A Combined Wye-Delta Connection to Increase the Performance of

advertisement

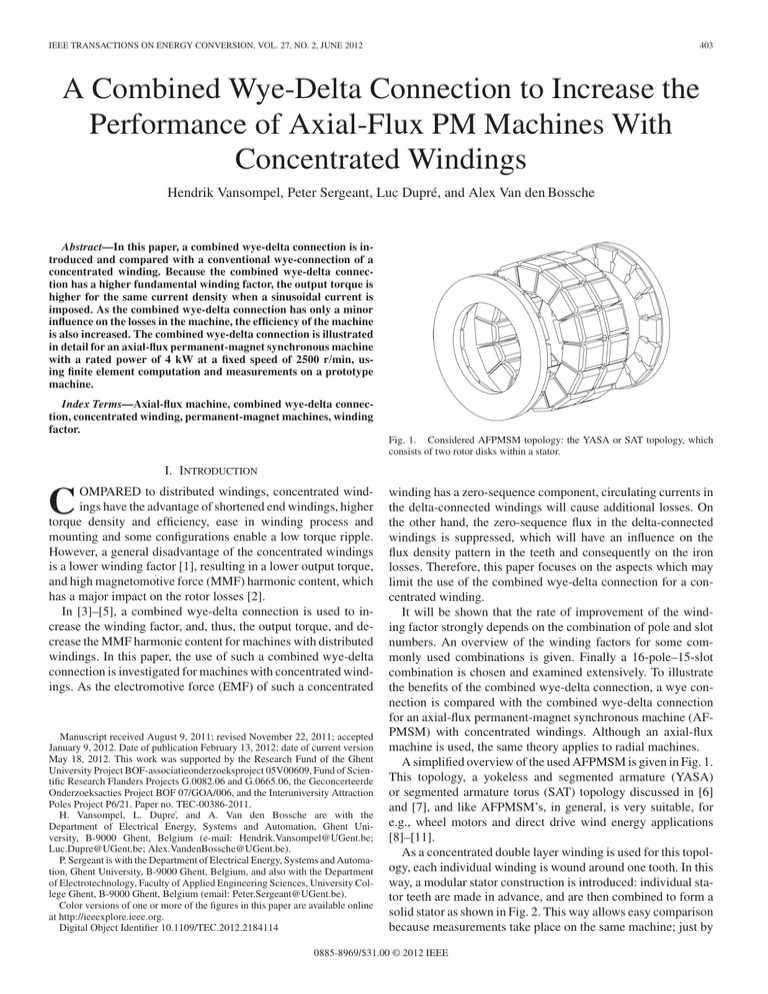

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 27, NO. 2, JUNE 2012 403 A Combined Wye-Delta Connection to Increase the Performance of Axial-Flux PM Machines With Concentrated Windings Hendrik Vansompel, Peter Sergeant, Luc Dupré, and Alex Van den Bossche Abstract—In this paper, a combined wye-delta connection is introduced and compared with a conventional wye-connection of a concentrated winding. Because the combined wye-delta connection has a higher fundamental winding factor, the output torque is higher for the same current density when a sinusoidal current is imposed. As the combined wye-delta connection has only a minor influence on the losses in the machine, the efficiency of the machine is also increased. The combined wye-delta connection is illustrated in detail for an axial-flux permanent-magnet synchronous machine with a rated power of 4 kW at a fixed speed of 2500 r/min, using finite element computation and measurements on a prototype machine. Index Terms—Axial-flux machine, combined wye-delta connection, concentrated winding, permanent-magnet machines, winding factor. Fig. 1. Considered AFPMSM topology: the YASA or SAT topology, which consists of two rotor disks within a stator. I. INTRODUCTION OMPARED to distributed windings, concentrated windings have the advantage of shortened end windings, higher torque density and efficiency, ease in winding process and mounting and some configurations enable a low torque ripple. However, a general disadvantage of the concentrated windings is a lower winding factor [1], resulting in a lower output torque, and high magnetomotive force (MMF) harmonic content, which has a major impact on the rotor losses [2]. In [3]–[5], a combined wye-delta connection is used to increase the winding factor, and, thus, the output torque, and decrease the MMF harmonic content for machines with distributed windings. In this paper, the use of such a combined wye-delta connection is investigated for machines with concentrated windings. As the electromotive force (EMF) of such a concentrated C Manuscript received August 9, 2011; revised November 22, 2011; accepted January 9, 2012. Date of publication February 13, 2012; date of current version May 18, 2012. This work was supported by the Research Fund of the Ghent University Project BOF-associatieonderzoeksproject 05V00609, Fund of Scientific Research Flanders Projects G.0082.06 and G.0665.06, the Geconcerteerde Onderzoeksacties Project BOF 07/GOA/006, and the Interuniversity Attraction Poles Project P6/21. Paper no. TEC-00386-2011. H. Vansompel, L. Dupre´, and A. Van den Bossche are with the Department of Electrical Energy, Systems and Automation, Ghent University, B-9000 Ghent, Belgium (e-mail: Hendrik.Vansompel@UGent.be; Luc.Dupre@UGent.be; Alex.VandenBossche@UGent.be). P. Sergeant is with the Department of Electrical Energy, Systems and Automation, Ghent University, B-9000 Ghent, Belgium, and also with the Department of Electrotechnology, Faculty of Applied Engineering Sciences, University College Ghent, B-9000 Ghent, Belgium (email: Peter.Sergeant@UGent.be). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TEC.2012.2184114 winding has a zero-sequence component, circulating currents in the delta-connected windings will cause additional losses. On the other hand, the zero-sequence flux in the delta-connected windings is suppressed, which will have an influence on the flux density pattern in the teeth and consequently on the iron losses. Therefore, this paper focuses on the aspects which may limit the use of the combined wye-delta connection for a concentrated winding. It will be shown that the rate of improvement of the winding factor strongly depends on the combination of pole and slot numbers. An overview of the winding factors for some commonly used combinations is given. Finally a 16-pole–15-slot combination is chosen and examined extensively. To illustrate the benefits of the combined wye-delta connection, a wye connection is compared with the combined wye-delta connection for an axial-flux permanent-magnet synchronous machine (AFPMSM) with concentrated windings. Although an axial-flux machine is used, the same theory applies to radial machines. A simplified overview of the used AFPMSM is given in Fig. 1. This topology, a yokeless and segmented armature (YASA) or segmented armature torus (SAT) topology discussed in [6] and [7], and like AFPMSM’s, in general, is very suitable, for e.g., wheel motors and direct drive wind energy applications [8]–[11]. As a concentrated double layer winding is used for this topology, each individual winding is wound around one tooth. In this way, a modular stator construction is introduced: individual stator teeth are made in advance, and are then combined to form a solid stator as shown in Fig. 2. This way allows easy comparison because measurements take place on the same machine; just by 0885-8969/$31.00 © 2012 IEEE 404 IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 27, NO. 2, JUNE 2012 Fig. 2. YASA or SAT topology allows to make an AFPMSM topology with a modular stator construction: individual stator teeth are made in advance, and are then combined to form a solid stator. Each module can be easily replaced which makes this topology very suitable for this research topic. TABLE I CHARACTERISTICS AND PARAMETERS OF THE CONSIDERED AFPMSG-PROTOTYPE Fig. 3. Phasorial diagram of one phase for the conventional wye connection for the example with 15 slots and 16 magnets. The EMF of one coil is indicated by E c , and the resulting EMF by E. the EMFs of the different coils E c exist, the total phase EMF E has an amplitude which is only a fraction kz 1 of the sum of the amplitudes of the contributing coil EMFs. This fraction, the so-called zone factor, is given by sin q α2 kz 1 = (1) q sin α2 rearranging and replacement of the stator modules, a change from wye connection to combined wye-delta connection is performed. This construction method is not only advantageous for easy manufacturing, but has general advantages quoting [12]: 1) shortened end windings leading to higher torque density and efficiency, 2) ease of winding process and high winding fill factor, 3) reduced mutual inductance between the machine phases resulting in improved phase independence and fault tolerance, and 4) reduced stator core weight due to the absence of the stator yoke. The comparison between a wye connection and a combined wye-delta connection is performed by finite element computation as well as by measurements on a prototype YASA AFPMSM [13], of which the main characteristics are summarized in Table I. II. COMBINED WYE-DELTA CONNECTION In [1]–[14], the winding factor kw Y 1 for a conventional wye connection for different combinations of slots and poles, which allow the realization of a balanced winding, is determined and summarized in Table II. The phasorial diagram for a conventional wye connection is represented in Fig. 3 for the example with 15 slots and 16 magnets. As phase differences between where q is the number of neighboring slots assigned to one phase, and α is the electric angle between two slots. As each coil consists of two wires lying in two neighboring slots, a phase difference between these neighboring EMFs exists, which reduces the coil EMF with a factor kp , the pitch factor, given by α . (2) kp = cos 2 The winding factor kw Y 1 , which is calculated in Table II for different slot and pole numbers can then be calculated by kw Y 1 = kz 1 kp . (3) In the considered example of 15 slots and 16 magnets, the zone factor kz 1 equals 0.9567 and the pitch factor kp equals 0.9945 leading to a winding factor kw Y 1 of 0.9514. As for easy construction, the individual winding is wound around one tooth, the pitch factor cannot be changed. However, by using the combined wye-delta connection, the zone factor can be increased and thus the winding factor. The phasorial diagram for a combined wye-delta connection is represented in Figs. 4 and 5 for the example with 15 slots and 16 magnets. By assigning the coils to the wye or the delta connection, depending on whether the phase of the coil best suits with the phase of the wye or delta connection, a higher zone factor can be obtained. In the 15-slots–16-magnets configuration, the zone factor increases from kz 1 = 1 + 2 cos (12◦ ) + 2 cos (24◦ ) = 0.9567 5 (4) VANSOMPEL et al.: COMBINED WYE-DELTA CONNECTION TO INCREASE THE PERFORMANCE OF AXIAL-FLUX PM MACHINES 405 TABLE II WINDING FACTORS FOR DIFFERENT SLOT–POLE COMBINATIONS WHICH REALIZE A BALANCED THREE-PHASE SYSTEM1 Fig. 4. Phasorial diagram of one phase for the combined wye-delta connection for the example with 15 slots and 16 magnets. The EMF of one coil is indicated by E c . The resulting EMFs of the wye- and delta-connected coils are indicated by E Y and E Δ , respectively. to 1 + 2 cos (12◦ ) + 2 cos (6◦ ) = 0.9891 (5) 5 which is an increase of 3.4%. The corresponding winding diagram and actual connections between the individual coils are given in Fig. 6. The same can be done for all combinations of slot and pole numbers. The obtained winding factors are summarized in Table II. In order to have the same output voltage in the wye connection as well as in the combined wye-delta connection, the kz 1 = Fig. 5. Three-phase phasorial diagram for the combined wye-delta connection for the example with 15 slots and 16 magnets. The EMF of one coil is indicated by E c . The resulting EMFs of the wye- and delta-connected coils are indicated by E Y and E Δ , respectively. √ delta-connected coils should have 3 times the numbers of the wye-connected coils. As the slot width is the same for wyeand√delta-connected coils, the wire section should be reduced by 3. In this way, Joule’s losses in both the wye- and deltaconnected coil windings are equal. In the prototype machine, the winding consists of two coils per tooth, one on each side of the tooth (see Fig. 1), and are put in parallel. For the wyeconnected teeth, on each coil 72 turns are placed in four layers of 18 turns, while on the delta-connected coils 125 turns are placed in five layers of 25 turns. The wire diameter of the wyeand delta-connected teeth is 1.05 and 0.8 mm, respectively. This 406 IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 27, NO. 2, JUNE 2012 Fig. 6. Winding diagram and actual connections between the individual coils in the combined wye-delta connection for the example with 15 slots and 16 magnets. combination of turn number and wire diameter results in the same output voltage and Joule’s losses in the windings. Finding the number of turns per layer, the number of layers and winding diameters in order to have a good copper filling factor for both wye- and delta-connected coils becomes more complicated as for the wye-connected machine. However, enameled copper wires are offered in many diameters. Moreover, the modular stator concept simplifies the winding process as each tooth can be wound outside the machine. Therefore, it is still possible to obtain good copper filling factors. The combined wye-delta connection will also have an influence on the losses in the machine. Due to the zero-sequence flux in the delta-connected coils, circulating currents are present and will result in additional Joule’s losses in the copper windings. As will be shown in the following paragraphs, the losses corresponding to the circulating currents in the copper windings are minor compared to global losses. As the circulating current in the delta-connected coils mitigates the zero-sequence flux, the iron losses in these teeth are smaller comparing to the wye-connected teeth and result in global lower iron losses. Next to the Joule losses in the copper windings and the iron losses in the teeth, the combined wye-delta connection also has an impact on the eddy current losses in the permanent NdFeB magnets as the airgap magnetic field harmonic content is changing. The magnitude of the eddy current losses is limited to ±3 and ±9 W for no-load and load, respectively. The increase in magnet eddy current loss due to the wye-delta connection for the examined prototype is only 3.5%, i.e., ±0.3 W, which is negligible to the global losses and is, therefore, not taken into account in the comparison. III. FINITE ELEMENT MODEL (FEM) The theory explained in previous paragraph is evaluated using an FEM. The FEM is the same for both wye and combined wyedelta connections, but differs in the way in which the currents are imposed. Because AFPMSM’s have an inherent 3-D structure, 3-D FEMs should be used in simulations. As these 3-D FEMs are very time consuming, “quasi-3-D” [15], [16] approximations using multiple 2-D FEMs at different radii are often used (see Fig. 7). The global solution is found as a weighted summation over the different 2-D FEM solutions. In this way, the computation time can be reduced. In such a 2-D FEM, the whole circumference of the machine is modeled, i.e., 15 teeth and 16 magnets. As the magnets are in an North-South (NS) topology [17], only half of the machine needs to be modeled by Fig. 7. Part of one of the six 2-D FEM solutions in which the circumference of the AFPMSM is modeled at a given radius. Left boundary is the symmetry axis of the vector-potential problem. Flux density levels are in Tesla. applying the Neumann boundary condition at the center part of the teeth. In circumferential direction, obtaining the right solution requires the use of periodic boundary conditions. An example of such a 2-D FEM is shown in Fig. 7. The torque of the generator is calculated by evaluating the Maxwell stress tensor along a line in the center part of the airgap. As the Maxwell stress tensor is very sensitive to numerical noise, a very fine mesh around the tooth tip and the airgap is required to obtain the right torque values. As this paper focuses on the stator teeth, an anisotropic material model based on the magnetic energy (variant on [18]) is applied. The anisotropic material model calculates the magnetization vector M as a function of the induction vector B. The equation for the magnetic potential A equals 1 ∇ × A − ∇ × M (∇ × A) = Je (6) ∇× μ0 where Je is the external current density. The magnetic potential equation is solved statically for different rotor positions using ±170.000 second-order elements. The voltage waveform is calculated a posteriori based on the calculated flux waveforms of the individual coils. The current waveforms, that are imposed by specifying Je , are calculated iteratively based on the voltage waveform in case of a resistive load. The circulating current in the delta-connected coils, for no load as well as full load, is done by iteration: for each static simulation, the current is modified until the zero-sequence flux is mitigated. The iron losses are calculated a posteriori, based on the simulated flux density patterns. The used model for the iron losses is based on loss separation [19], [20] and is explained in detail in [21]. The parameters in the anisotropic material model and the loss model are fitted from data retrieved by measurements on an Epstein frame. As the used material is grain oriented (GO), magnetic properties vary with respect to the direction in which VANSOMPEL et al.: COMBINED WYE-DELTA CONNECTION TO INCREASE THE PERFORMANCE OF AXIAL-FLUX PM MACHINES Fig. 8. Prototype AFPMSM: stator view without rotors. 407 Fig. 9. Simulated and measured back EMF waveforms of two consecutive teeth. For the 15-slot–16-pole combination, a shift of 12◦ exists between adjacent coil back EMFs. the field is applied. Therefore, strips in seven different directions, i.e., 0◦ , 15◦ , 30◦ , 45◦ , 60◦ , 75◦ , and 90◦ , were cut out of a insulated GO steel sheet. The complete determination of the material required measurements for various magnetic field amplitudes and different frequencies. IV. SIMULATION RESULTS AND EXPERIMENTAL VERIFICATION To check the validity of the simulations, a prototype AFPMSG shown in Fig. 8 was built. In Table I, the main characteristics of the suggested AFPMSM are listed. As only an increase of 3.4% in winding factor is expected, simulations and especially measurements should be done with great accuracy. However, when both wye and combined wyedelta-connected generators are connected to the same resistive load at the same speed, the power is equal to the square of the terminal voltage. This means that the output power of the combined wye-delta connected generator will be 1.069 times the output power of the wye-connected generator when connected to an equal resistive load at the same speed. This increase of 6.9% should be detectable in simulations as well as in measurements on a prototype. For simulations as well as for the measurements, a three-phase resistive load with a phase resistance of 30 Ω is chosen, and the reference speed is set to the nominal speed of 2500 r/min. The corresponding current delivered by the generator will in both cases not exceed the nominal current. To perform measurements on the suggested prototype AFPMSG, an experimental setup was built. In this setup, the AFPMSG is connected to a two-pole 7.5-kW induction motor via a torque sensor. This induction motor is fed by a 11-kW inverter that is controlled by laboratory virtual instrumentation engineering workbench. An optical position sensor is used to obtain the shaft speed, and a voltage measurement on the terminals of the AFPMSG is performed. Although each phase consists of five teeth, the winding of each individual tooth is accessible. The data retrieved from voltage, torque and speed measurement are sampled by a National Instruments data-acquisition system with a sampling speed up to 250 ksamples/s. Fig. 10. Simulated and measured back EMF waveforms of three wyeconnected teeth and two delta-connected coils. Circulating currents in the deltaconnected teeth mitigate zero-sequence components in the back EMF of the delta-connnected coils. In all subsequent figures, simulated and experimental data will be represented in the same axes to allow easy comparison. In Fig. 9, the no-load EMFs of two consecutive teeth are presented. Very good correspondence between simulated and measured data is found. As illustrated in the example in Section II, a shift of 12◦ exists between adjacent coil EMFs. Furthermore, it can be noticed that apart from fundamental harmonics, the coil EMFs contain additional harmonics. In the delta-connected teeth, the triple-harmonics in the flux will give rise to circulating currents. These currents strongly mitigate zero-sequence components in the coil EMFs (see Fig. 10). Simulation results of the wye and combined wye-delta connection are given in Table III. As predicted by the theory, a higher average torque output is achieved by the combined wyedelta connection: an increase of 7.8% and 7.2% for simulations and measurements, respectively, which is slightly above the expected 6.9%. 408 IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 27, NO. 2, JUNE 2012 Fig. 11. Simulated and measured waveform of the circulating current in the delta-connected coils. Corresponding Joule’s losses are limited due to the small resistance of the delta-connected coils. TABLE III COMPARISON SIMULATED DATA FOR WYE AND COMBINED WYE-DELTA CONNECTION: MACHINES CONNECTED TO A RESISTIVE LOAD OF 30 Ω Fig. 12. Simulated and measured phase voltage and phase current for the wye connection of the coils. In Fig. 11, the circulating current present in the deltaconnected coils is shown. Due to the relatively high inductance of the winding, the amplitude of the circulating current is limited. As the multilayer 2-D FEM does not take into account the effects of the end windings on the inductance, the simulated circulating current is higher than the measured one. As the resistance of a delta-connected winding is calculated to be 0.2 Ω, the Joule losses in the copper losses are very limited. Table III also shows that the no-load iron losses are slightly reduced. This small decrease can be explained by the absence of the zero-sequence components in the flux-density distribution in the delta-connected teeth. The full-load phase voltage and current waveforms of the wye and combined wye-delta connection are shown in Figs. 12 and 13, respectively. Good correspondence between simulations and measurements is found. Note that the full-load phase voltage waveforms are deformed due to the armature reaction. As can be seen in the current waveform of the delta-connected teeth in Fig. 13, the waveform is a superposition of the fundamental sinusoidal component and the circulation current. However, the effect of these circulation currents in the total Joule’s losses in the copper windings are limited and the losses in both connections are nearly equal. For both wye and combined wye-delta connection, the electric power output was measured using a three-phase power analyzer. Power outputs of 3776 and 4048 W were measured, which are in good correspondence with the simulated ones in Table III. Fig. 13. Simulated and measured phase voltage and phase current for the combined wye-delta connection of the coils. Values for the wye- and deltaconnected coils are indicated separately. Note that the current in the deltaconnected coils is a superposition of the load current and the circulating current. Moreover, the power ratio of the combined wye-delta connection is 7.2% higher than those of the wye connected, which means that the fundamental winding factor is increased with 3.5%. VANSOMPEL et al.: COMBINED WYE-DELTA CONNECTION TO INCREASE THE PERFORMANCE OF AXIAL-FLUX PM MACHINES 409 TABLE IV COMPARISON SIMULATED DATA FOR WYE- AND COMBINED WYE-DELTA CONNECTION: FUNDAMENTAL SINUSOIDAL CURRENT WITH AN RMS VALUE OF 6.67 A IS IMPOSED IN PHASE WITH THE BACK EMF Fig. 14. Simulated phase voltage and phase current for the combined wyedelta connection of the coils. Values for the wye- and delta-connected coils are indicated separately. Note that the current in the delta-connected coils is a superposition of the load current and the circulating current. Subtraction of the input mechanical power of the prime mover and the electrical power is used to estimate the losses in the machine. Losses at no and full load are significantly higher than the simulated ones: ±132 and ±250 W, respectively for both machines. However, next to the Joule losses in the copper and the losses in the iron of the stator teeth that are evaluated in the simulations, also bearing, windage and Joule’s losses due to eddy currents in the magnets are present when performing measurements on the prototype. Therefore, the measured efficiency of both machines is only 94%. As the output power increases for the same active mass, i.e., mass of copper windings, stator teeth iron, magnets, and rotor back iron, the power density increases. Fig. 15. Simulated full-load torque waveform of the wye- and combined wyedelta connection. Although a higher average torque output is achieved by the combined wye-delta connection, the torque ripple is higher than that for the wye connection. iron losses are even lower in the combined wye-delta machine due to the absence of triple harmonics in the delta connected teeth. As the losses remain the same while the output power increases, the efficiency of the machine improves. Despite the increase in torque and efficiency, Fig. 15 shows that the combined wye-delta connection has higher torque ripple. VI. CONCLUSION V. HIGHER EFFICIENCY In previous section, the increase in torque due to the higher winding factor of the combined wye-delta connection was illustrated. Good comparison between simulations and measurements proved the validity of the FEM. In this section, as in [22], the influence of load on the efficiency is studied. Therefore, simulations in which a fundamental sinusoidal current with an rms value of 6.7 A is imposed in phase with the back EMF are done for both wye and combined wye-delta connection. For the combined wye-delta connection, the voltage and current waveforms are shown in Fig. 14. However, this time the focus will be on the efficiency of the machine during operation. Comparison of the data in Table IV shows that the no-load losses due to the circulating current in the wye-delta-connected only result in small Joule’s losses. No load as well as full-load In spite of the many advantages of concentrated windings, an important drawback is that most configurations have a lower winding factor. In this paper, it was illustrated theoretically that in most configurations the winding factor can be increased by using a combined wye-delta connection instead of a common wye connection. The effectiveness of such a combined wye-delta connection was illustrated for a 16-magnet–15-slot YASA AFPMSM, by using finite element computations and measurements on a prototype machine. The increase in output torque is comparable with the increase in winding factor, as theoretically expected. On the other hand, the losses in the combined wye-delta connection were the same as those for a common wye-connected machine. As the power for the same machine was increased without supplementary losses, the machines efficiency is increased. 410 IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 27, NO. 2, JUNE 2012 REFERENCES [1] J. Cros and P. Viarouge, “Synthesis of high-performance PM motors with concentrated windings,” IEEE Trans. Energy Convers., vol. 17, no. 2, pp. 248–253, Jun. 2002. [2] L. Albert, E. Fornasiero, and N. Bianch, “Rotor losses measurements in an axial flux permanent magnet machine,” IEEE Trans. Energy Convers., vol. 26, no. 2, pp. 639–645, Jun. 2011. [3] J. Y. Chen and C. Z. Chen, “Investigation of a new AC electrical machine winding,” IEE Proc. Electr. Power Appl., vol. 145, no. 2, pp. 125–132, Mar. 1998. [4] R. Gjota, “Winding arrangement of a stator and/or rotor of a three phase generator or electromotor with improved performances,” U.S. Patent 4 710 661, Dec. 1, 1987. [5] M. V. Cistelecan, F. J. T. E Ferreira, and M. Popescu, “Adjustable flux three-phase AC machines with combined multiple-step star-delta winding connections,” IEEE Trans. Energy Convers., vol. 25, no. 2, pp. 348–355, Jun. 2010. [6] T. J. Woolmer and M. D. McCulloch, “Analysis of the yokeless and segmented armature machine,” in Proc. IEEE Int. Electr. Mach. Drives Conf., May3–5, 2007, pp. 704–708. [7] W. Fei and P. C. K. Luk, “Cogging torque reduction techniques for axial flux surface-mounted permanent-magnet segmented-armature-torus machines,” in Proc. IEEE Int. Symp. Ind. Electron., Jun. 30–Jul. 2, 2008, pp. 485–490. [8] M. Andriollo, M. De Bortoli, G. Martinelli, A. Morini, and A. Tortella, “Permanent magnet axial flux disc generator for small wind turbines,” in Proc. 18th Int. Conf. Electr. Mach., Sep.6–9, 2008, pp. 1–6. [9] T. F. Chan, L. L. Lai, and Xie Shuming, “Field computation for an axial flux permanent magnet synchronous generator,” IEEE Trans. Energy Convers., vol. 24, no. 1, pp. 1–11, Mar. 2009. [10] S. M. A. Sharkh and M. T. N. Mohammad, “Axial field permanent magnet DC motor with powder iron armature,” IEEE Trans. Energy Convers., vol. 22, no. 3, pp. 608–613, Sep. 2007. [11] T. F. Chan, W. Weimin, and L. L. Lai, “Performance of an axial-flux permanent magnet synchronous generator from 3-D finite-element analysis,” IEEE Trans. Energy Convers., vol. 25, no. 3, pp. 669–676, Sep. 2010. [12] W. Fei, P. Luk, and K. Jinupun, “A new axial flux permanent magnet segmented-armature-torus machine for in-wheel direct drive applications,” in Proc. IEEE Power Electron. Spec. Conf., 15–19 Jun., 2008, pp. 2197–2202. [13] H. Vansompel, P. Sergeant, and L. Dupr, “Optimized design considering the mass influence of an axial flux permanent-magnet synchronous generator with concentrated pole windings,” IEEE Trans. Magn., vol. 46, no. 12, pp. 4101–4107, Dec. 2010. [14] N. Bianchi, M. Dai Pré, and L. Alberti, “Theory and design of fractionalslot PM machines,” presented at IEEE Industry Applications Conf. Tutorial Course Notes Padova, Italy: CLEUP, 2007. [15] R. J. Wang and M. J. Kamper, “Evaluation of eddy current losses in axial flux permanent magnet (AFPM) machine with an ironless stator,” in Proc. 37th IEEE IAS Annu. Meet Conf. Rec., Pittsburgh, PA, Oct.2002, pp. 1289–1294. [16] A. Parviainen, M. Niemelä, and J. Pyrhönen, “Modeling of axial permanent-magnet machines,” IEEE Trans. Ind. Appl., vol. 40, no. 5, pp. 1333–1340, Sep./Oct. 2004. [17] S. M. Hosseini, M. Agha-Mirsalim, and M. Mirzaei, “Design, prototyping, and analysis of a low cost axial-flux coreless permanent-magnet generator,” IEEE Trans. Magn., vol. 44, no. 1, pp. 75–80, Jan. 2008. [18] T. Pera, F. Ossart, and T. Waeckerle, “Field computation in non linear anisotropic sheets using the coenergy model,” IEEE Trans. Magn., vol. 29, no. 6, pp. 2425–2427, Nov. 1993. [19] G. Bertotti, Hysteresis in Magnetism. San Diego, CA: Academic, 1998, pp. 391–430. [20] E. Barbisio, F. Fiorillo, and C. Ragusa, “Predicting loss in magnetic steels under arbitrary induction waveform and with minor hysteresis loops,” IEEE Trans. Magn., vol. 40, no. 4, pp. 1810–1819, Jul. 2004. [21] D. Kowal, P. Sergeant, L. Dupré, and A. Van den Bossche, “Comparison of non-oriented material and grain oriented material for an axial flux permanent-magnet machine,” IEEE Trans. Magn., vol. 46, no. 10, pp. 279–285, Feb. 2010. [22] F. J. T. E. Ferreira, A. T. de Almeida, G. Baoming, S. P. Faria, and J. M. Marques, “Automatic change of the stator-winding connection of variable-load three-phase induction motors to improve the efficiency and power factor,” in Proc. IEEE Int. Conf. Ind. Technol., (ICIT), 14–17 Dec. 2005, pp. 1331–1336. Hendrik Vansompel was born in Belgium in 1986. He received the Bachelor’s and Master’s degrees in electromechanical engineering from Ghent University, Ghent, Belgium, in 2008 and 2009, respectively, where he is currently working toward the Ph.D. degree at the Department of Electrical Energy, Systems and Automation. His research interests include electrical machines modeling and design, particularly for sustainable energy systems. Peter Sergeant received the M.S. and the Ph.D. degrees in electromechanical engineering from Ghent University, Belgium, in 2001 and 2006, respectively. He is a Postdoctoral Researcher for the Fund of Scientific Research Flanders since 2006, and a Researcher in the University College Ghent, Ghent, Belgium, since 2008. His current research interests include numerical methods in combination with optimization techniques to design nonlinear electromagnetic systems, in particular, electromagnetic actuators. Luc Dupré was born in 1966. He graduated in electrical and mechanical engineering in 1989 and received the degree of Doctor in applied sciences in 1995, both from the University of Gent, Belgium. Currently, he is full professor at the Faculty of Engineering and Architecture of Ghent University, Belgium. His research interests mainly include numerical methods for electromagnetics, modeling and characterization of soft magnetic materials, micromagnetism, inverse problems and optimization in (bio)electromagnetism. Alex Van den Bossche received the M.S. and Ph.D. degrees in electromechanical engineering from Ghent University, Ghent, Belgium, in 1980 and 1990, respectively. He was with Electrical Energy Laboratory, Ghent University, where since 1993, he has been a Professor in electromechanical engineering. He is an author of the book Inductors and Transformers for Power Electronics (Boca Raton, FL: Taylor & Francis, 2005). He was a starter of the spin-off companies Inverto n.v. (1990) and recently Alenco n.v. (2009). His research interests include electrical drives, power electronics on various converter types and passive components and magnetic materials. He is also interested in renewable energy conversion.