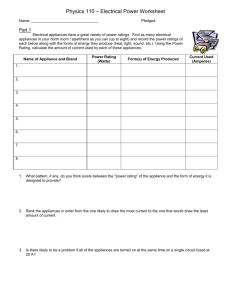

Can Energy-Efficient Electrical Appliances be considered

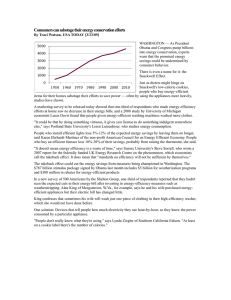

advertisement