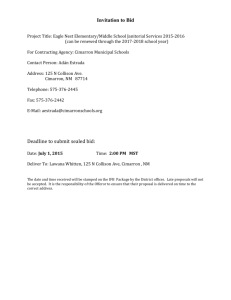

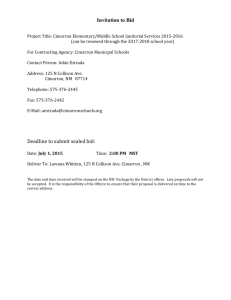

Cimarron Max Label

advertisement