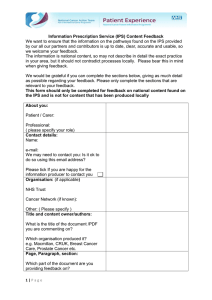

IPS e.max

advertisement