SST-A Bulletin 414-CERT copy:Layout 1

advertisement

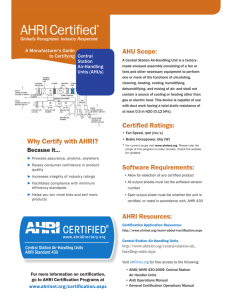

Bulletin 414-CERT Dear EVAPCO Customers: EVAPCO is pleased to introduce our new SST-A Series of stainless steel tube, aluminum fin evaporators! The SST-A thermal performance ratings are in accordance with AHRI Standard 420, “Performance Rating of Forced-Circulation Free-Delivery Unit Coolers for Refrigeration.” This rating method has been applied for each product family within the SST-A Series, including the SSTMA, SSTXA and SSTLA. More importantly, the thermal performance and power ratings for the SSTMA, SSTXA and SSTLA evaporator product lines are independently certified per the requirements outlined in the AHRI Operations Manual entitled Unit Coolers for Refrigeration Certification Program. The SSTMA, SSTXA and SSTLA Series are the three EVAPCO evaporator product groups covered in the AHRI certification program at this time. AHRI Evaporator Certification Program (1) Program Overview: The AHRI Evaporator Certification Program provides an independent verification of the evaporator manufacturer’s stated equipment performance based on thermal tests done in accordance with AHRI Standard 420–Performance Rating of Forced-Circulation Free-Delivery unit coolers for Refrigeration. Participation in AHRI’s Evaporator Certification Program is available to all manufacturers of products which fall into the scope of the program, whether or not the manufacturer is a member of AHRI. Participation in the program is voluntary. Program participants must comply with the provisions of the latest edition of AHRI Standard 420. A copy of the Standard is available for download from the AHRI website, www.ahrinet.org Product Definitions: EVAPCO’s decision to introduce AHRI Certified SSTMA, SSTXA and SSTLA evaporators reflects the company’s commitment to provide independently certified products throughout the world, whenever a recognized certification program exists. The thermal performance and power ratings of these new products have been verified as a result of full scale thermal testing by AHRI Certification Engineers in EVAPCO’s Low Temperature Laboratory, which was “certified” for product testing as part of the AHRI program. Forced-Draft Free-Delivery Evaporators for Refrigeration (Unit Coolers) As a result of this initiative, refrigeration engineers, contractors and end-users have the assurance that the EVAPCO industrial evaporators they select, install and operate will perform as specified based on the ratings methodology outlined in the AHRI Certification Program Operations Manual. Program Scope: EVAPCO is pleased to be leading this charge – it is the right thing to do and the right time to do it! Heat Transfer product performance and efficiencies are being increasingly regulated in Federal, State and Local building codes. In order for these codes to be properly enforced, and to create a level playing field for all manufacturers, we believe the product thermal performance must be determined using a standard ratings method and verified through a government recognized, third party certification program. AHRI is a highly regarded trade association which offers very stringent product certifications programs. As a result, regulators throughout all levels of government “are increasingly motivated to depend upon AHRI for the accurate and unbiased evaluation of HVACR equipment.” We believe federal, state and local regulations will continue to expand their emphasis on energy consumption and overall product efficiency in the future. Manufacturers of commercial and industrial heat transfer products will be required to offer only those products whose thermal performance have been independently certified. EVAPCO enthusiastically embraces this challenge. As a leading global supplier of heat transfer products, we are committed to use our extensive research and development and product marketing capabilities to improve heat transfer efficiency and promote certified products throughout the world. A factory made assembly including means for forced air circulation and elements by which heat is transferred from air to refrigerant without any element external to the cooler imposing air resistance. Evaporators utilize a volatile refrigerant fed by either direct expansion (DX) or liquid overfeed with ratings based on wet and/or dry conditions. The AHRI Evaporator Certification Program applies to production models of evaporators which meet the following criteria: 1. Use refrigerant R-404A or R-507A for direct expansion (DX) coils or R-717 for DX and/or liquid overfeed coils 2. Aluminum fin material 3. Single vertical coil 4. Horizontal only air flow direction (the airs flows to or from the inlet face of the coils from or to the fan inlet, with no change in direction) 5. Axial fans only EVAPCO model SSTMA, SSTXA and SSTLA units fall within the current scope of the AHRI Certification Program as outlined above. SSTWA and SSTDA models are outside the scope of the AHRI Unit Coolers Certification Program, but are rated in accordance with AHRI Standard 420. Evaporators which fall within the scope of the certification program but outside the testing capability of the Independent Third-party Laboratory contracted by AHRI, or AHRI Approved Test Stand within the Facility, must be certified under this program. Large unit coolers that cannot be tested in the Laboratory or the Participant’s facility shall be certified under the AHRI Unit Coolers Certification Program provided the following conditions are met: 1. The unit cooler coil number of rows, fin spacing, and fin thickness match a model that can be tested. 2. The air velocity entering the coil face falls within the range of calculated air velocities for the unit coolers that can be tested. 3. The Participant’s Selection Rating Software used to predict unit cooler capacity accounts for circuit temperature change and refrigerant side heat transfer as a function of refrigerant circuit loading and length. AHRI will approve the large Unit Cooler ratings only if all of the above conditions are met and the large unit coolers ratings are proportional to the unit coolers that can be tested. Sincerely, EVAPCO, Inc. William G. Bartley President & CEO ©2013 EVAPCO, Inc. AHRI Certification Program Qualification Process (1) Model Designation by Basic Model Group: Testing Requirements: Program Participant’s evaporator product lines are classified into Basic Model Groups (BMG) based on specific criteria as tube diameter, tube material, fin type, fin thickness, refrigerant, feed, etc. All Standard Ratings of Unit Coolers must be verified by tests conducted at Standard Ratings Conditions (Table 1.) in accordance with one of three Test Methods: 1. DX – Dual Instrumentation 2. DX – Calibrated Box 3. Liquid Overfeed EVAPCO’s AHRI Certified Evaporators are currently represented by the following BMG’s: 1. SSTMA & SSTXA Models - 5/8” stainless steel tube, enhanced fin or enhanced variable-fin with liquid overfeed. 2. SSTMA & SSTXA Models - 5/8” stainless steel tube, flat fin, flat heavy fin or flat variable-fin with liquid overfeed. 3. SSTMA & SSTXA Models – 5/8” stainless steel tube, enhanced fin or flat fin, direct expansion (DX) 4. SSTLA Models – 1.05” stainless steel tube, enhanced fin or enhanced variable-fin with liquid overfeed. 5. SSTLA Models – 1.05” stainless steel tube, flat fin, heavy fin or variable-fin with liquid overfeed. Selection and Qualification Testing: AHRI Certification thermal tests for evaporators using ammonia (R-717) as the refrigerant were tested at EVAPCO’s Low Temperature Laboratory located in Taneytown, Maryland. In order for EVAPCO’s Low Temperature Laboratory to be used in this manner, AHRI had to inspect and certify the laboratory to ensure that it meets specific testing requirements and is in compliance as outlined in Standard 420. Testing for all other refrigerants within the scope of the program will be performed at Intertek Group, plc located in Plano, Texas. The AHRI Certification Program requires that 20% of the participant’s BMG’s be tested, with a minimum of two (2) models each year. Within 90 days of submitting the performance ratings and published selection software to AHRI requesting qualification tests, EVAPCO was required to have the evaporator sample(s) available for testing. AHRI selected the point(s) of operation for the sample(s) based on the AHRI Standard 420. All regularly furnished equipment which affect performance must be in place during the test. The refrigerant used during the test must be the one which is published for use with the evaporator. Each Standard Rating test must be performed at either 50Hz or 60 Hz and the highest rated voltage as specified by the manufacture on the unit or motor nameplate. Precision instruments and automated electronic data acquisition equipment must be used to measure and record temperature, pressure and refrigerant flow rates. All measuring instruments and instrument systems; such as, data acquisition coupled to temperature, pressure or flow sensors, must be calibrated by comparison to primary or secondary standards with calibrations traceable to National Institute of Standards and Technology (NIST) measurements, other recognized national laboratories or derived from accepted values of natural physical constants. All measuring instruments must calibrated annually, whenever damaged or when the accuracy is called into question. All measuring instruments must be selected to meet or exceed the accuracy listed in Table 2. Qualification testing in accordance with the Standard is performed by a Third-Party contracted by AHRI on the sample unit(s) at the selected point of operation to verify the thermal capacity of the sample unit against the manufacturer’s published ratings. Table 1. – Standard Rating Conditions Condition Number Coil Condition 1 2 3 4 5 Wet Dry Dry Dry Dry Dry-Bulb Temperature Entering Air Wet-Bulb Relative Temperature Humidity1 Dew Point Temperature1 Refrigerant Saturation Temperature2 Temperature Difference °F °C °F °C % °F °C °F °C °F °C 50 50 35 10 -10 10 10 1.7 -12.2 -23.3 46.1 – – – – 7.83 – – – – 75 < 45 < 50 < 46 < 43 – < 30 < 20 < 5.0 < -25 – < -1.1 < -6.7 < -21 < 32 35 35 25 0 -20 1.7 1.7 -3.9 -17.8 -28.9 15 15 10 10 10 8.3 8.3 5.6 5.6 5.6 Notes: 1. The dry coil condition can be confirmed by measuring either the entering air dew point or relative humidity according to the instrumentation requirements of Table 2. At wet coil condition, relative humidity is for reference only. 2. Measured at coil outlet. Table 2. – Instrumentation Accuracy Measurement Temperature Relative humidity1 Air dry-bulb Air wet-bulb Refrigerant liquid Refrigerant vapor Air Dew Point Others Air Refrigerant Pressure Air Flow Electrical Minimum Accuracy I-P SI Medium Refrigerant Liquids Auxiliary kilowatt input (e.g. heater) Motor kilowatts /amperes / voltage Speed Motor / fan shaft Weight Oil / refrigerant solution Specific Gravity Brine Time Hours / minutes / seconds ± 0.10 °F ± 0.06 °C ± 0.5 °F ± 0.3 °C ± 0.5 °F ± 0.3 °C ± 1.0 °F ± 0.6 °C ± 3% points rh Pressure Pressure corresponding to corresponding to ± 0.2 °F of ± 0.1 °C of saturation saturation temperature temperature ± 0.05 inches of 169 Pa mercury 1% of reading 1% of reading Instrument Examples Resistance Temperature Device (RTD) Thermistor Special calibrated thermocouple Chilled mirror hygrometer Liquid-in-glass thermometer Capacitive or resistive rh sensor Transducer Barometer Mass flow meter Venturi 1% of reading Power meter Amp probe Multimeter 1% of reading Tachometer 0.5% of reading 1% of reading 0.5% of time interval Gravimeter (scale or analytical balance) Hydrometer Electronic clock Note: 1. Relative humidity and air dew point measurements are intended to confirm the dry coilcondition for the test condition numbers 2 through 5. Certified Data: At Standard Rating Conditions designated in the Standard, the following certified ratings are verified by test: 䡲 Gross Total Cooling Effect (Btu/h) 䡲 Rated Power (Watts or Horsepower) After successful verification of the evaporators thermal performance the manufacture is officially welcomed to the AHRI Certification Program and the certified products are listed in the AHRI Directory, www.ahridirectory.org. At that time, published ratings for the certified products must include the Standard Ratings at which the unit will be produced, marketed or sold. All claims made with regard to ratings for products within the scope of the standard must be accompanied by the statement, “Certified in accordance with the AHRI Unit Coolers Certification Program, which is based on AHRI Standard 420. Certified units may be found in the AHRI Directory at www.ahridirectory.org.” All claims to ratings made outside the scope of the standard must include the statement “Unit is outside of the scope of AHRI Unit Coolers Certification Program, but is rated in accordance with AHRI Standard 420.” Required Published Ratings All published Standard Ratings and Application Ratings must include the following: a. b. c. d. e. f. g. h. i. Model Number Gross Total Cooling Effect, Btu/h [W] Temperature Difference, °F [°C] Refrigerant designation(s) in accordance with ANSI/ASHRAE Standard 34 with Addenda Refrigerant Saturation Temperature, °F [°C] Rated Power W [kW] or hp [kW] Number of motors Coil fin density, fins per inch or coil fin spacing [mm]; Actual fin density or fin spacing shall be within 10% of published values. Airflow rate, cfm [m3/s] (1) References: ANSI/AHRI Standard 420 - 2008 Performance Rating of Forced-Circulation Free-Delivery Unit Coolers for Refrigeration. Operations Manual - Unit Coolers for Refrigeration Certification Program. Copies of reference documents are available @ www.ahrinet.org. SSTMA UNIT COOLERS Small to medium size unit coolers for freezers, coolers and docks requiring low, medium and high temperature applications. SSTMA Models offer improved accessibility features, clean cabinet/pan design and corrosion inhibiting materials of construction. SSTMA Evaporators are offered with Stainless Steel tube/Aluminum fins with hygienic cabinet design as standard. SSTMA Evaporators are certified in accordance with the AHRI Unit Coolers Certification Program, which is based on AHRI Standard 420. Certified units may be found in the AHRI Directory at www.ahridirectory.org. SSTLA PRODUCT COOLERS Large product coolers for low and medium temperature freezer or cooler applications. SSTLA Models combine high capacity models with maintenance friendly features for the best value in large evaporators. SSTLA Evaporators are available with Stainless Steel tube/Aluminum fins as standard. SSTLA Models are certified in accordance with the AHRI Unit Coolers Certification Program, which is based on AHRI Standard 420. Certified units may be found in the AHRI Directory at www.ahridirectory.org. SSTXA LOW PROFILE COOLERS Small to medium capacity, low profile product coolers for freezers, coolers and docks requiring low, medium and high temperature applications where height limitations exist. SSTXA Models offer improved accessibility features, clean cabinet/pan design and corrosion inhibiting materials of construction. SSTXA Evaporators are offered with Stainless Steel tube/Aluminum fin construction. SSTXA Evaporators are certified in accordance with the AHRI Unit Coolers Certification Program, which is based on AHRI Standard 420. Certified units may be found in the AHRI Directory at www.ahridirectory.org. SSTWA WORKROOM UNITS Low velocity air units for processing rooms. Units feature stainless construction with hinged panels for easy access. SSTWA Evaporators are designed to provide working comfort in high occupancy rooms. SSTWA Evaporators are offered with Stainless Steel tube/Aluminum fins as standard. SSTWA Workroom Units are outside the scope of the AHRI Unit Coolers Certification Program, but are rated in accordance with AHRI Standard 420. SSTDA LOW PROFILE DUAL COIL COOLERS Dual coil models for low, medium and high temperature applications in rooms with low ceiling height requirements. SSTDA Models feature a unique clean cabinet/pan design available in durable materials of construction. SSTDA Evaporators are offered with Stainless Steel tube/Aluminum fins as standard. SSTDA Dual Coil Low Profile Coolers are outside the scope of the AHRI Unit Coolers Certification Program, but are rated in accordance with AHRI Standard 420. Benefits of AHRI Unit Cooler Certification Program 䡲 䡲 䡲 䡲 Participating Evaporator Manufacturer’s Rate Products Using the Same Method Competitive Products and Equipment Proposals Easier to Evaluate Independent, Third-Party Verification of Published Thermal Performance & Power Ratings Participating Manufacturers Must Rate All of their Evaporator Products in Accordance with Standard 420 (Even Those Models Not Covered by the Scope of the AHRI Certification Program) 䡲 Specifying Engineers & Design-Build Contractors can Confidently Select the Optimum Evaporator to Meet the Thermal Performance and Power Requirement Using Equipment Selection Software which has been Verified by AHRI 䡲 End-users can Accurately Evaluate their “Return on Investment” E VA P C O P R O D U C T S ARE M A N U FA C T U R E D W O R L D W I D E . W World Headquarters/ Research and R Development Center D EVAPCO Facilities EVAPCO, Inc. — World Headquarters & Research/Development Center EVAPCO, Inc. • P.O. Box 1300 • Westminster, MD 21158 USA PHONE: 410-756-2600 • FAX: 410-756-6450 • E-MAIL: marketing@evapco.com EVAPCO North America EVAPCO Europe EVAPCO, Inc. World Headquarters P.O. Box 1300 Westminster, MD 21158 USA Phone: 410-756-2600 Fax: 410-756-6450 E-mail: marketing@evapco.com EVAPCO Northwest 5775 S.W. Jean Road, Suite 104 Lake Oswego, Oregon 97035 USA Phone: 503-639-2137 Fax: 503-639-1800 EVAPCO East 5151 Allendale Lane Taneytown, MD 21787 USA Phone: 410-756-2600 Fax: 410-756-6450 E-mail: marketing@evapco.com EVAPCO Newton 701 East Jourdan Street Newton, IL 62448 USA Phone: 618-783-3433 Fax: 618-783-3499 E-mail: evapcomw@evapcomw.com EVAPCO Midwest 1723 York Road Greenup, IL 62428 USA Phone: 217-923-3431 Fax: 217-923-3300 E-mail: evapcomw@evapcomw.com EVAPCO-BLCT Dry Cooling, Inc. 981 US Highway 22 West Bridgewater, New Jersey 08807 USA Phone: 1-908-379-2665 E-mail: info@evapco-blct.com EVAPCO West 1900 West Almond Avenue Madera, CA 93637 USA Phone: 559-673-2207 Fax: 559-673-2378 E-mail: contact@evapcowest.com A wholly owned subsidiary of EVAPCO, Inc. EVAPCO Iowa 925 Quality Drive Lake View, IA 51450 USA Phone: 712-657-3223 Fax: 712-657-3226 EVAPCO Iowa Sales & Engineering 215 1st Street, NE P.O. Box 88 Medford, MN 55049 USA Phone: 507-446-8005 Fax: 507-446-8239 E-mail: evapcomn@evapcomn.com EVAPCO Asia/Pacific Headquarters 1159 Luoning Rd. Baoshan Industrial Zone Shanghai, P. R. China, Postal Code: 200949 Phone: (86) 21-6687-7786 Fax: (86) 21-6687-7008 E-mail: marketing@evapcochina.com EVAPCO Europe, S.r.l. Via Ciro Menotti 10 I-20017 Passirana di Rho Milan, Italy Phone: (39) 02-939-9041 Fax: (39) 02-935-00840 E-mail: evapcoeurope@evapco.it EVAPCO (Shanghai) Refrigeration Equipment Co., Ltd. 1159 Louning Rd., Baoshan Industrial Zone Shanghai, P.R. China, Postal Code: 200949 Phone: (86) 21-6687-7786 Fax: (86) 21-6687-7008 E-mail: marketing@evapcochina.com Beijing EVAPCO Refrigeration Equipment Co., Ltd. Yan Qi Industrial Development District Huai Rou County Beijing, P.R. China, Postal Code: 101407 Phone: (86) 10 6166-7238 Fax: (86) 10 6166-7395 E-mail: evapcobj@evapcochina.com EVAPCO Europe GmbH Meerbuscher Straße 64-78 Haus 5 40670 Meerbusch, Germany Phone: (49) 2159-69560 Fax: (49) 2159-695611 E-mail: info@evapco.de 1520 Crosswind Dr. Bryan, TX 77808 USA Phone: 979-778-0095 Fax: 979-778-0030 E-mail: rvs@rvscorp.com EVAPCO Australia (Pty.) Ltd. 34-42 Melbourne Road P.O. Box 436 Riverstone, N.S.W. Australia 2765 Phone: (61) 2 9627-3322 Fax: (61) 2 9627-1715 E-mail: sales@evapco.com.au Flex coil a/s A wholly owned subsidiary of EVAPCO, Inc. Knøsgårdvej 115 DK-9440 Aabybro Denmark Phone: (45) 9824 4999 Fax: (45) 9824 4990 E-mail: info@flexcoil.dk EvapTech, Inc. A wholly owned subsidiary of EVAPCO, Inc. 8331 Nieman Road Lenexa, KS 66214 USA Phone: 913-322-5165 Fax: 913-322-5166 E-mail: marketing@evaptech.com EVAPCO Composites Sdn. Bhd No. 70 (Lot 1289) Jalan Industri 2/3 Rawang Integrated Industrial Park Rawang, Selangor, 48000 Malaysia Phone: 60 3 6092-2209 Fax: 60 3 6092-2210 EVAPCO S.A. (Pty.) Ltd. A licensed manufacturer of EVAPCO, Inc. 18 Quality Road Isando 1600 Republic of South Africa Phone: (27) 11-392-6630 Fax: (27) 11-392-6615 E-mail: evapco@evapco.co.za Tower Components, Inc. A wholly owned subsidiary of EVAPCO, Inc. 5960 US HWY 64E Ramseur, NC 27316 Phone: 336-824-2102 Fax: 336-824-2190 E-mail: mail@towercomponentsinc.com EvapTech Asia Pacific Sdn. Bhd A wholly owned subsidiary of EvapTech, Inc. Evap Egypt Engineering Industries Co. A licensed manufacturer of EVAPCO, Inc. 5 El Nasr Road Nasr City, Cairo, Egypt Phone: 2 02 24022866 /2 02 24044997 Fax: 2 02 24044667/2 02 24044668 E-mail: Primacool@link.net / Shady@primacool.net EVAPCO...SPECIALISTS IN HEAT TRANSFER PRODUCTS AND SERVICES. 3M/08-13/DGD EVAPCO Europe BVBA European Headquarters Industrieterrein Oost 4010 3700 Tongeren, Belgium Phone: (32) 12-395029 Fax: (32) 12-238527 E-mail: evapco.europe@evapco.be EVAPCO Europe, S.r.l. Via Dosso 2 23020 Piateda Sondrio, Italy Refrigeration Valves & Systems Corporation Visit EVAPCO’s Website at: EVAPCO Asia/Pacific B-6-1, IOI Boulevard Jalan Kenari 5, Bandar Puchong Jaya 47170 Puchong, Selangor Darul Ehsan Malaysia Phone: (60-3) 8070-7255 Fax: (60-3) 8070-5731 E-mail: marketing-ap@evaptech.com http://www.evapco.com Bulletin 414-CERT ©2013 EVAPCO, Inc. Scan this QR code to learn more about EVAPCO.