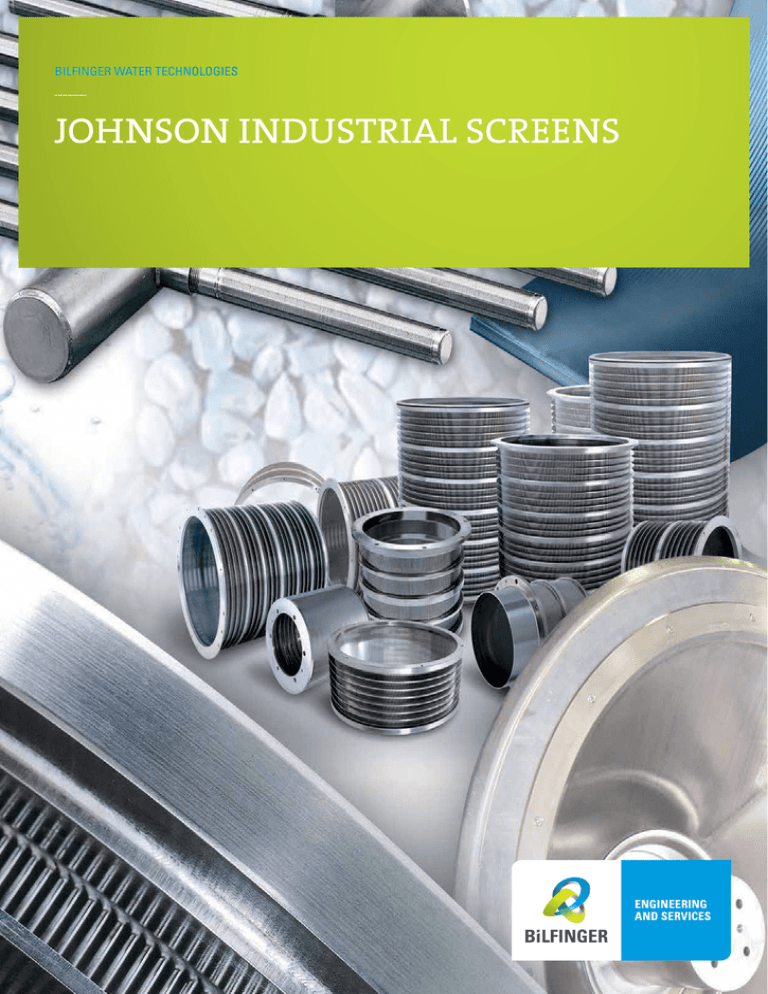

Bilfinger Water Technologies

______

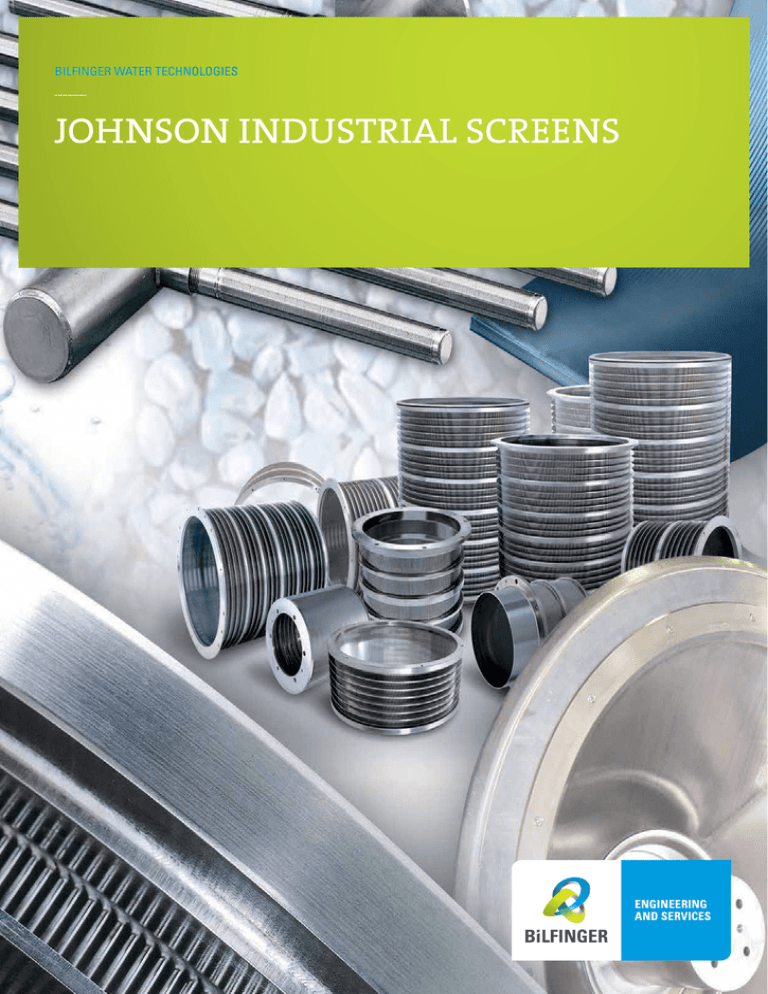

JOHNSON INDUSTRIAL SCREENS

2

JOHNSON SCREENS®:

AN OVERVIEW

INNOVATIVE DESIGN

______

Bilfinger’s brand of Johnson Screens® specialises in

the design and manufacture of stainless steel filter

elements for liquid/solid and gas/solid separation.

Our screens are known for great strength, long

service life and a very high level of adaptability for

high-efficiency liquid/solid separation.

Johnson’s screens are made by welding vee-shaped

wire on support rods, creating slots which enlarge

inwardly, meeting the most demanding standards

for ruggedness, durability, consistency and slot

openings. The vee-shaped opening allows only two

contact points with the particles, thus preventing

any risk of clogging.

CUSTOM DESIGNED AND ENGINEERED

Each project is designed to ensure complete

satisfaction. We provide guidance and support from

project conception to completion.

LONGER LASTING

Johnson’s manufacturing standards are the most

stringent in the industry. Featuring the Vee-Wire®

technology, the screens are extremely durable and

have high resistance to abrasion, corrosion and

impact damage.

LESS COSTLY

Superior operating efficiency, reduced maintenance

needs and extended service life combine to decrease

the cost of Johnson’s screens to plant operators.

MANY CONSTRUCTION OPTIONS

Johnson’s screen surfaces can be used:

• For direct screening

• As filter media support (sand bed, activated

carbon, resins, catalysts)

Screens are available in slot opening from 25 µm

up to 25 mm. Most common materials used are the

300 series stainless steel, but many exotic alloys are

available to suit specific applications.

Screens are available in a variety of shapes to suit

customer needs:

• Cylinders

• Flat or curved panels

• Cones

• Any form specific to a given application

The flexibility of the process allows the

manufacture of custom made screens for all types of

applications: new plant, expansions or upgrades.

LOWER MAINTENANCE

The rugged construction and high quality of the

materials produce a product that lasts longer and

requires less maintenance.

3

A HIGHLY TECHNICAL PRODUCT

MANY AREAS OF SCREEN APPLICATION

______

______

The design and manufacturing characteristics of Johnson’s

screen surfaces provide the following advantages:

The strength, precision and design flexibility that characterise

our screens makes them the choice in a broad range of

industries and applications.

•

•

•

•

•

•

•

•

4

Non-clogging surface

Large open area

Low pressure drop

Hydraulic efficiency

High flow rates

Mechanical strength

Abrasion-resistant

Easy cleaning

MARKET/INDUSTRY

• Water and waste water

• Pulp and paper

• Chemical

• Petrochemical

• Water supply

• Mineral and aggregate processing

• Plastics extrusion

• Machine coolant filtration

• Architectural applications

If your process involves any aspect of fluid/solid separation,

we have the products and experience to help you achieve

maximum efficiency and effectiveness.

APPLICATIONS

• Separating

• Filtering

• Media retention

• Sizing

• Dewatering

• Classifying

• Straining

• Drying

• Water intake

• Fish diversions

• Collection

QUALITY

______

The Johnson Screens® brand has been delivering high quality

screens to various industries for more than a century; and

though technology has changed, our commitment to quality

products and services has not.

Bilfinger is an ISO-certified company; each product is subject to

a procedure of self-inspection by each operator throughout the

manufacturing process. A final inspection guarantees delivery

of a product that fully meets the user’s technical specification.

Bilfinger can provide the following documents upon request:

•

•

•

•

•

•

•

Quality plan

Manufacturing plan and production schedule

Process qualification record (PQR)

Welding procedure specification (WPS)

Welder performance qualification (WQR)

In-house inspection reports / material certificates

Chemical and/or mechanical analysis certificates

5

CYLINDRICAL SCREEN FOR OUTSIDE →

INSIDE FILTRATION

STANDARD

______

External circumferential wire and

axial internal support rods.

Benefits:

• Economical

• Suitable for most applications

• Precision openings

•

Products:

• Filter cartridges

• Candle filters

01

• Header laterals

• Rotating drum screens

• Nozzles

• Resin traps

6

EXTERNAL AXIAL WIRE

(re-rolled)

CHANNEL ROD

CONSTRUCTION

______

______

External axial wire with internal

circumferential support rods.

Perforated U-section channels

replace the internal support

rods. When the filter is used as a

collector, flow is outside-in. When

it is used as a distributor, flow is

inside-out.

Benefits:

• Facilitates cleaning with an

external axial-movement

scraper

Products:

• Automatic filters

Benefits:

• Optimised collection and distribution

• Replaces perforated inner tube

•

Applications:

• Potable water treatment

• Ion exchange

• Oil refining processes

CYLINDRICAL SCREEN FOR INSIDE →

OUTSIDE FILTRATION

INVERTED

INTERNAL AXIAL WIRE

______

(wire-base)

INTERNAL CIRCUMFERENTIAL

WIRE (re-rolled)

External circumferential inverted

wire and axial internal support

rods.

Internal axial wire with external

circumferential support rods.

Internal circumferential wire with

external axial support rods.

Benefits:

• Smooth internal screen surface

• Facilitates cleaning with an internal axial-movement

scraper

• The flow moves across the wire edges for effective dewatering

Benefits:

• Smooth internal filter surface

• Custom inner diameter

Benefits:

• Economical

Applications:

• Inside-out flow

Products:

• Screw press

Products:

• Trommel screens with internal feed

• Systems with an internal rotor or screw

• Dewatering systems

• Baskets

• Automatic filters

7

PRODUCTS

FLAT SCREENS

CANDLE FILTERS

______

______

Bilfinger offers a variety of flat screens

for the malting and brewing industries.

These Johnson Screens® Vee-Wire® screens are

ideal for:

The filtration capacity can be modified easily

by varying the number of candle filters to

obtain the required filter area. Johnson Screens®

Vee-Wire® candle filters are used widely in the

brewing industry for filtration. Housed inside a

cylindrical vessel, the filtration capacity can be

modified easily by varying the number of candle

filters to obtain the required filter area. Features

include:

•

•

•

•

•

•

Lauder tubs

Germination

Kilning

Ultra filtration

Steeping

Malt extraction

Used in the kilning, germination and drying

phases of the malting process, Johnson Screens®

malting bed screens are the ideal choice for

malting floors and other screening needs in the

malting process.

• Small diameter usually less than 50 mm

• Substantial length usually greater than 1,000

mm

• Very fine openings: 25 to 150 µm, according to

the application

► IMAGE 02

These screen panels can be designed to

minimise “dead spots” in the malting floor, over

supports or other structures, to further improve

the overall process. In between malting batches,

the screens are very easy to clean, reducing

contamination during the process.

► IMAGE 01

01

8

02

SUPPORT GRIDS

OUTLET BASKETS

______

______

The support grid system is available in an

assortment of framing options and designs - as

a one-piece construction or in multiple sections

for on-site assembly and ease of retrofitting

through existing manways. Because of their

strength, durability and flow characteristics, our

support grids are widely used in hydrotreaters,

desulfurizers, molecular sieves, gas sweeteners,

ion exchangers and other absorption systems.

A large range of industries use cartridges.

Rugged, precise and easy to clean, these filter

elements are suitable for all industrial processes.

Benefits

• Self-supporting structure

• Exceptional resistance to collapsing or

buckling, even in operations where screens

must withstand extremely high loads

• More effective open area than grids using

wire mesh or grating

• Smooth surface of the screens reduces

abrasion of media

•

Features

• Slot size can be designed for direct media

retention

• Grids can be supplied with support beams,

rope packing, bolting and all necessary

accessories

They can be used for:

• Conventional filtration, outside-in

• Reverse filtration, inside-out

The use of extremely fine wire maximises the

open area. This process is all the more true for

slots smaller than 100 microns.

The following types of fittings can be welded

to allow incorporation of cartridges into any

process:

• Collars

• Flanges

• BSP or NPT threaded end fittings

• Machined rings for fittings with O-rings or

flat baskets

• Other fittings

► IMAGE 04

► IMAGE 03

03

04

9

10

JOHNSON SCREENS®

CENTRIFUGE BASKETS

CONTINUOUS CENTRIFUGE BASKETS

- STARCH PROCESSING

______

Bilfinger’s Johnson Screens® starch baskets are custom made to fit into any existing or new

centrifuge application. They improve starch refining by providing accurate and customised slot

sizes, specific to your needs. Features of this basket include:

• Increased fibre dewatering compared to nickel screens

• Extended wear life

• Custom manufactured to each centrifuge design

• Variable slot openings from 20 μm and up

• Fine Johnson Screens® Vee-Wire® construction prevents clogging

• Capable of withstanding high backwash pressures

CONTINUOUS CENTRIFUGE BASKETS

- SUGAR PROCESSING

______

Johnson Screens® patented fine Vee-Wire® continuous centrifuge basket is guaranteed to provide a

high mechanical strength, a precise slot opening and a larger percentage of open area, increasing the

amount of sugar crystal recovery.

The self-supporting structure of the basket is designed and engineered to withstand the high

stresses and load conditions of the sugar industry. Features of this basket include:

• Replaces electroformed and laser screens

• Variable slot openings from 20 μm and up

• Long lasting, fewer change-outs

• High resistance to abrasion

• Fast and easy installation

• Low maintenance, easy to clean

11

PRODUCTS

NOZZLES

Benefits

SCREW PRESSES

& SCREW PRESS BASKETS

• P

revents expensive resin/media loss into

piping distribution system

• Protects

downstream

pumping

Nozzles are used in liquid/solid or gas/Bilfinger’s unique

modular

design drainer

screw press

equipment

solid separation. Their design and quantity

offers a single drive

solution for conveying, washing,

• Vpressing

isibility of minor

resin/media

losses

will vary depending on application and

dewatering and

solids for

the removal

of in

prevention

of

major

equipment

failure

customer-flow requirements. Nozzles allow

free water. This screw press has separate washing and

______

______

a more effective use of the treatment media.

dewatering zones and reduces water content of the solids

Features

up to four times.

• Continuous slot design, allowing traps

Common applications include:

to capture

media

particles

ofthat

anyare

size,

• Collectors and distributors installed Bilfinger manufactures

screw

press

baskets

providing

open

to of

letscrew

to fit intosufficient

any make

andarea

model

uniformly across a plate or a header custom designed

process flow move smoothly

lateral arrangement

press.

•

Stainless steel construction (other alloys

• Demineralizers, water softeners and in

can be includes

used depending

on pressure

and

pressure and gravity sand filters

The variety of baskets

high strength,

Johnson

temperature)

Screens® Vee-Wire®

and drilled hole slotted designs,

Various options

for sizes,

shapes

and

Benefits

which provide• increased

open area,

enhanced

fibre

connections,

depending

• Economical design

retention and improved

effluent

clarity. on process flow

characteristics

► IMAGE 05

• Non-plugging design

• Designed for full system pressure

• High open area

• Increased strength & corrosion resistance

► IMAGE 07

120° SIEVE BEND SCREENS

SCREEN LATERAL SYSTEMS

______

Features

______

• Standard diameter: 50 mm

Johnson

• Typical slot opening ranging from 0.2

mm Screens® 120° sieve bend screens are used in

These

assemblies

consist

of a series ofAs

static sieves for

either

dewatering

or classification.

to 0.5 mm

screen

connected

either amade

central

the slurry flows

overlaterals

the inclined

screentosurface,

of

• Threaded end fittings or “L” bolts

header

pipe or a hub.

Theya are

designed

perpendicular

to flow,

layer

of slurryfor

is

• Primarily made of stainless steel; wires which are

sliced away. effective media retention in a wide range of

however, special spherical nozzles made

applications, including ion exchangers, clay

from ABS or Kynar® are also available

and

sand filtration

and carbon

► IMAGE 05

Made from our

patented

Johnsonapplications

Screens® Vee-Wire®

towers.

screens, the 120°

sieve bend screens can provide up to 50

RESIN TRAPS

______

percent more open area because of our greater range of

narrower wireBenefits

profiles.

• The design allows

a uniformBilfinger

collection

A resin trap is a safety device used on the

Considering manual-handling

restrictions,

or distribution

flow of

a gas orThe

liquid

overflow lines of ion exchange units, highdeveloped an innovative

split-sieve

concept.

design

treatment

media

without

purity water systems, activated carbonoffers

and a simple, through

economical benefit by reducing thedead

zones

media filters.

physical size and also the screen weight.

• The system can accommodate a wide

variety

of vessel

sizes and

shapes with

In many systems, a valve failure can allow

Features of the 120°

sieve

bend screen

include:

side, centre, top or bottom inlet piping

media to escape from the treatment vessel.

• The assemblies

can be designed

to

Not only is the loss of expensive media• Reduced equipment

and installation

costs

accommodate

flow in any direction

significant, but damage can easily occur

• to

Low maintenance

costs

downstream pumping equipment.

• Better flow rate and finer fibre removal

• Wide range of applications

Johnson’s resin traps, placed inline, provide

• Longer lifetime

positive protection. The traps can be • Slot sizes range from 25 μm to 10 mm

designed to capture media particles of •any

Typically made with 300 series stainless steel

► IMAGE 07

size.

12

Features

• Lateral spacing, length, diameter and slot opening

sizes are based on individual system needs: slot

size 0.05 mm and up in 0.01 mm increments, and

diameter from 20 mm up

• Assemblies are typically made with type 304SS,

316LSS or other exotic alloys

• Connections of the laterals can be threaded fittings,

couplings or flanges

through the system. The slurry is gravity fed to the

head box and then flows to the screen. The solids

retained from the screen gather for disposal or reuse.

These easy-to-install gravity screens feature low

operating and maintenance costs. The Bilfinger

team of engineers can customise according to client

specifications.

► IMAGE 08

► IMAGE 06

FRACTAL COLLECTORS & DISTRIBUTORS

______

Johnson Screens® gravity screens are typically

applied to make coarse separations ahead of

additional processing systems. The system uses a

Johnson Screens® Vee-Wire® dewatering screen

to retain the solids while allowing effluent to run

05

06

07

08

13

PRODUCTS

120° SIEVE BEND SCREENS

______

Johnson Screens® 120° sieve bend has a greater screening

capacity than a flat screen due to forces exerted as material flows

against the curved surface. This curved profile wire screen is

mounted in a frame with the screen openings perpendicular to

the flow.

09

In a typical feed situation, the leading edge of the wedge wire

removes the water and fine particles through the screen up to

the cut point size, as the oversized particles move across the top

of the screen.

Separation size is considerably smaller than screen openings,

usually about one-half the opening size.

Sieve bend screens are ideal for sizing and dewatering

applications in liquid/solid separation situations. It is

extensively used for fine fibre removal in the starch industry. It

also is used in other industries such as food processing, waste

water cleanup and corn wet milling.

Features of the Johnson Screens® 120° sieve bend screen include:

•

•

•

•

•

•

•

Reduced equipment and installation costs

Low maintenance costs

Better flow rate and finer fibre removal

Wide range of applications

Longer lifetime

Slot sizes range from 25 μm to 10 mm

Typically made with 300 series stainless steel

► IMAGE 07

CYLINDRICAL BASKETS

______

Cylindrical baskets can be designed for a flow from out to in

(standard construction) or from in to out (re-rolled construction).

They screens are adapted for self-cleaning filters or screw press

filters and can be cleaned with static scrapers.

Benefits

• Self cleaning surface

• High open area

• Strong construction

14

12

Features

• Dimensions adaptable to any specific needs

• Large range of constructions (wires, rods)

• All slot sizes from 25µm

• Flanges and reinforcement rings available depending on the

application

10

► IMAGE 12

PRESSURE SCREENS

______

Pressure screens are mainly used for the stock preparation in the

pulp and paper industry. They can be used for any application

regarding fibre or fine grain filtration.

Benefits

• The continuous slot gives a greater performance thanks to a

higher open area

Features

• Specific, contoured wire shape

• Diameters from 200 mm to 1,500 mm

• Increased screening efficiency

• Special surface chroming process allows for less frequent cylinder

replacement

11

SCREW PRESS

______

For dewatering using a screw press, Bilfinger can provide a screen

designed to meet your exact specifications. Our high-strength design

can withstand the rugged operation while providing an accurate

slot width and maximising open area to maximise dewatering. For

use in numerous industrial designs. Abrasion resistant options are

available.

Benefits

• High-strength design

• High open area

Features

• Accurate slot width

• Custom designed to fit any application

► IMAGE 13

15

TECHNICAL DATA

STANDARD WELDING CONSTRUCTION

______

Bilfinger’s standard welded construction uses resistance-welding

in a continuous elliptical motion to join the wire and rods. The

resistance welds the continuous length of wire to the rods as it

circulates.

Corner

Radius

Wire

Width

Slot

Wire

Height

Relief

Angle

Weld Penetration

Screens can be made in various formations, including cylindrical,

Support Rod

flat, or curved. Any variation of wire and rod sizes as well as slot

Height

opening can be chosen to develop the exact screen of your choice.

Screens are available in slot opening from 25 μm up to 25 mm. Most

common materials used are 300 series stainless steel, but many exotic alloys are available.

Screen

Height

WIRE AND RODS INFORMATION

______

A wide range of wire and rod shapes make it possible to achieve the optimum balance of strength, open area, abrasion resistance

and dewatering/separation efficiency.

JOHNSON SCREENS® ROUND AND STRIP SUPPORT RODS

Round rods are available in diameters ranging from 3.2 mm to 12.7 mm. Strip rods are available in widths

from 1.8 mm to 4.8 mm and heights ranging from 9.5 mm to 50.8 mm.

16

16

COMMON JOHNSON SCREENS® SHAPED

SUPPORT RODS

Our shaped support rods range in widths

from 0.7 mm to 3.8 mm and heights ranging

from 2.6 mm to 3.0 mm.

Q25

63

93

XJR

156

SR250

SR475

OPEN AREA CALCULATIONS

To calculate the open area of a certain screen, use the simple formula provided:

Open area (%) = Slot size * 100

Slot size + Wire width

JOHNSON SCREENS® VEE-WIRE® PROFILES

Bilfinger’s Johnson Screens®

Vee-Wire® profile wires range in

widths from 0.5 mm to 5.0 mm and

heights ranging from 1.0 mm to

9.0 mm. Other wire shapes are also

available.

20 30

47

63

69

93

118

130

191

17

17

EXCEPTIONAL PRODUCTS,

EXCEPTIONAL SERVICE

FIELD SERVICE

______

Bilfinger offers a complete field service activity with a team of specialised and experienced

supervisors available for various interventions like:

•

•

•

•

•

Full installation

On-site repairs

Technical assistance or expertise

Work supervision

Inspection

Flexibility and expertise allow us to propose this extended scope of services under tailor-made

contract conditions in order to better serve our clients’ requirements.

Our experienced welder/fabricators team is available for onsite installation, repairs and screen

replacement for emergency situations or scheduled as needed.

Able to evaluate the condition of screens and make recommendations as to the best course of

action, our field service team will be there to allow the screens to operate at maximum capacity.

Whether cleaning, making minor or major repairs, or doing a complete replacement of screens, our

technicians are equipped with all the tools, equipment and experience needed to provide the best

field service available.

Our experienced technicians are also available for supervision of installations and on-site repairs.

18

19

Bilfinger Water Technologies

General Industrial Business Unit

Australia

Phone +61 7 3867 5555

Fax +61 7 3867 5566

asiapacific.water@bilfinger.com

www.water.bilfinger.com

Quality

ISO 9001

Copyright ©2014 All rights reserved to Bilfinger Water Technologies Pty Ltd

01 _1013.00