cfrobot8

advertisement

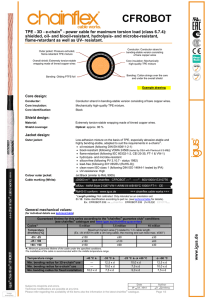

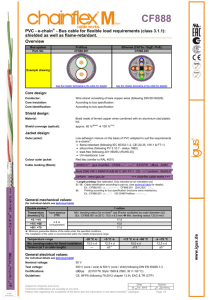

CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. Overview Ethernet Bus system Profibus CAN-Bus / Fieldbus Part. No. CFROBOT8.001 CFROBOT8.022 CFROBOT8.045 (see the chapter belonging to the bus system for details) (see the chapter belonging to the bus system for details) (see the chapter belonging to the bus system for details) (CAT 5e / GigE / PoE) Example drawing Profinet (Type C) CFROBOT8.060 Bus system Part. No. Example drawing (see the chapter belonging to the bus system for details) Core design: Image exemplary Stranded conductor in especially bending-stable version consisting of bare or tinned copper wires (following DIN EN 60228). Core insulation: According to bus specification. Core identification: According to bus specification. Shield design: Material: Torsion-stable braid made of tinned copper wires. Shield coverage: Linear: approx. 55% Optical: approx. 80% Jacket design: Outer jacket: Low-adhesion mixture on the basis of PUR (following DIN VDE 0281-10), highly abrasion- and bending-stable, adapted to suit the requirements in ® 3D - e-chains . oil-resistant (following DIN EN 50363-10-2) coolant-resistant flame-retardant (according to IEC 60332-1-2, CEI 20-35, VW-1) hydrolysis- and microbe-resistant MUD-resistant (following NEK 606 - status 2009) silicon-free (following PV 3.10.7 - status 1992) lead-free (following 2011/65/EU (RoHS-II)) clean room ISO class 1 (according to DIN ISO 14644-1 tested by IPA) UV-resistance: High Colour outer jacket: Steel blue (similar to RAL 5011) Cable marking (White): „00000 m“* igus chainflex CFROBOT8.--- --- E310776 яU AWM Style ----- VW-1 90°C 300 V EAC/CTP CE --- conform RoHS-II conform www.igus.de +++ chainflex cable works +++ * Length printing: Not calibrated. Only intended as an orientation aid. / : Cable identification according to part no. (see technical table for details). Ex.: CFROBOT8.001: …chainflex CFROBOT8.001 (2x0,35)C E… : Printing of the UL-Style (see chapter belonging to the cable). Ex.: CFROBOT8.001: …Style 20963 VW -1 AWM I/II A/B 80°C 30V FT-1… : Printing according to bus specification. Ex.: CFROBOT8.001: …CE Profibus conform… Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 1/8 www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ Conductor: CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. General mechanical values: (for individual details see technical table) ® Guaranteed lifetime for this series according to the "chainflex guarantee club" conditions ® (see chainflex catalogue and www.igus.eu/chainflex-guarantee) Cycles Temperature (from/to) [°C] 5 million 7,5 million 10 million Maximum torsion area [°] related to 1 m cable length. (Ex.: At ±180°/m with a 3m long cable, the moving end can twist max. ±540°) -25 / -15 -15 / +70 +70 / +80 ±150 ±180 ±150 ±90 ±120 ±90 ±30 ±60 ±30 : Minimum guarantee lifetime of the cable under the specified conditions. The installation of the cable is recommended within the middle temperature range. Temperature range ® Min. bending radius for 3D-e-chain use ® Min. bending radius for e-chain use Min. bending radius for fixed installation -40 °C -25 °C -15 °C +70 °C +80 °C ----- 12,5 x d 10,0 x d 7,5 x d 10,0 x d 7,5 x d 5,0 x d 12,5 x d 10,0 x d 7,5 x d 10,0 x d General electrical values: (for individual details see technical table and chapter belonging to the cable) CE, EAC & TR (CTP) Image exemplary www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ Guidelines: Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 2/8 CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. Dynamic values: Max. speed for ® 3D - e-chain use:** Twisted: v = 180 ° / s Max. acceleration for ® 3D - e-chain use:** Twisted: a = 60 ° / s Max. speed in ® e-chain use:** Unsupported: v = 10 m / s Max. acceleration in ® e-chain use:** a = 10 m / s ** 2 Gliding (up to 10 m): v = 2 m / s 2 These values are based on specific applications or tests. They do not represent the limit of what is technically feasible. Typical test setup for this cable group: Torsion: Torsion range T: ® 3D - e-chain length S: ± 180° / m 1m Test period: min. 3 - 5 million cycles Test speed: approx. 80 - 120 ° / s Test acceleration: approx. 40 ° / s 2 Test bending radius R: approx. 63 - 75 mm Test travel S2: approx. 1 - 12 m Test period (linear): min. 1,5 - 3 million double strokes Test speed: approx. 0,5 m / s Test acceleration: approx. 1,5 m / s 3D-e-chain® - servo cable for maximum torsion load: igus® chainflex® CFROBOT8 Image exemplary 2 highly abrasion-stable almost unlimited resistance to oil especially for torsion applications, but also for unsupported travel distances and up to 10 m in gliding applications UV-resistant CE, RoHS-II, UR, EAC & TR (CTP) Typical application areas: Indoor and outdoor applications. Robots, handling, spindles drives. Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 3/8 www.igus.de +++ chainflex® cable works +++ Linear: CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. Technical tables: Mechanical values: Part no. Number of cores & nominal cross section [mm²] External diameter (d)*** [max. mm] Copper index [kg / km] (2x0,35)C 8,0 29 62 (4x0,5)C**** 7,0 43 72 4x(2x0,14)C 8,5 39 69 (2x(2x0,34))C 8,5 36 70 Weight [kg / km] Profibus CFROBOT8.001 CAN-Bus / Fieldbus CFROBOT8.022 Ethernet (CAT5e / GigE / PoE) CFROBOT8.045 Profinet CFROBOT8.060 *** **** External diameters are maximum values and may tend toward lower tolerance limits. Star quad design (see the chapter belonging to the cable for details). Electrical values: Conductor resistance [approx. Ω / km] at 20 °C Max. current rating [A] at 30 °C (following) DIN EN 50289-1-2 DIN VDE 0298- 4 0,14 135 2,5 0,34 62 7 0,35 64 7 0,5 44 10 The max. current rating depends on factors such as the individual environmental conditions and the type of installation. Image exemplary www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ Nominal cross section [mm²] Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 4/8 CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. CFROBOT8.001 (Profibus) Conductor: Fine-wire strand in especially bending-stable version consisting of tinned copper wires Outer jacket: Pressure extruded PUR mixture Overall shield: Torsion-stable braid made of tinned copper wires Core insulation: Mechanically high quality TPE mixture (According to bus specification) Bending: Gliding PTFE-foil Filler: Plastic yarn Overall Banding: Plastic fleece Electrical values: Nominal voltage: 50 V Test voltage: 500 V Certifications: : (E310776: Style 1589 & 20963, 30 V / 80 °C) Operating capacity: approx. 30 pF / m ((at 1 kHz) following DIN EN 50289-1-5) Characteristic wave resistance: 150 ± 15 Ω ((at 3 MHz to 20 MHz) following DIN EN 50289-1-11) Construction table: Part No. CFROBOT8.001 Colour code 2x0,35 Cable construction red, green Image exemplary www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ (Back to overview or technical table) Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 5/8 CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. CFROBOT8.022 (CAN-Bus / Fieldbus) Conductor: Fine-wire strand in especially bending-stable version consisting of tinned copper wires Outer jacket: Pressure extruded PUR mixture Overall shield: Torsion-stable braid made of tinned copper wires Core insulation: Mechanically high quality TPE mixture (According to bus specification) Bending: Gliding PTFE-foil Filler: Plastic yarn Overall Banding: Plastic fleece Electrical values: Nominal voltage: 50 V Test voltage: 500 V Certifications: : (E310776: Style 1589 & 20963, 30 V / 80 °C) Operating capacity: approx. 40 pF / m ((at 1 kHz) following DIN EN 50289-1-5) Characteristic wave resistance: 120 ± 12 Ω ((at 0,425 MHz to 1 MHz) following DIN EN 50289-1-11) Construction table: Part No. CFROBOT8.022 Colour code 4x0,5 Cable construction white, green, brown, yellow (star-quad stranding) Image exemplary www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ (Back to overview or technical table) Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 6/8 CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. CFROBOT8.045 (Ethernet (CAT5e / GigE / PoE)) Conductor: Fine-wire strand in especially bending-stable version consisting of bare copper wires Outer jacket: Pressure extruded PUR mixture Element shield Torsion-stable braid made of tinned copper wires 34 mm Filler: Plastic yarn Core insulation: Mechanically high quality TPE mixture (According to bus specification) Element bending: Gliding PTFE-foil Overall bending: Plastic fleece Element bending: Plastic-foil Electrical values: Nominal voltage: 50 V Test voltage: 500 V Certifications: : (E310776: Style 1589 & 20236, 30 V / 80 °C) Operating capacity: approx. 40 pF / m ((at 1 kHz) following DIN EN 50289-1-5) Characteristic wave resistance: 100 ± 15 Ω ((at 1 MHz to 100 MHz) following DIN EN 50289-1-11) Maximum link length [m] Class D : ≤ 60 ( Cat 5e 100 MHz ) The specified max. link length is based on a direct connection (with two RJ45 connectors each with 0.8 db). Other configurations can affect the max. link length. Construction table: Part No. Image exemplary 4x(2x0,14)C Cable construction whitegreen/green, whiteorange/orange, whiteblue/blue, whitebrown/brown (According to EIA/TIA 568) (Back to overview or technical table) www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ CFROBOT8.045 Colour code Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 7/8 CFROBOT8 PUR - 3D - e-chain® - Bus cable for maximum torsion load requirements (class 6.7.3): shielded, oil- and coolant-resistant, hydrolysis- and microbe-resistant, notch-resistant as well as flame-retardant. CFROBOT8.060 (Profinet (Type C)) Conductor: Fine-wire strand in especially bending-stable version consisting of bare copper wires Outer jacket: Pressure extruded PUR mixture Overall shield: Torsion-stable braid made of tinned copper wires Core insulation: Mechanically high quality TPE mixture (According to bus specification) Bending: Gliding PTFE-foil Filler: Plastic yarn Overall Banding: Plastic fleece Electrical values: Nominal voltage: 50 V Test voltage: 500 V Certifications: : (E310776: Style 1589 & 20963, 30 V / 80 °C) Operating capacity: approx. 48 pF / m ((at 1 kHz) following DIN EN 50289-1-5) Characteristic wave resistance: 100 ± 5 Ω ((at 100 MHz) following DIN EN 50289-1-11) Maximum link length [m] Class D : ≤ 90 ( Cat 5e 100 MHz ) The specified max. link length is based on a direct connection (with two RJ45 connectors each with 0.8 db). Other configurations can affect the max. link length. Construction table: Part No. Image exemplary 2x(2x0,34) Cable construction white/blue, yellow/orange (Back to overview or technical table) www.igus.de igus® chainflex® CFROBOT8 +++ chainflex® cable works +++ CFROBOT8.060 Colour code Date Subject to misprints and errors. Technical modifications are possible at any time. 12 Nov. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items also the information in the latest chainflex® catalogue. Author D. Borsberg Page 8/8