Fully Integrated PLL Based Clock Generator for Implantable

advertisement

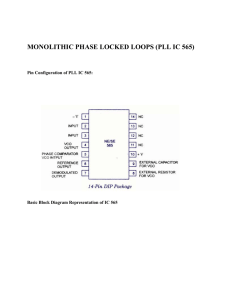

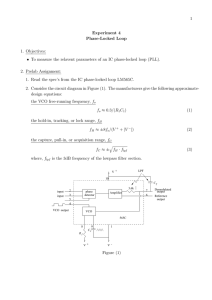

Fully Integrated PLL Based Clock Generator for Implantable Biomedical Applications Garrett Bischof, Ben Scholnick, and Emre Salman Electrical and Computer Engineering Stony Brook University, New York 11794 gbischof@ic.sunysb.edu, emre@ece.sunysb.edu Abstract – The design and verification of an ultra low power phase-locked loop (PLL) with application to implantable biomedical systems is presented. A systematic PLL design methodology is introduced, where the first step is a high level characterization of the system in MATLAB. The second step involves a transistor level implementation in Cadence using 0.35µm CMOS technology. The proposed low power and low area PLL consists of a phase-frequency detector, charge pump, secondorder low pass filter, and a ring oscillator based voltage controlled oscillator (VCO). The final design is fully integrated and has a power consumption of approximately 492µW. The operating frequency of the PLL is 6.78MHz, which is the lowest frequency designated for the Industrial, Scientific, and Medical (ISM) band. The phase margin and the bandwidth of the PLL are, respectively, 61.9° and 2.96 Mhz. designed to provide a continuous clock signal. Since the receiver is implanted within the human body, any circuit within the chip should consume ultra low power and area. An example application is a blood sugar monitoring device that is implanted under the skin to measure patient’s blood sugar. The rest of the paper is organized as follows. Background information about PLLs is provided in Section II. System level design considerations are described in Section III. Transistor level implementation of the PLL is explained in Section IV. Simulation results are presented in Section V. Finally, the paper is concluded in Section VI. II. BACKGROUND Keywords- PLL, VCO, implantable device, receiver, clock generator. I. INTRODUCTION A phase-locked loop is one of the most critical blocks in wireless/wire-line communication systems and clock generators [1]. A PLL is used to recover the clock signal from a corrupted incoming data signal. The recovered clock signal is used to sample the data and produce a clean data signal. The PLL is also used as a synthesizer to generate a stable clock signal from a reference signal. This clock signal is used for the digital blocks of a system. This paper addresses the problem of designing a low power and low area PLL in 0.35µm CMOS technology for use in implantable biomedical wireless systems that operate at 6.78MHz. These implantable circuits typically contain digital blocks for efficient signal processing of the sensed data [2]. Thus, a stable clock signal is required to synchronize these digital blocks within the receiver. A common approach is to extract the system clock signal from the carrier signal. Among different modulation schemes, on-off keying pulseamplitude modulation (PAM) or frequency-shift keying (FSK) are common schemes due to their relatively simple design and robustness against highly nonideal transmission medium within the human body [3]. A primary limitation of these schemes is that no carrier signal is provided during the off keying intervals. A dedicated clock generator, i.e., a PLL should therefore be 978-1-4244-9877-2/11/$26.00 ©2011 IEEE A PLL works by comparing the input data stream (reference signal) with the output of the voltage controlled oscillator (VCO) using a phase-frequency detector (PFD). Any difference in the phase and frequency of the two inputs of the PFD causes a predictable output signal which is used by the charge pump (CP) to either charge or discharge the capacitors in the low pass filter (LPF). If the VCO output is lagging behind the reference signal, the PFD will cause the CP to inject additional current into the LPF. The DC voltage at the output of the LPF will rise, thereby increasing the output frequency of the VCO. Once any phase or frequency differences have been eliminated, the circuit is referred to as “locked”. In the locked condition, the output signal of a PLL can be used as a stable clock signal to recover clean data from the corrupted incoming data signal. During on keying intervals, the carrier signal is utilized as the reference signal to synthesize a stable clock signal. Alternatively, during off keying intervals, the charge pump is disabled and the voltage of the LPF remains constant. PLL therefore continues to provide a stable clock signal during each operation mode of the receiver. A systematic PLL design methodology is introduced where the first step is a high level characterization of the system in MATLAB [4], as shown in Figure 1. The second step is to select values of the circuit parameters and verify the operation of the system also using MATLAB. This step ensures that the system is stable and fundamental constraints can be satisfied, i.e., system is capable of achieving the lock condition. Then, the transistor level design is achieved, and simulated with Cadence Spectre [5], to estimate the power consumption. To improve the performance of the system, Cadence simulations are completed with different parameters as well as different transistor designs. Drawing the physical layout and post layout verification of the system are the last steps. The PLL architecture discussed in this paper consists of four blocks: PFD, charge pump, low pass filter, and VCO. The charge pump and low pass filter are included to significantly improve the acquisition range of the PLL [6]. A second order loop filter is adopted to avoid stability issues and reduce high frequency jitter. Figure 3: Second order low pass filter. In order to ensure stability, the phase margin of the PLL should be greater than 60°. Also, a bandwidth smaller then the operating frequency is desirable to reduce high frequency jitter [6]. Other significant design constraints include low power dissipation and small chip area. Understanding the transfer function of the PLL is essential in determining the optimal values of the low pass filter (LPF) components, as well as the charge pump (CP) current and VCO gain. According to control theory, the transfer function of a closed loop system with negative feedback is given by (1) , 1 where HO is the open loop transfer function. The open loop transfer function of the system is · · (2) . Note that the unit of KVCO in (2) is Hz/V. The transfer function of the second order low pass filter illustrated in Figure 3 is 1 Figure 1: Design method illustrating the seven primary steps. Replacing (3) in (2) produces 1 III. SYSTEM LEVEL DESIGN Figure 2 introduces the system level representation of the 6.78MHz PLL and the transfer function of each block. . (4) Finally, replacing (4) in (1) gives 1 1 Figure 2: PLL architecture and the corresponding transfer functions. (3) . . (5) The phase margin of the PLL is determined through the bode plot of HO. The bode plot of HO crosses 0 dB at a specific frequency. The phase margin is equal to the phase shift at this frequency plus 180°. There is a tradeoff between the size of R1 and C1, and the phase margin. Smaller values of the low pass filter parameters permit on-chip integration, but decreasing R1 and C1 also degrades the phase margin. In order to obtain a phase margin close to 70° while keeping all of the components on- chip, R1 is selected to be 2KΩ, and C1 to be 800pF. Table 1: DESIGN PARAMETERS OF THE PLL, PHASE MARGIN, AND CHARGE PUMP CURRENT*VCO GAIN Value R1 2KΩ C1 800pF Value Phase Margin 61.9° C2 50pF ICP*KVCO 1020A/Vs Bandwidth 2.95MHz . PHASE MARGIN AS A FUNCTION OF KVCO*ICP 70 X: 1286 Y: 62.7 Bode diagram 150 50 Magnitude (dB) PHASE MARGIN (degrees) 60 40 30 100 50 0 -50 20 -100 -90 0 0 1000 2000 3000 4000 5000 ICP*KVCO (A/V*s) 6000 7000 8000 Phase (deg) 10 -120 -150 Figure 4: Relationship between phase margin and Kcp*ICP. -180 2 10 3 4 10 5 10 6 10 10 7 10 8 10 Frequency (Hz) Figure 5: Open loop transfer function to evaluate stability. Bode diagram 20 Magnitude (dB) 0 -20 -40 -60 -80 -100 0 Phase (deg) As determined by (4) and (5), KVCO and ICP always appear multiplied together, so in this part of the analysis, they can be treated as a single parameter since it is their combined value that determines the phase margin and bandwidth of the system. Later, the values of ICP and KVCO can be individually selected to minimize power disipation, ripple on the VCO control voltage, and to achieve an appropriate duty cycle for the VCO. As shown in Figure 4, the maximum phase margin occurs when the value of ICP*KVCO is 1286A/Vs. There is a direct relationship between ICP*KVCO and the power dissipation of the system. In this design, ICP*KVCO is selected to be 1020A/Vs. This produces a phase margin of 61.92° and a bandwidth of 2.95MHz. Achieving a phase margin greater than 60° is a more important design constraint than achieving a smaller bandwidth. Since C1 is already at a maximum size to fit on the chip, the only way to further decrease the bandwidth is to decrease R1 or ICP*KVCO. Decreasing either of these values will also decrease the phase margin. Since the phase margin cannot be reduced any further, the final parameters for the PLL are: R1 = 2KΩ, C1 = 800pF, C2 = 50pF, and ICP*KVCO = 1020A/Vs. C2 is selected to be 50pF in order to reduce the ripple on the VCO control voltage. Increasing C2 any further will decrease the phase margin. Figures 5 and 6 show, respectively, the bode plots of the open and closed loop transfer functions. Table 1 summarizes the parameter selection of the PLL. -45 -90 -135 -180 3 10 4 10 5 10 6 10 7 10 Frequency (Hz) Figure 6: Closed loop transfer function to evaluate bandwidth and peaking. 8 10 The next step is to verify that the PLL is able to obtain the locked condition. This verification is completed in Simulink using the model shown in Figure 7. Figure 8: Conceptual diagram of the PFD consisting of two D type flip-flops and a NOR gate. Figure 7: Simulink implementation of a PLL to verify stability and obtain locked condition. IV. TRANSISTOR LEVEL DESIGN After the system level design of the PLL has been completed and the PLL operation has been verified, as described in the previous section, the next step is to achieve the transistor level design of the PFD, CP, and VCO using 0.35µm CMOS with a reduced power supply of 2Volts. A. Phase-frequency detector The PFD is constructed using two true-single-phase-clock (TSPC) D-flip-flops (DFF), as shown in Figure 9 and a conventional NOR gate. The D input of the D-flip-flop is always grounded. This characteristic permits a DFF design with only six transistors. A small number of transistors makes this design a good choice to save power and space [7]. These DFFs are reset when there is logic high at the RESET input, and the output signal after reset is also logic high. Figure 10 shows the timing diagram of the PFD and gives some insight into the operation of the PFD and DFF. Since the D inputs of the DFFs are grounded, on the rising edge of the reference signal (VREF), a zero is sent to the output of the first flip-flop (UP). Then, on the rising edge of the VCO output, (VVCO), a zero is sent to the output of the second DFF (DOWN). When UP and DOWN are both zero, the output of the NOR becomes one, which causes both DFFs to reset, and the UP and DOWN signals both return to logic high. As shown in Figure 8, VREF is leading VVCO, this means that the VCO needs to speed up to match VREF. Correspondingly, Figure 10 shows more zeros in the UP signal than the DOWN signal, this corresponds to an increase in the VCO control voltage as well as the VCO output frequency. When the PLL is locked, the UP and DOWN signals become a nearly constant logic high value. Figure 9: Transistor level representation of a six transistor flip-flop where the data input is connected to ground . Figure 10: PFD timing diagram illustrating the reference voltage, VCO output voltage, UP, DOWN, and RESET signals. B. Charge pump and low pass filter The charge pump is incorporated into the PLL design in order to increase the acquisition range of the circuit [6]. The charge pump also has the ability to be easily tuned to meet the specifications of the circuit. The parameter ICP*KVCO should be 1020A/Vs to achieve a phase margin of 61.9°, as described in section III. The VCO gain is selected so that the VCO center frequency is around 6.78MHz. A VCO gain of 8.5MHz/V makes the center frequency around 6.78MHz. ICP is then determined by dividing 1020A/Vs by 8.5MHz/V resulting in 120µA. When there is a zero in the UP signal, the PMOS transistor in the CP as shown in Figure 11 closes and the top current source charges capacitors C1 and C2. When the DOWN signal is a zero, the zero gets inverted and produces a one at the input of the NMOS transistor. This signal closes the NMOS transistor and the lower current source discharges the two capacitors. The voltage Vctrl controls the frequency of the VCO. circuitry required for differential operation, the VDD-Vctrl input is grounded. This technique causes the top transistor of the transmission gate to be constantly conducting. Vctrl controls the VCO frequency by adjusting the resistance of the lower transistor in the transmission gate. The greater Vctrl is, the smaller the transmission gate resistance will be. From (6) and (7), a lower transmission gate resistance means a greater VCO frequency. The gain of this VCO is adjusted by altering the W/L ratios of the transistors until the center frequency is approximately 6.78MHz. This produces a VCO gain of 8.5MHz/V. Voltagefrequency characteristics of the VCO are illustrated in Figure 13. The output of the VCO is then connected to two inverters in order to convert the sinusoidal output into a square wave output. Figure 12: Transmission gate controlled VCO. C. Voltage controlled oscillator The voltage controlled oscillator (VCO) chosen for this design is a transmission gate controlled ring oscillator, as shown in Figure 12. The transmission gate controlled oscillator is designed to oscillate between 1KHz and 15MHz. This makes it suitable for lower frequencies such as 6.78MHz [8]. In this technology, it is difficult for a varactor controlled ring oscillator to operate at a frequency this low. The oscillation frequency of a ring oscillator is 1 (6) , 2 where N is the number of delay stages and tD is the delay per stage. tD is proportional to (7) , where R is the sum of the transmission gate and the inverter resistance and CL is the load capacitance. From (6) and (7), the oscillation frequency can be controlled by varying the resistance of the transmission gate [8]. Generally, this ring oscillator has two differential control inputs: Vctrl and VDD-Vctrl. In order to avoid the additional Table 2: W/L RATIOS OF THE TRANSISTORS WITHIN THE VCO M2 M3 M1 W/L [µm/µm] 0.6/5.0 4.0/2.5 0.6/2.5 6 15 FREQUENCY (MHz) Figure 11: Charge Pump and low pass filter. x 10 VCO FREQUENCY VERSUS VCTRL 10 X: 0.925 Y: 6.73e+006 5 0 0 0.5 1 VCTRL (V) 1.5 2 Figure 13: Voltage-frequency characteristics of the VCO. V. SIMULATION RESULTS Simulation is completed in Cadence Spectre [5] with the following parameter values: R1 = 2KΩ, C1 = 800pF, C2 = 50pF, ICP = 120µA, KVCO = 8.5MHz/V. Figure 14 depicts the variation of the VCO control voltage (Vctrl) as the PLL reaches the locked condition. According to this figure, when the PLL is locked, Vctrl is nearly constant. The ripple on the control voltage when the PLL is locked is 670µV which is equal to only 0.07% of the Vctrl. The UP and DOWN signals are mostly equal to VDD during the lock condition, as shown in Figure 15. At locked condition, the reference signal (VREF) and the VCO output (VVCO) have the same frequency and are in phase. The overall power consumption is 492µW. VCO CONTROL VOLTAGE 1.2 1.1 VCTRL (V) 1 0.9 VII. CONCLUSION This paper has presented a low-power PLL implemented in 0.35µm CMOS technology for an implantable biomedical device. The PLL is used to generate a stable clock signal at each mode of the receiver including the off keying intervals of the PAM scheme. The key design objectives are size, power consumption, and the signal acquisition ability of the system. This implementation of the PLL adequately addresses these design concerns, with the entire circuit consuming approximately 492µW of power, and is able to lock to an external 6.78MHz clock within a reasonable amount of time. The proposed low power, low area PLL has great potential in implantable biomedical systems. ACKNOWLEDGMENT 0.8 0.7 0.6 0.5 the addition of a frequency divider in the feedback loop. The next step will be to complete the physical layout, and to verify the operation of the post layout design. 0 5 10 TIME (µs) 15 20 Figure 14: Variation of Vctrl as the lock condition is achieved by the PLL. The authors greatly appreciate the advice received by a panel of mentors: Mr. Scott Abrams, CEO and President of Omnicon Croup, Hauppauge, NY; Mr. Andrew Braverman, President and CEO of Apptec Corp at Port Jefferson Station, NY; Ms. Yizhen Chen, Motorola, Inc., Holtsville, NY; Dr. David Hernandez, Access Systems – Honeywell, Shanghai, China; Mr. Steve Rubin, Patent Attorney, Dilworth and Barrese, LLP, Melville, NY; Ms. Yu Sun, Motorola, Inc., Holtsville, NY; Prof. Gerrit Wolf, College of Business at SBU; and Ms. Jade Zhang, Motorola, Inc., Holtsville, NY. The mentoring panel is supported by the National Science Foundation under Grant No. CNS 0829656 and IIP 0917956. Any opinions, findings and conclusions or recommendations expressed in this article are those of the authors and do not necessarily reflect the views of the National Science Foundation. REFRENCES [1] [2] [3] Figure 15: Vctrl, UP, DOWN, Vvco, and VREF signals when the PLL is in the locked condition. [4] [5] [6] VI. DISCUSSION AND FUTURE WORK [7] Future work includes jitter calculations. We will also investigate techniques to increase KVCO while reducing ICP to further reduce power dissipation. This modification will require [8] Young, I.A.; Greason, J.K.; Wong, K.L.; , "A PLL clock generator with 5 to 110 MHz of lock range for microprocessors," IEEE Journal of Solid-State Circuits, , vol.27, no.11, pp.1599-1607, Nov. 1992. Lee, E.; Hess, P.; Gord, J.; Stover, H.; Nercessian, P.; , "A 400MHz RF Transceiver for Implantable Biomedical Micro-Stimulators," IEEE Custom Integrated Circuits Conference, pp.173-176, Sept. 2007. G. Gudnason, E. Bruun, and M. Haugland, "An Implantable Mixed Analog/Digital Neural Stimulator Circuit," IEEE International Symposium on Circuits and Systems, pp.375-378, May 1999. Mathworks, Inc. <www.matlab.com>. Cadence Design Systems, Inc. <www.cadence.com>. B. Razavi, Design of Analog CMOS Integrated Circuits, McGraw-Hill, 2001. Van Helleputte, N.; Gielen, G.; “An Ultra-Low-Power Quadrature PLL in 130nm CMOS for Impulse Radio Receivers,” Biomedical Circuits and Systems Conference, pp. 63-66, Nov. 2007. Retdian, N.; Takagi, S.; Fujii, N.; “Voltage controlled ring oscillator with wide tuning range and fast voltage swing,” Proceedings of the IEEE Asia-Pacific Conference, pp. 201-204, 2002.