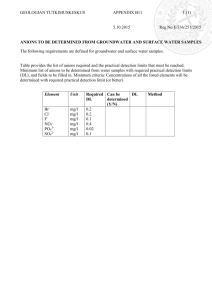

Reliability Assessment of Ion Contamination Residues on Printed

advertisement