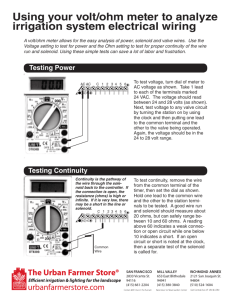

Troubleshooting Guide

advertisement