable is dedicated to producing: n cables that last longer in harsh mining environments n cables designed to help provide greater levels of safety and productivity n lowest cable cost per ton! Mining Cable Innovation n Designing insulating and jacketing materials that are more flexible with greater resistance to abrasion and moisture n Cable constructions that last longer providing reduced down time for increased production n New product development that addresses environmental, safety and cost reduction issues specific to your mining application. Operating Excellence n On-Time delivery – best in the cable industry n Standard lead-time of 8 to 10 weeks n Urgent response shipment capability of 2 to 4 weeks n Strategically located inventories throughout the major mining regions. n Nexans AmerCable is an ISO-9001 certified manufacturer Hands-on Field Support Our mine-experienced field application engineers are available 24/7 for on-site evaluation and solutions. They also conduct education and training sessions that address safety, splicing and cable handling issues. See page 47 for more information. SAVE TIME & MONEY Factory Installed Cable Assemblies See pages 46-47 for more information. mining@amercable.com www.amercable.com 1 36-311 Type W Flat 2/C Mold-cured Jacket • 600/2000 Volts Conductors Flexible tinned copper Application For use on D.C. off-track mining equipment. Especially designed for D.C. shuttle cars, drills, cutting and loading machines. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Insulation 90°C ethylene-propylene rubber (EPR) Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Reinforcement Synthetic yarn over assembly Jacket Mold-cured thermoset with cable identification via permanent marking. Standard Jacket: Black Also available: OrangeXL (Special Order) See Pages 42 for details D-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 2 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-311 • Type W Flat 2/C • 600/2000 Volts Power Conductors 36-311008 006 004 002 001 010 020 040 Size AWG 8 6 4 2 1 1/0 2/0 4/0 No. of Wires per Conductor 133 7x19 133 7x19 259 7x37 259 7x37 259 7x37 259 7x37 329 7x47 532 19x28 Insulation Thickness mils 60 60 60 60 80 80 80 80 Nominal Outside Dimensions in. 0.51 x 0.84 0.56 x 0.93 0.61 x 1.05 0.73 x 1.24 0.81 x 1.40 0.93 x 1.51 0.99 x 1.63 1.10 x 1.89 Approx. Weight lbs. per 1,000 ft. 340 440 580 850 1070 1310 1600 2300 Ampacity 1 40°C Ambient Temp 72 95 127 167 191 217 250 328 Primary Usage Recommendation Shuttle Car 1 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.030" Minor Dimension ± 0.040" Major Dimension Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 3 36-314 Type W Flat 4/C Mold-cured Jacket • 600/2000 Volts Conductors Flexible tinned copper Application For use on A.C. off-track mining equipment. Especially designed for A.C. shuttle cars, drills, cutting and loading machines. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Insulation 90°C ethylene-propylene rubber (EPR). Color coded black, white, red, green. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-33 and B-172 . Reinforcement Synthetic yarn over assembly Jacket Mold-cured thermoset with cable identification via permanent marking. Standard Jacket: Black Also available: OrangeXL (Special Order) See Pages 42 for details Square and D-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 4 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-314 • Type W Flat 4/C • 600/2000 Volts Power Conductors No. of Wires per Conductor 133 7x19 259 7x37 259 7x37 259 7x37 Size AWG 6 4 2 1 36-314006 004 002 001 Insulation Thickness mils 60 60 60 60 Nominal Outside Dimensions in. 0.68 x 1.71 0.76 x 1.91 0.82 x 2.25 0.98 x 2.54 Approx. Weight lbs. per 1,000 ft. 910 1220 1720 2240 Ampacity 40°C Ambient Temp 72 93 122 143 1 Primary Usage Recommendation Shuttle Car 1 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.050" Minor Dimension ± 0.080" Major Dimension Pump Roof Bolter Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 5 36-320 Type G Flat 2/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Ground Wire Uni-directional lay flexible tinned copper For use on D.C. off-track mining equipment. Especially designed for D.C. shuttle cars, drills, cutting and loading machines. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Reinforcement Synthetic yarn over assembly Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Insulation 90°C ethylene-propylene rubber (EPR) Jacket Mold-cured thermoset with cable identification via permanent marking. Also available: OrangeXL (Special Order) See Pages 42 for details D-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. All underground mining cables 䡲 Pennsylvania Department of Environmental Protection P-184. All underground mining cables. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 6 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-320 • Type G Flat 2/C • 2000 Volts Power Conductors Size 36-320- AWG 006 6 004 4 002 2 001 1 010 1/0 020 2/0 Grounding Conductor No. of Wires Insulation per Thickness Size Conductor mils AWG 133 7x19 60 8 259 7x37 60 7 259 7x37 60 5 259 7x37 80 4 259 7x37 80 3 329 7x47 80 2 No. of Wires per Conductor 270 6x45 180 6x30 168 6x28 168 6x28 204 6x34 246 6x41 Nominal Outside Dimensions in. 0.56 x 1.02 0.61 x 1.15 0.73 x 1.35 0.81 x 1.55 0.93 x 1.67 0.99 x 1.85 Approx. Weight Ampacity 1 lbs. per 40°C 1,000 ft. Ambient Temp 500 95 660 127 990 167 1230 191 1540 217 1870 250 1 Ampacity – Based on continuous duty at 90°C conductor temperature. Primary Usage Recommendation Shuttle Car Roof Bolter Tolerances – ± 0.030" Minor Dimension ± 0.040" Major Dimension Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 7 36-322 Type G-GC Flat 3/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Ground Wire Uni-directional lay flexible tinned copper with green covering For use on A.C. off-track mining equipment. Especially designed for A.C. shuttle cars, drills, cutting and loading machines. Recommended maximum continuous conductor temperature is 90°C. Ground Check Wire Uni-directional lay flexible tinned copper with yellow insulation Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Reinforcement Synthetic yarn over assembly Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Insulation 90°C ethylene-propylene rubber (EPR) Jacket Mold-cured thermoset with cable identification via permanent marking. Also available: OrangeXL (Special Order) See Pages 42 for details Square and D-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 8 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-322 • Type G-GC Flat 3/C • 2000 Volts Power Conductors Size 36-322- AWG 006 6 004 4 002 2 001 1 Grounding Conductor No. of Wires Insulation per Thickness Size Conductor mils AWG 133 7x19 60 8 259 7x37 60 7 259 7x37 60 5 259 7x37 80 4 No. of Wires per Conductor 270 6x45 180 6x30 168 6x28 168 6x28 Nominal Outside Dimensions in. 0.67 x 1.69 0.75 x 1.89 0.81 x 2.23 0.97 x 2.48 Approx. Weight lbs. per 1,000 ft. 940 1240 1690 2170 Ampacity 1 40°C Ambient Temp 79 104 138 161 Primary Usage Recommendation Shuttle Car 1 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.050" Minor Dimension ± 0.080" Major Dimension Pump Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Roof Bolter Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 9 36-431 Type W Round 3/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Especially suitable for general use where bare grounding conductors are not required or desired. Recommended maximum continuous conductor temperature is 90°C. Tape Non-conducting Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Insulation 90°C ethylene-propylene rubber (EPR) Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 42 for jacket color options. See Page 40-41 for Tiger Stripe options Round-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 10 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-431 • Type W Round 3/C • 2000 Volts Power Conductors 36-431008 006 004 002 001 010 020 030 040 Size AWG 8 6 4 2 1 1/0 2/0 3/0 4/0 No. of Wires per Conductor 133 133 259 259 259 266 323 418 532 Insulation Thickness mils 60 60 60 60 80 80 80 80 80 Nominal Outside Dimensions in. 0.91 1.01 1.17 1.34 1.51 1.65 1.75 1.89 2.04 Approx. Weight lbs. per 1,000 ft. 550 730 1020 1430 1800 2140 2580 2922 3800 Ampacity 2 40°C Ambient Temp 59 79 104 138 161 186 215 249 287 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. 2 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.030" 8-1 AWG ± 0.040" 1/0 - 2/0 AWG ± 0.050" 3/0 - 4/0 AWG Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 11 36-432 Type W Round 4/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Especially suitable for use with mobile mining equipment such as continuous miners, drills, cutters, loading machines and AC shuttle cars. Type W is for applications where bare grounding conductors are not required or desired. Recommended maximum continuous conductor temperature is 90°C. Tape Non-conducting Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Insulation 90°C ethylene-propylene rubber (EPR) Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. Pure Integral Fill for greater torsion resistance See Page 42 for jacket color options. See Page 40-41 for Tiger Stripe options Round-shaped cross-section Cable shown with optional Tiger Stripes. See page 46. Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 12 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-432 • Type W Round 4/C • 2000 Volts Power Conductors 36-432008 006 004 002 001 010 020 030 040 Size AWG 8 6 4 2 1 1/0 2/0 3/0 4/0 No. of Wires per Conductor 133 133 259 259 259 266 323 418 532 Insulation Thickness mils 60 60 60 60 80 80 80 80 80 Nominal Outside Dimensions in. 0.99 1.10 1.27 1.48 1.68 1.79 1.93 2.07 2.26 Approx. Weight lbs. per 1,000 ft. 670 890 1250 1800 2270 2680 3200 3627 4650 Ampacity 2 40°C Ambient Temp 54 72 93 122 143 165 192 221 255 Primary Usage Recommendation Shuttle Car Continuous Miner 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. 2 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.030" 8-1 AWG ± 0.040" 1/0 - 2/0 AWG ± 0.050" 3/0 - 4/0 AWG Pump Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Reel Correction Factors For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 13 36-442 Type G-GC Round 3/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application 2 Ground Check Conductor Flexible tinned copper with yellow polypropylene insulation Insulation 90°C ethylene-propylene rubber (EPR) Tape Non-conducting Especially suitable for use with mobile mining equipment such as continuous miners, drills, cutters, loading machines, AC shuttle cars and pumps. Type G-GC is for applications where grounding conductors and a ground check conductor are required. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184 MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Ground Wires Flexible tinned copper Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent Pure marking. Integral Fill Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. for greater torsion resistance See Page 42 for jacket color options. Pump Application Construction Also available with Extra-Tough Thermoplastic Polyurethane (TPU) jacket for extremely abrasive environments! See Pg. 42 See Page 40-41 for Tiger Stripe options Round-shaped cross-section 36-442 is available with insulated grounds for pump applications that require this specification. Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 14 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-442 • Type G-GC Round 3/C • 2000 Volts Power Conductors Grounding Conductors Nominal No. of Wires Insulation No. of Wires Outside Thickness Size Dimensions per per Size mils in. 36-442- AWG Conductor AWG Conductor 0.97 60 49 133 10 008 8 1.05 60 49 259 10 006 6 1.19 60 133 259 8 004 4 1.34 60 133 259 7 002 2 1.51 80 259 6 133 001 1 1.65 80 266 5 133 010 1/0 1.75 80 259 323 4 020 2/0 1.89 80 259 418 2 030 3/0 2.04 80 259 532 2 040 4/0 2.39 95 259 627 2 250 250 2.68 95 266 888 1/0 350 350 3.03 95 323 1221 500 500 2/0 Approx. Weight Ampacity 3 lbs. per 40°C 1,000 ft. Ambient Temp 600 59 750 79 1070 104 1480 138 1890 161 2340 186 2750 215 3377 249 3980 287 5000 320 6750 394 8900 487 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. Primary Usage Recommendation Shuttle Car Continuous Miner Roof Bolter 2 Ground Check Conductor – 10 AWG (minimum 49 strand 7x7) ground check conductor on 8 AWG through 2 AWG cable. 8 AWG (minimum 133 strand 7x19) ground check conductor on 1 AWG through 4/0 AWG cable. 6 AWG (minimum 133 strand 7x19) ground check conductor on 250 kcmil and larger cable. 3 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – ± 0.030" ± 0.040" ± 0.050" ± 0.060" 8-1 AWG 1/0 - 2/0 AWG 3/0 - 4/0 AWG 250 - 500 kcmil Correction Factors Reel Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 For use with ampacities when one or more layers of cable are wound on a reel. Cables must be derated to prevent over heating on reel.1 1 Pump Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 Number of Layers Multiplying Correction Factors 1 2 3 4 0.85 0.65 0.45 0.35 See Page 13 for AWG/Metric Cross Reference 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 15 36-503 Type SHD-GC Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Ground Check Conductor 2 Flexible tinned copper with yellow polypropylene insulation Ground Wires Flexible tinned copper Tape Non-conducting Insulation Shielding Tinned copper and color coded nylon braid Insulation 90°C ethylene-propylene rubber (EPR) Separator Tape Insulation 90°C ethylene-propylene rubber (EPR) Pure Integral Fill for greater torsion resistance Jacket3 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. Heavy duty portable power cable for use in circuits not exceeding 2,000 volts. Designed for applications such as longwall shearers, continuous miners, loaders, drills, conveyors, pumps and mobile equipment where grounding conductors, a ground check conductor and metallic shielding are required. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58. See Page 42 for jacket color options. Also available with Extra-Tough Thermoplastic Polyurethane (TPU) jacket for extremely abrasive environments! See Pg. 42 See Page 40-41 for Tiger Stripe options Round-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. 16 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-503 • Type SHD-GC 3/C • 2000 Volts Power Conductors Grounding Conductors Nominal Outside No. of Wires Insulation No. of Wires Jacket Thickness Dimensions per Thickness Size per Size mils in. mils 36-503- AWG Conductor AWG Conductor 70 155 1.29 133 10 49 006 6 70 155 1.40 259 8 133 004 4 70 170 1.59 259 6 133 002 2 80 190 1.76 259 5 133 001 1 190 1.86 266 80 4 259 010 1/0 205 2.00 323 80 3 259 020 2/0 80 205 2.13 418 2 259 030 3/0 220 2.31 80 259 532 1 040 4/0 220 95 2.51 266 627 1/0 250 250 235 95 2.81 323 888 2/0 350 350 265 95 3.19 532 1221 4/0 500 500 Primary Usage Approx. Recommendation Weight Ampacity 1 lbs. per 40°C 1,000 ft. Ambient Temp 1160 93 1490 122 Continuous 2000 159 Miner 2450 184 2840 211 3400 243 3680 279 Roof 4860 321 Bolter 5950 355 7400 435 10100 536 1 Ampacity – Based on continuous duty at 90°C conductor temperature. 2 Ground Check Conductor – 10 AWG (minimum 49 strand 7x7) ground check conductor on 8 AWG through 2 AWG cable. 8 AWG (minimum 133 strand 7x19) ground check conductor on 1 AWG through 4/0 AWG cable. 6 AWG (minimum 133 strand 7x19) ground check conductor on 250 kcmil and larger cable. 3 Jacket – Extra-Heavy-Duty (EHD) CPE jacket. Black is standard. Colored EHD CPE jackets available upon request. See page 42. Tolerances – ± 5% of nominal outside diameter Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 1 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 Longwall Miner AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 Pump Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 17 36-504 Type SHD-PCG • Longwall Mold-cured Jacket • 2000 Volts Insulation 90°C ethylenepropylene rubber (EPR) Conductors Flexible tinned copper Control Group 3 Conductors Flexible tinned copper ethylene polypropylene rubber insulation color coded black, white, red and an overall thermosetting jacket Application Tape Non-conducting Separator Tape Non-conducting Heavy duty portable power cable designed for use on longwall shearers, where three shielded power conductors, three unshielded control conductors, and a grounding conductor are required. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Insulation Shielding Tinned copper and color-coded nylon braid Ground Conductor Flexible tinned copper located in the center of the cable Pure Integral Fill Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. for greater torsion resistance 2 Jacket Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 42 for jacket color options. Round-shaped cross-section Photo courtesy DBT America Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 18 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-504 • Type SHD-PCG Longwall • 2000 Volts Power Conductors Size 36-504- AWG 020 2/0 030 3/0 040 4/0 Grounding Conductors No. of Wires per Size Conductor AWG 323 2 418 1 532 1/0 Control Conductors Nominal No. of Wires No. of Wires Outside per Size per Dimensions Conductor AWG Conductor in. 246 133 2.23 8 258 8 133 2.32 426 6 133 2.67 Primary Usage Approx. Recommendation Weight Ampacity 1 lbs. per 40°C 1,000 ft. Ambient Temp 3510 243 4075 279 4990 321 Longwall Miner 1 Ampacity – Based on continuous duty at 90°C conductor temperature. 2 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. See page 42. Tolerances – ± 5% of nominal outside diameter Factory Installed Cable Assemblies SAVE TIME & MONEY See pages 44-45 for more information. Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 19 36-505 Type SHD-CGC 3/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Ground Check Conductor 2 Flexible tinned copper with yellow insulation located in the center of the cable Tape Non-conducting Separator Tape Non-conducting Insulation Shielding Tinned copper and colorcoded nylon braid Ground Wires Flexible tinned copper Heavy duty portable power cable for use in circuits not exceeding 2,000 volts. Designed for applications such as longwall shearers, continuous miners, loaders, drills, conveyors, pumps, and other mobile equipment requiring grounding conductors, where a ground check conductor, and metallic shielding are required. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Insulation 90°C ethylene-propylene rubber (EPR) Pure Integral Fill 1 Jacket Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. for greater torsion resistance Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. See Page 42 for jacket color options. Also available with Extra-Tough Thermoplastic Polyurethane (TPU) jacket for extremely abrasive environments! See Pg. 42 See Page 40-41 for Tiger Stripe options Round shaped cross-section Photo courtesy Eickhoff Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 20 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-505 • Type SHD-CGC 3/C • 2000 Volts Power Conductors Grounding Conductors Nominal No. of Wires Insulation No. of Wires Jacket Outside Size per Thickness Size per Thickness Dimensions 36-505- AWG Conductor mils AWG Conductor mils in. 80 133 205 2.09 020 2/0 323 5 418 80 259 205 2.21 030 3/0 4 532 80 259 220 2.36 040 4/0 3 888 95 259 250 2.81 350 350 1 Primary Usage Approx. Recommendation Weight Ampacity 3 lbs. per 40°C 1,000 ft. Ambient Temp 3400 243 3934 279 Longwall Miner 4860 321 7400 435 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. See page 42. 2 Ground Check Conductor – 16 AWG tinned copper conductor, designed to withstand extreme flexing and be extensible, insulated with yellow polypropylene 3 Ampacity – Based on continuous duty at 90°C conductor temperature. Continuous Miner Tolerances – ± 5% of nominal outside diameter Factory Installed Cable Assemblies SAVE TIME & MONEY See pages 44-45 for more information. Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 21 36-506 Type SHD-CGC 3/C Mold-cured Jacket • 5000 Volts Conductors Flexible tinned copper Application Ground Check Conductor 2 Flexible tinned copper with yellow insulation located in the center of the cable Strand Shield Semi-conducting layer Insulation Shielding Tinned copper and colorcoded nylon braid Ground Wires Flexible tinned copper Insulation 90°C ethylene-propylene rubber (EPR) Heavy duty high voltage portable power cable for use in circuits not exceeding 5000 volts. Designed for applications such as longwall miners, continuous miners, conveyors, pumps, and other mobile equipment requiring grounding conductors, a ground check conductor, and metallic shielding overall. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 42 for jacket color options. Also available with Extra-Tough Thermoplastic Polyurethane (TPU) jacket for extremely abrasive environments! See Pg. 42 See Page 40-41 for Tiger Stripe options Round-shaped cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. 22 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-506 • Type SHD-CGC 3/C • 5000 Volts Power Conductors Grounding Conductors Nominal No. of Wires Insulation No. of Wires Jacket Outside Size per Thickness Size per Thickness Dimensions 36-506- AWG Conductor mils AWG Conductor mils in. 110 133 220 2.200 020 2/0 323 5 418 110 259 235 2.360 030 3/0 4 532 110 259 235 2.500 040 4/0 3 888 120 259 265 2.950 350 350 1 Primary Usage Approx. Recommendation Weight Ampacity 3 lbs. per 40°C 1,000 ft. Ambient Temp 3716 243 4130 279 Continuous Miner 5190 321 7571 435 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. See page 42. 2 Ground Check Conductor – 16 AWG tinned copper conductor, designed to withstand extreme flexing and be extensible, insulated with yellow polypropylene. 3 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – +8%/-5% of nominal outside diameter Factory Installed Cable Assemblies SAVE TIME & MONEY See pages 44-45 for more information. Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 Longwall Miner AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 23 36-510 Type SHD Flat 3/C Mold-cured Jacket • 2000 Volts Conductors Flexible tinned copper Application Ground Wires Flexible tinned copper covered with semiconductive thermoset compound Separator Tape Insulation 90°C ethylene-propylene rubber (EPR) Heavy duty portable power cable for use in circuits not exceeding 2,000 volts. Especially designed for use on continuous miners requiring grounding conductors and metallic shielding over each conductor. Recommended maximum continuous conductor temperature is 90°C. Insulation Shielding Tinned copper and textile braid Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Reinforcement Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Jacket Mold-cured thermoset with cable identification via permanent marking. Cross-section Photo courtesy Joy Mining Equipment Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 24 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-510 • Type SHD Flat 3/C • 2000 Volts Power Conductors Grounding Conductors Nominal No. of Wires Insulation No. of Wires Outside Size per Thickness Size per Dimensions 36-510- AWG Conductor mils AWG Conductor in. 020 2/0 329 7x47 80 3 204 6x34 1.205 x 2.970 Approx. Weight Ampacity 1 lbs. per 40°C 1,000 ft. Ambient Temp 3600 243 Primary Usage Recommendation 1 Ampacity – Based on continuous duty at 90°C conductor temperature. Continuous Miner Jacket – Extra-Heavy-Duty black neoprene is standard. Tolerances – ± 0.050 inch minor dimension ± 0.080 inch major dimension Factory Installed Cable Assemblies SAVE TIME & MONEY See pages 44-45 for more information. Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 25 36-515 Type SHD-GC 3/C Mold-cured Jacket • 5000 Volts Application Conductors Flexible tinned copper Ground Check Conductor 2 Flexible tinned copper with yellow polypropylene insulation Tape Non-conducting Insulation Shielding Tinned copper and color coded nylon braid Strand Shield Semi-conducting layer Ground Wires Flexible tinned copper Insulation 90°C ethylene-propylene rubber (EPR) Assembly Taped core Separator Tape Heavy duty portable power cable for use in circuits not exceeding 5,000 volts (see next page for continuous miner circuit requirements exceeding 2000 volts). Designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58. Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. Tiger® Brand Cable meets or exceeds ASTM B-172 and B-33. See Page 42 for jacket color options. Also available with Extra-Tough Thermoplastic Polyurethane (TPU) jacket for extremely abrasive environments! See Pg. 42 See Page 40-41 for Tiger Stripe options Round-shaped cross-section Tiger ® Brand cables come in six colors for safe, easy circuit identification. See page 42 for details. Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -50°C Type SHD-GC, SHD-BGC up to 25kV Type W, G, G-GC, G-BGC up to 2kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 26 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-515 • Type SHD-GC 3/C • 5000 Volts Power Conductors Grounding Conductors Nominal Outside No. of Wires Insulation No. of Wires Jacket Thickness Dimensions per Thickness Size per Size mils in. mils 36-515- AWG Conductor AWG Conductor 110 185 1.56 133 10 49 006 6 110 185 1.68 259 8 133 004 4 110 205 1.87 259 6 133 002 2 110 205 1.95 259 5 133 001 1 220 2.08 266 110 4 259 010 1/0 220 2.20 323 110 3 259 020 2/0 110 235 2.36 418 2 259 030 3/0 235 2.50 110 259 532 1 040 4/0 250 120 2.69 266 627 1/0 250 250 265 120 2.95 323 888 2/0 350 350 280 120 3.31 532 1221 4/0 500 500 1 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. See page 42. 2 Ground Check Conductor – 8 AWG (minimum 133 strand 7x19) ground check conductor on 6 AWG through 4/0 AWG cable. Primary Usage Approx. Recommendation Weight Ampacity 3 lbs. per 40°C 1,000 ft. Ambient Temp 1560 93 1920 122 2500 159 Longwall Miner 2860 184 3390 211 3830 243 4418 279 Continuous 5300 321 Miner 6450 355 7880 435 10440 536 Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 6 AWG (minimum 133 strand 7x19) ground check conductor on 250 kcmil and larger cable. 3 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – +8%/-5% of nominal outside diameter Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 1 2300V Continuous Miner Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 See Page 13 for AWG/Metric Cross Reference Applications Heavy duty orange/green jacketed portable power cable for use in continuous miner circuits exceeding 2,000 volts. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58. 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 27 36-516 Type SHD-PCG • Longwall Mold-cured Jacket • 5000 Volts Insulation 90°C ethylenepropylene rubber (EPR) Conductors Flexible tinned copper Control Group 3 Conductors Flexible tinned copper ethylene polypropylene rubber insulation color coded black, white, red and an overall thermosetting jacket Application Tape Non-conducting Heavy duty portable power cable designed for use on longwall shearers, where three shielded power conductors, three unshielded control conductors, and a grounding conductor are required. Recommended maximum continuous conductor temperature is 90°C. Strand Shield Cable carries “P-184-MSHA” marking indicating Semi-conducting acceptance as flame resistant by the Pennsylvania layer Separator Tape Non-conducting Department of Environmental Protection and the Mine Safety and Health Administration. Insulation Shielding Tinned copper and color-coded nylon braid Pure Integral Fill Ground Conductor Flexible tinned copper located in the center of the cable for greater torsion resistance Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-172 and B-33. Jacket2 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 42 for jacket color options. Round-shaped cross-section Photo courtesy 20 Mile Coal Mine Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 28 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-516 • Type SHD-PCG 3/C • 5000 Volts Power Conductors Size 36-516- AWG 002 2 010 1/0 020 2/0 030 3/0 040 4/0 Grounding Conductors No. of Wires per Size Conductor AWG 259 4 266 3 323 2 418 1 532 1/0 Control Conductors Nominal No. of Wires No. of Wires Outside per Size per Dimensions Conductor AWG Conductor in. 168 8 133 2.03 222 8 133 2.27 246 8 133 2.45 259 8 133 2.58 426 6 133 2.76 Primary Usage Approx. Recommendation Weight Ampacity 1 lbs. per 40°C 1,000 ft. Ambient Temp 2769 159 3571 211 Longwall Miner 3774 243 4752 279 6030 321 1 Ampacity – Based on continuous duty at 90°C conductor temperature. 2 Jacket – Extra-Heavy-Duty (EHD) black CPE is standard. Colored EHD CPE jackets available upon request. See page 42. Tolerances – +8%-5% of nominal outside diameter Factory Installed Cable Assemblies SAVE TIME & MONEY See pages 44-45 for more information. Correction Factors For ampacities for various ambient temperatures above or below 40°C.1 1 Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 .90 Tables reproduced from standards publication ICEA-S-68-516, NEMA WC-8 AWG/Metric Cross Reference AWG/ kcmil Size 22 20 18 16 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 600 750 800 1000 Area of Nearest Standard AWG/kcmil Metric Cond. mm2 in mm2 0.35 0.50 0.52 0.50 0.82 1.00 1.31 1.50 2.08 2.50 3.31 4 5.26 6 8.37 10 13.30 16 21.15 25 33.62 35 42.41 50 53.49 50 67.43 70 85.01 95 107.2 120 126.7 120 152.0 150 177.3 185 202.7 240 253.4 240 304.0 300 380.0 400 405.4 400 506.7 500 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 29 36-601/602/604 Type MP-GC 3/C • Mine Power Feeder • 5/8/15kV Mold-cured Jacket • 100% Level (Grounded) Conductors Copper Application Ground Check Conductor 8 AWG 7-wire copper with yellow polypropylene insulation Connections between units of mine distribution systems not exceeding the rated voltage when installed in duct, conduit or open air and for direct burial in wet and dry locations. Recommended maximum continuous conductor temperature is 90°C. Insulation Shielding Semi-conducting layer under copper tape (phase identification provided) Strand Shield Semi-conducting layer Insulation 90°C ethylene-propylene rubber (EPR) Ground Wires Tinned copper Cable carries “P-7K-184-MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Assembly Taped core Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-8 and B-33. Jacket1 Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 42 for jacket color options. Round-shaped cross-section Cable may be suspended vertically by using a messenger and special mechanical connectors. Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Insulated Cable Engineers Association S-75-381. Design standard for mining cables. Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 30 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 5000 Volts • 36-601 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Outside No. of Wires Insulation No. of Wires Jacket Thickness Size Thickness Dimensions Size per per mils mils in. 36-601- AWG Conductor AWG Conductor 7 90 7 110 1.42 004 4 8 7 90 6 7 110 1.56 002 2 19 90 5 7 110 1.65 001 1 19 90 4 7 110 1.76 010 1/0 19 90 3 7 110 1.88 020 2/0 19 90 1 19 140 2.14 040 4/0 37 90 1/0 19 140 2.23 250 250 140 37 90 19 2.47 350 350 2/0 140 37 90 19 2.70 500 500 4/0 Primary Usage Approx. Recommendation Weight Ampacity 2 lbs. per 40°C 1,000 ft. Ambient Temp 1441 122 1827 159 Mine 2168 184 Power Feeder 2602 211 Vertical 3010 243 Mine Power 4190 321 Feeder 4825 355 6062 435 8427 536 Horizontal 8000 Volts • 36-602 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Approx. Outside Weight Ampacity 2 No. of Wires Insulation No. of Wires Jacket Thickness Dimensions lbs. per per Thickness Size per Size 40°C mils in. 1,000 ft. Ambient Temp mils 36-602- AWG Conductor AWG Conductor 110 1608 115 7 1.54 004 4 7 8 122 110 1919 115 7 1.66 002 2 7 6 159 110 2507 115 7 1.78 001 1 19 5 184 110 2660 115 1.89 010 1/0 19 4 7 211 110 3257 115 2.03 020 2/0 19 3 7 243 140 4382 115 2.28 040 4/0 19 1 19 321 140 4965 115 2.31 250 250 37 1/0 19 355 140 2.58 6484 115 19 350 350 37 2/0 435 140 2.88 8857 115 19 500 500 37 4/0 536 15000 Volts • 36-604 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Approx. No. of Wires Insulation No. of Wires Jacket Outside Weight Ampacity 2 Size per Thickness Size per Thickness Dimensions lbs. per 40°C 36-604- AWG Conductor mils AWG Conductor mils in. 1,000 ft. Ambient Temp 002 2 7 175 6 7 110 1.98 2517 164 1 19 175 5 7 110 2.11 3023 187 001 010 1/0 19 175 4 7 110 2.18 3296 215 020 2/0 19 175 3 7 110 2.30 3679 246 040 4/0 19 175 1 19 140 2.54 5146 325 250 250 37 175 1/0 19 140 2.61 5618 359 350 350 37 175 2/0 19 140 2.80 7055 438 500 500 37 175 4/0 19 170 3.15 9405 536 1 Jacket – CPE jacket. Black is standard. Colored CPE jackets available upon request. See page 42. 2 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – + 8%/-5% of nominal outside diameter 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 31 36-621/622/624 Type MP-GC 3/C • Mine Power Feeder PVC Jacket • 100% Level (Grounded) Conductors Copper Ground Wires Tinned Copper Application Ground Check Conductor 8 AWG 7-wire copper with yellow polypropylene insulation Strand Shield Semi-conducting layer Insulation 90°C cross-linked polyethylene Fillers Insulation Shielding Semi-conducting layer under copper tape (phase identification provided) Connections between units of mine distribution systems not exceeding the rated voltage when installed in duct, conduit or open air. For direct burial in wet and dry locations. Recommended maximum continuous conductor temperature is 90°C. Cable carries “P-7K-184-MSHA” marking indicating listing by the Mine Safety and Health Administration and the Pennsylvania Department of Environmental Protection. Tiger® Brand Mining Cable meets or exceeds ICEA Standards S-75-381/NEMA WC-58, ASTM B-8 and B-33. Binder Tape Assembly Taped core Jacket1 Polyvinyl chloride (PVC), cable identification via permanent surface marking. PVC jacket color options are the same as CPE. See Page 42 Cable may be suspended vertically by using a messenger and special mechanical connectors. Round-shaped cross-section Ratings & Approvals 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association File 82346, FT1, FT5, -35°C Type MP-GC, MPF up to 25kV 䡲 Tiger® Brand Mining Cables meet or exceed ICEA Standards S-75-381 & CSA Standards C 22.2 #96.1 Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 32 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 5000 Volts • 36-621 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Outside No. of Wires Insulation No. of Wires Jacket Thickness Size Thickness Dimensions Size per per mils mils in. 36-621- AWG Conductor AWG Conductor 7 90 7 110 1.42 004 4 8 7 90 6 7 110 1.56 002 2 19 90 5 7 110 1.65 001 1 19 90 4 7 110 1.76 010 1/0 19 90 3 7 110 1.88 020 2/0 19 90 1 19 140 2.14 040 4/0 37 90 1/0 19 140 2.23 250 250 140 37 90 19 2.47 350 350 2/0 140 37 90 19 2.70 500 500 4/0 Primary Usage Approx. Recommendation Weight Ampacity 2 lbs. per 40°C Mine Power 1,000 ft. Ambient Temp Feeder 1224 122 1653 159 Horizontal 1950 184 2200 211 Mine Power 2721 243 Feeder 3845 321 Vertical 4321 355 5652 435 7721 536 8000 Volts • 36-622 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Outside No. of Wires Insulation No. of Wires Jacket Thickness Dimensions per Thickness Size per Size mils in. mils 36-622- AWG Conductor AWG Conductor 110 115 7 1.54 004 4 7 8 110 115 7 1.66 002 2 7 6 110 115 7 1.78 001 1 19 5 140 115 1.89 010 1/0 19 4 7 140 115 2.03 020 2/0 19 3 7 140 115 2.28 040 4/0 19 1 19 140 115 2.31 250 250 37 1/0 19 140 2.58 115 19 350 350 37 2/0 140 2.88 115 19 500 500 37 4/0 Note: Approx. Weight Ampacity 2 lbs. per 40°C 1,000 ft. Ambient Temp 1366 122 1727 159 2174 184 2656 211 2895 243 3983 321 4484 355 5827 435 7893 536 Cable may be suspended vertically by using a messenger and special mechanical connectors. 15000 Volts • 36-624 • Type MP-GC 3/C Power Conductors Grounding Conductors Nominal Approx. No. of Wires Insulation No. of Wires Jacket Outside Weight Ampacity 2 Size per Thickness Size per Thickness Dimensions lbs. per 40°C 36-624- AWG Conductor mils AWG Conductor mils in. 1,000 ft. Ambient Temp 002 2 7 175 6 7 140 1.98 2021 164 001 1 19 175 5 7 140 2.11 2503 187 010 1/0 19 175 4 7 140 2.18 2658 215 020 2/0 19 175 3 7 140 2.30 3066 246 040 4/0 19 175 1 19 140 2.54 4369 325 250 250 37 175 1/0 19 140 2.61 4875 359 350 350 37 175 2/0 19 140 2.80 6412 438 500 500 37 175 4/0 19 170 3.15 8610 536 1 Jacket – PVC 2 Ampacity – Based on continuous duty at 90°C conductor temperature. Tolerances – + 8%/-5% of nominal outside diameter 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 33 36-202-018 Longwall Signal Cable 2- 9 Conductors • 50 Volts Application Power Conductors Extra flexible stranded per ASTM B-174 A flexible signal cable for use in Longwall and other underground mining applications. The TPU jacket provides extra-tough physical characteristics needed in the mining environment. Cable is available with full copper braid shielding upon request. Insulation Chemically cross-linked, non-chlorinated thermosetting, flame retardant polyolefin Jacket Thermoplastic Polyurethane (TPU) Colors Available: Black (standard) Orange (optional) Round-shaped cross-section Part Number 36202-018 203-018 204-018 205-018 206-018 207-018 208-018 209-018 202-016 203-016 204-016 205-016 206-016 207-016 208-016 209-016 202-014 203-014 204-014 205-014 206-014 207-014 208-014 209-014 Number of Size AWG Conductors 2 18 3 18 4 18 5 18 6 18 7 18 8 18 9 18 2 16 3 16 4 16 5 16 6 16 7 16 8 16 9 16 2 14 3 14 4 14 5 14 6 14 7 14 8 14 9 14 Diameter Over Insulation (Inches) 0.115 0.115 0.115 0.115 0.115 0.115 0.115 0.115 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.140 0.140 0.140 0.140 0.140 0.140 0.140 0.140 Overall Diameter (Inches) 0.440 0.460 0.490 0.520 0.560 0.560 0.630 0.660 0.460 0.480 0.510 0.550 0.590 0.590 0.660 0.690 0.490 0.510 0.550 0.590 0.630 0.630 0.710 0.750 Weight (lbs./ft.) 0.087 0.100 0.117 0.136 0.156 0.163 0.197 0.215 0.099 0.114 0.133 0.158 0.183 0.190 0.225 0.247 0.118 0.138 0.166 0.196 0.225 0.238 0.278 0.300 Tolerances – ± 5% of nominal outside diameter Ratings & Approvals 䡲 90°C Temperature Rating 䡲 Tiger® Brand Mining Cables materials meet or exceed industry specifications 䡲 Mine Safety and Health Administration 184-MSHA 䡲 Pennsylvania Department of Environmental Protection P-184 Tiger® Brand is a registered trademark of AmerCable Incorporated, a Nexans Company. 34 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 36-202-118 Underground Lighting Cable 2- 9 Conductors • 110 Volts Application Power Conductors Extra flexible stranded per ASTM B-174 Insulation Chemically cross-linked, non-chlorinated thermosetting, flame retardant polyolefin A flexible insulated cable for use in longwall and other mine lighting systems. The TPU jacket provides extra-tough physical characteristics needed in the underground mining environment. Cable is available with full copper braid shielding upon request. Colors Available: Black (standard) Orange (optional) Jacket Thermoplastic Polyurethane (TPU) Round-shaped cross-section Photo courtesy 20 Mile Coal Mine Ratings 䡲 90°C Temperature Rating 䡲 Tiger® Brand Mining Cables materials meet or exceed industry specifications Part Number Number Size of AWG Conductors 36202-118 18 2 203-118 18 3 204-118 18 4 205-118 18 5 206-118 18 6 207-118 18 7 208-118 18 8 209-118 18 9 202-116 16 2 203-116 16 3 204-116 16 4 205-116 16 5 206-116 16 6 207-116 16 7 208-116 16 8 209-116 16 9 202-114 14 2 203-114 14 3 204-114 14 4 205-114 14 5 206-114 14 6 207-114 14 7 208-114 14 8 209-114 14 9 202-112 12 2 203-112 12 3 204-112 12 4 205-112 12 5 206-112 12 6 207-112 12 7 208-112 12 8 209-112 12 9 202-110 10 2 203-110 10 3 204-110 10 4 205-110 10 5 206-110 10 6 207-110 10 7 208-110 10 8 209-110 10 9 Diameter Over Insulation (Inches) 0.115 0.115 0.115 0.115 0.115 0.115 0.115 0.115 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.140 0.140 0.140 0.140 0.140 0.140 0.140 0.140 0.160 0.160 0.160 0.160 0.160 0.160 0.160 0.160 0.180 0.180 0.180 0.180 0.180 0.180 0.180 0.180 Overall Diameter (Inches) 0.440 0.460 0.488 0.520 0.560 0.560 0.640 0.660 0.460 0.480 0.512 0.550 0.590 0.590 0.670 0.690 0.490 0.510 0.550 0.588 0.630 0.630 0.720 0.755 0.526 0.555 0.596 0.642 0.690 0.690 0.770 0.815 0.570 0.598 0.645 0.698 0.750 0.750 0.835 0.875 Weight (lbs./ft.) 0.087 0.100 0.116 0.135 0.156 0.163 0.198 0.215 0.106 0.114 0.134 0.158 0.183 0.191 0.225 0.247 0.119 0.138 0.166 0.195 0.225 0.238 0.278 0.302 0.148 0.177 0.213 0.254 0.297 0.316 0.388 0.426 0.186 0.226 0.276 0.331 0.401 0.462 0.519 0.626 Tolerances – ± 5% of nominal outside diameter 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 35 37-119 Flexible Power Cable • DLO EP/CPE • RHH, RHW-2 • 2000 Volts Conductor Application Flexible-stranded, tin-coated annealed copper Nexans AmerCable’s 2000V Diesel Locomotive Cable (DLO) is a single conductor portable power cable suitable for use in applications needing great flexibility, excellent wearability and good flex life. Applications include motor and generator leads, battery leads, shipyards, telecommunications power, heavy earth moving equipment, and renewable energy applications. Separator Suitable separator tape provides easy stripping of insulation Features 䡲 A two layer composite of flame retardant, oil and sunlight resistant Chlorinated Polyethylene (CPE) outer layer and Ethylene-Propylene rubber (EPR) inner layer. Composite design provides significant diameter reductions compared to designs using full thickness jackets. Insulation Ethylene-Propylene rubber (EPR) 䡲 Suitable for continuous operating temperatures of 90°C, wet or dry Jacket Flame retardant, oil and sunlight retardant Chlorinated Polyethylene (CPE) 䡲 Rated RHH, RHW-2; 2/0 – 1111 kcmil listed and marked “for CT use” 䡲 UL listed as Sunlight Resistant 䡲 UL listed as Marine Shipboard Cable (4/0 and larger) See Page 34 for jacket color options. Special order only 䡲 Insulation and jacket meet hazardous waste regulations, per Round-shaped cross-section Extremely flexible stranding for increased overall cable flexibility and ease of installation Code of Federal Regulations 40 Section 261 (40CFR261) for characteristic lead content 䡲 Flame Resistance: FT-4/IEEE1202 for 2/0 1111 kcmil and UL VW-1 䡲 Meets smoke release and other requirements of Vertical Cable Tray Test UL 1685 and is marked “ST-1” for 2/0 – 1111 kcmil Ratings & Approvals 䡲 UL Standard 44: Thermoset Insulated Wires & Cables, Types RHH, RHW-2. UL VW-1. 䡲 UL Standard 1685: Vertical Tray Fire propagation and Smoke Release Test for Electrical and optical Fiber Cables. (UL, LS) 䡲 AAR 591 Wire and Cable Insulating Material: Strand Construction except 3/0 and 4/0. 䡲 ASTM B-33: Standard Specification for Tinned Soft or Annealed Copper Wire for Electrical Purposes. 䡲 ASTM B-172: Standard Specification for Rope-Lay-Stranded Copper Conductors having Bunch-Stranded Members, for Electrical Conductors. 䡲 MSHA P-184 36 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 37-119 • Portable Power Cable • 2000 Volts Part No. 37-119201 202 203 204 205 207 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 Size AWG/ kcmil 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 262 313 373 444 535 646 777 929 1111 Minimum Wires per Conductor 19 19 27 37 61 105 147 224 266 323 418 532 646 777 925 1110 1332 1591 1924 2318 2745 Nominal Insulation Thickness in. 0.045 0.045 0.045 0.055 0.055 0.055 0.055 0.065 0.065 0.065 0.065 0.065 0.075 0.075 0.075 0.075 0.090 0.090 0.090 0.090 0.130 * Ampacity – Calculated with at 90°C conductor temperature and 30°C ambient air, per 2002 NEC, Table 310-17 Nominal Jacket Thickness in. 0.015 0.015 0.015 0.030 0.030 0.030 0.030 0.045 0.045 0.045 0.045 0.045 0.065 0.065 0.065 0.065 0.065 0.065 0.065 0.065 0.065 Nominal Outside Diameter in. 0.214 0.233 0.257 0.326 0.365 0.460 0.498 0.618 0.664 0.704 0.789 0.839 0.973 1.029 1.094 1.169 1.295 1.368 1.488 1.583 1.707 Approx. Weight lbs. per 1,000 ft. 31 41 58 86 124 198 261 400 468 561 725 888 1048 1227 1436 1691 2034 2395 2837 3448 4156 *Ampacity 90°C 35 40 55 80 105 140 190 220 260 300 350 405 467 522 591 652 728 815 904 1005 1119 • Cable diameters are subject to +/-5% manufacturing tolerance • Sizes above 1000 kcmil are not UL listed 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 37 36-501 VFD Power Cable • Shielded • 2000 Volts 3 Conductors + 3 Grounds + Ground Check(s) Power Conductor Extra flexible tinned rope stranded conductors per ASTM-172 and B-33 Ground Conductors (x3) Flexible tinned rope stranded conductors per ASTMB-172 and B-33, Insulated and colored green Insulation Type II EPDM (EPR) suitable for continuous operation at 90°C. Ozone resistant. Ground Check Wire(s) Flexible tinned copper with yellow insulation. Center ground check available Shield Overall tinned copper braid plus aluminum/ polyester tape providing 100% coverage Application A flexible, braid and foil shielded, 2kV power cable specifically engineered for use in variable frequency AC motor drive (VFD) applications. Cable carries “P-184-MSHA” marking indicating acceptance as flame resistant by the Pennsylvania Department of Environmental Protection and the Mine Safety and Health Administration. Tiger® Brand Mining Cable materials meet or exceed ICEA Standard S-75-381/NEMA WC-58 for Type SHC constructions. ASTM B-172 and B-33. Ratings & Approvals 䡲 90˚C Temperature Rating 䡲 Tiger® Brand Mining Cable materials meet or exceed ICEA Standard S-75-381/ NEMA WC-58. 䡲 Mine Safety & Health Administration 184-MSHA. 䡲 Pennsylvania Department of Environmental Protection P-184. 䡲 Canadian Standards Association (pending) File 82346 CSA Phase Color ID available on MTO Jacket Reinforced mold-cured thermosetting Chlorinated Polyethylene (CPE) Jacket. Cable identification via permanent marking. See Page 34 for jacket color options. Round-shaped cross-section Power Conductor Size AWG/ Part No. kcmil 36-501 002 001 010 020 030 040 250 350 500 2 1 1/0 2/0 3/0 4/0 250 350 500 Correction Factors Grounding Conductors Size AWG1 Nominal Jacket Thickness in. Nominal Diameter in. Approx. Weight lbs./ft. Ampacity2 90°C 8 7 6 5 4 3 3 1 1 0.155 0.170 0.170 0.190 0.190 0.220 0.220 0.220 0.265 1.43 1.64 1.74 1.89 2.01 2.17 2.40 2.68 3.03 1790 2150 2550 3100 4050 4390 5950 7840 9730 159 184 211 243 279 321 355 405 536 For ampacities for various ambient temperatures above or below 40°C. Ambient Temp. Degrees C Multiplying Correction Factors 10 20 30 40 50 1.26 1.18 1.10 1.00 0.90 *Cable diameters are subject to a +/- 5% manufacturing tolerance 1 Ground Check Conductor – #16 AWG extensible strand for center groundcheck. #14 AWG is the minimum size for non-center ground check wires 2 Ampacity Ratings – based on continuous duty at 90°C conductor temperature 38 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 Other Available Nexans AmerCable VFD Cable Constructions 37-102VFD 37-102VFD 37-102VFD 37-108VFD Standard Type VFD Power Cable Low Smoke Halogen-Free Type VFD Power Cable CIR Type VFD Power Cable Flexible Type TC-ER VFD Power Cable • 2kV • Rated 110°C • Gexol® Insulated • 2kV • Rated 110°C • Gexol® Insulated • 2kV • Rated 110°C • Gexol® Insulated • Crush & Impact resistant without external armoring • 600V • Rated 90°C VFD CABLE R S T PE VFD U V W PE MOTOR V LL 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 39 Tiger Stripes – Reflective Nexans AmerCable’s reflective Tiger Stripes can extend cable life by reducing run-overs in low visibility situations and improve mine safety by providing easier visual circuit identification. ■ Increased safety for personnel through easier circuit identification ■ Available on CPE round jacketed cables only. Black Blue Green Orange Yellow (standard) 40 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 Red Tiger Stripes – Standard Nexans AmerCable’s standard Tiger Stripes provide additional color combinations by vulcanizing a contrasting colored stripe into the jacket of our round CPE cables. Shown below are a few examples of the many possible jacket / stripe combinations. Consult with your AmerCable rep or the factory for a complete list of available stripe options. Black/Red Blue/White Yellow/Rred Orange/Green Red/White Green/White Black/White Blue/Green Yellow/Green Orange/White Red/Blue Black/Green Available only from AmerCable Safety through easier circuit identification Assign to specific equipment to make visual inventory simpler Available only on round CPE jacketed cables 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 41 Jacket Materials & Color Options Nexans AmerCable CPE Jackets Nexans AmerCable TPU Jackets Nexans AmerCable’s thermoset Chlorinated Polyethylene jacket provides the physical performance and strength needed to resist wear, tear, abrasion and compression cuts caused by everyday mining use. For extremely abrasive environments, AmerCable’s Thermoplastic Polyurethane (TPU) jacket provides the extra-tough physical characteristics needed in the roughest mining environments. Compared to Nexans AmerCable’s standard CPE jacketing material, TPU provides: This tough, durable jacket is a proven performer in mines throughout the world. Nexans AmerCable’s engineered cable construction includes a taped-core, integral fill and tandem extrusion of the jacket layers. Two-pass jackets, extruded in tandem, yield an inseparable bond between the layers. Integral filling of the cable core reduces torsion-induced damage. Black Blue (standard) Green Orange Yellow Red 5X more abrasion resistance Up to 2X more tear resistance 8% Less 2X more tensile strength Jacket Weight Colored jackets experience no loss of physical properties compared to our black jacket. Black Blue Green Orange Yellow Red (standard) These brightly colored cables can improve mine safety by providing easy circuit identification. ORANGE XL Shuttle Car Productivity Solutions 42 ORANGE XLTM is Nexans AmerCable’s high strength, highly visible proprietary jacketed flat Shuttle Car cable. This cable jacket is extremely resistant to tear and abrasion. This highly durable shuttle car cable improves productivity through 30-50% greater service life. Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 Safety, Training, and Education MineCable-Safe is an investment in Safety and Productivity that brings the knowledge and experience of our field engineers to your mine. High voltage cables require special handling to get maximum service life and keep personnel safe. Can you identify the difference between a productivity problem and a safety issue? Our experts can. We deliver a highly-valuable report that clearly identifies safety and productivity issues. The report includes recommendations on how to deploy, move and utilize cables more safely and to make your mine more productive. Follow-up can also include training sessions and engineered solutions. Field Technical Support Safety and maximized cable productivity are Nexans AmerCable’s top priorities for our customers. Surface or underground – 24/7 – all shifts – Nexans AmerCable’s mine-experienced field reps are ready to provide on-site cable evaluation, safe handling training and innovative productivity solutions. A few extra minutes spent in cable repair can save hours of costly downtime. Cable Splicing Training Splice Kits Our field reps can conduct on-site training (all shifts) on the correct way to splice cables to extend their service life. (CPE or TPU) 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 43 Factory Installed Cable Assemblies Factory Installed Cable Assemblies from Nexans AmerCable are professionally assembled in our El Dorado, Arkansas manufacturing facility. Our team of experienced handlers join cables and connectors that match yourexact specifications. Our assemblies are designed to perform in your harshest operating conditions. Factory prepared cable assemblies or terminations are a reliable way to lower your overall cable connectivity costs through enhanced reliability, reduced handling and lower installation time. Why Use FACTOREYD INSTALL Cable Assemblies? ■ Your cable assembly, built to your exact specifications, arrives ready for immediate use ■ Reduced prep, handling and installation time Constructions 2 - 25kV ■ Stress Cones & fill ■ ID Labeling ■ Pothead Assemblies ■ Lower Overall Cost Enhanced Reliability Applications Surface Mining ■ Underground Mining ■ Reeling ■ Reduced Installation Time ■ No need to maintain expensive connector inventory ■ Professionally assembled ■ Factory electrical testing after termination/refurb ■ Nexans AmerCable’s on-time delivery rate and short lead times are #1 in the cable industry Victor plug installed on 240mm² 307S 44 Manufactured by Nexans AmerCable • (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 Molded Potheads Couplers Nexans AmerCable has the coupler you need for immediate installation upon arrival. (up to 25kV) Factory installed couplers from Nexans AmerCable are a reliable way to lower your overall cable connectivity costs. Longwall Refurbishment Get maximum service life from your Tiger ® Brand longwall cables. Our refurb team will expertly, clean, inspect, repair and splice in new sections as needed. We then deliver them back to the mine – ready to power your longwall system. Before Refurb Saves up to 60% when compared to the cost of a new longwall cable. After Refurb 350 Bailey Road • El Dorado, Arkansas USA • www.amercable.com • e-mail: mining@amercable.com 45 Nexans AmerCable is the leading global manufacturer of surface and underground mining cables. Nexans AmerCable is an ISO 9001 certified cable manufacturer that combines leading-edge technology, proven manufacturing techniques, and high quality service to deliver the finest mining cable products available. Nexans AmerCable serves a worldwide customer base from our manufacturing facility in El Dorado, Arkansas. Our professional field engineers and customer support team work directly, or in partnership with a network of independent distributors, to deliver productivity enhancing cable solutions. What can you expect from Nexans AmerCable? ■ High Quality Cable with an Emphasis on Safety ■ On-Time Delivery ■ Professional Sales, Support and Service ■ Strategic Inventory Locations El Dorado, Arkansas ■ Short Lead Times Made in America Nexans AmerCable’s Mining & Industrial Cable Products & Services Surface Mining Underground Mining Industrial Reeling Factory Installed Cable Assemblies 350 Bailey Road • El Dorado, Arkansas USA (870) 862-4919 • (800) 643-1516 • Fax (870) 862-9613 • e-mail: mining@amercable.com • www.amercable.com © 2012, AmerCable Incorporated 7_12