Untitled - Physikalisch-Technische Bundesanstalt

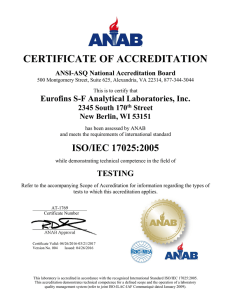

advertisement