Industry:

Printing Equipment

Manufacturing

Application:

Differential Speed

Measurement

Printing equipment manufacturer

controls paper stretch and eliminates

print registration problems

Profile:

A leading manufacturer of digital imaging

and printing technology

Solution:

LaserSpeed® 9000-303

Results:

Control stretch and slippage to

eliminate registration problems

Accurate, reliable speed measurements

No encoder recalibration

Easy setup and use

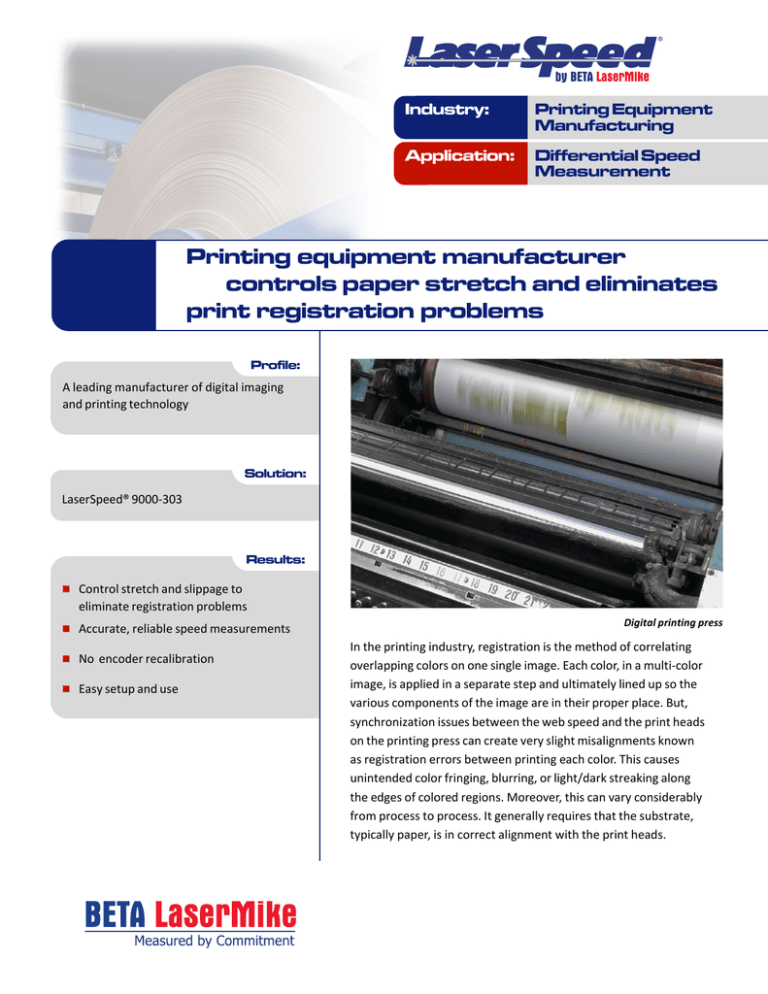

Digital printing press

In the printing industry, registration is the method of correlating

overlapping colors on one single image. Each color, in a multi-color

image, is applied in a separate step and ultimately lined up so the

various components of the image are in their proper place. But,

synchronization issues between the web speed and the print heads

on the printing press can create very slight misalignments known

as registration errors between printing each color. This causes

unintended color fringing, blurring, or light/dark streaking along

the edges of colored regions. Moreover, this can vary considerably

from process to process. It generally requires that the substrate,

typically paper, is in correct alignment with the print heads.

The Challenges:

Differential Speed Measurement

A U.S. based printing equipment manufacturer was having a

registration problem on one of its digital printing machines at

its R&D center. During product testing, the product engineers

recognized that the registration of the cyan, yellow, magenta,

and black colors in the printer’s multi-color process were off

by several microns. This condition was a recurring problem.

The engineers believed that the problem could be due to one or

more of the following reasons:

Paper stretch due to tension or the applied ink

Paper slippage on the drive roller

Differences in mechanical wheel encoder speed

versus actual web speed

The Solution:

Most printing press systems use encoders on the drive rollers

or contact wheel encoders riding on the substrate to measure

the speed of the web during printing processes. While drives

on drive rollers are becoming sophisticated and more

accurate, the simulated encoder output from the drive cannot

compensate for slippage. Every substrate has some amount of

slipping on the drive roller. The amount that this material slips

can vary based on texture, composition, or even tension at

other points on the line. A contact encoder attached to the

drive roller has the same problems.

A contact encoder riding on the web has even more problems.

The wheel can either wear down or have dirt build up, both of

which change the calibration. This, along with the same types

of slippage problems, makes any sort of contact measurement

a poor choice when high accuracy is desired.

LaserSpeed® 9000-303

After investigating several alternative measurement

technologies, the printing equipment manufacturer selected

Beta LaserMike’s differential speed measurement system. This

solution includes the LaserSpeed Length Differential Indicator

(LDI) and two LaserSpeed 9000-303 non-contact encoders.

The LS9000-303 encoder uses laser-based technology that

projects a unique pattern on the surface of the substrate. As

the product moves, light is scattered back to the LS9000-303

encoder. This information is translated into product speed.

The LS9000-303 can read forward and backward product speed

up to ±4,000 m/min (±13,100 ft/min). Speed measurements

are captured with better than ±0.05% accuracy.

Used as a diagnostic tool, the product engineers can use this

differential speed measurement system to monitor the line

speed of the printing system at any two locations on the web.

Since the LS9000-303 encoder measures the product itself and

not a roller, slippage is not a problem. Adding the fact that the

LS9000-303 encoder has a measurement accuracy of ±0.05%,

the stretch measurement will be reliable and correct.

LaserSpeed LDI System

Critical Process Factors. The engineering team wanted to ensure

there was no paper stretch and that all drive rollers were

pulling the product through the press at the same speed. This

meant the non-contact encoder system needed to measure the

differential speed with the highest degree of accuracy and

repeatability. The encoder also had to be compact and rugged,

so it can installed at any location on the press. Another

critical factor was the ability of the encoder to reliably read

any material surface, as the paper substrate and coatings

may change from application to application. One final factor

required the non-contact laser encoder to provide the same

outputs as a contact encoder. This allowed for simple

plug-and-play installation with minimal modifications

required to the printing press and current web control process.

Installation. Gauge mounts are installed at several points

along the line, enabling the LS9000-303 encoders to be

positioned at two different desired locations to determine the

differential speed between the drive rollers and the web. The

encoders are positioned perpendicular and 12 inches from

the web. This setup allows the product engineers to monitor

and measure web tension at critical points for paper stretch,

as well as monitor paper slippage on the drive roller. The

LDI system is also used to compare speed measurements from

the contact wheel encoder and LS9000-303 gauge via direct

input of encoder pulses. The LDI system includes an RS-232

output which can be interfaced with a PLC to control the

differential speed.

The Results:

Beta LaserMike’s differential measurement system with LaserSpeed encoders offers the printing equipment

manufacturer a number of key benefits:

High accuracy and repeatability

Low cost of ownership due to no moving parts

No slippage problems from non-contact method

Permanent calibration for increased uptime

Compact design for installation flexibility

As the R&D team at the printing equipment manufacturer continue to use the LaserSpeed system,

Beta LaserMike will learn more about the long-term value of the solution.

Beta LaserMike’s LaserSpeed non-contact encoders are the most

accurate, reliable, and cost-effective measurement solution for

controlling stretch or draw of product during manufacturing.

To learn more, visit: www.laserspeedgauge.com

Beta LaserMike USA

8001 Technology Blvd.

Dayton, OH 45424 USA

Ph: +1 937 233 9935

Fax: +1 937 233 7284

Beta LaserMike Europe Beta LaserMike Asia

Unit 3, First Avenue

Globe Park, Marlow

Buckinghamshire, SL7 1YA

United Kingdom

Ph: +44 1628 401510

Fax: +44 1628 401511

Unit 401, Xinmao Plaza,

Building 9, No. 99 TianZhou Rd.

Shanghai 200233, China

Ph: +86 21 6113 3688

Fax: +86 21 6113 3616

© Copyright 2010 Beta LaserMike. All rights reserved. 1010 Printed in the USA.