a novel control scheme for five level five phase diode clamped inverter

advertisement

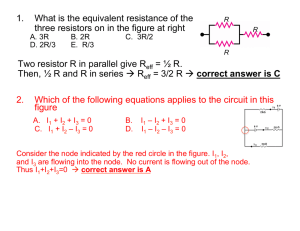

A NOVEL CONTROL SCHEME FOR FIVE LEVEL FIVE PHASE DIODE CLAMPED INVERTER 1 PAGIDIPALLI SURESHKUMAR, 2N.NAGENDRA 1,2 Department of EEE, Sasi Institute of Technology &Engineering, Tadepalligudem, A.P, India@sasi.ac.in E-mail:1153sureshkumar@gmail.com, 2nagendra232@sasi.ac.in Abstract— In this paper the five level five phase diode clamped inverter dc link capacitor voltages are balanced by combination of TLBC and the additional balancing circuit at high power factor and modulation index. Keywords— DC-link capacitor voltage balancing, diode clamped, multilevel inverter, three-level boost converter (TLBC). it can applied in certain cases where proper conditions in converter exit. This method is based on load current but it is independent on load and additional passive circuit. For diode clamped inverters more than three levels a passive frond-end capacitor voltage balancing method is only achievable, if the modulation index is limited to above 60%of its maximum value for loads of 0,8power factors. If the modulation index is more than this values then the central capacitor start to discharging, and finally the inverter output becomes at three levels. To overcome the problem an inverter can be equipped with an external isolated dc sours, this circuit acting as a active front end solution to balance the capacitor voltages,[7] [8].Many authors proposed PWM strategies for capacitor voltage balancing to avoid extra cost when using active front-end or balancing circuit. This method is found to have limitation on the range of operation with the changing of the power factor and modulation index [9], [10], [11]. Once a PWM strategy is employed for dc-link capacitor voltage balancing, solving problems such as total harmonic distortion, common-mode voltage cancellation, and leakage current elimination with the same strategy is not feasible. I. INTRODUCTION The multi level inverter can be classified into three catego- ries according to their topologies, they are neutral point clam- ped, flying capacitor and cascade H-bridge.[1] an inverter is applied to an ac motor system harmonics are injected in the drive systems. Due to this the performance of the motor is reduced to its specific value. To overcome this problem many authors proposes so many techquenics.pwm is the one of the technology is used to reduce the harmonics and to improve the performance of the motor.[2] A multi level technology is very effective in ac drive sys- tems by using proper pwm techniques to improve the control of output voltage from the harmonic content in the system. The multi level inverter has the advantage over the convent- ional inverter is the possibility of low switching frequency, and low electromagnetic interference.[3] Three highly popular voltage-source multilevel inverters can be divided into three categories according to their topology: neutral point clamped, flying capacitor, and cascade H-bridge [4]–[5], [6], The flying-capacitor converter was introduced as viable multi level converter topology it has some distinct advantages over the diode clamped inverter including the absence the diodes and ability to regulate the voltage across the fc through redundant state selection (rss) even when the number of voltage level is greater than three. The main disadvantage of the active voltage balancing method is the need for measuring the voltage of the flying capacitor which Leeds to using extra hardware The neutral point clamed converters are still investigated to solve the problem of dc link capacitor voltage balancing. Improper voltage sharing on dc link capacitor leads to an over voltage on switches and finally a frailer of the converter. This problem is solved in npc converter in some alternative methods; it can be achieved by natural balancing. Method that control the neutral point current has some limitations because they are only efficient at specific load conditions and method with additional circutery increase the expense of the inverter. The natural balancing methods assures the dc link capacitor voltage balance any additional circuitry but II. DESCRIPTION OF THE SYSTEM In this paper, a five-level boost converter (TLBC) is used t- o supply a five-level diode-clamped inverter as shown in Fig.2 Fig 1. five level five phase diode clamped inverter with TLBC and balancing circuit. Proceedings of 11th IRF International Conference, 8th May 2016, Hyderabad, India, ISBN: 978-93-86083-09-8 42 A Novel Control Scheme For Five Level Five Phase Diode Clamped Inverter inductor starts disc- harge and which is flowing through the two capacitors C2 and C3 and the voltages VC2 and Vc3 gradually rises. The inductor current flowing direction is shown in thick solid line. during the time interval t3 to t4 are also both the switches are turned off. Fig 2. Switching signals and inductor current wave forms of TLBC. TLBC is used to control the two inner capacitors C1, C2 . Because it is in simple structure. it is also use to reduce the switching losses and the reverse recovery losses. The inter leaving technique is utilized for for three level boost conver- ter to reduce the input filter size by input current cancellation. Five level five phase diode clamped inverter dc link capacitor voltages are balanced by the combination of both TLBC and additional balancing circuit. The TLBC is used to control the both inner capacitor C2, C3 and the balancing circuit is used to control both outer capacitors C1 C4 by transferring the charge. All control functions are implemented fully in software with a single chip microprocessor. C. SWITCH S2 IS TURN ON III. INNER CAPACITORS BALANCING WITH TLBC A. SWITCH S1 TURN ON Fig 3. The inner capacitor voltage balancing using TLBC. During the interval t2 to t3 switch S2 is turn on and the switch S1 is turn off. and again the inductor LS is start to char- ge and the the capacitor C2 voltage (Vc2) gradually rises. The voltage across the capacitor C2 is increased by increasing duty ratio (D) and the time duration from t0 to t1. And the voltage across the capacitor C3 is increased by increasing the duty ratio (D) and the time duration from t2 to t3. The TLBC can be operated in different algorithms but here we can use only The output voltage of TLBC is written as follows V0 = VC2 + VC2 = 2VS/ (2 – D ) (1) Where D = duty ratio ( 2t1/ T ) D is varied from 0 to 1 The current ripple for conventional boost inverter can be written as When switch S1 is closed during the interval t0 to t1. The inductor LS start to charge and the voltage (VC3) across the capacitor C3 gradually rises. the inductor current flowing in the circuit is shown in solid line. In this interval switch S2 is turn off B. BOTH THE SWITCHES S1 AND S2 TURN OFF During the time interval t1 to t2 both the switches S1 and S2 are turn off. And the energy stored in the Proceedings of 11th IRF International Conference, 8th May 2016, Hyderabad, India, ISBN: 978-93-86083-09-8 43 A Novel Control Scheme For Five Level Five Phase Diode Clamped Inverter ∆I = VSDTSW / LS (2) Where TSW = switching frequency The current ripple for TLBC ∆I = V0 (1 – VS/V0 ) (2 VS/V0 –1 )/2LSfsw ( 3 ) Where fsw = switching frequency of conventional boost converter The control diagram of balanced circuit is shown in fig 6.a PID controller is used to control the duty ratio of the two switches.and it designed to have a propotional gain (kp) of 0.001, an integral gain (ki) of 0.01, and derivative gain of (kd) of 0. From the equations ( 2 ) and ( 3 ) the currnt ripple produced by the TLBC is half of the current ripple produced by the conve- ntional conveter. That’s way we can use small size inductor. Now to obtained the equal voltages across the two inner capacitors C2 and C3 the voltage balancing controller callad PID is used. The duty ratio of the switches S1 and S2 is contr- olled and to get the reference voltage Vref across the two capa- citors.fig 4. The PID controller is designed to have a propotional gain (Kp) of 0.003 , an integral gain (Ki) of 0.02, and a derivative gain (Kd) of 0.the below fig shows the control diagram of TLBC. Fig 6. Control diagram Fig for balancing circuit. Increasing the duty ratio of S3 and S4 will reduce the charging time of VC1 and VC4, respectively. However, if the duty ratio is too high, the middle capacitors will over disch- arge and reduce the voltage at the capacitors.to reduce this problem the contrller must be oprated slower then the TLBC controller. V. SIMULATION RESULTS The simulation results of five level five phase diode clamp- ed inverter is shown in the fig by using matlab simulink softw- are.here the dc link capacitor voltages are controlled by the TLBC and additional circuit.the input voltage to the TLBC is 136 volts and the voltage across the balancing the capacitors 82 volts, and the RL load is 150Ω and 28.7 mh. The frequ- ence of the load voltage is 50 hz. Fig 4. Control diagram of TLBC chopper. IV. THE OUTER CAPACITORS BALANCING PARAMETERS OF THE SIMULATION CIRCUIT The two outer capacitors C1 and C4 is controlled by the add- itional balancing circuit which is shown in the fig 5.the two capacitors are connectd across the two balancing circuits. .the voltages across the capacitors are controlled by the two swi- tches S1 and S2 by varying the duty ratio D. Fig 7. Dc link capacitor voltages VC1, VC2, VC3, VC4 at 82 volts at high resistive load ( power factor 0.99 ) Fig 5. Outer capacitor balancing circuit. Proceedings of 11th IRF International Conference, 8th May 2016, Hyderabad, India, ISBN: 978-93-86083-09-8 44 A Novel Control Scheme For Five Level Five Phase Diode Clamped Inverter [4] [5] [6] [7] Fig 8. Inverter five phase output voltages VAM, VBM, VCM, VDM, VEM. At high resistive load ( power factor 0.99 ) [8] CONCLUSION [9] The dc link capacitor voltages of the five level five phase diode clamped inver is controlled by connecting the three level boost converter at the two inner capacitors C2, C3 and the balancing circuit at the two outer capacitors C1, C4 at high power factor and and high modulation index. [10] [11] REFERENCES [1] [2] [3] A. Nabae, I. Takahashi, and H. Akag, “A new neutralpoint-clamped PWM inverter,” IEEE Trans. Ind. Appl., vol. IA-17, no. 5, pp. 518–523, Sep. 1981 M. Marchesoni and M. Mazzucchelli, “Multilevel converters for high power ac drives: A review,” in Proc. IEEE Int. Symp. Ind. Electron., 1993, pp. 38–43. K. Hasegawa and H. Akagi, “Low-modulation-index operation of a five level diode-clamped PWM inverter with a dc-voltage-balancing circuit for a motor drive,” [12] [13] IEEE Trans. Power Electron., vol. 27, no. 8, pp. 3495– 3504, Aug. 2012 M. Khazraei, H. Sepahvand, K. A. Corzine, and M. Ferdowsi, “Active capacitor voltage balancing in singlephase flying-capacitor multilevel power converters,” IEEE Trans. Ind. Electron., vol. 59, no. 2, pp. 769– 778, Feb. 2012. R. Stala, “A natural dc-link voltage balancing of diodeclamped inverters in parallel systems,” IEEE Trans. Ind. Electron., vol. 60, no. 11, pp. 5008–5018, Nov. 2013. A. Bendre, S. Krstic, J. Vander Meer, and G. Venkataramanan, “Comparative evaluation of modulation algorithms for neutral-point-clamped converters,” IEEE Trans. Ind. Appl., vol. 41, no. 2, pp. 634–643, Mar./Apr. 2005. N. Hatti, Y. Kondo, and H. Akagi, “Five-level diodeclamped PWM converters connected back-to-back for motor drives,” IEEE Trans. Ind. Appl., vol. 44, no. 4, pp. 1268–1276, Jul./Aug. 2008. M. Saeedifard, R. Iravani, and J. Pou, “Analysis and control of dc capacitor-voltage-drift phenomenon of a passive front-end five-level converter,” IEEE Trans. Ind. Electron., vol. 54, no. 6, pp. 3255–3266, Dec. 2007 M. Saeedifard, R. Iravani, and P. Josep, “A space vector modulation strategy for a back-to-back five-level HVDC converter system,” IEEE Trans. Ind. Electron., vol. 56, no. 2, pp. 452–466, Feb. 2009. S. A. Khajehoddin, A. Bakhshai, and P. K. Jain, “A simple voltage balancing scheme for m-level diode-clamped multilevel converters based on a generalized current flow model,” IEEE Trans. Power Electron., vol. 23, no. 5, pp. 2248–2259, Sep. 2008. K. Jung-Min, K. Bong-Hwan, and N. Kwang-Hee, “Threephase photovoltaic system with three-level boosting MPPT control,” IEEE Trans. Power Electron., vol. 23, no. 5, pp. 2319–2327, Sep. 2008. M. Hengchun, D. Boroyevich, and F. C. Lee, “Multi-level 2-quadrant boost choppers for super conducting magnetic energy storage,” in Proc. Appl. Power Electron. Conf. Expo., 1996, vol. 2, pp. 876–882. K. Amei, Y. Takayasu, T. Ohji, and M. Sakui, “A maximum power control of wind generator system using a permanent magnet synchronous generator and a boost chopper circuit,” in Proc. Power Convers. Conf., 2002, vol. 3, pp. 1447–1452. Proceedings of 11th IRF International Conference, 8th May 2016, Hyderabad, India, ISBN: 978-93-86083-09-8 45