DynoAir™ System - API of NH/Delta T

advertisement

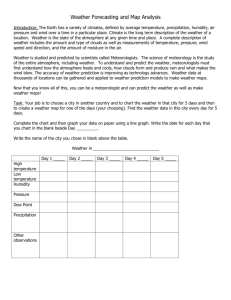

™ Controlled Air Delivery Systems Precision Air Conditioning For Precise Engine Testing SEI Stowe Enterprises, Inc. P.O. Box 3095 Mooresville, NC 28117 1.800.315.6751 Fax: 1.800.315.6751 web: www.stoweenterprises.com e-mail: stoweenterprises@aol.com ™ The DynoAir™ system was created to meet an urgent need in the ever more competitive sport of auto racing. Delivering 100% outdoor air with precision temperature and humidity control, DynoAir™ enhances the accuracy and reliability of engine dynamometer testing. The effect of changes in ambient temperature and humidity are no longer a factor when testing engine performance using DynoAir™. Whether it is hot, cold, wet, or dry outdoors, DynoAir™ conditions the air to be supplied to the engine carburetor at the temperature and humidity condition required – accurate to +/- 0.25ºF and +/- 2.5% RH*. DynoAir™ packaged systems are manufactured by Des Champs Laboratories Incorporated of Natural Bridge Station, VA, a unit of Entrodyne Corporation. DynoAir™ systems are distributed and installed by Stowe Enterprises, Incorporated of Mooresville, NC. For 27 years, Des Champs has been a recognized leader in the manufacture of quality energy recovery and precision air conditioning systems. Stowe Enterprises is a highly respected contracting firm that has served the automotive racing industry for more than 10 years. Des Champs and Stowe Enterprises worked together to develop the DynoAir™ system. Merging state-of-the-art air conditioning technology and engineering with more than 10 years of expertise in servicing the demanding needs of the racing industry, DynoAir™ is exactly what high performance engine test engineers have long dreamed of. DynoAir™ conditions any ambient point, located inside the green boundary, to a precise 70ºF DB, and a precise dew point as selected by the operator, between 45ºF and 55ºF. The DynoAir™ precision air conditioning system is built for years of reliable operation with minimal maintenance. The industrial quality, heavy-duty constructed unit ships fully assembled for outdoor installation on a concrete slab, roof curb, or structural steel support frame. Heating, cooling, dehumidification, and humidification systems are integral to the unit. A DDC control system is factory mounted and wired for precise control of all unit functions. The control algorithm responds to the outdoor air temperature and humidity condition by automatically adding or removing moisture, and heating or cooling as required to achieve the desired set point conditions. With DynoAir™, the uncertainty in your engine test results, caused by day to day changes in air temperature and humidity, is one less variable of concern. DynoAir™ elevates the standard in engine testing to a higher level, allowing you to be more confident that you are making the correct engine component adjustments. * At supply air dry bulb temperature set point of 70ºF, supply air dew point set point between 45ºF and 55ºF, and ambient conditions from winter extreme of 20ºF DB/50%RH to summer extreme of 95ºF DB/77ºF WB. Benefits of DynoAir • Allows for more accurate and reliable engine testing all year long • State-of-the-art temperature and humidity controls permit engine testing on your time schedule… regardless of the weather • Provides for an elevated level of confidence in making the correct engine component adjustments • Permits optimization of engine performance over a wide range of anticipated on track temperature and humidity conditions • Gives you one more tool to achieve success Design and Construction Features Base Frame: All-welded structural "C" channel steel frame, painted with one coat of metal primer, followed by two coats corrosion and weather resistant 100% acrylic latex paint. Unit Casing and Floor: 2" galvannealed steel double wall (18ga. outer skin with 22ga. inner liner). 2" 1.5-lbs. insulation secured between inner & outer walls. Interior of unit shall be aluminum in humidifier and coil sections. Exterior of unit shall be painted with two coats acrylic latex paint. Hinged access doors shall be provided for inspection/maintenance of all sections of unit. Access doors shall be gasketed, insulated, double-wall constructed with full-length stainless steel piano-type hinges for rigidity and airtight enclosure. Two heavy duty cast aluminum, adjustable, handle-type door latches shall be furnished for each door. Floor shall be constructed of all-welded 16-gauge aluminized steel, and shall be insulated with 2-inch closed cell foam insulation. Floor shall be coated with tile clad epoxy paint. Multiple floor drains shall be provided to route moisture out either side or bottom, through 1-1/2 inch NPT drain connections. All drains must be trapped separately and heat traced as required. Filters: 2" 30% outdoor air filters with differential pressure gauge for dirty filter indication (factory furnished and installed) Precool/Reheat Heat Exchanger: Counterflow 5 row aluminum heat pipe air-to-air heat exchanger housed in stainless steel casing. Supply Fan and Drive: Airfoil plenum type, belt driven with high efficiency EPACT ODP motor sized to handle up to 2.0" E.S.P.. Fan chassis to be spring isolated. Cooling & Dehumidification Coil: DX coil with copper tubes, aluminum fins, and stainless steel casing. A sloped stainless steel drain pan shall be provided under DX coil. Air Cooled Condensing Unit (ACCU): DLI ACCU sized to deliver 100% outdoor air at a 45°F dewpoint (70°F dry bulb) with 95°F DB/77°F WB ambient. ACCU to be integrally mounted and fully factory piped. ACCU shall have a minimum EER of 11.6 and shall have four steps of control. All refrigerant specialties, including TXV’s, etc. shall be furnished and factory installed. A five-year compressor warranty shall be included. Condenser coil has copper tubes, aluminum fins, and galvanized steel casing. Intake Hood With Bird Screen: Factory mounted, special design to minimize water entry into unit. Dampers: Low leak, galvanized steel outdoor air shutoff damper with two-position actuator & control. Aluminum heat exchanger face & bypass dampers (for control of precool/reheat) with modulating actuator and control Electrical: Single point wiring connection to unit mounted disconnect on AHU electrical panel. Power feed may be 460V/3 phase, 230V/3 phase, or 208V/3 phase (customer to specify at time of order). Fused branch motor circuit, fused control transformer, motor starter, Johnson Metasys DX9100 DDC controller and terminals for interconnecting control wiring included in AHU electrical panel. DX coil discharge temperature sensor, outdoor air temperature & humidity sensors, heat pipe leaving air temperature sensor (reheat pass), and supply fan current switch for supply fan status shall be factory furnished and wired. Supply air temperature and humidity sensors shall be factory furnished, shipped loose for field wiring. Remote panel (Metasys DX LCD Display Terminal) shall be fully factory programmed. Remote panel ships loose for field installation and wiring. Heating Coils: Preheat and reheat open wire electric heat grid with SCR control. Humidifier: 12" adiabatic saturation media (glasdek). All welded 304 S.S. sump, PVC water piping and water distribution header, 3/4" make-up, 3/4" line drain, and 1-1/2" sump drain solenoid valves (shipped loose for field piping and wiring), recirculation water pump, float valve and sump level switch (to prevent pump operation unless sump is full) is included. Pump motor shall be factory wired to starter located in unit control panel. Sump freeze protection and automatic sump dump cycle included. Water supply to unit must be insulated and heat traced to prevent freezing in winter. Control: Unit shall provide precise supply air temperature and humidity control at ambient conditions between 20°F DB/50% RH and 95°Fdb/77°F WB. Unit shall be capable of controlling supply air dry bulb temperature at 70°F (+/- 0.25 F) and supply air dew point at setpoints ranging from 45°F to 55°F (+/- 1.0F). As the ambient dry bulb temperature rises above 20°F, unit will be capable of controlling supply air at dry bulb temperatures greater than 70°F. Similarly, at summer part load conditions, unit can deliver air colder than 70°F while still maintaining 45°F dew point. In the winter, as the ambient dew point rises above the design condition of 20°F/50%RH, unit may control supply air at dew points above 55°F. DynoAir™ is available in three standard sizes: 1500 CFM (serves one engine dynamometer), 2000 CFM (serves one engine dynamometer with reserve capacity for the future), and 3000 CFM (serves two engine dynamometers). Sizes are based on current automotive intake air requirements. Larger units are available on a custom basis. The operating range of DynoAir™ shall be between 115°F and -20°F as standard for all units. The range of positive control is between 20°F/50% RH and 95°F DB/77°F WB. All units shall be factory assembled, internally wired, and 100% run tested to check over all operation, including fan and blower rotation and control sequence, before leaving the factory. Wiring internal to the unit shall be numbered for simplified identification. Units shall be ETL listed and labeled, classified in accordance with UL 1995/CAN/CSA/ No. 236-M90. All DynoAir units are manufactured under the ISO-9001 quality management system as implemented by Des Champs. The units are constant volume, 100% outdoor air temperature and humidity control air handling systems, designed for mounting on a concrete pad, roof curb, or structural steel support frame. Supply air duct connection may be out bottom or end of unit (customer to specify at time of order). DES CHAMPS Heat Exchangers & Energy Recovery Saving Systems © 2000 Des Champs Laboratories Incorporated DYNO10.00/500C Supersedes: DYNO1199/500C