specification

advertisement

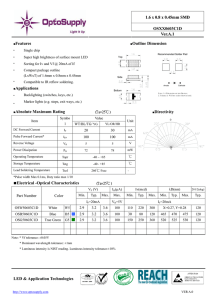

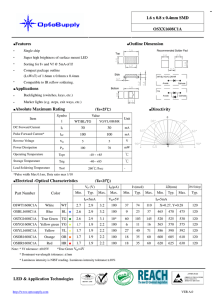

NANYA ROAD,MUGANG ZHAOQING CITY GUANGDONG CHINA. LEDTECH ELECTRONICS CORP. TEL:86-758-2875541,2870651,2877464,2876185,2877017 FAX:86-758-2878014 Http://www.ledtech.com.tw SPECIFICATION PART NO. : LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Approved by Checked by Prepared by Tung Lian Yu Fang LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Package Dimensions 1.9 2.8 0.8 3.6 K 2.2 3.2 2.4 0.9 0.14 A 0.6 0.8 Notes: 1. All dimensions are in mm. 2. Tolerance is ±0.25mm unless otherwise noted. Description LED Chip Part No. LT5K13-AA-UJF7-SA8 Material Emitting Color AlGaInP/Si Hyper Red Lens Color Water Clear VER.: 01 Date: 2006/12/30 Page: 1/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Absolute Maximum Ratings at Ta=25 ℃ Parameter Symbol Rating Unit Power Dissipation PD 78 mW Reverse Voltage VR 5 V D.C. Forward Current If 30 mA If(Peak) 100 mA Operating Temperature Range Topr. -25 to +85 ℃ Storage Temperature Range Tstg. -40 to +100 ℃ Soldering Temperature Tsld. Peak Current(1/10Duty Cycle,0.1ms Pulse Width.) Reflow Soldering: 260℃ for 10 sec. Hand Soldering: 350℃ for 3 sec. Electrical and Optical Characteristics: Parameter Symbol Condition Min. Typ. Luminous Intensity IV If=20mA 200 400 Forward Voltage Vf If=20mA 2.1 Peak Wavelength λP If=20mA 632 nm Dominant Wavelength λD If=20mA 625 nm Reverse Current Ir Vr=5V Viewing Angle 2θ1/2 If=20mA 120 deg ∆λ If=20mA 20 nm Spectrum Line Halfwidth Max. Unit mcd 2.6 100 V µA Notes: 1.The datas tested by IS tester. 2. Customer’s special requirements are also welcome VER.: 01 Date: 2006/12/30 Page: 2/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Typical Electrical/Optical Characteristic Curves 50 500 40 400 Relative Luminous Intensity Forward Current IF(mA) (25℃ Ambient Temperature Unless Otherwise Noted) 30 20 10 1.4 1.6 1.8 2.0 2.2 300 200 100 0 2.4 10.0 0.0 30.0 Forward Current (mA) Applied Voltage (V) Forward Current VS. Applied Voltage Forward Current VS. Luminous Intensity 50 Forward Current IF(mA) 20.0 0° 20° 10° 30° 40 30 40° 1.0 20 50° 0.9 0 60° 0.8 10 20 40 60 80 100 Ambient Temperature Ta (。C) Ambient Temperature VS. Forward Current 70° 80° 90° 0.7 0.5 0.3 0.1 0.2 0.4 0.6 Radiation Diagram VER.: 01 Date: 2006/12/30 Page: 3/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE PRECAUTION IN USE Storage Recommended storage environment Temperature: 5oC ~ 30oC (41oF ~ 86oF) Humidity: 60% RH Max. Use within 7 days after opening of sealed vapor/ESD barrier bags. If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment : 60±5℃ for 24 hours. Fold the opened bag firmly and keep in dry environment. Soldering Reflow Soldering Lead Solder Lead – free Solder 120~150℃ 180~200℃ Pre-heat Pre-heat time 120sec. Max. 120sec. Max. 240℃ Max. 260℃ Max. Peak temperature Soldering time 10sec. Max. 10sec. Max. Condition refer to refer to TemperatureTemperatureprofile 1 profile 2 *After reflow soldering rapid cooling should be avoided. [Temperature-profile (Surface of circuit board)] Use the conditions shown to the under figure. <1 : Lead Solder> 240°C Max. 10sec. Max. 2.5~5°C/sec. Pre-heating 120~150°C 120sec. Max. 60sec. Max. Hand Soldering Temperature Soldering time 350℃ Max. 3sec. Max. (one time only) <2 : Lead-free Solder> 260°C Max. 10sec. Max. 1~5°C/sec. Pre-heating 180~200°C 120sec. Max. 60sec. Max. 1~5°C/sec. 2.5~5°C/sec. [ Recommended soldering pad design ] Use the following conditions shown in the figure. 1.4 1.8 1.4 2.2 (UNIT:mm) VER.: 01 Date: 2006/12/30 Page: 4/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Handling of Silicone Resin LEDs Handling Indications During processing, mechanical stress on the surface should be minimized as much as possible. Sharp objects of all types should not be used to pierce the sealing compound Figure 1 In general, LEDs should only be handled from the side. By the way, this also applies to LEDs without a silicone sealant, since the surface can also become scratched. Figure 2 When populating boards in SMT production, there are basically no restrictions regarding the form of the pick and place nozzle, except that mechanical pressure on the surface of the resin must be prevented. This is assured by choosing a pick and place nozzle which is larger than the LED’s reflector area. VER.: 01 Date: 2006/12/30 Page: 5/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Dimensions for Tape 4.0 2.0 2.24 1.5 1.75 5.5 4.0 12.0 0.25±0.05 4.0 60.0±0.5 57 178.0± 1 Dimensions for Reel 13.2±0.5 16.2±0.5 Notes: 1.All dimensions are in mm, tolerance is±2.0mm unless otherwise noted. 2.Specifications are subject to change without notice. VER.: 01 Date: 2006/12/30 Page: 6/7 LT5K13-AA-UJF7-SA8 3.2 x 2.8mm SMD TYPE Packing REEL QUANTITY: 2,000 PCS : LTXXXX-XX-XXX : 3,000PCS : B3(X:0.298±0.01;Y:0.296±0.01) : 3.3-3.4V : T1(700-800mcd) : Year / Month / Day 178±1 Product NO. QUANTITY W/D(nm) VF IV(mcd) LOT NO. LEDTECH ELECTRONICS CORP. PART NO :LTXXXX-XX Q'TY : PCS LOT NO :XXXXXXXXX DATE : BIN CODE: 溼氣敏感材料 MOISTURE SENSITIVE DEVICES 1. 在5°C~30°C密封貯藏,1年有效。 Shelf life in sealed bag : 12 months at 5° C~30°C . 2. 開封後需在168小時內使用。 LEDTEC H ELE PART NO. :LTCTRONI QTY 8AB3-51CS COR LOT P. :40 00 PCS -UAF1 DAT NO. : XXX E BIN COD :20 XXXXXX X E : X 03.06.04 moun this bag ted withi n is open ed . INSIDE BOX QUANTITY: 4 BAGS TOTAL: 8,000 PCS s after Q'TY : PCS LOT NO :XXXXXXXXX DATE : BIN CODE: MOISTU 溼氣敏感 LEDTECH ELECTRONICS CORP. PART NO :LTXXXX-XX RE SEN 材料 1. 在5° C~30 SITI Shel f °C密封貯藏 VE DEV life in at 5° seale d ,2年有效 ICES bag : 。 2. 開封 C~30° C 24 mont . 後需 在72小 hs Devi 時內 ces 使用 72 hour have to 。 be BAG QUANTITY: 2,000 PCS 230± 1.0 Devices have to be mounted within 168 hours after this bag is opened . 270±1.0 2 5± 27 23 5± 2 LEDTECH ELECTRONICS CORP. PART NO :LTXXXX-XX 75±2 Q'TY : PCS LOT NO :XXXXXXXXX DATE : BIN CODE: Notes: 1.All dimensions are in mm, tolerance is±2.0mm unless otherwise noted. 2.Specifications are subject to change without notice. VER.: 01 Date: 2006/12/30 Page: 7/7